future designs lcd displays made in china

As China witnesses the phenomenal growth of its display industry, its global counterparts also face new challenges. Large-scale production of traditional LCD panels has fallen into a “dilemma of abundance”, where the current focus of display enterprises has shifted to how to best develop the potential of new technologies.

Previously, vehicle display pursued an integrated design with a relatively long life cycle. However, an increasing number of separation screen designs is emerging with a shorter life cycle, which demonstrates five major visible development trends in consumer electronics display.

Large screen – a major trend in vehicle display. With the nonstop development of intelligent driving technology, cars will become more interactive and intelligent. Akin to mobile phone screens, vehicle display size will also continue to expand. Moreover, vehicle screens can now be expanded horizontally and vertically so as to provide a wider display space. In fact, a multitude of vehicles has begun to carry large screens. For example, all Byton vehicles come equipped with a 48-inch LCD screen.

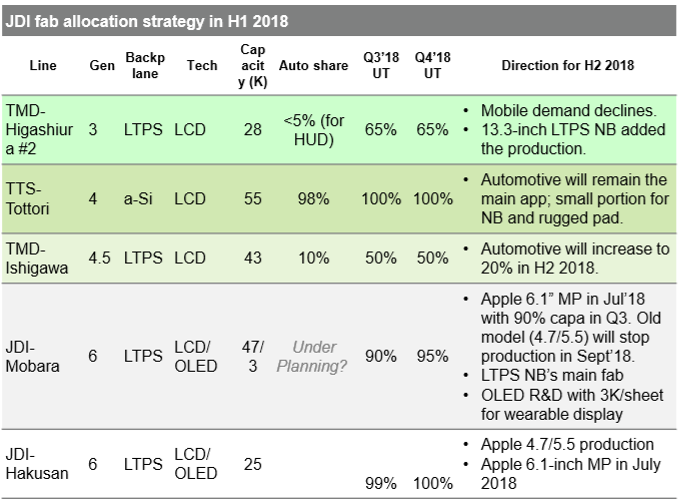

High-definition – as mobile phone screens continue on a path of development, consumers will continue to propose higher requirements for vehicle display resolution. Low-resolution display has lost the ability to meet market demand, leading vehicle display closer towards higher resolution. LTPS LCD has better electron mobility than a-Si LCD, which is capable of meeting higher-resolution requirements. Due to its advantages of narrow bezel, high brightness and In-cell, LTPS is now widely adopted by manufacturers. JDI and Innolux were the first to move into mass production of LTPS, according to Sigmaintell, while TIANMA, LGD and AUO are currently in the game. In addition, panel makers, led by JDI, have been recommending LTPS technology to vehicle manufacturers since 2017. In the same year, LTPS took up 2% of the market share in the vehicle display industry. In effect, in addition to resolution, high-definition vehicle display has also led to higher requirements in contrast, field of view, optical index and response speed.

Multi-screen - In addition to dashboard and central-control displays, much more is coming in the vehicle display arena. TIANMA believes that multi-screen can be viewed from two angles. The first is “from 0 to 1”, which means vehicles, where no screen existed before, can now be equipped with one, such as a rear seat control display or vehicle key display. The second is “from 1 to an”". HUD and Mirror were previously only installed in high-end vehicles. Due to security demands and the introduction of AR technology, HUD and Mirror have since seen significant development.

CODA and Reed Exhibitions Kuozhan will be holding DISPLAY CHINA 2019 on June 26-28, 2019. Its show floor will feature a 180-square-meter area, namely the New Vehicle Display Innovation Display Area. Invitees will include professional visitors of all levels from the automotive electronics industry, together with touchscreen and display panel factories. The concurrently held Smart Cabin & Vehicle Display and Intelligent Interactive Technology Conference 2019 will be held in cooperation with New Energy Times on June 28. This conference will discuss hot topics such as next-generation, vehicle image display control technology and flexible OLED applications, the latest solutions in multi-screen integration, DLP projection technology, holographic technology, vehicle display full-fit processes (OCA, OCR full-fit technology, full-fit process and problem analysis, In cell/On-cell technology application in vehicle), as well as exploring and predicting the development and future trends of the smart cabin market.

The organizers of DISPLAY CHINA long foresaw these trends, along with the struggle to promote industry development. To that end, they have striven to create an exclusive commercial platform dedicated to intelligent and interactive display, where buyers and industry leaders from commercial display, digital sign factories, vending machine manufacturers and interactive machine manufacturers can experience and purchase the latest touch display technology. The concurrently held Intelligent Interactive Development Summit will discuss the future development model of digital cities with, among others, industry experts, panel exhibitors and logo production buyers, who’ll be sharing their experiences and insights with a focus on the aspects of new framework materials, environmental protection and sustainable development to new display technologies, new software integration solutions and current commercial space solutions.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

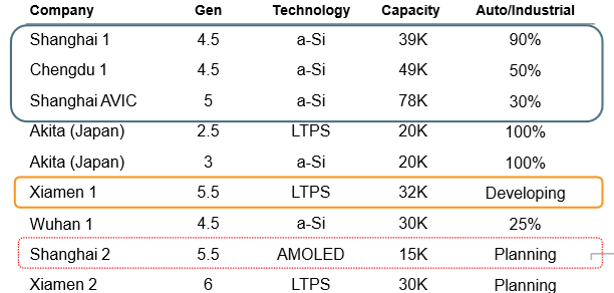

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

The largest 5mm LED screen in China has been ceiling mounted at a shopping centre in the country’s ancient capital city Xi’an. The 1,200 sqm screen from LianTronics is described as a “giant sky screen” which is “creating a stunning 24K, 3D future world”.

The new sky screen follows previous projects in which LianTronics LED displays were used to create giant, glasses-free 3D LED walls in the Sino-Ocean Taikoo Li Chengdu and Chongqing MICC Building projects.

Amid rising concerns about the availability of LCD panels from Korean firms, television brands are revising their sourcing strategies to make greater use of Chinese suppliers, according to IHS Markit | Technology, now part of Informa Tech.

Korean LCD TV panel makers are undergoing fab restructuring and shutdowns in 2020. This event is likely to result in changes to the supply chain that will spur TV makers to seek alternative supply bases that are both reliable and competitive enough to ensure they meet their increased shipment targets in 2020, as reported by the TV Display & OEM Intelligence Service.

The global top-three TV brands are set to increase their purchasing from Chinese suppliers to 62.6 million displays in 2020, an increase of 35 percent from 2019.

The competition between major Chinese suppliers BOE Technology and China Star Optoelectronics Technology is intensifying, particularly in the realm of LCD panel supplies from Gen 10.5 fabs. Meanwhile supply availability is improving at emerging Chinese panel makers such as HKC, Nanjing CEC-Panda LCD Technology and Xianyang Caihong Optoelectronics Technology (CHOT).

Although panel supply still exceeds demand, top-tier TV brands are signing long-term supply agreements with both captive and selective external panel suppliers to ensure they get the highest priority business in 2020. Current supply dynamics and competitive changes have led the brands to rethink their purchasing plans for this year as well as the future.

In-house support, both on the supply and demand sides, is becoming critical. As such, it is important for LCD panel suppliers and TV makers together to build a strong fully integrated TV (FIT) business model.

In 2020, Samsung’s panel sourcing from its captive supplier, Samsung Display, will be further reduced. Samsung Display has plans to convert its LCD TV panel capacity to quantum dot displays. Additionally, the availability of Samsung Display’s LCD-TV panels will be limited from this year onwards, significantly cutting down its panel supply to external customers, particularly Chinese TV makers.

LG Electronics’ sourcing volumes from LG Display will also be slashed in 2020. Nevertheless, LG is likely to purchase from external vendors such as BOE Technology, HKC and Nanjing CEC-Panda LCD Technology to make up for the possible loss of LCD TV panel supply availability from LG Display in 2020.

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

Introduction: Global LCD industry shift and automotive intelligence together to promote the rapid development of China’s LCD panel industry, which will bring a continuous increase in demand for backlight modules, China’s backlight module industry has greater potential for development.

LCD panel backlight module consists of a backlight light source, light guide, optical film, and a plastic frame, which is an important component of LCD display panel. As the backlight module has technology-intensive and labor-intensive attributes, with abundant high-skilled labor advantage China is attracting the global LCD panel industry to the domestic rapid transfer.

From LCD application to the present, the global LCD panel industry capacity transfer has gone through three periods, 2000 Japan dominated the global LCD industry; 2000 – 2010, Japan’s production capacity to South Korea and Taiwan; 2010 to the present, Japanese manufacturers gradually withdraw from the LCD panel industry, production capacity began to transfer to mainland China, so far, mainland China LCD production capacity has occupied the global half of the world.

In recent years, South Korea’s Samsung and LG display will shift their business focus to OLED, and will gradually shut down their LCD production lines and withdraw from the LCD panel industry; at the time of South Korean manufacturers’ withdrawal, domestic enterprises are stepping up new construction to expand LCD production capacity.

BOE, Huaxing photoelectric, Huike, CEC in 2020 – 2021, a total of eight 7 generation LCD production lines completed and put into operation, and domestic panel manufacturers have further expansion plans, the next few years domestic LCD production capacity will continue to increase.

LCD panel manufacturers tend to choose the nearby supporting module suppliers for the safety of the key component supply chain and cost reduction considerations. LCD panel production capacity transfer to China will bring opportunities to domestic backlight module manufacturers and drive the development of the domestic backlight module industry.

The future of the car will pay more attention to the human driving experience, to the intelligent development, which will bring the increasing demand for car display. On the one hand, the number of car displays gradually increased, for example, the instrument panel, rearview mirror, central control platform more to display the way, the passenger and rear position with entertainment display. On the other hand, the car display is constantly to a large screen, multi-screen development, especially in high-end models, the large display has become standard, for example, Tesla Model S screen size of 17 inches, Mercedes-Benz A-class car configuration of two 10.5-inch display.

At the same time, there is also a huge demand for new cars in China. Although China’s car sales have reached 25 million, the current per capita car ownership in China is only a quarter of the developed countries, the future potential for new car demand is still very large. Therefore, China’s car display market growth potential is large, which will directly drive the domestic backlight module demand continues to increase.

According to the terminal application size, backlight module can be divided into large, medium, and small size, of which small size backlight module is mainly used in smartphones, wearable devices, and other terminals, the medium size used in notebook computers, tablet PCs, car screens and other terminals, the large size is mainly used in LCD TV.

From the industry development trend, smartphone display is transitioning to OLED, LCD TV market is gradually saturated, the future of large size and small size backlight module market potential is relatively small; and the future of the car display market potential is huge, by the backlight module manufacturers are unanimously optimistic, are currently accelerating the layout ( see Table 2 ). Focusing on the traditional medium-sized backlight module field, Hanbo Hi-Tech and Weishi Electronics have significant advantages in core technology patents, downstream customer resources, process experience accumulation, production costs, etc., and have more development advantages in the future.

The current global LCD display panel industry is rapidly moving to China, which brings development opportunities to China’s backlight module industry. In addition, automotive intelligence will also bring a continuous increase in demand for medium-sized car displays, the first to enter the field of medium-sized backlight module manufacturers with its customer resources, core technology, scale efficiency, and other advantages will be more beneficial.

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Given the relatively low resolution of printing technology, QLED shall be difficult to reach a resolution greater than 300 PPI (pixels per inch) within a few years. Thus, QLED might not be applied for small-sized displays at present and its potential will be medium to large-sized displays.

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

Although we cannot say that our advantages triumph over ROK, where Samsung and LG have been dominating the field for many years, we have achieved many significant progresses in developing the material and parts of OLED. We also have high level of innovation in process technology and designs. We already have several major manufacturers, such as Visionox, BOE, EDO and Tianma, which have owned significant technological reserves.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

After I returned to China, NajingTech (co-founded by Peng) purchased all key patents invented by me in the United States under the permission of US government. These patents cover the basic synthesis and processing technologies of quantum dots. NajingTech has already established capability for large-scale production of quantum dots. Comparatively, Korea—represented by Samsung—is the current leading company in all aspects of display industry, which offers great advantages in commercialization of quantum-dot displays. In late 2016, Samsung acquired QD Vision (a leading quantum-dot technology developer based in the United States). In addition, Samsung has invested heavily in purchasing quantum-dot-related patents and in developing the technology.

Peng: If electroluminescence can be successfully achieved with printing, it will be much cheaper, with only about 1/10th cost of OLED. Manufacturers like NajingTech and BOE in China have demonstrated printing displays with quantum dots. At present, QLED does not compete with OLED directly, given its market in small-sized screen. A while ago, Dr. Huang mentioned three stages of technological development, from science issue to engineering and finally to mass production. For QLED, the three stages have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Huang: But customers may not accept only better wider color range if they need to pay more money for this. I would suggest QLED consider the changes in color standards, such as the newly released BT2020 (defining high-definition 4 K TV), and new unique applications which cannot be satisfied by other technologies. The future of QLED seems also relying on the maturity of printing technology.

Peng: New standard (BT2020) certainly helps QLED, given BT2020 meaning a broad color gamut. Among the technologies discussed today, quantum-dot displays in either form are the only ones that can satisfy BT2020 without any optical compensation. In addition, studies found that the picture quality of display is highly associated with color gamut. It is correct that the maturity of printing technology plays an important role in the development of QLED. The current printing technology is ready for medium-sized screen and should be able to be extended to large-sized screen without much trouble.

Peng: Domestic industry sector has begun to invest in these future technologies. For example, NajingTech has invested about 400 million yuan ($65 million) in QLED, primarily in electroluminescence. There are some leading domestic players having invested into the field. Yes, this is far from enough. For example, there are few domestic companies investing R&D of printing technologies. Our printing equipment is primarily made by the US, European and Japan players. I think this is also a chance for China (to develop the printing technologies).

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

Zhao: Today there are really good observations, discussions and suggestions. The industry-academics-research collaboration is crucial to the future of China"s display technologies. We all should work hard on this.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

Foxconn, which received controversial state and local incentives for the project, initially planned to manufacture advanced large screen displays for TVs and other consumer and professional products at the facility, which is under construction. It later said it would build smaller LCD screens instead.

Rather than a focus on LCD manufacturing, Foxconn wants to create a “technology hub” in Wisconsin that would largely consist of research facilities along with packaging and assembly operations, Woo said. It would also produce specialized tech products for industrial, healthcare, and professional applications, he added.

Rather than manufacturing LCD panels in the United States, Woo said it would be more profitable to make them in greater China and Japan, ship them to Mexico for final assembly, and import the finished product to the United States.

He said that would represent a supply chain that fits with Foxconn’s current “fluid, good business model.”FILE PHOTO: A shovel and FoxConn logo are seen before the arrival of U.S. President Donald Trump as he participates in the Foxconn Technology Group groundbreaking ceremony for its LCD manufacturing campus, in Mount Pleasant, Wisconsin, U.S., June 28, 2018. REUTERS/Darren Hauck

The company may be prepared to walk away from future incentives if it is unable to meet Wisconsin’s job creation and capital investment requirements, according to the source familiar with the matter.

For more than a decade, smartphone designers have stuck closely to the humble rectangular slab. Yet of late, manufacturers are experimenting with wilder forms. We"ve seen devices with multiple displays, phones of different shapes, and handsets of varying sizes. Last year, Samsung and Motorola made clamshell-shaped flip phones that opened up to look like normal smartphones. Even Microsoft waded into the weird end of the pool with the Duo, a book-like phone with dual displays connected by a vertical hinge in the center.

The biggest barrier to widespread adoption of phones with these new designs is their high price. Samsung"s first foldable phone launched in 2019 for $1,980. Last year"s Z Flip cost $1,380, and Microsoft"s Surface Duo sells for $1,400. However, these technologies will start to get a little more accessible this year according to industry analyst Patrick Moorhead, founder and President of Moor Insights & Strategy.

"There is a price issue. I see that coming down this year," Moorhead says. "If there could be some penetration pricing done to get the entry level to $1,000, that would start to drive some considerable volume." Moorhead also expects we will see more of these foldable designs at the Mobile World Congress tradeshow in June. (MWC usually takes place at the end of February in Barcelona, but the show was pushed back to June due to the Covid-19 pandemic.)

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

DISPLAY VISIONS (before: ELECTRONIC ASSEMBLY) is THE manufacturer for high quality industrial displays. See here where and how these displays are developed and manufactured.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey