which is better oled or lcd screen made in china

Over the years, with the wider and wider application of LCD screens, more and more brand products have been favored by the people. Together, more and more LCD manufacturers have emerged. Of course, the most popular brands in China are BOE, INNOLUX, CHIMEI, AUO, CSOT, etc. So, Which is the best brand of

It is better to say who is more professional than good or bad. In fact, the above mentioned LCD screen manufacturers are very professional, and the quality is guaranteed. But the most popular must be BOE and INNOLUX, these two panel manufacturers are also obvious to all. They all have multiple distributors, but not every distributor has the best size and price.

SZ XIANHENG TECHNOLOGY CO., LTD. is the agent of AUO, BOE, INNOLUX, SHARP, IVO and Mitsubishi, and other domestic and foreign well-known brands of small and medium-sized LCD display; specializing in customized production of touch screen display, LCD and industrial touch display and other high-tech products. According to the needs of customers, we can provide various LCD products: high-brightness LCD screen, LCD driver board, touch screen, booster board, all kinds of LCD special wires, etc. to produce industrial displays.

What brand of LCD screen is good? If you choose BOE, INNOLUX, CHIMEI, AUO or CSOT, you can buy them from us. 18.5 inch LCD screen, 21.5 inch LCD screen and other small and medium size, our price is the lowest in the industry.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

Not sure which one will be best for you? Don’t worry! We’re here to help you figure out the right display for your project or application. In this post we’ll break down the pros and cons of these display types so you can decide which one is right for you.

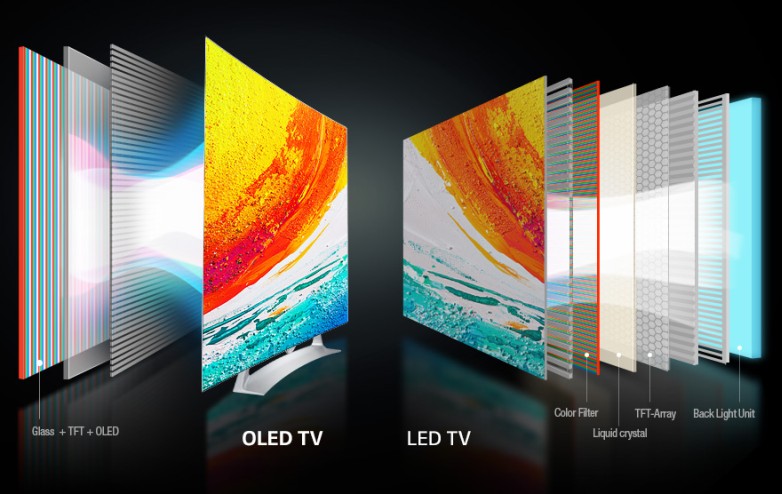

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

These different technological approaches to display technology have big impact in some features including contrast, brightness, viewing angles, lifespan, black levels, image burn-in, and price.

Everything from the environment your display will be used in, your budget, to the lighting conditions and the required durability will play a part in this decision.

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

► When the leading Korean players Samsung Display and LG Display exit LCD production, BOE will be the most significant player in the LCD market. Though OLED can replace the LCD, it will take years for it to be fully replaced.

► As foreign companies control evaporation material and machines, panel manufacturers seek a cheaper way to mass-produce OLED panels – inkjet printing.

When mainstream consumer electronics brands choose their device panels, the top three choices are Samsung Display, LG Display (LGD) and BOE (000725:SZ) – the first two from Korea and the third from China. From liquid-crystal displays (LCD) to active-matrix organic light-emitting diode (AMOLED), display panel technology has been upgrading with bigger screen products.

From the early 1990s, LCDs appeared and replaced cathode-ray tube (CRT) screens, which enabled lighter and thinner display devices. Japanese electronics companies like JDI pioneered the panel technology upgrade while Samsung Display and LGD were nobodies in the field. Every technology upgrade or revolution is a chance for new players to disrupt the old paradigm.

The landscape was changed in 2001 when Korean players firstly made a breakthrough in the Gen 5 panel technology – the later the generation, the bigger the panel size. A large panel size allows display manufacturers to cut more display screens from one panel and create bigger-screen products. "The bigger the better" is a motto for panel makers as the cost can be controlled better and they can offer bigger-size products to satisfy the burgeoning middle-class" needs.

LCD panel makers have been striving to realize bigger-size products in the past four decades. The technology breakthrough of Gen 5 in 2002 made big-screen LCD TV available and it sent Samsung Display and LGD to the front row, squeezing the market share of Japanese panel makers.

The throne chair of LCD passed from Japanese companies to Korean enterprises – and now Chinese players are clinching it, replacing the Koreans. After twenty years of development, Chinese panel makers have mastered LCD panel technology and actively engage in large panel R&D projects. Mass production created a supply surplus that led to drops in LCD price. In May 2020, Samsung Display announced that it would shut down all LCD fabs in China and Korea but concentrate on quantum dot LCD (Samsung calls it QLED) production; LGD stated that it would close LCD TV panel fabs in Korea and focus on organic LED (OLED). Their retreats left BOE and China Stars to digest the LCD market share.

Consumer preference has been changing during the Korean fab"s recession: Bigger-or-not is fine but better image quality ranks first. While LCD needs the backlight to show colors and substrates for the liquid crystal layer, OLED enables lighter and flexible screens (curvy or foldable), higher resolution and improved color display. It itself can emit lights – no backlight or liquid layer is needed. With the above advantages, OLED has been replacing the less-profitable LCD screens.

Samsung Display has been the major screen supplier for high-end consumer electronics, like its own flagship cell phone products and Apple"s iPhone series. LGD dominated the large OLED TV market as it is the one that handles large-size OLED mass production. To further understand Korean panel makers" monopolizing position, it is worth mentioning fine metal mask (FMM), a critical part of the OLED RGB evaporation process – a process in OLED mass production that significantly affects the yield rate.

Prior to 2018, Samsung Display and DNP"s monopolistic supply contract prevented other panel fabs from acquiring quality FMM products as DNP bonded with Hitachi Metal, the "only" FMM material provider choice for OLED makers. After the contract expired, panel makers like BOE could purchase FFM from DNP for their OLED R&D and mass production. Except for FFM materials, vacuum evaporation equipment is dominated by Canon Tokki, a Japanese company. Its role in the OLED industry resembles that of ASML in the integrated circuit space. Canon Tokki"s annual production of vacuum evaporation equipment is fewer than ten and thereby limits the total production of OLED panels that rely on evaporation technology.

The shortage of equipment and scarcity of materials inspired panel fabs to explore substitute technology; they discovered that inkjet printing has the potential to be the thing to replace evaporation. Plus, evaporation could be applied to QLED panels as quantum dots are difficult to be vaporized. Inkjet printing prints materials (liquefied organic gas or quantum dots) to substrates, saving materials and breaking free from FMM"s size restriction. With the new tech, large-size OLED panels can theoretically be recognized with improved yield rate and cost-efficiency. However, the tech is at an early stage when inkjet printing precision could not meet panel manufacturers" requirements.

Display and LGD are using evaporation on their OLED products. To summarize, OLED currently adopts evaporation and QLED must go with inkjet printing, but evaporation is a more mature tech. Technology adoption will determine a different track for the company to pursue. With inkjet printing technology, players are at a similar starting point, which is a chance for all to run to the front – so it is for Chinese panel fabs. Certainly, panel production involves more technologies (like flexible panels) than evaporation or inkjet printing and only mastering all required technologies can help a company to compete at the same level.

Presently, Chinese panel fabs are investing heavily in OLED production while betting on QLED. BOE has four Gen 6 OLED product lines, four Gen 8.5 and one Gen 10.5 LCD lines; China Star, controlled by the major appliance titan TCL, has invested two Gen 6 OLED fabs and four large-size LCD product lines.

Remembering the last "regime change" that occurred in 2005 when Korean fabs overtook Japanese" place in the LCD market, the new phase of panel technology changed the outlook of the industry. Now, OLED or QLED could mark the perfect time for us to expect landscape change.

After Samsung Display and LGD ceding from LCD TV productions, the vacant market share will be digested by BOE, China Star and other LCD makers. Indeed, OLED and QLED have the potential to take over the LCD market in the future, but the process may take more than a decade. Korean companies took ten years from panel fab"s research on OLED to mass production of small- and medium-size OLED electronics. Yet, LCD screen cell phones are still available in the market.

LCD will not disappear until OLED/QLED"s cost control can compete with it. The low- to middle-end panel market still prefers cheap LCD devices and consumers are satisfied with LCD products – thicker but cheaper. BOE has been the largest TV panel maker since 2019. As estimated by Informa, BOE and China Star will hold a duopoly on the flat panel display market.

BOE"s performance seems to have ridden on a roller coaster ride in the past several years. Large-size panel mass production like Gen 8.5 and Gen 10.5 fabs helped BOE recognize the first place in production volume. On the other side, expanded large-size panel factories and expenses of OLED product lines are costly: BOE planned to spend CNY 176.24 billion (USD 25.92 billion) – more than Tibet"s 2019 GDP CNY 169.78 billion – on Chengdu and Mianyang"s Gen 6 AMOLED lines and Hefei and Wuhan"s Gen 10.5 LCD lines.

Except for making large-size TVs, bigger panels can cut out more display screens for smaller devices like laptops and cell phones, which are more profitable than TV products. On its first-half earnings concall, BOE said that it is shifting its production focus to cell phone and laptop products as they are more profitable than TV products. TV, IT and cell phone products counted for 30%, 44% and 33% of its productions respectively and the recent rising TV price may lead to an increased portion of TV products in the short term.

Except for outdoor large screens, TV is another driver that pushes panel makers to research on how to make bigger and bigger screens. A research done by CHEARI showed that Chinese TV sales dropped by 10.6% to CNY 128.2 billion from 2018 to 2019. Large-size TV sales increased as a total but the unit price decreased; high-end products like laser TV and OLED TV saw a strong growth of 131.2% and 34.1%, respectively.

The change in TV sales responded to a lifestyle change since the 4G era: people are getting more and more used to enjoy streaming services on portable devices like tablets and smartphones. The ‘disappearing living room" is a phenomenon common for the young generation in Chinese tier-1 cities.

Millions of young white-collars support the co-leasing business in China and breed the six-billion-dollar Ziroom, a unicorn company that provides rental and real estate management services. As apartments can be leased by single rooms instead of the whole apartment, living rooms become a public area while tenants prefer to stay in their private zones – it hints that the bedroom is too small to fit in a TV.

Besides the tier-1 cities" "disappearing living rooms," the mobile Internet gives another reason to explain the declining TV sale in China. Various streaming services and high-speed networks allow people to watch programs wherever and whenever they would like to. However, the change in life does not imply TV will disappear. For families, the living room is still a place for family members to gather and have fun. The growth of high-end TV sales also tells the "living room" economy.

The demand for different products may vary as lifestyles change and panel fabs need to make on-time judgments and respond to the change. For instance, the coming Olympics is a new driving factor to boost TV sales; "smart city" projects around the world will need more screens for data visualization; people will own more screens and better screens when life quality improves. Flexible screens, cost-efficient production process, accessible materials, changing market and all these problems are indeed the next opportunity for the industry.

Employees put finishing touches to TV displays at a production facility in Suining, Sichuan province, in November. [Photo by Liu Changsong/For China Daily]

China is set to take a lead in the state-of-the-art organic light-emitting diodes (OLED) semiconductor display technology, which has broad application prospects in the field of high-end smartphones, televisions, wearable devices, augmented reality and virtual reality display segments, industry analysts said.

OLED is a relatively new technology and part of the recent innovations in displays. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is thinner and can be made flexible and foldable, compared with the traditional LCD display panel.

The shipment of OLED panels used in smartphones is expected to rise to about 100 million units in the Chinese market this year from 83 million units last year, as major smartphone makers have ramped up efforts to launch foldable handsets, said Sigmaintell Consulting, a Beijing-based market research firm.

Display panel supplier BOE Technology Group Co Ltd topped the domestic market with OLED panel shipments of 16 million units in the third quarter. It became the world"s second-largest OLED maker next to South Korea"s Samsung Display. Visionox Technology Inc took second place domestically with shipments of 6.3 million units in the third quarter.

China will overtake South Korea to become the biggest OLED manufacturer by 2024, as more Chinese companies have invested heavily in new OLED production lines, said Zhou Hua, chief analyst at CINNO Research, a Chinese flat panel display consultancy firm.

Zhou said that at present, China has become the world"s largest display panel producer, and is foreseen accounting for about 76 percent of global OLED production capacity by 2025.

Li Yaqin, general manager of Sigmaintell, said demand for flexible OLED panels used in foldable smartphones will continue to increase this year on the back of commercial application of 5G technology, and panel makers should further improve their yield rate capacities and reduce production costs.

According to market research company Omdia, OLED panel shipments for smartphones will reach 812 million units globally next year, an increase of 38.8 percent compared with the estimated 585 million units in 2021.

Chinese smartphone makers have increased the number of high-end smartphones integrating flexible active-matrix organic light-emitting diodes, or AMOLED, panels, said Brian Huh, principal analyst of small and medium-sized displays at Omdia.

Xu Fengying, vice-president of Visionox, said AMOLED panels will have wider applications in smartphones, computers, smart wearables, vehicles, virtual reality and augmented reality because of surging demand for flexible display screens.

"The AMOLED market will continue to grow, and the penetration rate of flexible display products is expected to rise," said Zhu Xiujian, general manager of Visionox"s product engineering center, adding the flexible and foldable screens will play a vital role in bolstering the growth of small and medium-sized smartphones.

In addition, global shipments of televisions are expected to fall to 232 million units this year, down 7.1 percent on a yearly basis. TV sales in the domestic market, which fell 15.9 percent year-on-year to 25.89 million units in the January-September period, will slump to 41 million units by the end of the year, said Sigmaintell.

Chinese television maker Skyworth Group has been producing OLED TVs in partnership with South Korea"s largest panel maker, LG Display, since 2013. Other home appliance manufacturers such as Hisense, Konka, Huawei and Sony have also tapped into the OLED TV market.

OLED TVs will become the future development direction of the TV industry and present an opportunity for TV manufacturers to expand their profit margins, said Wen Jianping, president of Beijing-based market consultancy All View Cloud.

According to the Korean media reports, BOE’s OLED screen will give a strong competition to Samsung in the next 2 years. BOE may start shipping the OLED panels to Apple in 2020. According to the South Korean analysts, BOE will ship 45 million OLED panels for the iPhone in 2021.

Samsung will still keep the bulk of iPhone orders, but the orders have dropped last year. Samsung has been the biggest OLED display supplier to Apple’s iPhone in 2017.

It was first suggested back in 2017 that BOE was pitching Apple for OLED orders, with a report in February of this year that Apple was considering this. The idea was boosted by a subsequent report that BOE was investing in the same next-generation OLED tech as Samsung.

Existing iPhone screens have a separate touch-sensitive layer which sits on top of the actual display. But Samsung offers a next-generation design known as touch-integrated flexible OLED panels which, as the name suggests, allow both jobs to be achieved within a single layer.

The Korea Herald today reports that Chinese display manufacturer BOE is investing in the same technology. It has already picked up orders from Huawei and is hoping to do the same with Apple.

Apple likes to diversify its supply-chain, one reason it has supported rescue plans for Japan Display, another potential supplier of OLED screens for future iPhones. So both Chinese-made OLED screens and Japanese ones are likely to be on the cards in the next few years.

BOE Technology Group and TCL China Star Optoelectronics Technology (TCL CSOT) are among the Chinese panel makers to have ramped up output since around 2019 with generous state subsidies. China is gaining on South Korea, whose share of capacity is seen reaching 55% for 2022 in an October estimate by U.S. market intelligence firm Display Supply Chain Consultants (DSCC).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This year, Samsung, LG, and other Korean panel giants have announced the cessation of LCD panel production. In addition, to the local retention of part of the production capacity, these companies are basically out of the LCD market. They will now focus on the OLED market but even here, the competition is growing. In the OLED market, Chinese companies are catching up even faster, and the competition in this market is not easy.

According to recent reports, in 2019 the global OLED panel market, Samsung leads all other manufacturers. The South Korean manufacturer had an 85.4% market share. In second place was Chinese display manufacturer, BOE, with only 3.6% market share. LG ranks fourth with 2.8% market share after Pfizer in third position. However, LG’s strength is in the large size OELD panels market. It only recently started entering the small/medium panels market.

Although Samsung and LG are conveniently leading the OLED market presently, Chinese manufacturers are rising fast. The likes of BOE, Huaxing Optoelectronics, Pegasus Microelectronics, Vivienne, and other companies are vigorously building a 5.5 generation / 6 generation line of OLED production. There are speculations that the Chinese production of OLED panels in the next three years will increase significantly.

Recent research shows that Chinese companies have put into operation 12 OLED production lines in recent times. In addition, there are seven more that are under construction. So far, Chinese companies have invested over 350 billion yuan ($49 billion). Of this sum, BOE alone accounts for 139.5 billion yuan ($19.5 billion).

South Korean companies are worried that not only have Chinese companies have increased their production capacity significantly but after mastering LCD and OLED panel production technologies, they also have the same competing capital in the new generation of display technologies, such as mini LEDs, micro LEDs, and other emerging display panels. South Korean companies fear that if such development continues, Chinese companies will sooner or later take control of the entire industry chain, from upstream equipment to downstream products.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

For the convenience of understanding, we reduce some layers, after removing the vertical and horizontal polarizer and the positive and negative circuit, only left to luminous plate, liquid crystal layer and color filter. and then we can see the lcd display module’s layer work as a shutter.

The backlight emits light, and the shade adjusts the Angle to determine how much light passes through the color filter. Different percent of the RGB tri-color light mix to produce different colors of light. Does that sound good? If you want the pixels at this location to display pure red, then ideally the shade under the blue and green blocks should be completely closed. At this point, only the red color can be displayed accurately. But it is only ideal status, the reality is different to we would think. Complete closure is only theoretical, and in fact, there are more or less incomplete closures. Something like this, more or less a little white light is leaking out. It lead to the problem that colors mixed and colors inaccuracy.

arrays, which have become one of the distinguishing features of OLED screens. The main cause for OLED screen life time is the blue pixel. Since the luminous efficiency of blue pixels is much lower

to reduce the blue pixel current to improve the oled life time. This is also the diamond arrangement and so on. The original pixel arrangement scheme was Samsung"s RGB

PAJU, South Korea – South Korea’s LG Display said Monday that it will change its investment priority to advanced displays called OLEDs as Chinese manufacturers quickly catch up with their South Korean rivals in the LCD market.

LG Display Co., a supplier to Apple Inc., said that over the next three years it plans to spend 10 trillion won ($8.4 billion) on future displays including OLED, flexible displays and high-end LCD screens. It did not give breakdown figures, saying the size for each type of display will hinge on market situations.

LG Display and LG Electronics are the lone manufacturers of OLED TVs, which are still more expensive and more difficult to produce than LCD TVs. LG Display’s OLED business has been losing money.

OLEDs, or organic light-emitting diodes, require no backlight and can be made into a flexible display. Rival Samsung Electronics uses OLEDs only for small-size devices such as smartphones, saying that big-size OLED TVs face challenges in prices and productions.

LG Display’s CEO said that while the Chinese firms will eventually catch up to South Korean makers in the LCD market, there is still an opportunity in the future displays.

On the back of massive investments, South Korean electronics companies surpassed Japanese companies to become the world’s largest supplier of flat display panels in the early 2000s. Those displays are used to produce televisions, computer screens and mobile devices.

But helped by government support, Chinese companies are quickly narrowing the gap with South Korean firms, threatening the Korean companies’ leading position.

Chinese display makers are expected to account for 27 per cent of global LCD production in 2020, up from 16 per cent this year, according to LG Display.

LG believes its giant investment will pay off as the OLED market poses a greater growth opportunity than the LCD market, where growth has stagnated. DisplaySearch, a market research firm, forecasts OLED shipments to jump about threefold to $28.3 billion in 2022 from $8.7 billion in 2014.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

In Topway, we work side by side to help you overcome any technical and none technical challenges that may arise during product design, manufacture or installation. We can even take care of component sourcing and manufacturing for you.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Chinese electronics giant recently unveiled a 95-inch 8K OLED TV with a 120Hz refresh rate at Display Week 2022 – and market research firm DSCC thinks it could be offered for commercial use.

"DSCC sources in China have learned that BOE plans to commercialize the 95" 8K White OLED TV panel shown at Display Week. I must admit, I heard this at the exhibit during Display Week but did not believe it, but our sources in China confirm BOE’s intent," reads Bob O"Brien"s report.

BOE"s monster panel boasts an ultra-thin bezel and a resolution of up to 7680×4320 pixels, together with a contrast ratio of 1,000,000:1 and a DCI-P3 99% wide color gamut. The display is understood to be equipped with an HDR algorithm that allows for deeper black levels, and a peak brightness of 800 nits.

Price wars in the LCD TV market have forced LG and Samsung to concentrate on premium OLED panels. Samsung Display is expected to cease production of its LCD panels in June, while LG has already slashed its LCD production.

With any luck, BOE"s rumoured entry into the OLED market will make it cheaper to buy an ultra-large TV. Currently, an 88-inch 8K LG Z29 OLED TV will set you back £25,000 (around $30,000 / AU$43,000), so a more affordable OLED solution would be most welcome.

By Kim Bo-eunKorea"s display makers currently lead the global market in organic light-emitting diodes (OLED) displays, but they have been growing increasingly alarmed by how fast Chinese rivals have caught up in terms of technology.They worry that they may lose their competitive edge in OLED technology, which is what happened with liquid crystal displays (LCD), where Chinese players now account for close to 60 percent of the global market share. Korean display makers are eyeing the timing of exiting the LCD market, given their profitability has deteriorated due to Chinese players that offer the panels at lower prices.OLEDs are considered as the next-generation display, because the panels are thinner, lighter and show improved picture quality compared to LCDs.Market researchers forecast that Chinese players will quickly expand their share of the market for small-and medium-sized OLEDs used in smartphones.According to Omdia, Chinese companies are expected to account for 27 percent of the global market for smartphone OLED panels next year, up from 15 percent this year. Samsung Display, the market leader in small- and medium-sized OLEDs, is subsequently set to see its market share fall to 65 percent next year from 77 percent this year.The figures are projections based on forecasted panel shipments according to investments into production facilities and market conditions.Chinese companies caught up with Korean LCD manufacturers in a matter of years after a decade of Korea"s dominance from the mid-2000s to 2016, backed by substantial financial support from Beijing.The Chinese government is now backing the development of OLED displays, which has Korean players on their toes, given it could be only a matter of years before Chinese rivals end up dominating the market.Chinese companies are moving quickly to set up large-scale production bases to churn out OLEDs. BOE is constructing a production plant for smaller OLEDs in the southwestern Chinese city of Chongqing. The OLED production line is set to be the largest for a single factory in China, producing 115 million panels on an annual basis.Chinese players have not yet started production of large-size OLED panels, but they have entered mass production of smaller panels and are supplying them to major companies."The technological gap between Korean and Chinese companies" small-size OLED displays has narrowed significantly," an industry official said."For large-size OLED displays for TVs, we estimate that Chinese players are three to four years behind in technology, but they could catch up in a year or an even shorter time span."Chinese firms are scouting key personnel at Korean display makers by offering significantly greater compensation to secure technology, a practice that has been going on for years.Meanwhile, Chinese players are known to receive up to 70 percent in financial support from the central as well as local governments when setting up production facilities.Local display manufacturers are calling for OLED technology to be included among the country"s strategic technology sectors that receive support in R&D and facility investments. The government is currently seeking to include semiconductors, EV batteries and vaccines in these sectors receiving state support.

Standard Digital includes access to a wealth of global news, analysis and expert opinion. Premium Digital includes access to our premier business column, Lex, as well as 15 curated newsletters covering key business themes with original, in-depth reporting. For a full comparison of Standard and Premium Digital, click here.

For cost savings, you can change your plan at any time online in the “Settings & Account” section. If you’d like to retain your premium access and save 20%, you can opt to pay annually at the end of the trial.

You may also opt to downgrade to Standard Digital, a robust journalistic offering that fulfils many user’s needs. Compare Standard and Premium Digital here.

Any changes made can be done at any time and will become effective at the end of the trial period, allowing you to retain full access for 4 weeks, even if you downgrade or cancel.

LG Display announced Monday it will be channeling future resources to the development of OLED TVs to stay ahead of Chinese competitors that are catching up rapidly in the LCD sector, reported Associated Press.

The Apple supplier said it plans to spend US $8.4 billion on future display technologies including OLED over the next three years. Investments in OLED are aimed to making flexible displays and high-end LCD screens. LG Display did not give breakdown figures, only saying the size for each display will depend on market situations.

Despite being the only OLED TV manufacturer left in the industry, and bleeding heavily in its OLED business, LG Display insist on investing OLED TV technology.

OLED technology faces challenges including low yield rates, and high production costs. However, the merits of using OLED panels is it requires no additional backlight, and its flexible properties.

LG has chosen OLED technology to give it a competitive edge over Chinese companies. According to LG Display CEO Han Sangbeom Chinese firms are catching up with South Korean makers in the LCD market, but there is still a gap in OLED.

Supported financially with massive investments, South Korean electronics companies overtook Japanese companies to become the world’s largest supplier of flat panels in early 2000s. The displays were used to make televisions, computer screens and mobile devices.

LG is optimistic its investment will pay off, since the OLED market has more growth potential than the LCD market, where growth has stagnated. DisplaySearch estimates the OLED market will jump threefold to $28.3 billion in 2022 from $8.7 billion in 2014.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey