how to repair an lcd display supplier

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

The main control buttons may be faulty. Clean them with a metal cleaner, or jostle to attach a loose connection. If necessary, locate the circuit board they are attached to and re-solder any broken connections.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

How to repair LCD displays? Three visual inspection methods can help you solve problems, including external inspection, internal inspection and electrical inspection.

(1) External inspection: LCD display inspection should start from the outside, according to the working mode of the machine to check whether the buttons and switches on the operation panel are normal, whether the power connection is good, whether the video signal line is normal, etc.

(2) Internal inspection: LCD display in the external inspection did not find any abnormalities, open the display shell, check the internal circuit. Observe whether the solder joints and connecting wires of components are virtual soldering, de-soldering, whether the pins are mildewed or not, whether the plug-ins are loose, whether the circuit lines of printed circuit boards are broken, whether the components are burnt, burst or leakage, etc.

(3) Electricity check: LCD display is connected to the power switch to observe whether the power indicator light is on, whether there is fire, fever, burning odor and smoking in the machine.

People often ask how to repair the LCD display. In fact, this is a very professional problem, because precision instruments can not be explained in one word or two, so today I will tell you

3. #If all the above is OK, measure the LVDS voltage value. Under normal conditions, the LVDS signal’s RX+/ RX-voltage value is about 1.2v, and RX+/ RX-difference value is about 200mV. At the same time, the resistance of the LVDS signal to ground and the resistance between the LVDS signal pairs can be measured (100 ohms). If there is an exception to these values, try replacing the ASIC.

1. #Confirm whether the COF on side X is hot compared with the normal temperature, whether there is fracture or wear crack, and whether the COF is burnt.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

4. #Determine whether the gate IC is OK. There is a signal test point on the back of COG-IC, and the green paint can be scraped for measurement confirmation; If there is a gate IC problem, which IC fault can be confirmed. The confirmation of gate IC fault is only for analysis when you are interested, and this method is not recommended.

1. #Measure GM1~GM14, the values are arranged from large to small. In general, a certain gamma value will be abnormal in the case of NG, then try to replace gamma-IC;

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

Polarizer / CELL damaged To change the polarizer, a polarizer attaching machine is required The degree of whitening of the picture changes with different viewing angles

1. #Adjust the VR knob to see whether it can be adjusted and whether the screen performance changes. At the same time, confirm the VCOM value (about 7v), if NG, replace the VR knob.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

3. #If the whiteness changes significantly with the view Angle, and above 1&2 analysis is all OK, polarizer NG or CELL NG can be basically determined.

3. #Confirm whether the gate IC is OK. There is a signal test point on the back of COG IC, which can scrape the green paint for measurement confirmation; Or cut COF halfway from G3. If there is a gate-ic problem, which IC fault can be confirmed.

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

3. #Confirm whether FP1 is open; if open, replaces fuse. If the 12V accessory of this model has a reverse diode, confirm the continuity of the diode and check whether it is burnt.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

6. #Disconnect RP32 to confirm VAA, if NG, try to change the PWM IC (in general, it will be good), if still NG, try to change the gamma-ic or corresponding to the VAA several large capacitances (in general, it is rare, this situation is generally accompanied by VAA to the ground short circuit).

3. #Shaking module, if vertical lines disappear or reappear, then it can be judged that the possible cause is COF pin broken, and the crease should be found under the OM microscope.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

Lamp line is broken Replace the lamp tubing Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

4. #The above disassembly judgment can basically solve the problems of point-off in the market. If you can’t tell the truth, you can directly change the lamp tube.

Lamp line is broken Reconnect / replace lamp tubing Depending on the protection status of the power board, it may be a backlight with a dark band or it may be a point-off.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Your choice of equipment between reputable brands such as Barco, NEC, Panasonic, and Sony, as well as Ampronix’s in-house, manufactured medical displays: CHROMAMAXX, LUMIMAXX, MEDVIX, MODALIXX and VERSAPAXX - all offer universal solutions to your current system.

Commercial LCD displays are flat-panel monitors that use light modulating properties of liquid crystals to reflect or produce images in color or monochrome. Negating the use of phosphors, LCD screens do not suffer image burn-in in their depiction of arbitrary images. These displays are utilized in a number of applications such as computer monitors, televisions, instrumental panels, as well as indoor and outdoor signage.

The service center at Ampronix is available to repair your medical-grade LCD monitors capabilities with a turnaround time in as little as 24hrs. Hot-swap exchanges are also available for customers, for our goal is to provide a cost-effective method to extend and maintain the life of your imaging equipment. All commercial-grade monitor repairs are performed onsite by experienced technicians and come with a minimum one year warranty.

As a leader in medical imaging technology since 1982, Ampronix develops, distributes, and services groundbreaking solutions that promote optimal patient outcome. Our goal is to offer the assurance necessary to overcome operational and financial obstacles of the evolving healthcare industry.

The world-class Research and Development team at Ampronix specializes in developing innovative medical imaging solutions to overcome challenges created by gaps in current technology. Our expert engineers design products as a solution for OEM (Original Equipment Manufacturer) companies that always exceed their expectations.

After 40+ years of building relationships with industry leaders, Ampronix has become an established master distributor for many reputable brands. Maintaining these prosperous partnerships is how Ampronix is able to offer high caliber products with preferred pricing. Moreover, we equip international distributors with a variety of our innovative products in order to support their growth.

With over a century of combined experience, Ampronix’s state of the art service facility employs highly qualified technicians to diagnose and repair all types of imaging equipment and peripherals. In fact, our experts expose and correct manufacturer weaknesses, which result in longer-lasting, more efficient equipment.

Since our humble beginnings, we have focused on putting the satisfaction of clients first, as professionalism is our cornerstone. With reliability, safety, and quality at the core of our philosophy, Ampronix is dedicated to helping others save lives and create a healthier tomorrow for future generations.

manufacturer is not shown here, it is very likely we can be of assistance. Just contact us for more information using our Contact page, or call 800-605-6419

With an array of different timing profiles and the use of a video-signal generator, full testing is available on most display models we can offer support for.

CRT Monitors: given the nature of the CRT displays, repairing them is often not a viable option. To a large extent this depends on the severity of the damage. When something fails within a CRT display, it often triggers deterioration of other components at the same time. This sometimes leads to a repaired CRT monitor fail again and again, even after a thorough repair.

When a CRT monitor is damaged beyond repair, we have a wide range of different retrofit options available to help get that machine back up and running with an even brighter and clearer image compared to the original monitor.

Neoti certified technicians will repair or replace diodes, modules, shaders, receiving cards, hub boards, power supplies, and more. We approach each LED display screen repair with industry knowledge, skill, and experience. Our passionate, dedicated team commits their time and energy to solve any display problem that arises. We diagnose and develop the right course of action to restore your screen.

We also know that a damaged screen can impact your visitors’ experience or even delay an upcoming event. To help you move forward, we execute LED panel repairs quickly and efficiently. We complete repairs for various industries, such as broadcast, education, stadiums, and corporate organizations.

Affordable service contracts are available, so you can keep up with routine maintenance for your LED panels. We can also step in and perform repairs as needed.

When your LCD display has broken, needs replaced or simply needs a technology upgrade, and you have design/equipment elements to consider, you will want to look for a replacement part instead of replacing the unit.Problems may arise when you are sourcing the new panel from your original manufacturer.For example, by the time your panel has degraded, your LCD may be end of life, making it difficult to source;original manufacturers may be charging premium prices for their replacementLCD parts.AGDisplays offers a drop in replacement service for customers who need to replace an LCD or LCD component when their original panel/part is unavailable;this service is also for customers who are looking for a cost effective, suitable replacement or upgrade to their existing LCD. AGDisplays offers availability of standard or custom high-quality LCDs of virtually all shapes and sizes.

Replacing or upgrading the LCD component of your equipment sounds intimidating. It is rather simple if you begin your search with AGDisplays. By simply providing us with your panel part number, general specifications (if possible) and any other upgrade requirements or desires that you might have, we source these products for you or we can source an equivalent replacement, as desired. Using a replacement LCD does not compromise on quality and compatibility;we ensure functionality and performance are top priority because we know how critical the LCD interface is for your application.

You may receive notifications from your original equipment manufacturer about your LCD panel. There are a couple of announcements to pay attention to. The most important two are the end of life (EOL) announcement and the end of sale date. The end of life announcement will officialize a future cease production date for the indicated part number. It may also indicate the end of sale date, which is the last date customers are able to order the product through the manufacturer. After this date, the product will no longer be for sale. Typically end of life announcements come six to twelve months before the last time buy date. A few months later is when your last time buy will ship.

If you decide by this point that your equipment is well suited to use the LCD replacement, you may want to grab these panels when they get into the last time buy phase. If you find yourself ready to upgrade after EOL and last time buys have passed, don’t fret.A drop in replacement unit extends the lifecycle of your unit in the case of EOL or unavailability of original parts. Products are matched for compatible integration without compromising quality. AGDisplays offers a full line of compatible replacement industrial LCD display systems. When your design requires an upgrade in features but you still want to retrofit the LCD into your existing equipment, AGDisplays works together with you, discussing requirements and performance options. Our experts have an eye on the safety and longevity of your electrical components. We source alternative panel with same specifications to replace the panel in your equipment. Our drop in replacement LCD displays are selected carefully, with safe and stable compatibility in mind.

At AGDisplays, we have global sources with preferential pricing from our vendors. We verify continuity of supply for steady demand so you are assured your products will be available when you need them. Our International Procurement Office in China verifies these resources and quality of the companies we do business with;we have a secure list of trusted vendors with whom we maintain current business practices. Samples are always tested and verified before placing large orders. Our competitively priced products are sourced in a timely and efficient manner, so your company never misses a deadline.

AGDisplays provides our customers with the opportunity to replace LCD or components so you can avoid having to spend big bucks to OEM companies. With AGDisplays, our customers receive unparalleled attention and support without the hefty price tag that you may get elsewhere.

There are many signs an LCD will give the user to indicate that it may be due for replacement or upgrade. Even users who are not LCD experts will be able to tell when it is time to replace.

Outwardly, your LCD will show physical signs of damage such as a cracked or scratched, foggy or contaminated screen.Mostly, these damages are quickly noticeable to the naked eye and the first obvious sign that your panel may need a replacement. These are clear indications that the outside of your LCD has been damaged and is in need of evaluation or replacement. The application environment will determine the urgency in which you’ll want to replace the LCD. Cracks in the LCD may leave the LCD vulnerable to contamination and dust, which in turn can extend damage and/or decrease visual readability of the display.

Most LED technology estimate LED lifetimes to be upwards of 100,000 hours of useful life. This works out to be about six hours of usage a day—and 45 years of service, whew! So one can assume that LCD components will fail before the LED backlighting system will degrade. However, degradation does happen with long term usage. If your LCD is looking less bright than it should be, it is possible that a component in the display’s backlighting system needs replaced or upgraded.

LCDs that are broken internally may only show a black screen, a white screen, or even show no data when turned on. Other indications will be white/grey/black discoloration spots (called mura) of the display itself when it is turned on, regardless of the data/color that is shown on screen.

Another indication of a dying LCD aredamaged pixels. If you notice a small speck of white or black on your screen that does not go away, even as the screen changes, you may have a damaged pixel or two. There are a few different types of pixel defects, hot, stuck and dead pixels. Hot pixels present themselves as always ‘on,’ they always appear white in color. Dead pixels are always ‘off,’ and look black at all times. Now a stuck pixel is either stuck ‘on’ or ‘off’ so they may appear the same as a hot or dead pixel. These (sometimes) are solved by switching from bright to dark colored screens quickly to unstick these. However, this isn’t a reliable treatment for stuck pixels.

If you’ve notice defective pixels on your LCD screen, do not panic! Some manufacturers have a standard in which it allows a certain amount of pixels in production. Overall, if the LCD in question has an increased rebellion of pixels, whether hot, dead or stuck, the LCD may be of low quality or the pixels are going bad.

Sometimes white, black or multi colored streaks appear running horizontally or vertically along the display. If this is happening on every screen, this is a likely sign that something is wrong inside the LCD.

Signs of LCD degradation include those missing pixels, the dimming of screen brightness over time, and even the loss of color and contrast in a display. If you need more assurance the LCD is the problem, consult AGDisplays to discuss our replacement options.

Broken screen replacement service is provided from thousands of repairs stores and phone parts wholesalers worldwide, iPhone of which are mostly engaged in. So how to purchase reliable LCD screens among so many quality grades from China suppliers? Let me firstly elaborate on the quality grades of the iPhone LCD digitizer assembly that most repair stores and traders used to replace the broken ones.

According to the investigation, 90% of the Chinese iPhone LCD screen suppliers are found selling third-party manufactured screens and seldom sell genuine original LCD screens. Therefore, if your phone screen is broken, there would be a high chance for your screen to be replaced with a non-original one. Why? Maybe the cost and quality are relatively competitive, so why not?

As known, Foxconn is authorized to assemble iPhone, so there are some original iPhone LCD screens leaked from the assemble factory. And there are brought out from the factory for replacement. However the price is definitely high and still, some people care more about the quality of the screen than how much they cost, so for this group of customers, the Original Quality of LCD digitizer assemblies are preferred.

For some LCD digitizers, the LCDs are still working while the front glasses are broken, which can be recycled. Some factories recycled these broken screens by removing the broken front glass and attach a new one, then the LCD digitizer assembly would be new again, which is what called refurbished. Brand new original LCD screens are limited, and the refurbished ones can replenish the shortage of the new original LCD digitizer assemblies, for their quality would be more stable than the third-party manufactured.

Some Chinese factories purchase the original single LCD display, not compete LCD screen from the original factory, and then attach high copy front glass, backlight, etc, materials into a complete LCD screen, which quality is not stable and the display color is slightly different from the ones with high copy backlight. Well, their price would be cheaper and loved by many repair shops and wholesalers.

Under the shortage of original LCD screens, many Chinese factories begin to produce the high copy LCD screen. The stock and supply are getting less and less since about 2015, which leads the price goes higher and higher. Therefore the Chinese manufacturer starts to produce LCD screens with high copy raw materials. With competitive prices and good quality that meet most iPhone users’ needs, they are also popular among many wholesalers and repair shops.

With the premium quality of LCD and OLED screens tested strictly, we’ve helped many clients enlarge their markets worldwide. If you wholesale the LCD digitizer assembly or retail them in your repair shop, more information and sample are supported for your reference, please do not hesitate to contact us or leave your comment to discuss more.

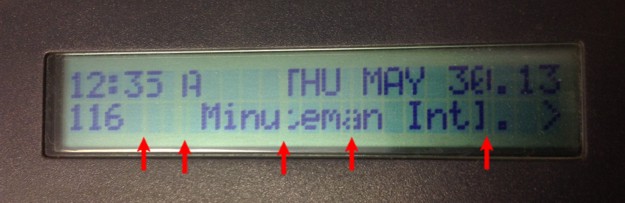

I have a TASCAM DR-05 audio recorder that has a monochrome orange LCD whose display has partially been damaged. Only the bottom half can be read while the top half is blank. I would like to attempt to change out the LCD by finding a replacement. I need help in finding a source for a replacement LCD. I’ve included a picture of the LCD on the PC Board just in case it might help. Would you please be able to point me in the right direction? Thanks in advance for your time and help.

P.S. I am aware it is not worth the effort to repair and it would definitely be more prudent to just buy another DR-05. That’s not the point. It’s a personal challenge to see if I can fix it. This is purely for fun, therefore no need to be tempted to let me know that I should just buy another DR-05. It’s not what I want to do. Thanks.

Over the years, LCD modules and LCD displays have grown in popularity. Companies in many different industries, including but not limited to the medical, automotive, consumer, food services, industrial, and technology sectors rely on at least one TFT LCD module or TFT LCD display on a daily basis. Although touchscreens are very durable and designed to withstand the hands of time, older modules and displays sometimes need to be repaired. When weighing the cost of having your displays repaired, you should take the time to consider your options.

After doing some research on the cost of repairs, many business owners find that it makes more sense to have their TFT LCDs replaced. Although units may cost less to repair initially, the cost of having to repair your older displays over and over again can add up. This is because older units may need to be repaired more than once. Even if multiple repairs will not cost any additional money, repairs lead to downtime and can have a tremendous impact on your business.

Older units in need of repair can have a long-term impact on a company’s bottom line. This is because outdated displays do not perform as well as new and improved displays. As many business owners have come to discover, new and improved touchscreen technology can increase efficiency, boost productivity, and improve customer satisfaction. This a top reason why so many companies decide to have a TFT LCD display or module replaced.

If you are thinking about having your older touchscreens repaired, then you should consider how having newer technology in place will help your business grow. Focusing strictly on the cost of replacing your displays can have a long-term impact on your business in more ways than one. For better results, you should consider all of the benefits of having new custom touchscreens specifically manufactured for your business. Ultimately, having new and improved displays in place for your employees and customers to use will be a business decision that pays for itself over time.

However, if the digitizer or LCD is also damaged during a fall, that screen no longer carries value because it cannot be refurbished. Repair shops cannot sell broken LCDs to refurbishing companies; therefore, they cannot offset the cost of an LCD repair. That is why repair stores often charge a little extra if there is damage to the LCD or digitizer, to make up for that loss. Repair stores that don’t have an additional charge for an LCD repair typically inflate their glass repair price to make up for the loss from damaged LCDs. If they have one price, that means everyone is paying more to cover the cost of customers who have damaged LCDs and customers who only have cracked glass. This is why TCR separates the price of glass and LCD repairs for you! If you only have cracked glass, you only have to worry about paying to replace the cracked glass.

If your phone or tablet’s glass is shattered there will be cracks or chips on the screen itself. If it is just the glass that is damaged, the device may still function and you may be able to use it normally. If this is the case, it is likely that only the glass needs to be replaced. To prevent further damage to your device it is best to get it repaired quickly. For example, if liquids seep through the cracks it could cause permanent damage to the LCD.

Many people may continue to use their touchscreen with shattered glass and delay fixing the glass on their devices; however, if the touchscreen isn’t responsive, it could be a sign of more significant damage to the device’s digitizer which is integrated with the LCD screen.

A pixelated screen can indicate LCD damage. This would look like a patch of multicolored dots, a line or lines of discoloration, or a screen with rainbow colors. For many people, these colors are an easy way to know that their LCD is broken and that they should get it repaired.

Dropping your phone isn’t the only reason you’ll end up with a pixelated screen. Over time, your screen’s LCD may break down through regular use. This happens to other devices aside from your smartphone or tablet. Pixelation can happen to TVs and computers, too. People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.

A black screen or black spots on your smartphone or tablet is an indication of a damaged LCD. Often with a bad LCD, a phone may still turn on and make noises, but there is no clear picture. This does not necessarily mean any other part of the phone is damaged and a simple screen replacement will get it functioning again. Sometimes it can mean a battery or other internal component is damaged. It is best to have a highly qualified phone repair technician diagnose what is wrong so the appropriate repair can be made.

Fortunately, your mobile device is fixable whether you cracked the glass or damaged the LCD. Stop by or call TCR: Triangle Cellular Repair at (919) 263-2699 for a free diagnostic and quick, affordable cell phone repair in Chapel Hill and surrounding areas. We’re always happy to help!

Finding a TFT LCD replacement can sometimes be a challenge. Just recently TFT display manufactures, such as Seiko Display products and Standish Displays have discontinued production of all their LCD display modules; these, of course, include Thin-Film-Transistor Displays (TFT).

Other LCD suppliers have discontinued production of selected TFT models, requiring many OEM customers to quickly locate another LCD supplier for their current production needs.

We receive calls and e-mails asking us to find a drop-in equivalent TFT displays. The customer’s goal is to locate a LCD module that will be 100% interchangeable with their current product. Sometimes this is easy and does not require any tooling or modifications cost; other times the customer will need to invest in a one-time tooling fee.

Modifying the size or dimensions of the TFT glass is not a good option. The cost to modify TFT glass is very, very expensive. On previous custom TFT LCD designs, we have seen tooling cost starting at $500K, and this does not include the extremely high Minimum Order Quantities (MOQ) involved with such a modification. Unless you are a Google, Amazon or Microsoft, choose a standard size glass.

If your product requires a unique size of TFT glass, redesign your product to accept a standard size glass or switch to a different LCD technology such as OLED or FSC. This will save you money and reduce the number of headaches.

There are other modifications that may be necessary to manufacture a TFT display this is 100% equivalent. This includes the relocation of the cable, the lengthening of the cable, adding a resistive touchscreen or increasing the brightness of the backlight. All of these can be accomplished with a much lower tooling cost and acceptable MOQs.

TFT display manufactures choose backlight brightness for their product. The brighter the backlight, the more the displays stands out, but also the more power that is required to drive. This is a key element to consider if your product is battery powered or you have a limited power budget.

We are able to modify our current TFT LCD Displays and increase their brightness with a low (one-time) tooling cost. Let us know what intensity you require and we will make the necessary adjustments.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For most customers, visiting a professional repair provider with certified technicians who use genuine Apple parts is the safest and most reliable way to get a repair. These providers include Apple and Apple Authorized Service Providers, and Independent Repair Providers, who have access to genuine Apple parts.* Repairs performed by untrained individuals using nongenuine parts might affect the safety of the device or functionality of the display. Apple displays are designed to fit precisely within the device. Additionally, repairs that don"t properly replace screws or cowlings might leave behind loose parts that could damage the battery, cause overheating, or result in injury.

Depending on your location, you can get your iPhone display replaced—in or out of warranty—by visiting an Apple Store or Apple Authorized Service Provider, or by shipping your iPhone to an Apple Repair Center. Genuine Apple parts are also available for out-of-warranty repairs from Independent Repair Providers or through Self Service Repair.*

The iPhone display is engineered together with iOS software for optimal performance and quality. A nongenuine display might cause compatibility or performance issues. For example, an issue might arise after an iOS software update that contains display updates.

* Independent Repair Providers have access to genuine Apple parts, tools, training, service guides, diagnostics, and resources. Repairs by Independent Repair Providers are not covered by Apple"s warranty or AppleCare plans, but might be covered by the provider"s own repair warranty. Self Service Repair provides access to genuine Apple parts, tools, and repair manuals so that customers experienced with the complexities of repairing electronic devices can perform their own out-of-warranty repair. Self Service Repair is currently available in certain countries or regions for specific iPhone models introduced in 2021 or later. To view repair manuals and order parts for eligible models, go to the Self Service Repair page.

Vicpas provide lcd display screen of worldwide brand, such as Hitach, Mitsubishi, sharp, NEC, Kyocera, BOE, ALPS. there also have many special lcd screen display for siemens, lcd display for AB Allen bradlay, lcd display for B&R powerpanel, lcd display for Beckhoff, lcd display for proface, lcd display for Schneider, lcd display for Kuka, lcd display for ABB, lcd display for KEBA, lcd display for YASKAWA, lcd display for KAWASAKI, lcd display for FUJI Hakko, lcd display for Beijer, lcd display for Bosch, lcd display for Cutler-Hammar, lcd display for Delta, lcd display for Hitech, lcd display for eview, weinview, weintech, lcd display for Eaton Microinnovation, lcd display for ESA, lcd display for Uniop, lcd display for EZ automation, lcd display for Fujistu, lcd display for keyence, lcd display for lenze, lcd display for lauer, lcd display for IDEC, lcd display for KOYO, lcd display for Omron, lcd display for Panasonic, lcd display for Parker, lcd display for Red lion.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

How do we do it? Our agile workforce – from engineers and developers to supply chain experts – work together to respond quickly to a dynamically changing market, customizing solutions to fit each customer’s unique requirements.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey