lcd panel pinouts diagram in stock

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

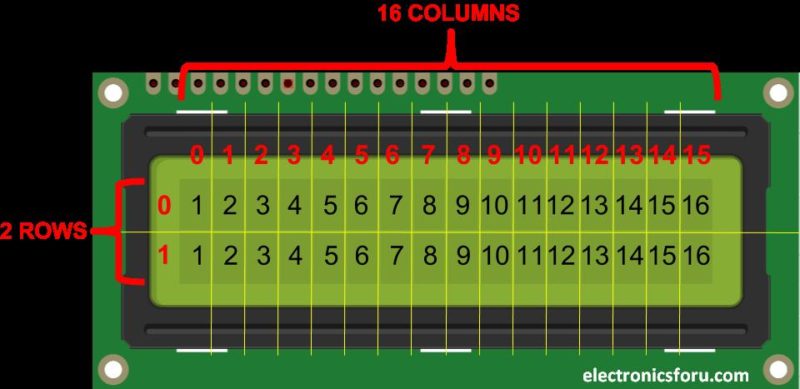

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

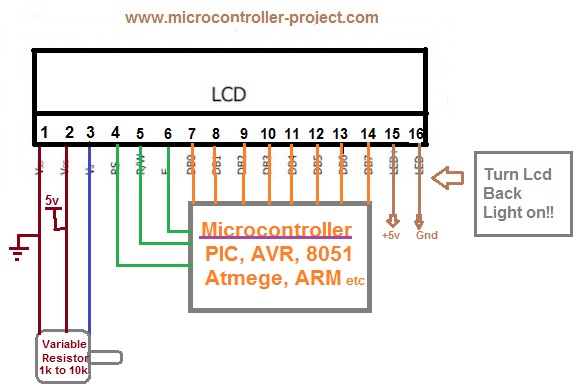

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

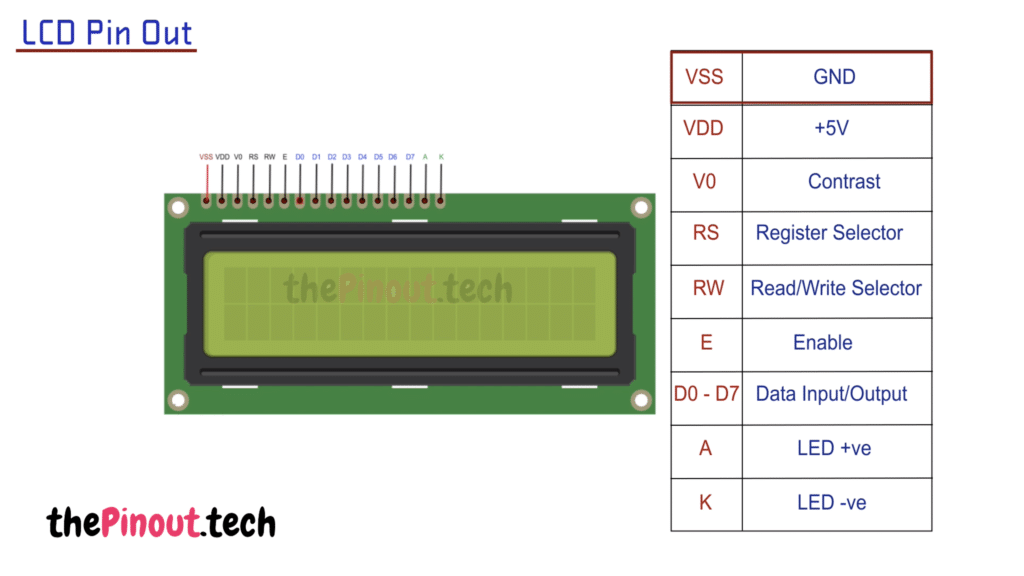

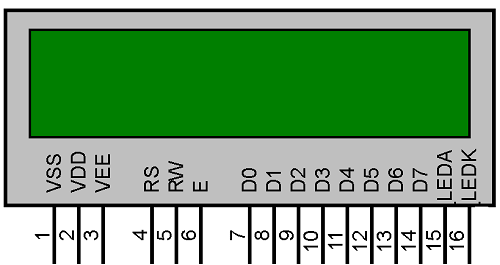

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

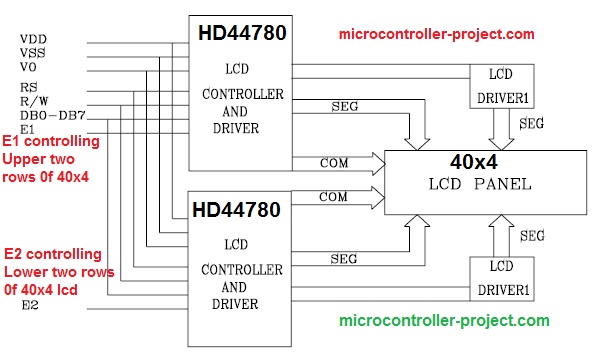

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Text: is a Dot-Matrix LCD controller which support both text and graphics mode. It built-in two Display , /8822 Version 1.1 Two Layers Character/Graphical LCD Controller 3. Block Diagram Figure 3-1 is the internal block diagram of RA8803. The RA8803 consists of Display RAM, 512Kbyte Font ROM, Command , Figure 3-2 : RA8822 Block Diagram 4. Pin Definition 4.1 MPU Interface Pin Name I/O Description , this pin before accessing RA8803/8822. 4.2 LCD Driver Interface Pin Name I/O YD O

Text: block diagram of RA8822. The major different of RA8803 and RA8822 is the Display RAM size. The RA8803, /Graphical LCD Controller KR[7.0] KC[7.0] 240x160x2(Two Page) 8x8 Key Scan DISPLAY DATA SRAM , CIRCUIT 10 Bit ADC Figure 3-2: RA8822 Block Diagram 4. Pin Definition 4.1 MPU Interface Pin , to poll this pin before accessing RA8803/8822. 4.2 LCD Driver Interface Pin Name I/O YD , Display OFF This signal is used to control the LCD Display ON or OFF. LCD Driver Data Bus LD[7.0

Text: 2-1 Pin Assignment Pin COM0COM3, seg633, seg35 Function 4 29 LCD display Vlc0 , Figure 2-4 shows circuit diagram for LCD display . U10 SEG0 SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7 , . 2-3 2.3.4 LCD Display , . 3-12 3.2.9 LCD Display , . 2-3 LCD Display Circuit

Text: the H8/38024 functions used for A/D conversion and LCD display . Figure 2.1 shows the block diagram of , variable resistor is connected to the AN1 pin . The A/D-converted value is displayed on the LCD as a , AN1 CPU LCD driver LCD display data LCD circuit Figure 2.1 H8/38024 Functions Used , A/D Conversion on an LCD 2. Figure 2.2 shows the block diagram of the LCD controller/driver used , generator Segment driver LCD RAM 16 bytes Display data SEG1 [Legend] LPCR: LCD port

Text: improve the display quality by RA8806. RA8806 is a powerful and flexible LCD controller. It provides the , www.raio.com.tw RA8806 Version 1.1 Two Layers Character/Graphic LCD Controller 3. Block Diagram Figure 3-1 is the internal block diagram of RA8806. The RA8806 consists of Display Data RAM, Font ROM , : RA8806 Block Diagram LCD Driver LCD Panel MPU RA8806 Booster (Contrast Adj.) LCD , LCD Controller 4. Pin Definition 4-1 MPU Interface Pin Name I/O DATA[7:0] I/O ZRD

Text: Display Support LCD power-down sequencing. s SYSTEM BLOCK DIAGRAM CPU Data and Control Signals , SED1375 is a color/monochrome LCD graphics controller with an embedded 80K Byte SRAM display buffer. The , colors on passive STN and active matrix TFT/D-TFD LCD panels. Split Screen Display : allows two , MOD LCD Display WAIT# CKIO FPDAT[7:0] BCLK LCDPWR RESET# 2 RESET , WE0# FPLINE MOD LCD Display WAIT# CKIO FPSHIFT FPLINE RD# WAIT# D[3:0

Text: HL15203 Contents 1. General Description 2. Features 3. Block Diagram 4. Pin Diagram 5. Pin , 2 HL15203 1. General Description The HL15203 is 1/3 duty LCD display driver. It can drive directly maximum 156 segments. 2. Features · LCD display · · · · , SCK SEG35 SEG34 CE SEG33· 4. Pin Diagram SEG49 SEG50 SEG51 SEG52 COM1 COM2 COM3 , . . . . . 3. Block Diagram HL15203 5. Pin Description PIN Name I/O Pin Number

Text: . Block Diagram 4. Pin Diagram 5. Pin Description 6. Serial I/O Data Format 7. Registers 8. Key Scan Function 9. LCD Function 10. INH and Display Control 11. Power Down Mode 12. Oscillator Port 13 , HL15203 is 1/3 duty LCD display driver. It can drive directly maximum 156 segments. 2. Features · LCD , SEG40 SEG39 SEG38 SEG37 SEG36 SEG35 SEG34 SEG33 4. Pin Diagram 33 32 48 49 HL15203, LCD Bias Pins OSC I 1 Oscillator Input Pin CE I 1 Serial I/O Control Pin

Text: This block diagram , Figure 2.1, shows the interconnect required for the Vinco to drive the LCD display , how the Vinco module can be used to provide an interface to a LCD display . Future Technology , 2 line, 16 character, monochrome LCD display . The application note also provides "C" source code , .: FTDI# 177 1.2 Topway LCD Display This application example uses the Topway LMB162ABC 16 character 2 line LCD display . The display is driven by a 5V power supply and 4 data lines control the characters

Text: . 15 SOC-3000 LCD DISPLAY PIN CONFIGURATION , : Revision B SOC-3000 PIN CONFIGURATION FOR LCD DISPLAY , .15 SOC-3000 QUICK REFERENCE PIN CONFIGURATION FOR LCD DISPLAY .18 SOC , shown in Figure 5, page 15. The physical pin configuration for an LCD display is shown in Figure 6 , 19. TABLE 1: PIN SOC-3000 PIN CONFIGURATION FOR LCD DISPLAY NAME DESCRIPTION Keyboard

Text: - DISPLAY PATTERN 64 X 240 LCD - 0 49 1 1 - 0.04 BLOCK DIAGRAM DISPLAY PATTERN 1 - , DIAGRAM 00-D7 R /W _ 128 CONTROL LSI DISPLAY PATTERN 128x240 LCD ` 240 m \1 - 0.0 1 4K X , PATTERN BLOCK DIAGRAM RSËT ; C/D MD2 FS1 CONTROL LSI T6963C DISPLAY PATTERN 128 X 240 LCD I- 0.40 , Available (-20°C to +70°C) BLOCK DIAGRAM DISPLAY PATTERN BLOCK DIAGRAM ¡- 0.48 YES YES , CONNECTOR ASSIGNMENT Pin No. Symbol 6 7 d2 Function Display data H.Dot on, L.Dot off Power supply for

Abstract: Epson KS 110 16 X 2 LCD Panel Display MC68K SED1375 24 PIN TFT MOBILE DISPLAY epson lcd display mod. sec AB14 MC68000 MC68030 schematic hitachi lcd power supply unit

Text: /D-TFD LCD panels. Register level support for EL panels. Hardware Portrait Mode Split Screen Display Virtual Display Support LCD power-down sequencing. s SYSTEM BLOCK DIAGRAM CPU Data and Control , FPFRAME 8-bit FPLINE DRDY FPLINE MOD LCD Display WAIT# CKIO FPDAT[7:0] BCLK , # WE0# FPFRAME FPFRAME 4-bit DRDY WE0# FPLINE MOD LCD Display WAIT# CKIO , SED1375 FPLINE BS# DRDY RD/WR# FPLINE MOD LCD Display WAIT# LCDPWR CLK RESET

Text: . 7 Adjusting the LCD display contrast , Display Specifications 1) LCD Display Mode : STN, Positive, Transflective 2) Display Color : Display , Drawing for details) 1.3 Block Diagram LCD Power Booster Circuit SEG1 | SEG64 LED , Positive Power Supply 3 V0 Power LCD Contrast reference 4 RS Input RS = H; DB0 DB7 = Display RAM , backlight Note: *1. Display or instruction data could write into the LCD module"s driver/controllers

Text: . 7 Adjusting the LCD display contrast , : 2 of 11 TOPWAY LCD Module User Manual LMB162ABC 1. Basic Specifications 1.1 Display Specifications 1) LCD Display Mode : STN, Positive, Transflective 2) Display Color : Display Data = â , Setting To drive the LCD module correctly and provide normally display , please use the following setting , should issue to the LCD module while start up. *2. See the Display Commands section for details. 4.2

Abstract: walkie-talkie diagram walkie-talkie circuit AP-902 clock display AP902M-004 divide-by-10 6- 7 segment 24 hr clock circuit 7 segment display 30 pin configuration clock 5 digit 7 segment LCD display pin configuration

Text: display and start at AM 7:00. 8.4 LCD Interface Information LCD driver pin configuration and 0 to 9 , 30 MHz 3 commons, 13 segments, 1/3 bias LCD display drivers which support 4 digits LCD display On , DIAGRAM POR LCD DRIVER V LCD IF FMIN PRESCALER DIV. BY 10 AMP FREQ COUNTER , diagram of AP902M 7. DEVICE PIN DESCRIPTION COB PIN NO 1 2 3 4 5 6 7 8 9 10 11 12 13 14 , Drive Signal for Driving LCD Display LCD Common Drive Signal for Driving LCD Display LCD Common Drive

Text: . 7 Adjusting the LCD display contrast , 10 TOPWAY LCD Module User Manual LM19264B 1. Basic Specifications 1.1 Display Specifications 1) LCD Display Mode : STN, Positive, Transflective 2) Display Color : Display Data = "1" , attached Outline Drawing for details) 1.3 Block Diagram SEG1 | SEG64 LCD Power Booster , section of the LCD module (*1) 19 /RST Input Reset signal /RST = L; Display off display start line

Text: . 7 Adjusting the LCD display contrast , : 2 of 10 TOPWAY LCD Module User Manual LM19264D 1. Basic Specifications 1.1 Display Specifications 1) LCD Display Mode : STN, Positive, Transflective 2) Display Color : Display Data = "1" , attached Outline Drawing for details) 1.3 Block Diagram SEG1 | SEG64 LCD Power Booster , Power Positive Power for LED backlight Note: *1. Display or instruction data could write into the LCD

Abstract: LM12864LFC SCROLLING LED DISPLAY CIRCUIT diagram scrolling led display circuit LM12864L S6B0107 S6B0108 topway 128 lcd module 128x64 SAMSUNG samsung cs21

Text: . 7 Adjusting the LCD display contrast , Display Specifications 1) LCD Display Mode : STN, Negative, Transflective 2) Display Color : Display , Drawing for details) 1.3 Block Diagram LCD Power Booster Circuit SEG1 | SEG64 LED , Positive Power Supply 3 V0 Power LCD Contrast reference 4 RS Input RS = H; DB0 DB7 = Display RAM , backlight Note: *1. Display or instruction data could write into the LCD module"s driver/controllers

Text: . 7 Adjusting the LCD display contrast , Display Specifications 1) LCD Display Mode : STN, Positive, Transflective 2) Display Color : Display , attached Outline Drawing for details) 1.3 Block Diagram SEG1 | SEG64 LCD Power Booster , normally display , please use the following setting Display start line (Z address)= 0 LCD Display = on , Instructions section for details. LM19264A 4.2 Adjusting the LCD display contrast A Variable-Resistor must

Text: LCD Display LCDPWR CKIO RESET# BCLK RESET# Typical System Diagram (SH-3 Bus) 2 S1D13704F00A, FPLINE MOD LCD Display LCDPWR CLK RESET# BCLK RESET# Typical System Diagram (M68K #2 Bus) 3 , if CNF4 = 1 LCD Power Control 1 if CNF4 = 0 This pin has multiple functions. · TFT/D-TFD Display , color / monochrome LCD graphics controller with an embedded 40K Byte SRAM display buffer. The high , , 2/4/16/256-level color display . x Package · 80 pin QFP14 package. 1 S1D13704F00A s TYPICAL

Abstract: LCD tv display pinout diagram HITACHI lcd tv power supply diagrams sharp lcd panel pinout 30 Pinout panel lcd lcd color 176 132 Hsync Vsync RGB signal LCD laptop 8 Pinout monochrome lcd 14 laptop lcd pin configuration WD90C20

Text: VGA flat-panel display controllers and a variety of LCD color display pan els. The WD90C55 also acts , adjustment for TFT color LCD panel Uses a 44- pin MQFP package The WD90C55 supports laptop computers that use color or monochrome LCD panels. The WD90C55 interfaces with the following VGA flatpanel display , flat-panel display controllers and a variety of LCD panels. Including TFT and STN color panels. It also acts , from the VGA flat-panel display controllers are passed along to LCD monochrome panels. These inter face

Text: how the Vinculo module can be used to provide an interface to a LCD display . Future Technology , a 2 line, 16 character, monochrome LCD display . The application note also provides "C" source code , .: FTDI# 177 1.2 Topway LCD Display This application example uses the Topway LMB162ABC 16 character 2 line LCD display . The display is driven by a 5V power supply and 4 data lines control the characters , 1.2 Topway LCD Display . 2 2

Text: display (RS stock no. 195-4188) wiring diagram Colour LCD panel Double connector Controller card J3 , Interface board 7.7inch display (RS stock no. 195-4194) wiring diagram Colour LCD panel Double , display (RS stock no. 195-4217) wiring diagram Power supply for backlight Colour LCD panel , the speed of creating images. The display modules require an LCD controller kit (RS stock no , fluorescent backlight is included with the display . Once the display is connected to a PC the LCD will

Abstract: S1D13705F00A MC68K 15 Pinout monochrome lcd color space look-up table mapping S1D13705 specifications LCD TFT common backplane voltage S1D13705F00 8 Pinout monochrome lcd tft lcd pinout

Text: FPLINE MOD LCD Display LCDPWR CKIO RESET# BCLK RESET# Typical System Diagram (SH-4 Bus , FPLINE DRDY FPFRAME FPLINE MOD LCD Display LCDPWR CKIO RESET# BCLK RESET# Typical System Diagram , / monochrome LCD graphics controller with an embedded 80K byte SRAM display buffer. The high integration of the , 80K byte SRAM display buffer. · 256 simultaneous of 4096 colors on color passive and active matrix LCD , Display Support · · · · · · · 4/8-bit monochrome LCD interface. 4/8-bit color LCD interface. Single-panel

Text: ) S1D13748(PFBGA 121- pin or QFP 144- pin ) Connecting EPSON Display Controllers to Casio LCD Panels (Rev , DI / DE 29 SCK / REV Pin Name Connecting EPSON Display Controllers to Casio LCD Panels , (-) Connecting EPSON Display Controllers to Casio LCD Panels (Rev 1.00) S1D13513 QFP Pin , Connecting EPSON Display Controllers to Casio LCD Panels Rev.1.00 NOTICE No part of this , .82 Connecting EPSON Display Controllers to Casio LCD Panels (Rev 1.00) EPSON i 8.2.3 Connecting the

Nowadays, we always use the devices which are made up of LCDs such as CD players, DVD players, digital watches, computers, etc. These are commonly used in the screen industries to replace the utilization of CRTs. Cathode Ray Tubes use huge power when compared with LCDs, and CRTs heavier as well as bigger. These devices are thinner as well power consumption is extremely less. The LCD 16×2 working principle is, it blocks the light rather than dissipate. This article discusses an overview of LCD 16X2, pin configuration and its working.

The term LCD stands for liquid crystal display. It is one kind of electronic display module used in an extensive range of applications like various circuits & devices like mobile phones, calculators, computers, TV sets, etc. These displays are mainly preferred for multi-segment light-emitting diodes and seven segments. The main benefits of using this module are inexpensive; simply programmable, animations, and there are no limitations for displaying custom characters, special and even animations, etc.

A 16×2 LCD has two registers like data register and command register. The RS (register select) is mainly used to change from one register to another. When the register set is ‘0’, then it is known as command register. Similarly, when the register set is ‘1’, then it is known as data register.

The main function of the data register is to store the information which is to be exhibited on the LCD screen. Here, the ASCII value of the character is the information which is to be exhibited on the screen of LCD. Whenever we send the information to LCD, it transmits to the data register, and then the process will be starting there. When register set =1, then the data register will be selected.

Thus, this is all about LCD 16×2 datasheet, which includes what is a 16X2 LCD, pin configuration, working principle, and its applications. The main advantages of this LCD device include power consumption is less and low cost. The main disadvantages of this LCD device include it occupies a large area, slow devices and also lifespan of these devices will be reduced due to direct current. So these LCDs use AC supply with less than 500Hz frequency. Here is a question for you, what are the applications of LCD?

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

This instructable will guide a user step-by-step in wiring and programming a Hitachi HD44780 (or a compatible) chipset LCD screen to an Arduino, using the LiquidCrystal Library. Programming examples are provided for all the Library calls.

The Hitachi HD44780 chipset or compatible LCD"s generally have a very standard pin set. Those without backlights may have only 14 pins, omitting the final two pins powering the light. Please refer to the datasheet for your unit to make sure they match up.

LiquidCrystal(rs, enable, d4, d5, d6, d7)- Creates a variable of type LiquidCrystal. You are asked to define the Ardunio pins the LCD is connected to.

I finally did it! Thank you man.. I can feel your passion through this post as you"ve made sure, not only to give all of the basic info, but also interesting extra stuff that helps with specific projects. The step by step explanation did me a lot of good, my failure was due to the fact that my LCD doesn"t have backlight implemented and instead of documenting myself on each individual pin I would just blindly try to make it look like in the pictures provided by other guides, ending up connecting data pins 13 and 14 to vcc and ground...

I know this is a bit late, but it appears it will work. According to the link you had in your comment "Pins 4, 5, 6, 7, 8, 9 and 10 are used to interface with the LCD", so you"d just change the code to say "LiquidCrystal lcd(4, 5, 6, 7, 8, 9)". According to the manual linked on the same page, pin 10 is the backlight control, so you"d just set pin 10 high. You could also dim the display by using the analogWrite function on pin 10. Hopefully this helps!0

There are two cable options for connecting the PanelDue, both options are included with the PanelDue V3 kit. Option 1 is the included 4-wire cable with Molex KK connector ends. Option 2 is the included 10-wire ribbon cable. For some boards, both cables need to be plugged in to enable both TFT panel and SD card socket.

The length of the 4-way cable is not critical, however the resistance per conductor should not exceed 0.1 ohm. The SD card socket on the TFT panel will not be functional. The cables supplied by Escher3D and Duet3D are about 800mm long. There have been reports of cables up to 1500mm long being successfully used. Take care to route the cable away from motor and endstop cables. Twisting the cables may help prevent cross talk interference.

A PanelDue can be connected to connector IO_0 using a 4-core cable wired like the one shown in the images below. The 4-wire cable supplied with the PanelDue has a 4-way Molex KK connecter on each end, but is supplied with a 5-way Molex KK connector for use with Duet 3. You will need to rewire one end. The 4-wire cable does not allow access to the SD card socket on the PanelDue.

Older versions of the Duet 2 WiFi/Ethernet need both the 4-wire and ribbon cable to be plugged in to use the TFT Panel and the SD card socket, when connecting PanelDue v2.0 or v3.0.

Use a 4-core cable terminated in a Molex KK or compatible connector at the PanelDue end and a 2x4 Dupont-style connector at the Duet end. This plugs into the end of the expansion connector. See https://miscsolutions.wordpress.com/pane....

In order to use the SD card slot on the PanelDue, you must use the ribbon cable option. If you do not wish to use the SD card slot, it"s recommended to use the 4-wire cable option described in Option 1.

The Duet 3 MB6HC has no PanelDue_SD socket. To use the external SD card, it requires RRF 3.4 or later, and a special wiring scheme; see "Duet 3 MB6HC using ribbon cable" section below.

Connect a 10-way ribbon cable between socket X5 on the PanelDue and socket CONN_SD (Duet 2) or PanelDue_SD (Duet 3). The connector is a standard 10 pin 2 row 2.54mm pitch box connector that accepts IDC connectors for 1.27mm ribbon cable.

Caution: if you are using a thermocouple and/or PT100 daughter board, the use of long ribbon cables between the Duet and PanelDue may affect communication between the Duet and the daughter boards, because the ribbon cable connection to the SD card on PanelDue uses the same SPI bus as the daughter boards.

Although the Duet 3 MB6HC does not have a connector for the PanelDue ribbon cable, if access to the SD card on PanelDue is required then this is possible using a special wiring arrangement. You must use RepRapFirmware 3.4 or later, and you must enable the external SD card using this command:

Note: if you are using an older version of either PanelDue 7i or PanelDue 5i, or a non-integrated version of PanelDue, then those do not support the CD signal. In that case you should omit the second port, for example:

The card detect signal (CD) is used to tell the Duet whether a card is inserted or not. Non-integrated versions of PanelDue (V2, V3) and older versions of PanelDue 5i and 7i (v1.0 of the 5i and v2.0 of the 7i) do not provide a card detect signal.

Duet 2 boards do not support the card detect signal on the external SD card, so can never tell whether a card is inserted or not except by trying to read it, and can"t detect a card being removed. No modifications are required connected older or newer PanelDue, or other external SD card adapters, to Duet 2 boards.

Duet 3 boards do support the card detect signal. Newer versions of the PanelDue 5i and 7i (v1.01 and later of the 5i and v2.01 and later of the 7i) provide this signal.

However, if you use a non-integrated versions of PanelDue or older versions of PanelDue 5i and 7i with Duet 3, it is necessary to ground the card detect signal, or the firmware will permanently think no card is inserted. There are a number of ways to achieve this.

This mod will enable the card detect signal. See the pictures below showing how to modify a PanelDue 5i v1.0. Connect a wire (thin enamelled copper in this instance) from the SD card socket Card Detect pin to the appropriate pin on the ribbon cable connector.

Generally it is best to run the latest version of the PanelDue firmware that is supported by the RepRapFirmware version on your Duet mainboard. See: Installing and Updating PanelDue Firmware

From RRF v3.2, PanelDue firmware releases are co-ordinated with the RRF release, and share the same version number. Use the PanelDue firmware version that matches your Duet mainboard"s firmware version.

PanelDue will display the bed heater H0 first (even if it is disabled), then iterate the defined tools. It then iterates the defined heaters below this. It expects a 1:1 relationship between tools and heaters. This means:if you have a machine that uses one heater for more than one tool (eg a 2-into-1, filament-swapping hot end), it will display more tools than heaters. Tools may not line up with their respective heaters.

The PanelDue also iterates the heaters from the first defined heater to the last, including all heaters in between, whether defined or not. This means if you have a heater defined on H0 (bed) and one on H5 (Duex output), it will show all the ones in between, eg H0, H1, H2, H3, H4 and H5. For an example, see |https://forum.duet3d.com/post/136207|this forum post|. Ideally, configure heaters on consecutive heater connections.

Due to constraints on display resolution, PanelDue can only display 7 heaters in total on 5" and 7" panels, and 5 on 4.3" panels. If there are more heaters and/or tools than this, some columns will overlap.

These restrictions are largely removed in later versions of the PanelDue firmware. However, they will require you to update RepRapFirmware on your Duet mainboard.

You can use the external SD card socket on the LCD panel if you have used a ribbon cable as described above. Please note, the SPI interface provided by this SD card socket is much slower than the on-board SD card socket built into the Duet. Therefore we recommend that you do not upload files to this card over the network. Use the external SD card socket only if you want to write files to the SD card on a PC and then move the SD card to your printer.

Caution! Do not use an SD extender cable from the SD socket on the Panel Due. Some types of SD card extender cable have been found to damage the SD card socket. Damage to the SD card socket from using an extender cable is not covered by the warranty.

You will need to make a custom 5-way cable using this table of connections. For the PanelDue 1.1, the X5 connector pins are numbered from the bottom end of the connector (the end close to the X5 legend). On the Duet 0.6 and 0.8.5 you need RepRapFirmware 1.17d or later to get support for the second SD card.

SD signal namePanelDue 1.1 X5 pin #PanelDue 2.0 X5 pin #Duet 2 signal nameDuet 2 CONN_SD pin #Duet 0.6/0.8.5 signal nameDuet 0.6/0.8.5 Expansion pinDueX4 Expansion1 pin

These displays are typically clones of the RepRapDiscount Full Graphic Smart Controller and look like this. The better ones include a contrast adjustment potentiometer. Unfortunately some manufacturers of other displays using the same controller chip reverse the pinouts on the two ribbon cable connectors. The ST7920 controller chip is invariably powered from 5V, which means that the display need 5V input signal levels.

An example of this is the Fysetc Mini 12864 Panel. The controller chip is run from 3.3V, so these displays normally include level shifters which tolerate a wide range of input voltages.

Duet 3 Mini provides two 2x5 ribbon cable headers for connecting a Fysetc 12864 Mini Panel version 1.2 or 2.1 (not 2.0) or compatible ST7567-based controller. When using a version 2.1 controller, the colours of the three Neopixel LEDs built into the display can be set using the M150 command with LED type parameter X2.

Use the pins +5V, GND, IO_0_OUT and IO_0_IN on the IO_0 header (Duet 3), or +5V, GND, TX and RX on the PanelDue header (Duet 2). These should be connected to +5V, GND, TX and RX on the TFT, making sure that TX and RX are swapped.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey