beaglebone lcd display made in china

Continuity loss? Used a multimeter to check connections to the FPC. All looks good, nothing strange. Somewhere in between this testing the LED backlight wasn"t lighting up when I connected the LCD. Whoops! I burn 4 LED drivers in the process (but they seem to have open LED "protection"?). Add a 16V Zener across the LED lines to prevent re-occurrence. The LEDs are in a 3-series (and currently unknown parallel lines) configuration and draw 9.5V.

Maybe some signal integrity issues? It"s Scope time.Put cape on the BBB, LCD disconnected. Probe signal pins. The highest frequency signal, PCLK (@30 MHz) appears clean enough. Data lines look good as well.

Look at the LCD panel under strong light. Was able to make out the Beagle on the screen, once again. The screen looks stable (a direct consequence of the fact that the signals look good on the scope).

Okay, now that we know the issue, we should need to just add some bypass caps to fix it? Sprinkle a few 10uF 0805 ceramic caps, one before the LED driver and the other across the LED driver output still the display appears to be as unstable as it was before.

At this point I asked in the HaD channel, and with feedback that maybe the onboard 3.3V of the BBB is not supplying enough current to power everything, try to power the entire cape with a 1117-3.3 fed from the 5V of the BBB. An unstable display, still.

I look at existing cape reference designs (CircuitCo BB-VIEW7 and 4DSystems 70T) and find that they power their LED drivers off the 5V rail, and not the 3V3 VDD rail. Maybe they knew something about ripple from LED drivers affecting the LCD supply?

Note: There are two models of LCD CAPE, LCD CAPE (4.3inch) and LCD CAPE (7inch), each one corresponds our 4.3inch or 7inch resistive touch screen respectively. Some batches of LCD CAPE provide both interfaces. If the CAPE connected to the LCD by a wrong interface, it may damage the LCD and the main board.

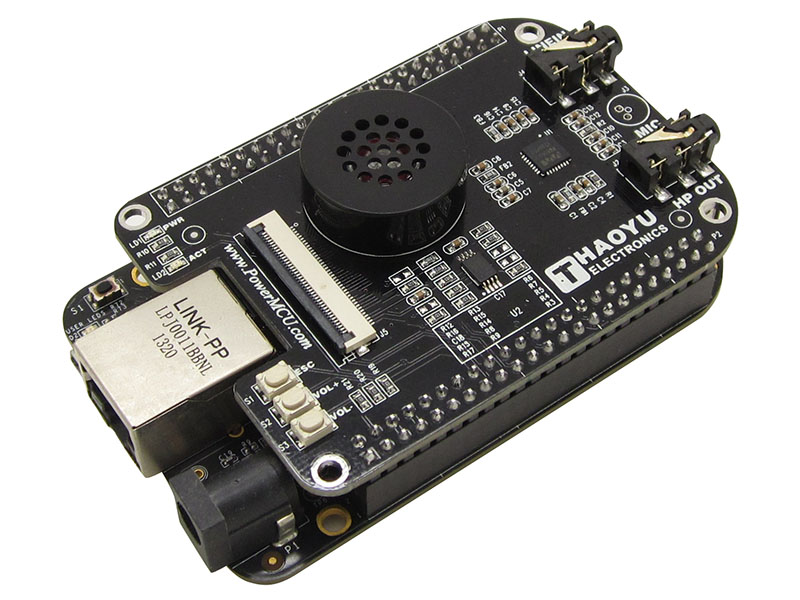

Two BeagleBone Black and two RS485/CAN CAPEs are required for this testing. Set jumper to enable UART1(RXD1, TXD1). Connect two CAN Board to CAN1 interface separately, connect the CANH, CANL of one module to the CANH, CANL of another module via jumper wires.

Two BeagleBone Black and two RS485/CAN CAPEs are required for this testing. Set jumper to enable UART2(RXD2, TXD2). Connect two RS485 Boards to UART2 interface separately. Connect the A, B of one module to the A, B of another module via jumper wires.

NHD-7.0CTP-CAPE-N | BeagleBone Black Cape with TFT Display | 7.0" Sunlight Readable LCD | Capacitive Touchscreen | EEPROM with On-Board Dip Switches | Developing with Android & Linux

Engineered in Elgin IL USA, we designed this BeagleBone Cape to be a perfect fit for our 7.0” TFT displays and upgraded it with the sunlight readable NHD-7.0-800480EF-ASXN#-CTP display model. With capacitive 5-point multi-touch functionality and 800x480 resolution screen, this cape works seamlessly while developing with operating systems like Android and Linux. It includes an on-board dip switch for configuring EEPROM and secondary headers for additional cape connections. In addition to the secondary cape slot, we added four 3.5mm mounting holes that are compatible with standard M3 screws, a reset button, write protection pins, PWM backlight control, and an LED power indicator. With this cape we’ve made it easy to take your design process from concept to reality. When paired with the BeagleBone Black board (sold separately by beagleboard.org) you’ll have everything you need to plug-in and start developing.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Finally, I ended up choosing a 2.2" 18-bit color TFT LCD display that was branded and transplanted onto a breakout board by Adafruit. It"s fairly large and has decently robust graphical rendering capabilities for it"s price, although it was somewhat overkill for this project.

Note:The PocketBeagle used in this project has had its P1 VBUS and VIN pins solder bridged, in addition to its DN and DP pins. Refer to the below wiring diagram to clarify confusion at any point (also acknowledge that the SPI display below is not the exact same as the one used in this procedure).

This should run the script! It may take a few seconds before the screen refreshes and begins displaying readings. Ideally, it"ll function something like this:

Thus, I implemented my main loop to not display a reading for PM0.5 initially, then only update when a valid reading comes in (and leave that reading there until a new valid reading comes in). This is really just a workaround at this point, though the AHT10 and CCS811 sensors seem to work fairly well. The above video is close to a best-case scenario, it is not unlikely for the PM0.5 reading to stay on WAIT for upwards of 30 seconds to a minute.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey