reference design for tft lcd panel quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

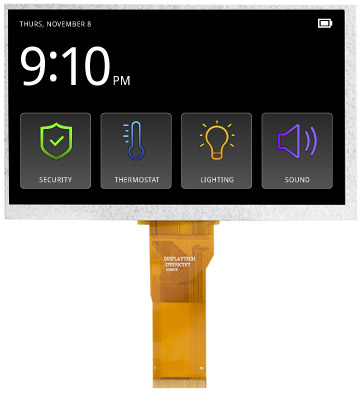

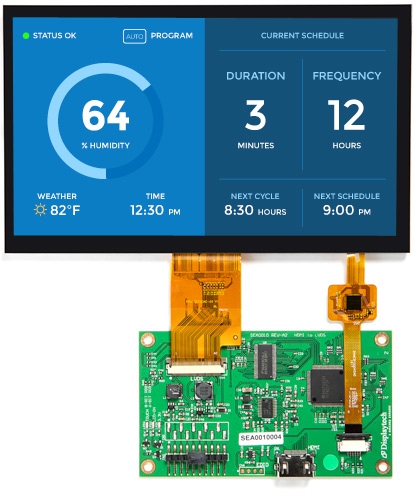

Showcase high quality graphics and images on our 800 x 480 7” TFT display! The DT070CTFT LCD module is an upgraded version to our DT070ATFT module. Compared to the previous model, this new 7 inch display offers improved viewing angle and brighter LEDs. The DT070CTFT also uses the Himax HX8264E + HX8664B display drivers. This LCD display is available with a resistive or capacitive touchscreen panel.

Improve your product design by adding the DT010ATFT: a small, simple 1” TFT LCD with IPS technology. This mini TFT display is perfect as a status indicator presenting graphic icons or simplified information. The IPS technology included in this display allows your content to be crisp and clear no matter what angle your user is viewing it from. The ST7735S driver IC provides on-chip storage and power system. This IC allows for fewer components and a simple design to easily integrate the DT010ATFT into your next product.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

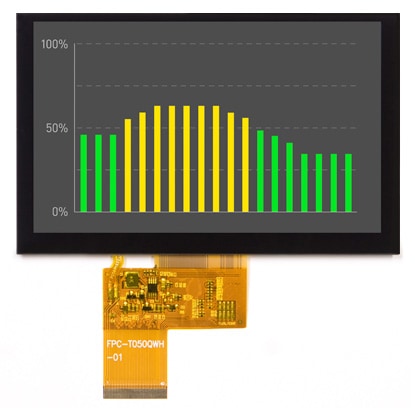

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Wider viewing angles are not always welcome or needed. Image you work on the airplane. The person sitting next to you always looking at your screen, it can be very uncomfortable. There are more expensive technologies to narrow the viewing angle on purpose to protect the privacy.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED. If you have budget leftover, you can also add touch screen functionality as most of the touch nowadays uses PCAP (Projective Capacitive) touch panel.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Since the reference voltages are connected to all channels, many DACs may use the same reference voltage. The more DACs there are connected to a single reference voltage, the larger the required C-DAC settling time. This study simulates the settling time for different numbers of connected DACs using a 0.35-μm 5-V CMOS model. Figure 11 shows the simulated results where the settling time is measured at 99.9% of its final voltage for a full swing (0.266 V ~ 4.75 V). The settling time is 5.2 μs when 200 DACs are connected to a single reference voltage. Although a column driver IC contains several hundreds or even up to a thousand DACs, these DACs are distributed to 256 (28) reference voltages. This means that not all the DACs are connected to a single reference voltage. A typical UXGA (1600×1200) display has a pixel clock frequency of 162 MHz and a horizontal scanning time of 9.877 μs [4]. Hence, the proposed column driver is suitable for UXGA displays.

Due to the limited silicon area, the proposed LCD column driver has only four channels. The 10-bit LCD column driver with R-DAC and C-DAC was fabricated using a 0.35-μm 5-V CMOS technology. Table I shows the device sizes used in the proposed column driver, where Rtop, Rmid, Rbot, and Ri are designated in Figure 7. Figure 12 is a photograph of the die. Except for the resistor string of the R-DAC, the die area is 0.2×1.26 mm2 for four channels. Each RGB digital input code is 10-bits wide.

The Differential Nonlinearity (DNL) and Integral Nonlinearity (INL) are typically measured for a DAC. However, it is difficult to determine these two specifications for a nonlinear DAC. To demonstrate the performance of the proposed circuit, the nonlinear gamma voltages are not applied to the R-string and the resistor values of the resistor string are made equal. Since an LCD panel needs several column drivers, the uniformity of different drivers is very important. Figure 13 shows the measured transfer curves of a DAC for eight off-chip column drivers. To show the deviation between different chips, Figure 14 provides an

enlarged view of the transfer curves, where the maximum deviation is 3.5 mV from the mean. This deviation is mainly due to process variations. The approach in this study uses no error correction. Hence, the deviation can be reduced by applying an offset canceling technique to the buffer amplifier. Figures 15(a) and (b) show the DNL values for positive and negative polarities, respectively. Figures 16(a) and (b) show the INL values for positive and negative polarities, respectively. The combination of R-DACs and C-DACs creates two groups of DNL values. The maximum DNL and INL values are 3.83 and 3.84 LSB, respectively. This study uses a 1-LSB voltage of 2.44mV to calculate the INL and DNL values. The linearity, however, is less important than the deviations between off-chip drivers for LCD drivers [2].

The measured output waveform of two neighboring channels under dot inversion for the RGB digital inputs of ‘1111111111’, where the voltage levels for negative and positive polarities are 0.266 V and 4.75 V, respectively.

The measured output waveform of two neighboring channels under dot inversion for the RGB digital inputs of ‘0000000000’, where the voltage levels for negative and positive polarities are 2.425 V and 2.598 V, respectively.

Figure 17 shows the measured output waveforms of two neighboring channels under dot inversion for the RGB digital inputs of ‘1111111111.’ Here, the voltage levels for negative and positive polarities are 0.266 V and 4.75 V, respectively. A load resistor of 5 kΩ and a capacitor of 90 pF were used. Figure 18 shows a similar waveform for ‘0000000000’ inputs, where the corresponding voltage levels for negative and positive polarities are 2.425 V and 2.598 V, respectively. These two figures show that the settling time is within 3 μs, which is smaller than that of previously published work [2] and standard UXGA displays [5]. Table II summarizes the performance of the proposed column driver IC. The average area per channel is 0.063 mm2, which is smaller than the reported areas of fully R-DAC-based column drivers [5, 8]. These experimental results show that the proposed column driver is suitable for UXGA LCD-TV applications.

The adoption of LCD technology in vehicular displays has happened quite quickly and smart displays have by now pretty much replaced the mechanical dashboards of yesteryears in cars. In an interview with our team, Rei Tjoeng from Sharp Devices revealed some interesting information regarding automotive-grade LCDs, the recent trends, and specific characteristics that make some LCD displays different from the others available in the market.

A. Adoption of TFT in 2-wheeler cluster applications has increased in a big way. The global automotive industry is widely believed to be on the cusp of tremendous change in terms of manufacturing, sales, and the overall business model, owing to the rapid advances in new-age technologies such as autonomous driving, augmented reality, and big data.

Advanced driver-assistance systems (ADAS)—such as parking assistance, forward collision, lane-departure warnings, and blind-spot monitoring—are frequently hailed as the technologies that will usher us into an age of autonomous transportation, but drivers are still either untrusting or too trusting of these features. This has led to an evolution of sorts in the in-car user experience interfaces, and more so with the way automotive display makers are developing new products.

The future for ergonomic conformal displays, display-based dash, central console, in-door wing mirrors, and transparent displays that offer unobtrusive visual information during journeys is bright. Head-up displays are fast gaining popularity as an ideal interface for disseminating crucial information such as navigation messages, vehicle speed, and warnings.

A. Yes, reflective LCDs, which use ambient light to reflect in order to read. In 2W cluster applications, where TFT is exposed to direct sunlight, readability is a major issue. Sharp Reflective LCD is a solution as visibility is crystal clear without any glare and is available in colour too. Equipped with a backlight, it can be used at night also.

Normal TFT has to pump more power through the backlight, which results in more power consumption and backlight life also gets affected to a large extent. This reflective LCD consumes very little power and could be the best fit-in product for the EV segment.

A. The market is now shifting to large-size TFT displays in the automotive segment. These displays are automotive-grade LCDs and are tested for shock, vibration, high and low temperature, etc. For more protection and safety, glass bonding is done over TFT. Glass bonding with a cover glass on the LCD protects it from shock, as the hardened adhesive behind the glass acts as a shock absorber. Shakes and shocks are less likely to damage the display and glass, making this an important benefit for transportation applications. In the unlikely event that the glass is damaged, shards of broken glass will remain stuck to the optical adhesive.

A. Reflective LCD and Progressive Super View are the two technologies which are effective under high ambient light. In progressive super view technology, internal and external reflection is cut down, which results in a clear view without glare. And the beauty of this technology is that it happens without pumping more power from the backlight. This helps in more lifetime of the backlight and less power consumption.

Reflective LCD is another technology that uses ambient light to reflect in order to read, hence there is more clarity under sunlight and very less power is needed. It is more beneficial for EV applications.

A. Automotive-grade LCDs have strict requirements. The LCD must remain working during the extreme environment, for example, Indian summertime. For example, our LCDs are tested for storage temperature of -40 to 95°C and operating temperature of -30 to 85°C.

From a design engineer’s perspective, what are the top factors—besides the obvious ones like price, size, brand, after-support, etc—that should be borne in mind while selecting the right LCD panel?

There are a few LCD specs the design engineers need to consider at high priority when they select the LCD. The first specification will be the screen size and aspect ratio. The aspect ratio is the ratio between the length and width of the LCD. Some common ratios are 4:3, 5:4, 16:9, and so on. Of course, sometimes marketing people will also consider these specs as they will affect the whole outlook and design of the product.

Then the engineer may need to consider the LCD’s resolution and interface, whether they are matching with the motherboard. If the product is a semi-outdoor or outdoor application, then the engineer needs to also check the LCD’s brightness and operating temperature range, because these are very important specs if the product is located in the sunshine.

A. The smartphone has become very popular in recent years and it is influencing the engineers’ design. We saw some EV companies use the smartphone LCD as the cluster or GPS display for their first-generation products. The smartphone LCD is nice but, unfortunately, it is not designed for automotive applications, especially not for 2-wheeler outdoor usage. When the 2-wheeler is under the sunshine, the driver can barely see anything from the smartphone LCD. And, also, the smartphone LCD’s lifetime becomes much shorter under the automotive application scenario.

A. Sharp Singapore has been in this region for many years. We understand our customers. First, our team will get the customer’s requirements from both the marketing and engineering sides. We will check the customer’s motherboard’s graphics capability, display interface, and other necessary technical details. We will propose the best suitable LCDs to the customer and explain the reason. We will explain what we observe from the market trend and help the customer to know the best options.

LCD samples and demo kits are available for the engineers to see the actual performance. There is also technical support available to help the design engineers to evaluate the LCD and design-in the LCD.

Q. Do you have some form of sampling programme for them to receive samples during their prototyping stages? Do you have development or evaluation kits for your LCD displays?

A. Sharp Singapore understands that samples and evaluation kits are important in the project’s early stage. Evaluation kits are available for the engineer to evaluate the LCD performance during the proof of concept stage. Then we will provide sample LCDs for the customer’s prototype builds.

A. We have salespersons stationed in India at New Delhi and Bangalore. They are working closely with the customers’ design engineers. There are technical support persons in Singapore and Japan. Our Indian team can support the customer onsite and bridge as technical person effectively between India and Singapore.

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

Recently, screen sizes of LCD TVs have become wider and larger. The glass substrates from AGC enable this trend of larger LCD TV sizes. Glass substrates also play a key role to reproduce clear and beautiful screen images as one of the core components of LCDs.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

An LCD has a layer of liquid crystal sandwiched between two sheets of glass. The most remarkable feature of liquid crystal is its optical characteristics of being both a liquid and a solid. Applying voltage to the layer of liquid crystal causes the orientation of the molecules in the liquid crystal to change relative to each other. This molecule rearrangement controls the light transmission from the backlight; the light passes through color filters of red, blue, and green, and eventually rich images appear on the screen.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

Recently, displays with higher resolution such as 4K and 8K are being developed one after another and have made it possible for viewers to enjoy vivid and fine picture even in very large screen sizes.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Through production and supply of LCD glass substrates, which is a key material of LCDs, AGC helps create a more convenient and comfortable life through integrating various technologies within the Group.

This application note describes the interfacing of Ampire AM-800480STMQW-TA1 display to BoraEVB and BoraXEVB. Main characteristics of this 7" TFT LCD panel are:

is also equipped with a linear regulator generating 2.5V. This voltage is used as power supply for the VDDIO_BANK13 rail. This voltage is required to implement LVDS differential pairs that drive display.

In case of BoraXEVB, no adapter board is needed. LCD panel is directly connected to J26 connector where PL bank 13"s signals implementing LVDS interface are routed (see page 14 of the schematics). I/O voltage of bank 13 is set to 2.5V by configuring JP25 as shown in the following table.

To implement frame buffer, a portion of main SDRAM is used. This area is allocated at runtime by linux frame buffer driver. Even if LCD is 18 bpp, each pixel is represented by 32-bit word in memory. In fact each pixel is in RGB666 format, so for each colour only the six most significant bits of the frame buffer RGB888 are used to drive the display.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%).

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

(**) On the adapter this signal is routed (via configurable 0R) to multiple pins of the EVB connector to meet all the features of the EVB. Please make sure to configure the Adapter for the use of the LVDS connector.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

Once the kernel has completed boot, frame buffer can be accessed from user space applications via /dev/fb0 device file (for more details please refer to https://www.kernel.org/doc/Documentation/fb/framebuffer.txt).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey