tft display interface with 8051 quotation

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

ER-DBT028-4 is a microcontroller 8051(80C51) demonstration and development kit for 2.8 inch tft lcd display with ILI9341 controller.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8-bit,8080 16-bit parallel interface and 3-wire,4-wire serial interface.

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

ER-DBT035-6 is a microcontroller 8051(80C51) demonstration and development kit for ER-TFT035-6 product that is 3.5 inch tft lcd display with ILI9488 controller.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8-bit,8080 16-bit parallel interface and 3-wire,4-wire serial interface.

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

The schematics for this project is fairly easy as the only thing we will be connecting to the Arduino is the display. Connect the display to the Arduino as shown in the schematics below.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The second example is the graphics test example from the more capable and heavier Adafruit ST7735 Arduino library. I will explain this particular example as it features the use of the display for diverse purposes including the display of text and “animated” graphics. With the Adafruit ST7735 library installed, this example can be accessed by going to examples -> Adafruit ST7735 library -> graphics test.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

Next, we move to the void setup function where we initialize the screen and call different test functions to display certain texts or images. These functions can be edited to display what you want based on your project needs.

All the functions called under the void setup function, perform different functions, some draw lines, some, boxes and text with different font, color and size and they can all be edited to do what your project needs.

Uploading the code to the Arduino board brings a flash of different shapes and text with different colors on the display. I captured one and its shown in the image below.

That’s it for this tutorial guys, what interesting thing are you going to build with this display? Let’s get the conversation started. Feel free to reach me via the comment section if you have any questions as regards this project.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

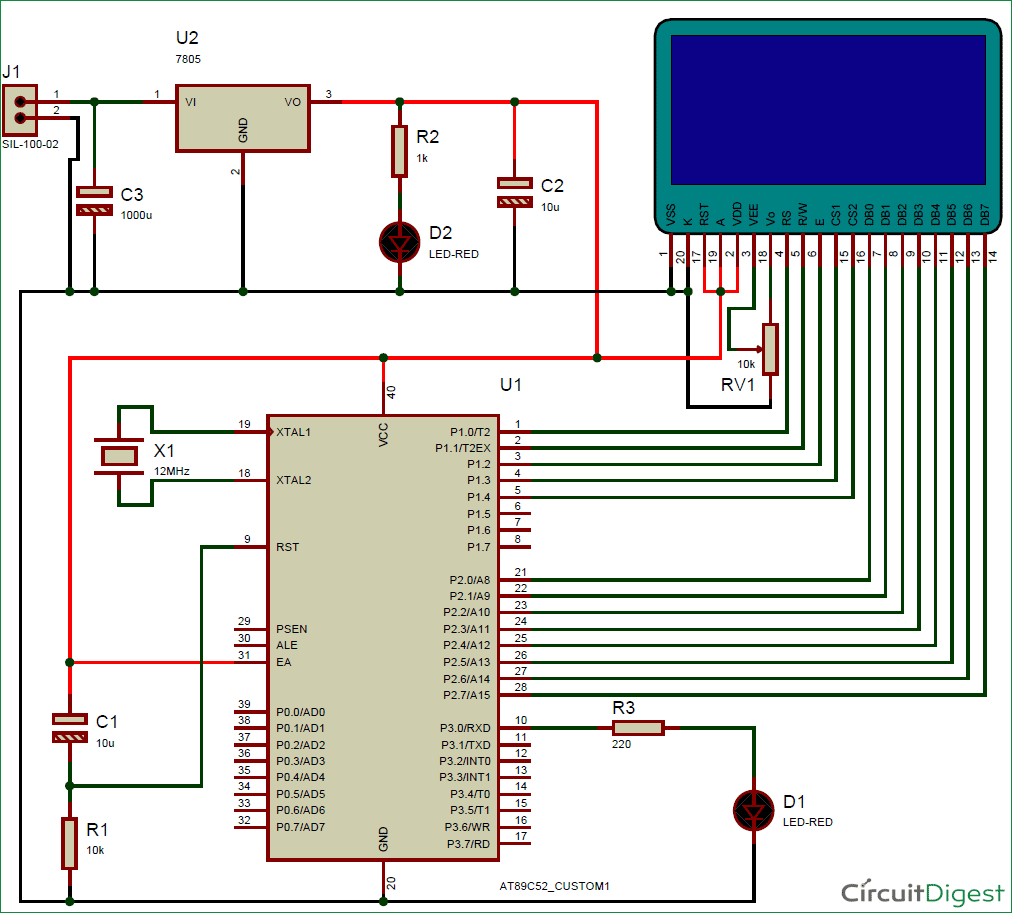

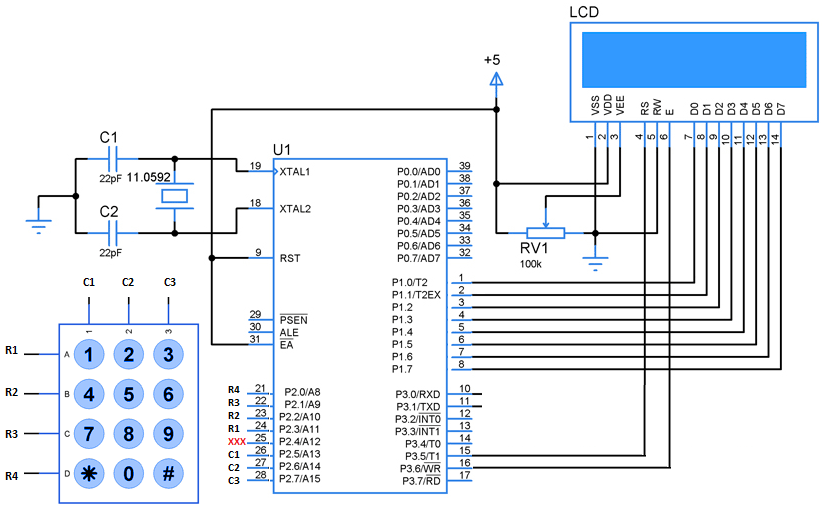

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

The voltage source of this display is +5 V connected to Pin 2 (VCC) and GND power supply connected to Pin 1 (VSS) and Pin 16 (GND); Pin 1 (VSS) and Pin 16 (GND) are combined together and connected to the GND of the power supply.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

This TFT display module comprises a 7" TFT with capacitive touch and an EVE accelerator PCB. The EVE accelerator PCB simplifies interfacing with the display as it makes the display, touch, backlight, and any added audio features appear to the host MCU as a memory-mapped SPI device. The host controller can send high-level commands to the EVE chip to quickly and easily describe images, text, buttons, tables, and more.

At 7" on the diagonal, this display offers plenty of space, making it a great choice for an information panel, menu, etc. Plus, thanks to the extremely wide viewing angle achieved using in-plane switching (IPS), this display can be read equally well above or below eye level.

Between the Crystalfontz demo code (available in the right-hand sidebar) and the FTDI/Bridgetek"s development tools, there are lots of resources available to make creating a beautiful, responsive, and functional user interface easier than ever.

Note: ILI9163C Datasheets improperly (not traditional) refer to SPI as a Serial Interface. Please see timing diagram in 6.2.1 called "3-line Serial Interface Protocol"

The DT018ATFT does not support 4-Wire SPI (also known as "4-line Serial Interface Protocol", 8-bit data, which includes a separate D/C signal line). DT018ATFT does not support this since the signal in ILI9163C datasheet called "SPI4" is hard coded to 0. However, a custom version of the FPC can be tooled to expose the proper 4-Wire SPI signals - please contact us for more details.

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function.

The traditional mechanical instrument lacks the ability to satisfy the market with characters of favorable compatibility, easy upgrading, and fashion. Thus the design of a TFT-LCD (thin film transistor-liquid crystal display) based automobile instrument is carried out. With a 7-inch TFT-LCD and the 32-bit microcontroller MB91F599, the instrument could process various information generated by other electronic control units (ECUs) of a vehicle and display valuable driving parameters on the 7-inch TFT-LCD. The function of aided parking is also provided by the instrument. Basic principles to be obeyed in circuits designing under on-board environment are first pointed out. Then the paper analyzes the signals processed in the automobile

instrument and gives an introduction to the sampling circuits and interfaces related to these signals. Following this is the functional categorizing of the circuit modules, such as video buffer circuit, CAN bus interface circuit, and TFT-LCD drive circuit. Additionally, the external EEPROM stores information of the vehicle for history data query, and the external FLASH enables the display of high quality figures. On the whole, the accomplished automobile instrument meets the requirements of automobile instrument markets with its characters of low cost, favorable compatibility, friendly interfaces, and easy upgrading.

As an essential human-machine interface, the automobile instrument provides the drivers with important information of the vehicle. It is supposed to process various information generated by other ECUs and display important driving parameters in time, only in which way can driving safety be secured. However, the traditional mechanical automobile instrument is incompetent to provide all important information of the vehicle. Besides, the traditional instrument meets great challenge with the development of microelectronic technology, advanced materials, and the transformation of drivers’ aesthetics [1, 2]. Moreover, the parking of the vehicle is also a problem puzzling many new drivers. Given this, traditional instruments should be upgraded in terms of driving safety, cost, and fashion.

The digital instrument has functions of vehicle information displaying, chord alarming, rear video aided parking, LED indicating, step-motor based pointing, and data storage. The instrument adopts dedicated microcontroller MB91F599, a 7-inch LCD, and two step-motors to substitute for the traditional instrument. All the information generated by other ECUs can be acquired via not only the sample circuits but also the CAN bus.

The instrument provides interfaces for different types of signals and the CAN bus. All types of signals (such as square wave signal, switching signal, resistance signal, analog voltage signal, etc.) coming from other ECUs can be acquired either from different types of sampling circuits or from the CAN bus. This makes it suitable for both the outdated application where the information from other ECUs can only be acquired via the sampling circuits and the modern application where the information from other ECUs are transmitted via the CAN bus.

The CAN bus interface and the 7-inch TFT-LCD make it more convenient to upgrade the instrument without changing the hardware. If the software needs to be upgraded, we need not bother to take the instrument down and program the MCU. Instead, we can upgrade the instrument via the vehicle’s CAN network without taking the instrument down, which makes the upgrading more convenient. Most of the information from other ECUs can be transmitted via the CAN bus; so, we do not have to change the hardware circuits if some of the ECUs’ signals are changed in different applications. Besides, since most of the driving parameters are displayed on the TFT-LCD, and the graphical user interface can be designed with great flexibility by programming, only the software needs to be revised to meet different requirements of what kind of driving parameters to display and so forth. These characters, together with the reserved interfaces, enhance the instrument’s compatibility in different applications.

It is a trend to incorporate the instrument into the vehicle information system via the CAN bus. The CAN bus interface gives the instrument access to the vehicle CAN network which enables easier fault diagnosing [3, 4] and information sharing. The fault diagnosing could be realized by accomplishing the fault diagnosing protocol above the low-speed CAN bus.

On the one hand, there are some automobile instruments which adopt 8-bit MCUs or 16-bit MCUs which have limited peripherals, so it is difficult for them to meet some requirements such as rearview video and high real-time data processing performance. And many extra components are needed if the designer wants to accomplish some functions such as video input. On the other hand, there are some advanced automobile instruments which adopt high performance MCUs (such as i.MX 53, MPC5121e, and MPC5123) and run Linux on them. They even use larger TFT-LCDs (such as the 12.3-inch TFT-LCD with a resolution of 1280 × 480 pixels) to display driving parameters. These automobile instruments show higher performances than the instrument in this paper. However, they are more expensive than this automobile. This instrument is able to provide almost all the functions of the advanced automobile instrument with a lower cost.

The instrument receives signals from other ECUs via the sampling circuits or the CAN bus interface. It can also receive commands from the driver via the button interface. The signals are then processed by the MCU, after which the MCU may send the vehicle information to the LCD or light the LEDs and so forth, according to the results. Therefore, the automobile instrument can be viewed as a carrier of the information flow. And the design of the system can be viewed from two aspects: the hardware system and the information flow based on it.

Overvoltage protection circuits should be placed at the interfaces of power supply and important signals (such as the CAN bus interface) in case of voltage overshoots.3.1.3. Generality

Reserved interfaces should be taken into consideration to shorten the development cycle of subsequent similar instruments and optimize the instrument for general use.3.1.4. Inventories

The automobile instrument receives and processes information from other ECUs such as the tachometer, the speedometer, the cooling water temperature gauge, the oil pressure gauge, and the fuel gauge. The signals coming from these ECUs are of different types, according to which different kinds of sampling circuits and interfaces should be designed. Accordingly, a classification of the input signals is first carried out, as shown in Table 1.

Respecting the above mentioned factors, we finally chose the MB91F599 produced by Fujitsu as the microcontroller. The MB91F599 is particularly well-suited for use in automotive instrument clusters using color displays to generate flexible driver interfaces. It integrates a high performance FR81S CPU core which offers the highest CPU performance level in the industry. Besides, it has a graphics display controller with strong sprite functionality, rendering engine, and external video capture capabilities. These greatly reduce the need for extra components and enhance the stability of the system. The rendering engine can operate in combination with the video capture to enable image manipulation. Overlaid graphics such as needles or parking guidelines can be rendered in conjunction with captured video, which helps to accomplish the aided parking. What is more, multiple built-in regulators and a flexible standby mode enable the MB91F599 to operate with low power consumption.

Figure 6 shows RGB with sync in NTSC format. The RGB varies in a positive direction from the “black level” (0 V) to 700 mV. Meanwhile, a sync waveform of −300 mV is attached to the video signal. Since the output video signal of the camera is AC-coupled, a clamp circuit is needed to clamp the RGB and sync to a reference voltage and leave the others to vary. If not clamped, the bias voltage will vary with video content and the brightness information will be lost [5].

Here, the sync signal is not present, so the clamp level is controlled by the clamp level output pin of the microcontroller, which is called “keyed clamp” [5]. The graphics display controller of the microcontroller let the clamp level output occur in coincidence with the sync pulse; that is, the clamp level output occurs during the sync tip in Figure 6, thus we get the “sync tip clamp” [5].

Since the FLASH size of the microcontroller is only 1 MB which is limited for the storage of pictures displayed on the LCD, external FLASH is needed to store different kinds of meaningful pictures such as the background of the dial. Two S29GL256N chips with a memory capacity of 256 Mb are chosen for picture data storage for their high performance and low power consumption. The application circuits of the chips are provided in their datasheets, so it is unnecessary to go into the details of them here.

Controller Area Network (CAN) is widely deployed in automobile, industry, and aerospace domains. As a major trend of the technological development of in the automation industry, CAN is now reputed as a local area network in automation [6]. Its low cost and ability to integrate with most microcontroller silicon families have made it a standard for automobile applications [7–9].

For this design, only the CAN transceiver and its auxiliary circuit are needed since the MB91F599 is integrated with two CAN controllers, which are connected to the high-speed and low-speed CAN bus, respectively. TJA1040 is chosen as the CAN transceiver for its low consumption in standby mode. Besides, it can also be woken up via CAN bus, which is required by some automobile instruments. Detailed circuit is provided in the datasheet of TJA1040, so the repetitious details need not be given here. Note that for high-speed CAN, both ends of the pair of signal wires must be terminated. ISO 11898 requires a cable with a nominal impedance of 120 Ω [19]; therefore, 120 Ω resistors are needed for termination. Here, only the devices on the ends of the cable need 120 Ω termination resistors.

The 7-inch TFT-LCD has a resolution of pixels and supports the 24-bit for three RGB colors. The interface of the 60-pin TFT-LCD can be categorized into data interface, control interface, bias voltage interface, and gamma correction interface.

The data interface supports the parallel data transmitting of 18-bit (6 bits per channel) for three RGB colors. Thus, a range of colors can be generated. The control interface consists of a “horizontal synchronization” which indicates the start of every scan line, a “vertical synchronization” which indicates the start of a new field, and a “pixel clock.” This part is controlled by the graphics display controller which is integrated in the MB91F599. We just need to connect the pins of the LCD to those of the microcontroller correspondingly.

Bias voltages are used to drive the liquid crystal molecules in an alternating form. The compact LCD bias IC TPS65150 provides all bias voltages required by the 7-inch TFT-LCD. The detailed circuit is also provided in the datasheet of TPS65150.

The greatest effect of gamma on the representations of colors is a change in overall brightness. Almost every LCD monitor has an intensity to voltage response curve which is not a linear function. So if the LCD receives a message that a certain pixel should have certain intensity, it will actually display a pixel which has intensity not equal to the certain one. Then the brightness of the picture will be affected. Therefore, gamma correction is needed. Several approaches to gamma correction are discussed in [20–22]. For this specific 7-inch LCD, only the producer knows the relationship between the voltage sent to the LCD and the intensity it produces. The signal can be corrected according to the datasheet of the LCD before it gets to the monitor. According to the datasheet, ten gamma correction voltages are needed. These voltages can be got from a resistive subdivision circuit.

For this instrument, the LED indicators, the backlight, and the chord alarm need to be supplied with a voltage of +12 V; the CAN transceiver, the EEPROM, and the buttons need to be supplied with a voltage of +5 V; the video buffer circuit, the external FLASH, and the data interface of the LCD need to be supplied with a voltage of +3.3 V. Besides, the microcontroller needs to be supplied with voltages of +5 V and +3.3 V simultaneously. Figure 8 offers a detailed block diagram of the power supply for the automobile instrument.

The main task for the program is to calculate the driving parameters of the vehicle and display them on the TFT-LCD. The calculation is triggered by the input signals via the sampling circuits or the CAN bus. The main program flow chart of the system is shown in Figure 10.

The design scheme of a TFT-LCD based automobile instrument is carried out form aspects of both the hardware and the main program flow chart. The MB91F599 simplifies the peripheral circuits with its rich on-chip resources and shows high performance in real-time data processing. The automobile instrument is capable of displaying the velocity of the vehicle, the engine speed, the cooling water temperature, the oil pressure, the fuel volume, the air pressure, and other information on the TFT-LCD, which contributes a lot to driving safety and satisfies drivers’ aesthetics. Besides, the rearview video makes the parking and backing easier and safer for the driver. Moreover, the CAN bus interface and TFT-LCD make it easier for the upgrading of the instrument without changing the hardware, thus saving the cost.

Have you ever asked yourself what LCD is? No worries, we are here for you. Therefore, like in any display gadget, liquid crystal display coordinates with a microprocessor or microcontroller. The MCPU and MCU send the brightness that every pixel should produce. It creates the required color of the pixel for your LCD screen.

However, the mode of communication between the MPU/MCU and an LCD segment is known as the interface. We shall discuss more of the LCD interface in this guide.

The LCD interface is a link between the flat panel display module and the multimedia processor. Therefore, the interface can be separated or incorporated as part of the structure on the chip. Additionally, the application produces an image, and then the screen displays it using an LCD interface for the user.

The Serial Peripheral Interface is a data bus with several lines for the data. It accurately harmonizes the two ends of the data transmission. Therefore, the signal clock rotates, indicating when to sample the data bits on the line.

Besides, the serial peripheral interface has another component known as the slave select (SS) or chip select. The function of the SS is to wake the peripheral to receive or send data. For instance, since the SPI can support several peripherals, the SS can wake particular peripherals instead of all. Finally, you can use the SPI in graphic, character, digit, and small TFT LCDs. It allows simple interfacing, affordable hardware, and faster speeds than in the SCI.

It is another serial interface in LCDs that resembles the SPI with slave, clock functions, and master. The I²C does not integrate the SS line as in SPI. Therefore, a process known as addressing is essential in selecting a slave to communicate. A frame of the signal is sent on the data bus to address a specific slave after the first bit. Nevertheless, the output signal gets to every slave connected with, although only the slave with the corresponding address to the signal will receive the message.

The MCU interface is essential because it can write and read data stored in the internal frame bugger or the gadget"s storage. Therefore, if you want to store images for future use, MCU is the best match for you.

Additionally, in MCU parallel interface for Liquid Crystal Displays, data signals are sent through data lanes on either 18-bit, 16-bit, 9-bit, or 8-bit data channels. Besides, the MCU interface is simple, although it requires a display RAM for its memory functionality. Also, you can use it in graphic LCDs, character LCDs, and small TFT LCDs.

LVDS is an acronym for Low-Voltage Differential Signaling. This type of interface is essential as a complement for large LCDs and peripherals that require high bandwidth, such as HD graphics and fast frame rates. Therefore, it is a good choice due to its fast data transmission while consuming low voltage. One of the LVDS interface wires carries the precise inverse of its companion. Additionally, the electric charge from one wire is correctly masked by the other wire, reducing the interference to the wireless system nearby. Finally, at the recipient end, a circuit checks the variation in voltage between the two wires.

Red Green and Blue (RGB) interface functions are to link with color displays. It transmits 8 bits of data for each of the colors in every clock oscillation. Therefore, this means there are 24 bits of data sent for every clock oscillation.

Currently, you must have seen an improvement in terms of performance as electronic devices become smaller and easy to use. Therefore, this has led to the introduction of an embedded display port. The interface connects a video device to a display device and carries USB, audio, and other data forms. Moreover, this display port offers a high-performance external A/V interface hence high display resolutions of 4K. Additionally, the motive behind the development of this interface is due to several computing requirements. First of all, the main requirement is hardware integration.

This is a new technology development from the MIPI alliance. Mobile Industry Processor Interface has become a preferred option for mobile developers. This interface uses the same signaling as in LVDS. It uses a clock pair and 1-8 data lanes. Mobile Industry Processor Interface supports complex rules that allow low power and high-speed modes. Additionally, it reads data coming from the display at low rates.

When choosing the correct display interface for your device, you need to consider several factors. Therefore, it requires you to know how to connect the display to your electronic system. Nevertheless, it would be best if you choose the correct interface for your display. Additionally, consider the amount of data transferred and the refresh rate your system requires.

Finally, we have made it easier as we have given you all the details on each display interface, including the pros and cons. Therefore, having gone through our guide, you will never have issues when making your choice.

ER-TFT050-2 is 480x272 dots 5" color tft lcd module display with ILI6482 driver IC,optional 5 points capacitive multi-touch panel with controller GSL1680 and optional 4-wire resistive touch panel screen,superior display quality,super wide view angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO, ARM and Raspberry PI .It can be used in any embedded systems,car,mp4,gps,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports rgb interface. FPC with zif connector is easily to assemble or remove.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey