stone tft display free sample

Fingerprint product development: the development of fingerprint lock, fingerprint safe, fingerprint access control, fingerprint attendance Fingerprint integration application: integrated in all kinds of security products, such as intercom, switch, personnel identification, permission management. 5 inch STONE STVC050WT 4:3 TFT-LCD module 480*272 LCD-TFT Displayer introduction In this project, I would like to use the display screen of STONE STVC050WT to display the status of the fingerprint module (fingerprint entry status, fingerprint contrast status and deletion of fingerprint data).

This display has been integrated with the driver chip, and the development software can be provided for the user to use, the user just need to add the designed UI picture through the computer software button, text box, and then generate the configuration file to download into the display and then run. The STVC050WT display communicates with MCU through uart-ttl signal. In theory, STONE display screen and fingerprint module can communicate directly. However, due to the different communication data protocols of the two modules, it is impossible to shake hands. Therefore, a MCU is still needed for conversion.

We just need to add the designed UI images through menu bar options for buttons, text boxes, background images, and page logic through the host computer, then generate the configuration file, and finally download it into the display and it is ready to run.

To develop based on our STONE TFT LCD, you first need to use to an upper computer development software STONE designer, in this upper computer, all screen-related settings are carried out in this upper computer, so how to download it, click the link below to go to the official website:https://www.stoneitech.com/support/download

First add a button control to the temperature, select “button” control, and draw the corresponding area; then in the right feature settings, set the button effect, here select page 2, that is, when the button is pressed, the corresponding area to display the effect of page 2; then select the page switch function, here select the No. 4 page, that is, when this button is pressed, the page will immediately switch to page 4, that is, the temperature display interface.

Under the temperature display interface, a text display control is needed to display the real-time temperature data passed by the Arduino, so it is necessary to add a data variable control, as shown in the following figure.

First of all, you need to set the variable address of the control, this address is very important, the data of the micro-controller can only be displayed by sending data to this address, and then set the format of the display, here choose 2 integers and 1 decimal.

If you feel that the font size of the display is too small to see clearly, you can also adjust the font size, and finally the alignment, I generally choose the center alignment, of course, there are also left-aligned, right-aligned to choose.

The STONE TFT LCD sometimes needs to control the micro-controller to achieve a two-way interaction, which is also the case here, and needs to implement the start and stop acquisition function, using the START button as an example.

First set the key effect, here select page 2, when the key is pressed it will display the effect of page 2, here there is no need to switch pages, so select null, it should be noted that it is also necessary to set a variable address.

After setting, click compile, then insert the U disk, wait for the recognition to finish and click download to copy the project into the U disk, and plug in the display to upgrade. In this way, the whole project is finished.

Just a simple reminder, if you run into problems with your development, Stone has an official forum where you can ask technology-related questions https://forum.stoneitech.com/

A: We don’t have to write any code for the display or program the driver. Our display set include CPU and memory, you can directly use .jpg file to generate a GUI and use it to send HEX command set to communicate with your micro control unit.

A: We provide 3 years unconditional warranty for our I-serial and A serial display, 1 year unconditional warranty for the C-serial display. You can get a free replacement if your display was damaged or failed.

In the application of this paper, I will use the STONE TFT LCD screen, esp32 microprocessor, photosensitive resistance sensor, and DHT11 temperature and humidity sensor to realize the real-time monitoring of the surrounding environment and push the collected data to the TFT LCD screen for display. The communication mode of esp32 and STONE TFT LCD adopts serial port communication.

This application function is divided into three parts: temperature monitoring, humidity monitoring, and light monitoring. After startup, there will be a boot interface first. After a moment, you will enter the main function interface. In this interface, we can select the monitoring items, such as temperature, humidity and illumination. There will be a text box under the temperature monitoring interface to display the temperature data transmitted from esp32, a “start” button, and a “stop” button to start and stop the temperature monitoring. If you want to exit the interface, you can select the “return” button; the second item is humidity monitoring, and there is also a text box under this interface for displaying esp 32. For the humidity data transmitted, the “start” and “stop” buttons are used to start and stop monitoring, and a return button is used to exit the current interface. The third item is light intensity monitoring. Different from the previous two functions, counting is used here, and one is added every time there is light.

To make this application, first of all, on device selection, this application needs to use DHT11 temperature and humidity sensor, photosensitive resistance sensor, some DuPont wires, an esp32 as the main controller, and a STONE TFT LCD screen for communication with the MCU.

Touch screen control / display image / display text / display curve / read and write data / play video and audio. It is suitable for various industries.

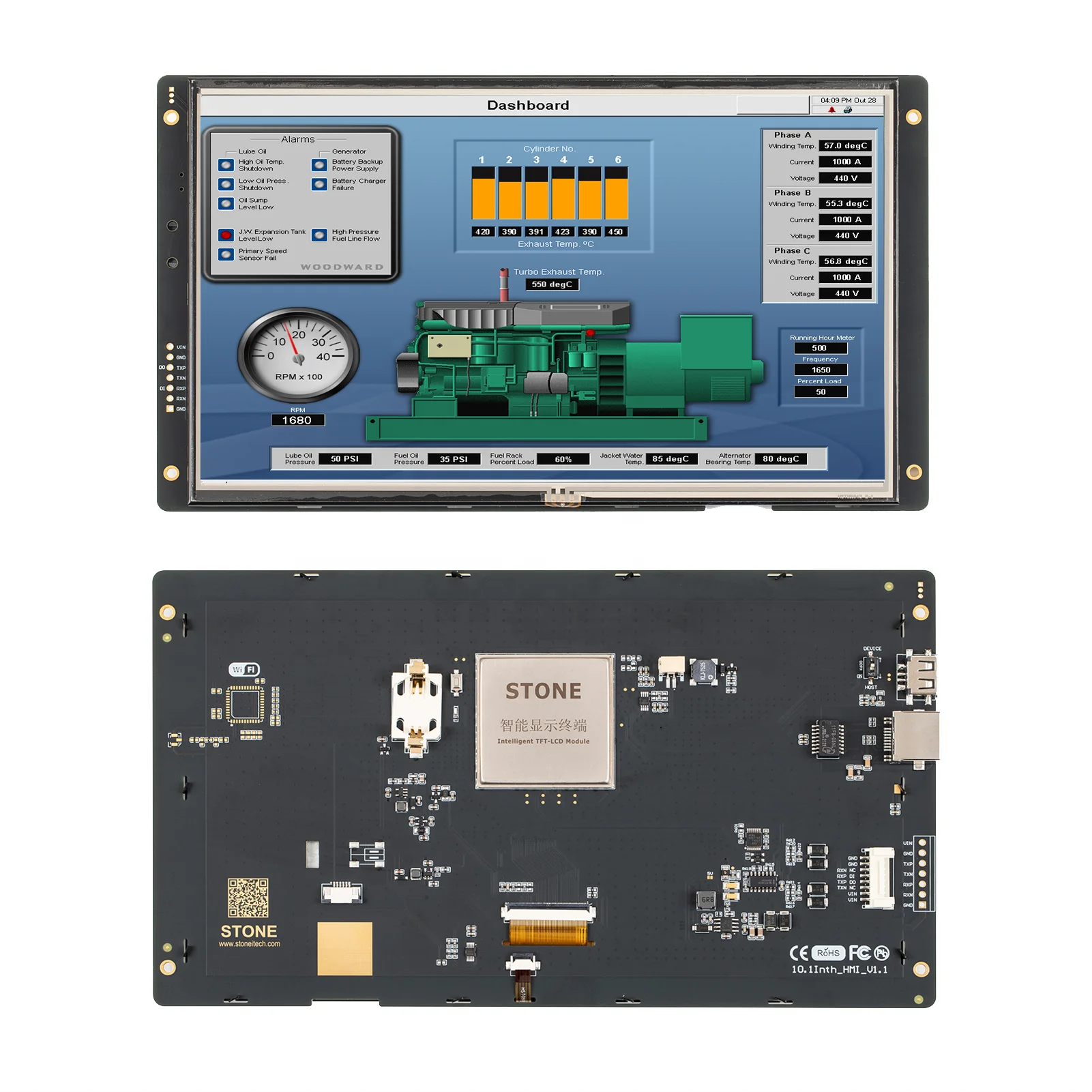

STVC101WT-01 module communicates with MCU through serial port, which needs to be used in this project. We only need to add the designed UI picture through the upper computer through the menu bar options to buttons, text boxes, background pictures, and page logic, then generate the configuration file, and finally download it to the display screen to run.

To develop based on our STONE TFT LCD, we need to use a host computer development software tool 2019. On this host computer, all screen related settings are carried out on this host computer.

Select “New project”, set the screen size to 1024 * 600, and set the project name to STONE. Finally, select the path to save the project, and then click OK.

First, add a button control to the temperature, select the “button” control, and draw the corresponding area; then, in the feature setting on the right, set the button effect. Here, select Page 1, that is, when the button is pressed, the effect of page 1 will be displayed in the corresponding area; then, select the page switching function, and the page No. 3 selected here will immediately press this button Switch to page 3, which is the temperature display interface.

In the temperature display interface, a text display control is needed to display the real-time temperature data transferred from esp32. Therefore, it is necessary to add a data variable control, as shown in the figure below.

First of all, you need to set the variable address of the control. This address is very important. The data of MCU can only be displayed by sending data to this address. Then set the display format. Here, select 2-digit integer and 1-digit decimal. If you think the displayed font size is too small to see clearly, you can also adjust the font size. Finally, the alignment method is used. Generally, I choose the center alignment However, there are also left and right alignment options.

Sometimes the STONE TFT LCD also needs to control the microcontroller to achieve a two-way interaction. This is also the case here. It is necessary to realize the functions of start acquisition and stop acquisition. Take stop button as an example.

First of all, set the key effect. Select Page 1 here. When the key is pressed, the effect of page 1 will be displayed. There is no need to switch the page here, so select null. It should be noted that a variable address should also be set. This variable address cannot be repeated, otherwise it may be invalid. The variable address here is set to 0x000E, and a key value needs to be set to 0x0003, this value will also be issued as the key is pressed.

After setting, click compile, and then insert the U disk. After the identification is completed, click download to copy the project into the U disk, and plug in the display screen to upgrade. In this way, the whole project is completed.

I decided to use Arduino to verify the heart rate and blood oxygen collection function of MAX30100. WithSTONE TFT LCD screen for monitoring blood pressure.

The driver chip has been integrated inside the display screen, and there is software for users to use. Users only need to add buttons, text boxes, and other logic through the designed UI pictures, and then generate configuration files and download them into the display screen to run.

The display of STVI070WT-01 communicates with MCU through the UART RS232 signal, which means that we need to add a MAX3232 chip to convert the RS232 signal into a TTL signal so that we can communicate with Arduino MCU.

If you think the level conversion is too troublesome, you can choose other types of displayers of STONE Tech, some of which can directly output UART-TTL signal.

The Arduino Mini Pro development board and STVI070WT-01 TFT-LCD display screen are connected through UART, which requires level conversion through MAX3232, and then the Arduino Mini Pro development board and MAX30100 module are connected through the IIC interface. After thinking clearly, we can draw the following wiring picture:

First of all, we need to design a UI display image, which can be designed by PhotoShop or other image design tools. After designing the UI display image, save the image in JPG format.

First, perform step 1, then insert the USB flash drive into the computer, and the disk symbol will be displayed. Then click "Download to u-disk" to Download the configuration file to the USB flash drive, and then insert the USB flash drive into STVI070WT-01 to complete the upgrade.

If you need to change the display content in the corresponding space, you can change the display content by sending data to the corresponding address of the display screen through the serial port of Arduino.

We can see that when the fingers leave the MAX30100, the heart rate and blood oxygen display 0. Place your finger on the MAX30100 collector to see your heart rate and blood oxygen levels in real-time.

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino Project Ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino Project.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE TOOLBox . This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU . Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

STONE TOOLBox features a drag-and-drop mechanism and comes with simple instructions. Hence, even beginning engineers can quickly and seamlessly create an impressive user interface within minutes.

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

With faster project timelines comes greater production savings. Stone’s modules are cost-effective and since they have superior quality, you’re assured of a quick return-on-investment (ROI) with fewer costs on maintenance and repairs in the long run.

STONE creates modules that are easy to assemble if you’re doing an HMI project. Add to that its user-friendly GUI software that lets you seamlessly create GUIs for your new HMI device.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

Over the years, Stone’s modules have been used to create numerous projects featuring its reputable HMI technology. These project ideas cater to a wide variety of fields and industries.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The finished product displays information about the connected oxygen tank such as concentration levels and other advanced data. All these data are displayed on a streamlined interface developed using TOOLBox software.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

This project resulted in a simple electronic scale made by connecting STONE’s 5-inch touch screen to a development board, an ADC conversion module, and a pressure acquisition module. The finished product can:

STONE TOOLBox and graphics software such as Adobe Photoshop was used to design the user interface. Meanwhile, the hardware pieces were wired together and an MCU code was written for the electronic scale to be functional.

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey