lcd panel common problems factory

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

Usually, assembly of cell and IC is under heat and should be positioned accurately. Problems with IC connection will be checked out very soon, followed by the adjustment on machine parameter.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

If you ever notice multi-coloured or single-coloured vertical lines on your laptop screen, it may be a result of a hardware failure or due to damage to the screen. To try fixing it yourself, first unplug your laptop, hold the power button for 30 seconds and restart the laptop. If you continue to see coloured lines, the issue is probably with the LCD screen, which will need to be replaced from the brand’s service center. To be sure about the LCD screen problem, try connecting your laptop to another monitor and see if the issue persists. If it does, the issue is certainly in the LCD panel.

Firstly, check if your laptop’s brightness level is set to maximum. If the display is still dim, try restarting the device. This could just be a system error that can be resolved by restarting the device. Also, check if the AC adapter cord is loose and firmly connect it to the outlet and laptop. If the issue still persists, it is mostly due to a failure of the LCD. Behind the LCD, there is an inverter board and backlight bulb which control the picture.

The inverter board converts the low voltage your laptop uses, into higher voltage required by the long bulb that lights up the LCD screen. If the inverter board or bulb fail, you will experience the problem of a dimmed display. Even if one of these two components fail, the screen will need to be replaced, unless the service center can help by just replacing the bulb. We wouldn’t recommend you try resolving it yourself, as this is more complex and you could end up damaging the circuit board and the backlight lamp. So, it’s best to leave this job to an expert.

Laptops are fragile and can easily break, especially with more and more thinner and lighter models being launched now. Some of the most common ways how a laptop is damaged include: when it accidentally falls and the screen cracks, when it’s held at an awkward angle or if you unknowingly placed something heavy on the laptop. Remember, a cracked laptop screen can affect the overall functioning of the device in some cases.

Need an expert to take a look at your laptop? Book Onsitego’s on-demand repair service. Besides taking care of common laptop problems like battery draining or laptop hanging, we can help with issues like setting up the operating system or removing malware/virus from your device. Our service engineers are qualified and use only good-quality spare parts while repairing. The best part is that our service is backed with a 90-day post-service warranty.

Dell Technologies recommends ensuring that the device drivers and BIOS are up to date using the SupportAssist application for optimal video performance and to help resolve common video-related issues.

Performance issues may occur if there is any type of damage that is caused to the display cables or the LCD screen. LCD screen may show that symptoms like LCD screen stops working, work intermittently, color mismatch, flickering, display horizontal or vertical lines if there is damage to the display cables or the LCD screen.

Windows updates can support your Windows operating system in many ways. Windows updates can solve specific problems, provide protection from malicious attacks, or even add new features to the operating system.

If you find that the Dell touch-capable monitor is unresponsive to touch or touch works intermittently, you can try some common troubleshooting steps to help fix the issue.

Dell recommends ensuring that the device drivers and BIOS are up to date using the SupportAssist application for optimal video performance and to help resolve common video-related issues.

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Windows updates can support your Windows operating system in many ways. Windows updates can solve specific problems, provide security patches and protection from malicious attacks, or even add new features to the operating system.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If you find that the Dell laptop is unresponsive to touch, touch stops working entirely, or other touch-related issues, you can try some common troubleshooting steps to help fix the touch-related issue.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

If the screen flickers, make sure the display settings in Windows match the native resolution and refresh rate for the display. Find the native resolution of a flat panel display on the box, in the specifications, or in the printed material that came with the display. Some common native resolutions are 800 x 600, 1024 x 768, 1920 x 1200, and 1680 x 1050. The most common refresh rate for LCD displays is 60 Hz. This normally cannot be changed for flat panel displays using Plug and Play settings. However, if you are using special video software to increase or decrease the refresh rate, change the refresh rate to match the default refresh rate specification of the display.

My touch screen is not working.All touch panels must be connected to a computer via USB or RS232 cable. This allows the touch panel to communicate with the computer.

If you recently downloaded a new touch panel driver, you must also delete the old driver and reboot your computer. Make sure you have deleted any old touch panel drivers and then restart your computer.

My touch screen is not registering correctlyAll non-HID compliant touch panels will need to be calibrated during the initial start-up and may need recalibrating at some other point in the future. This is accomplished via the touch panel software installed on your computer. For a detailed walk through, please contact us.

Certain touch panels are susceptible to issues due to grease/dust/water and therefore may need added care. If this is a constant problem, please contact us for further assistance.

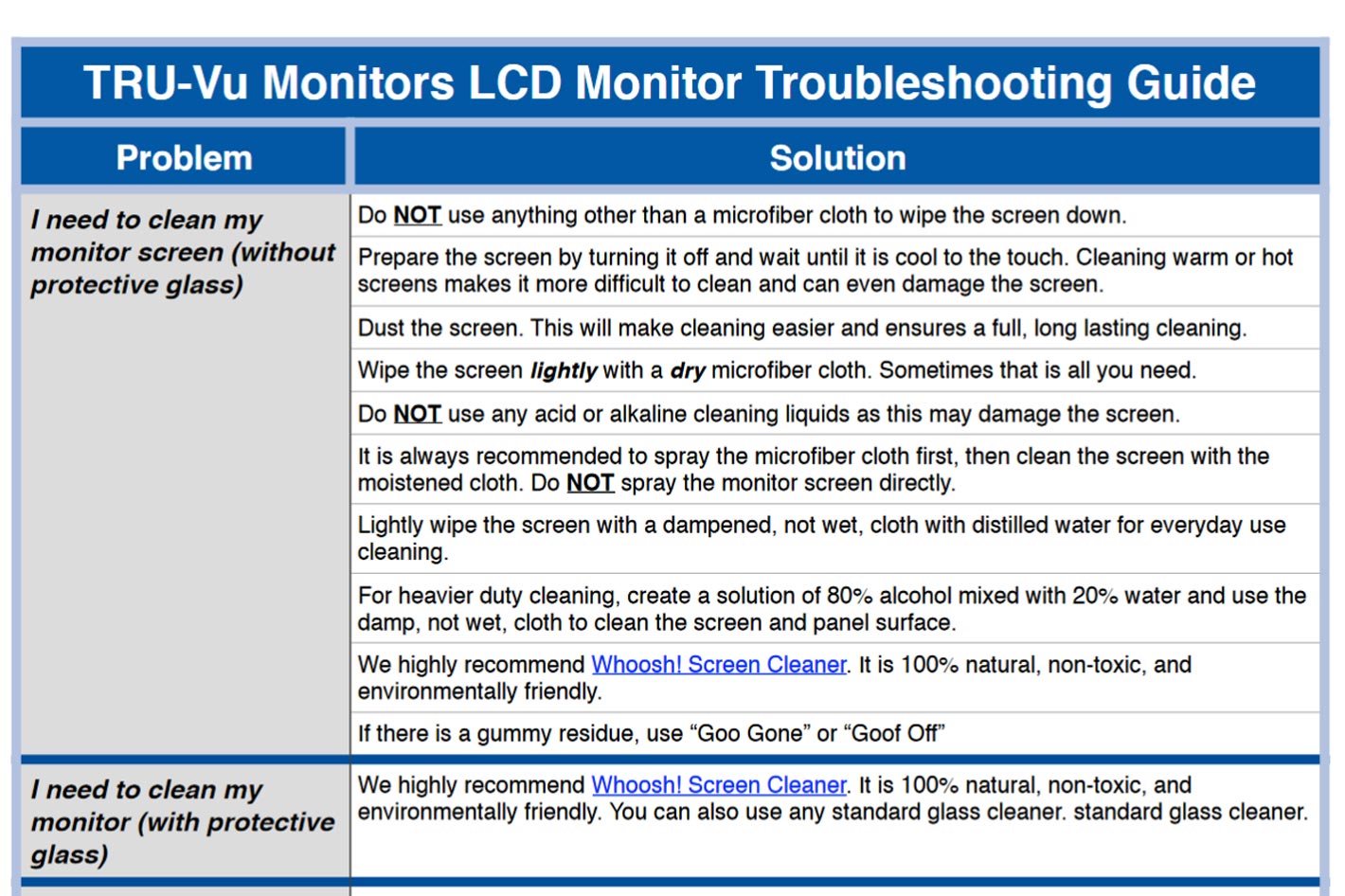

For heavier duty cleaning, create a solution of 80% alcohol mixed with 20% water and use the damp, not wet, cloth to clean the screen and panel surface.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey