lcd screen diffuser manufacturer

Moreover, lcd light diffuser sheets with lcd can be used in a wide range of colors, sizes, and designs. Additionally, lcd light diffuser sheets with lcd are easy to maintain and have a low in consumption compared to normal light diffuser sheets with LEDs, and the majority of light diffuser sheets with LEDs have significantly reduced energy need.

At wholesale prices, Alibaba.com offers a wide variety of light diffuser sheets available in a variety of styles, colors, and styles to suit the customers" needs. LED lights can reduce energy waste, while LED lights can reduce the amount of energy waste.

Lcd essential diffusers can improve sleep and give off wonderful aromas which can boost your mood. At the same rate as lcd oil diffusers, they are more affordable, and offer a wide range of essential oils. A battery powered oil diffuser plate is an ideal choice for those who are looking for an essential oil diffuser that can improve their health and quality of life. Lcd oil diffusers provide a affordable and environmentally friendly option to those who are looking for a mini essential oil diffuser, or also for essential use.

Moreover, battery powered diffusers work in a similar setting to a oil diffuser. They can also be used as essential oil diffusers, because they are more portable and can be used in many ways. Moreover, they are more convenient to use in LEDs and battery powered diffusers can work with all devices of the same.

Lcd essential oil diffusers, among other appliances, are also popular appliances, as they give more moisture and the ability to produce irritating chemicals that dictate the health of their customers. oil diffusers can improve the health of their homes and offices, as they are so popular appliances, and oil fresheners, on Alibaba.com. Theycd oil diffusers can reduce pain and and aor of acid from penetration of the products.

There are many lcd diffusers for sale that are affordable, easy to find and buy in bulk at Alibaba.com. Looking for lcd diffusers that are an affordable, easy online wholesale option. Check out Alibaba.com for great wholesale prices and find a variety of lcd diffusers for sale at wholesale prices on Alibaba.com. Browse through Alibaba.com for great wholesale prices and find a variety of products at wholesale prices.

Wholesale looking for lcd diffusers of different shapes can be found on Alibaba.com, where there are many popular items like, oil-based lcd diffusers for candles, perfumes, and more. One of the most popular items like, Alibaba.com, where one can buy custom lcd diffusers with different shapes or colors to create their own atmosphere. B2B wholesale marketplace like Alibaba.com, where one can find a variety of lcd diffusers in different colors and styles to find one of the most popular items like, essential oil diffuser or mini lcd diffuser plate. One of the most popular items like, Alibaba.com or the B2B wholesale marketplace such as Alibaba.com to find wholesale lcd diffusers for sale with a wide range of colors and styles to choose from. For consumers, buy custom lcd diffusers in bulk or at an.

These types of lcd diffusers are readily available at wholesale prices in Alibaba.com. As a result, they are not readily available online, at Alibaba.com a great option for those who want to buy in bulk or for other purchases. At a very affordable prices, led diffusers have a range of different colors and styles to choose from, some of which are readily available online. At Alibaba.com with a wide range of different lcd diffusers and readily available at wholesale prices, such as at Alibaba.com.

Our led products: each pixel can be controlled individually. But normal led products one only show one color at the same time. That means, digital led products more colorful and even can be used as led display screen.

Having been known as one of the professional lcd led backlight diffuser sheet suppliers, Rina Technology is a successful company of lcd led backlight diffuser sheet. We have hundreds of well-educated and experienced staff working in our factory who are dedicated to developing, manufacturing and selling of high quality products. With many products in stock, we warmly welcome you to get our customized products at low price.

diffuser sheet offers the widest selection of high efficiency light diffuser components with a patented product family that reaches new metrics for efficiency and light control. Our industry leading performance is derived from several innovations in materials and process technology to produce precision volumetric and surface micro-optics in a wide range of form factors and materials. Our components set new benchmarks for performance in key metrics such as transmission efficiency for a given level of diffusion or hiding power, beating holographic, surface relief and bulk diffuser techniques light diffuser sheet.

We are led diffuser sheet manufacturer,the light diffuser sheet for led light transmission is normally 90%、85%、80%、76%、60%, can tailor to customer’s requirements.It has outstanding LED hiding ability, Our diffuser sheet being widely used for the panel light, Down light, linear light and so on, that"s because our diffuser sheet with different levels of light diffusion to meet various fixture performance requirements.

Find out more about the Diffuser Sheet in LCD and LED applications. Our lcd diffuser has a number of thicknesses available. And, buy your cut to size lcd diffuser from us and you’ll benefit from great customer service, fast delivery and precision cutting techniques ensuring excellent levels of accuracy.

Do you want to purchase eco-friendly, energy saving and high quality diffuser plate led made by professional manufacturers? With hundreds of professional staff in our factory, R…

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

ISO 9001:2008 certified manufacturer of plastic injection molded parts and fabricator of custom injection molds for light diffusers. Services include precision plastic injection molding, part design, mold design, mold construction, engineering, contract manufacturing, automated & manual assembly, cellular manufacturing, rapid prototyping, R&D, mold maintenance, mold repair, joining, decorating, packaging, and chemical bonding. Materials include difficult-to-process engineering resins, rubber replacement and metal replacement plastics, ABS, Acrylic, TPE, TPU, PC, PE, PP, Nylon (PA), PS, PPS, PI, PEI, PPS, PES, Ultem®, Radel, PEEK, Ryton, Lexan®, Valox® and other engineering plastics with additives. Industries serviced include medical, dental, life safety, lighting, military, automotive, aerospace, and consumer products.

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Led Backlight Panel Diffuser, The Backlight, Edge-Lit Led Panel, Curtain Led Strip,Led Light Bar. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success! The product will supply to all over the world, such as Europe, America, Australia,Buenos Aires, Colombia,Japan, French.Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

SILICON VALLEY, Calif., May 03, 2022--(BUSINESS WIRE)--Nanosys, the industry innovator and leading supplier of quantum dot and microLED technologies for advanced displays, today received the 2022 Display Industry Awards Display Component of the Year award for its xQDEF™ Diffuser Plate quantum dot technology from the Society for Information Display (SID).

Now, for the first time, everyday consumers shopping for TVs that cost less than $500 can experience quantum dot picture quality at home. The xQDEF Diffuser Plate simplifies the manufacturing process for TVs, eliminating unnecessary layers and significantly lowering the cost of ownership for quantum dot technology.

"We continue to see a broad range of innovations coming from the display industry," said Wei Chen, chair of the DIA Committee. "The miniLED backlight technology helps to push the performance of LCDs to a new level for electronic tablets, notebook computers, as well as LCD TVs. Foldable display technology continues its rapid pace of improvement.

The xQDEF Diffuser Plate is a new type of display component for LCDs that brings together diffuser plate technology with air-stable quantum dots. Developed in partnership with leading diffuser plate manufacturer Nangtong Changed New Material Co., Ltd., known as CYD, the xQDEF Diffuser Plate has been enthusiastically embraced by the display industry with over 1 million units shipped from Tier 1 consumer electronics brands in 2021.

Nanosys will receive the award in conjunction with SID’s annual Display Week, held in San Jose, California, May 8-13, 2022. Visitors to the Display Week show can also see a demonstration of the xQDEF Diffuser Plate at Nanosys booth #426. Visit the Nanosys event landing page for more information: www.nanosys.com/displayweek2022

CYD (Nantong Changed New Material Co., Ltd) is the global leader in developing, manufacturing and marketing high quality quantum dot diffuser plates and other optical components to the display industry. As of 2021, the company is the first and only company in the world that provides quantum dot diffuser plates in mass production, which has been widely used by leading TV manufacturers such as TCL, Hisense, and Skyworth. Established in November 2016, CYD operates the world’s largest quantum dot diffuser plates manufacturing facility in Nantong, China with 9 production lines in operation and 12 more production lines to be installed soon. CYD currently owns around 100 issued and pending patents worldwide.

The invention relates to optical displays, and more particularly to liquid crystal displays (LCDs) that may be used in LCD monitors and LCD televisions.

Liquid crystal displays (LCDs) are optical displays used in devices such as laptop computers, hand-held calculators, digital watches and televisions. Some LCDs include a light source that is located to the side of the display, with a light guide positioned to guide the light from the light source to the back of the LCD panel. Other LCDs, for example some LCD monitors and LCD televisions (LCD-TVs), are directly illuminated using a number of light sources positioned behind the LCD panel. This arrangement is increasingly common with larger displays, because the light power requirements, to achieve a certain level of display brightness, increase with the square of the display size, whereas the available real estate for locating light sources along the side of the display only increases linearly with display size. In addition, some LCD applications, such as LCD-TVs, require that the display be bright enough to be viewed from a greater distance than other applications, and the viewing angle requirements for LCD-TVs are generally different from those for LCD monitors and hand-held devices.

Some LCD monitors and most LCD-TVs are commonly illuminated from behind by a number of cold cathode fluorescent lamps (CCFLs). These light sources are linear and stretch across the full width of the display, with the result that the back of the display is illuminated by a series of bright stripes separated by darker regions. Such an illumination profile is not desirable, and so a diffuser plate is used to smooth the illumination profile at the back of the LCD device.

Currently, LCD-TV diffuser plates employ a polymeric matrix of polymethyl methacrylate (PMMA) with a variety of dispersed phases that include glass, polystyrene beads, and CaCO3particles. These plates often deform or warp after exposure to the elevated temperatures of the lamps. In addition, some diffusion plates are provided with a diffusion characteristic that varies spatially across its width, in an attempt to make the illumination profile at the back of the LCD panel more uniform. Such non-uniform diffusers are sometimes referred to as printed pattern diffusers. They are expensive to manufacture, and increase manufacturing costs, since the diffusing pattern must be registered to the illumination source at the time of assembly. In addition, the diffusion plates require customized extrusion compounding to distribute the diffusing particles uniformly throughout the polymer matrix, which further increases costs.

One embodiment of the invention is directed to a liquid crystal display (LCD) unit that has a light source and an LCD panel that includes an upper plate, a lower plate and a liquid crystal layer disposed between the upper and lower plates. The lower plate faces the light source, and includes an absorbing polarizer. An arrangement of light management films is disposed between the light source and the LCD panel so that the light source illuminates the LCD panel through the arrangement of light management films. The arrangement of light management films is attached to the lower plate of the LCD panel, the arrangement of light management films comprises at least a first diffuser layer.

Another embodiment of the invention is directed to a liquid crystal display (LCD) unit that includes a light source and an LCD panel. An arrangement of light management layers is disposed between the light source and the LCD panel so that the light source illuminates the LCD panel through the arrangement of light management layers. The arrangement of light management layers includes a diffuser plate and at least one of a brightness enhancing layer and a reflective polarizer. The diffuser plate has a substantially transparent substrate attached to a first diffusing layer that diffuses light propagating from the one or more light sources towards the LCD panel.

FIG. 1 schematically illustrates a back-lit liquid crystal display device that is capable of using a diffuser plate according to principles of the present invention;

FIGS. 4A-4K schematically illustrate additional embodiments of diffuser plates incorporating additional light management layers, according to principles of the present invention;

FIG. 5A-5C schematically illustrate exemplary embodiments of a diffuser assembly attached to the lower plate of a liquid crystal panel, according to principles of the present invention;

FIGS. 6A-6C schematically illustrate embodiments of diffuser assemblies attached to a flat fluorescent light source, according to principles of the present invention;

FIG. 8A presents a graph showing brightness uniformity plotted against overall brightness for control samples and example diffuser plates fabricated in accordance with principles of the present invention;

FIG. 12 presents a graph showing brightness uniformity plotted against overall brightness for control samples and example diffuser plates fabricated in accordance with principles of the present invention, when used with a brightness enhancing layer and a reflective polarizer;

FIG. 13 presents a graph showing luminance as a function of position across a screen for two control samples and sample diffuser plates S2 and S8 when used with a brightness enhancing layer and a reflective polarizer;

FIGS. 18A and 18B schematically present other embodiments of arrangements for fabricating laminated assemblies used in diffuser plates of the present invention;

FIG. 19 presents a graph showing brightness uniformity plotted as a function of single pass transmission through the diffuser plate for several sample uniform diffuser plates and for a printed diffuser plate;

FIGS. 20A, 20C and 20E schematically illustrate embodiments of arrangement for fabricating a diffuser assembly according to principles of the present invention

FIGS. 20B, 20D and 20F schematically illustrate the diffuser assemblies manufactured using the arrangements shown in FIGS. 20A, 20C and 20E respectively;

FIGS. 21A and 22A schematically illustrate another embodiment of an arrangement for fabricating a diffuser assembly according to principles of the present invention; and

FIGS. 21B-21D and FIG. 22B schematically illustrate the diffuser assembly at various stages of manufacture at different points along the arrangements illustrated in FIGS. 21A and 22A.

The present invention is applicable to liquid crystal displays (LCDs, or LC displays), and is particularly applicable to LCDs that are directly illuminated from behind, for example as are used in LCD monitors and LCD televisions (LCD-TVs).

The diffuser plates currently used in LCD-TVs are based on a polymeric matrix, for example polymethyl methacrylate (PMMA), polycarbonate (PC), or cyclo-olefins, formed as a rigid sheet. The sheet contains diffusing particles, for example, organic particles, inorganic particles or voids (bubbles). These plates often deform or warp after exposure to the elevated temperatures of the light sources used to illuminate the display. These plates also are more expensive to manufacture and to assemble in the final display device.

The invention is directed to a directly illuminated LCD device that has an arrangement of light management layers positioned between the LCD panel itself and the light source. The arrangement of light management layers includes a diffuser plate having a rigid organic or inorganic substrate and a polymeric volume diffusing sheet possessing a specific transmission and haze level directly adjacent to one side of the substrate. Another polymeric volume diffusing sheet may be positioned on the other side of the substrate. The transmission and haze levels of each component are designed to provide a direct-lit LC display whose brightness is relatively uniform across the display.

Diffuser plates of the present invention are simple to manufacture and provide a high degree of flexibility in the materials and processes used in manufacturing. In the diffuser plate according to the present invention, the structural and optical requirements are separated: the substrate provides the structural performance and the attached diffusing layer, or layers, provides the optical performance. By separating these functions, the cost advantages of using common transparent materials and common diffuser sheets can be exploited, to reduce overall costs. This also permits the introduction of warp resistant plates, for example glass plates, at low cost. In addition, it is easier to control the diffusion properties more precisely when the diffuser is contained in a layer separate from the plate. Patterned diffuser films may also be applied with less expense than with patterned, rigid, bulk diffuser plates.

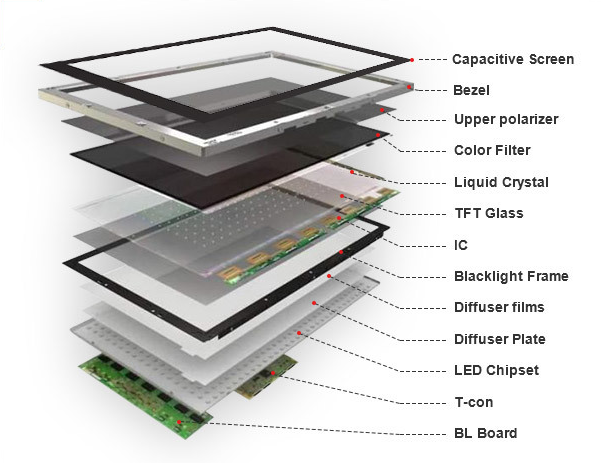

A schematic exploded view of an exemplary embodiment of a direct-lit LC display device 100 is presented in FIG. 1. Such a display device 100 may be used, for example, in an LCD monitor or LCD-TV. The display device 100 is based on the use of an LC panel 102, which typically comprises a layer of LC 104 disposed between panel plates 106. The plates 106 are often formed of glass, and may include electrode structures and alignment layers on their inner surfaces for controlling the orientation of the liquid crystals in the LC layer 104. The electrode structures are commonly arranged so as to define LC panel pixels, areas of the LC layer where the orientation of the liquid crystals can be controlled independently of adjacent areas. A color filter may also be included with one or more of the plates 106 for imposing color on the image displayed.

The backlight 112 includes a number of light sources 116 that generate the light that illuminates the LC panel 102. The light sources 116 used in a LCD-TV or LCD monitor are often linear, cold cathode, fluorescent tubes that extend across the display device 100. Other types of light sources may be used, however, such as filament or arc lamps, light emitting diodes (LEDs), flat fluorescent panels or external fluorescent lamps. This list of light sources is not intended to be limiting or exhaustive, but only exemplary.

An arrangement 120 of light management layers is positioned between the backlight 112 and the LC panel 102. The light management layers affect the light propagating from backlight 112 so as to improve the operation of the display device 100. For example, the arrangement 120 of light management layers may include a diffuser plate 122. The diffuser plate 122 is used to diffuse the light received from the light sources, which results in an increase in the uniformity of the illumination light incident on the LC panel 102. Consequently, this results in an image perceived by the viewer that is more uniformly bright.

Unlike conventional diffuser plates used in LCD-TVs, a diffuser plate according to an embodiment of the present invention has separate structural and diffusing members. One exemplary embodiment of a diffuser plate 200 is schematically illustrated in FIG. 2A. The diffuser plate 200 includes a substrate 202 and a diffuser layer 204 attached to the substrate.

The substrate 202 is a sheet of material that is self-supporting, and is used to provide support to the layers to which it is attached. While each of the layers in a laminate contributes to the stiffness of the laminate, the substrate is the layer that contributes most to the stiffness, i.e. provides more resistance to bending than any of the other layers of the laminate. A substrate does not significantly deform under its own weight, although it may sag to a certain extent. The substrate 202 may be, for example, up to a few mm thick, depending on the size of the display. In one exemplary embodiment, a 30″ LCD-TV has a 2 mm thick bulk diffuser plate. In another exemplary embodiment, a 40″ LCD-TV has a 3 mm thick bulk diffuser plate.

The substrate 202 may be made of any material that is substantially transparent to visible light, for example, organic or inorganic materials, including glasses and polymers. Suitable glasses include float glasses, i.e. glasses made using a float process, or LCD quality glasses, referred as LCD glass, whose characteristic properties, such as thickness and purity, are better controlled than float glass. One approach to forming LCD glass is to form the glass between rollers.

The diffuser plate and one or more other light management layers may be included in a light management unit disposed between the backlight and the LCD panel. The light management unit provides a stable structure for holding the diffuser plate and the one or other light management layers. The structure is less prone to warping than conventional diffuser plates, particularly if the supporting substrate is formed of a warp-resistant material such as glass. Also, the ability to supply a display manufacturer with a diffuser plate attached together with one or more other light management layers as a single integrated unit results in simplified assembly of the display.

The diffusing particles may be any type of particle useful for diffusing light, for example transparent particles whose refractive index is different from the surrounding polymer matrix, diffusely reflective particles, or voids or bubbles in the matrix. Examples of suitable transparent particles include solid or hollow inorganic particles, for example glass beads or glass shells, solid or hollow polymeric particles, for example solid polymeric spheres or polymeric hollow shells. Examples of suitable diffusely reflecting particles include particles of titanium dioxide (TiO2), calcium carbonate (CaCO3), barium sulphate (BaSO4), magnesium sulphate (MgSO4) and the like. In addition, voids in the polymer matrix may be used for diffusing the light. Such voids may be filled with a gas, for example air or carbon dioxide. Commercially available materials suitable for use in a diffusing layer include 3M™ Scotchcal™ Diffuser Film, type 3635-70 and 3635-30, and 3M™ Scotchcal™ ElectroCut™ Graphic Film, type 7725-314, available from 3M Company, St. Paul, Minn. Other commercially available diffusers include acrylic foam tapes, such as 3M™ VHB™ Acrylic Foam Tape No. 4920.

The diffuser layer 204 may be applied directly to the surface of the substrate 202, for example where the polymer matrix of the diffuser layer 204 is an adhesive. In other exemplary embodiments, the diffuser layer 204 may be attached to the surface of the substrate 202 using an adhesive layer 206, as is schematically illustrated in FIG. 2B. In some exemplary embodiments, the diffuser layer 204 has a diffusion characteristic that is uniform across its width, in other words the amount of diffusion experienced by light passing through the diffuser is the same at points across the width of the diffuser layer.

The diffuser layer 204 may optionally be supplemented with an additional patterned diffuser 204 a. The patterned diffuser 204 amay include, for example, a patterned diffusing surface or a printed layer of diffuser, such as particles of titanium dioxide (TiO2). The patterned diffuser 204 amay lie on the substrate 202, between the diffuser layer 204 and the substrate 202, or above the diffuser layer 204. The patterned layer 204 amay be, for example, printed onto the diffuser layer 204, as illustrated in FIG. 2A, or onto a sheet that lies above the diffuser layer 204.

The diffuser plate may be provided with protection from ultraviolet (UV) light, for example by including UV absorbing material or material in one of the layers that is resistant to the effects of UV light. In particular, one of the layers of the diffuser plate, such as the substrate 202, may include a UV absorbing material, or the diffuser plate may include a separate layer of UV absorbing material. Suitable UV absorbing compounds are available commercially, including, e.g., Cyasorb™ UV-1164, available from Cytec Technology Corporation of Wilmington, Del., and Tinuvin™ 1577, available from Ciba Specialty Chemicals of Tarrytown, N.Y. The diffuser plate may also include brightness enhancing phosphors that convert UV light into visible light.

Other materials may be included in one or more of the layers of the diffuser plate to reduce the adverse effects of UV light. One example of such a material is a hindered amine light stabilizing composition (HALS). Generally, the most useful HALS are those derived from a tetramethyl piperidine, and those that can be considered polymeric tertiary amines. Suitable HALS compositions are available commercially, for example, under the “Tinuvin” tradename from Ciba Specialty Chemicals Corporation of Tarrytown, N.Y. One such useful HALS composition is Tinuvin 622. UV absorbing materials and HALS are further described in co-owned U.S. Pat. No. 6,613,619, incorporated herein by reference.

In other exemplary embodiments, the diffuser plate 300 may be double-sided, having a first diffuser layer 304 aon one side of the substrate 302 and a second diffuser layer 304 bon another side, as is schematically illustrated in FIG. 3A. The diffuser layers 304 aand 304 bmay each be applied directly to the respective surface of the substrate 302, as is illustrated in FIG. 3A, or may be attached using a layer of adhesive 306 a, 306 b, as is schematically illustrated in FIG. 3B.

The double-sided diffuser plate 300 may be symmetrical, with the two diffuser layers 304 a, 304 bhaving the same diffusion properties, or may be asymmetric, with the diffuser layers 304 a, 304 bhaving different diffusing properties. For example, the diffuser layer 304 amay possess a different transmission or haze level from the second diffuser layer 304 b, or may be of a different thickness.

In other exemplary embodiments, the diffuser plate may include more than one substrate. One such embodiment is schematically illustrated in FIG. 3C, which shows a diffuser plate 320 formed with first and second substrates 302 aand 302 b. Other optical layers in the diffuser plate 320 may be positioned symmetrically, with other optical layers positioned between the substrates 302 a, 302 b, or asymmetrically, with one or more of the other optical layers positioned to the other side of one of the substrates 302 a, 302 b. In the exemplary embodiment illustrated in FIG. 3C, a diffuser layer 306, is located between the substrates 302 a, 302 b, and may be attached to the two substrates 302 a, 302 bvia adhesive layers 306 a, 306 b. In another approach, where the diffuser layer 304 is an adhesive layer, the adhesive layers 306 a, 306 bmay be omitted.

Another exemplary embodiment of diffuser plate 340 is schematically illustrated in FIG. 3D. This diffuser plate 340 includes two substrates 302 a, 302 b, with a diffuser layer 304 and a reflective polarizer 308 between the substrates 302 a, 302 b. In this particular embodiment, the diffuser layer 304 is also an adhesive layer, and so the diffuser layer 304 may be used to attached the reflective polarizer 308 to the lower substrate 302 a. Another adhesive layer 306 may be positioned between the reflective polarizer 308 and the upper substrate 302 b.

Other configurations of diffuser plate having two substrates may also be used. For example, additional optical layers, such as a brightness enhancing layer, may be placed between the substrates, In addition, one of the substrates may comprise a plate of another element of the display. For example, the upper substrate of the diffuser layer may comprise the lower plate of the liquid crystal display panel, or the lower substrate may comprise the plate of a flat fluorescent display. Both of these configurations are described further below.

Other exemplary embodiments of a diffuser plate may also incorporate additional light management layers. For example, a diffuser plate 400 may include a substrate attached to one side of a diffuser layer 404, with a reflective polarizer 406 attached to the other side of the diffuser layer 404, as is schematically illustrated in FIG. 4A. The reflective polarizer 406 may be attached using an optional layer of adhesive 408, as shown in the illustrated embodiment. Optionally an additional coating 409 may be provided over the reflective polarizer 406. For example, the coating 409 may be a protective hard-coat layer.

In another exemplary embodiment, not illustrated, the diffusing layer 404 and the reflective polarizer 406 may be co-extruded as a combined layer, without the need for a layer of adhesive 408 between the diffuser 404 and the reflective polarizer 406. The combined layer of the diffuser 404 and reflective polarizer 406 may then be mounted to the substrate 402, for example with an adhesive layer.

In another exemplary embodiment, the diffuser layer 404 is an adhesive layer, and may be used to mount the reflective polarizer 406 to the substrate 402, as is illustrated in FIG. 4B.

In other embodiments, the diffuser layer 404 may itself comprise a diffuse adhesive layer, in which case the reflective polarizer 406 may be attached directly to the diffuser layer 404. Adhesive diffusive layers are discussed in greater detail in International (PCT) Patent Publications WO99/56158 and WO97/01610, incorporated herein by reference. Adhesive diffusive layers may be used in any of the diffuser plate embodiments discussed herein.

In addition, a brightness enhancing layer 412, such as a prismatic brightness enhancing layer, may optionally be used with the diffuser plate 400. The brightness enhancing layer 410 may be attached to the reflective polarizer 406, as is schematically illustrated in FIG. 4C, for example using via an adhesive layer 412. In other exemplary embodiments, the brightness enhancing layer 410 may not be attached to the reflective polarizer 406, but may be free-standing relative to the diffuser plate 400, with an air gap between the reflective polarizer 406 and the brightness enhancing layer 410.

In another exemplary embodiment 430, schematically illustrated in FIG. 4D, a brightness enhancing layer 432 may be attached to the diffuser layer 404. The brightness enhancing layer 432 may be attached directly to the diffuser layer 404, for example if the diffuser layer 404 is adhesive, or may be attached to the diffuser layer 404 using an intermediate layer of adhesive 434.

Other approaches to forming voids, and thus providing an air interface to light entering the brightness enhancing layer, may be used. For example, the brightness enhancing layer 432 may have a flat lower surface 440, with the adhesive 434 being structured with protrusions. These, and additional approaches, are discussed in co-owned U.S. Patent Publication No. 2003/0223216 A1, incorporated herein by reference. Any of the embodiments of diffuser plate discussed herein may be adapted to provide an air interface for light entering the brightness enhancing layer.

Another exemplary embodiment of a diffuser plate 450 is schematically illustrated in FIG. 4E. In this embodiment, an air gap 452 is formed between the brightness enhancing layer 410 and the layer from which the light passes to the brightness enhancing layer 410, in this case the diffusing layer 404. The air gap 452 may be formed by providing a layer of adhesive 454 between diffusing layer 404 and the brightness enhancing layer 410, around the edge of the plate 450. A reflecting polarizer 406 may optionally be provided above the brightness enhancing layer 410, and may be attached to the brightness enhancing layer 410. In a variation of this embodiment, brightness enhancing layer 410 may be replaced with a reflective polarizer that has a brightness enhancing structure on its upper side.

Another exemplary embodiment of a diffuser plate 460 is schematically illustrated in FIG. 4F. In this embodiment, an air gap 462 is formed between the brightness enhancing layer 410 and the diffuser layer 404. The diffuser layer 404 is provided as an adhesive that may be higher at the edges of the diffuser plate 460 than in the central region. The edge portions 464 of the adhesive attach to the brightness enhancing layer 410. An intermediate layer 466 may be provided in the gap 462, for example a blank buffer layer or a reflecting polarizer. In this particular embodiment, the edge portions 464 of the adhesive are higher than the intermediate layer 466.

In some embodiments it is desired, although it is not a limitation, that optical layers placed between the reflective polarizer and the LCD panel, in this and other embodiments, be polarization preserving. This avoids or reduces adverse affects on the polarization of the light that has been polarized by the reflective polarizer. Hence, it would be preferred in this embodiment for the brightness enhancing layer 410 to demonstrate little or no birefringence.

In another exemplary embodiment of diffuser plate 470, schematically illustrated in FIG. 4G, the edge portions 464 are not higher than the intermediate layer 466. Thus, when the brightness enhancing layer 410 is attached to the edge portions 464, the higher intermediate layer 466 bows the brightness enhancing layer 410 out, to produce an air gap 472 between the intermediate layer 466 and the brightness enhancing layer 410.

One example of a suitable diffuser layer 404 is an acrylic foam tape: the foam tape deforms when the intermediate layer 466 is pushed into the foam tape, creating a recessed region that the intermediate layer 466 sits in. Another exemplary embodiment of an arrangement 475 of light management films is schematically illustrated in FIG. 4H. In this embodiment, the intermediate layer 466 is disposed on a diffuser layer 476. An adhesive tape 478 is disposed at the edges of the diffuser layer 476, forming a recessed region 479 that the intermediate layer 466 is located within, and a brightness enhancing layer 410 is disposed over the intermediate layer 466.

In some exemplary embodiments, the diffuser film and other films may be attached together without necessarily being attached to the substrate, although they may be attached to the substrate. For example, in FIG. 4I, the embodiment of diffuser plate 480 includes a film assembly 484 that has a reflecting polarizer 406 attached to one side of a diffuser layer 404 as an upper layer. The diffuser layer 404 may be, for example, a diffusing adhesive, or an acrylic foam tape. In other exemplary embodiments the diffuser layer 404 may be a non-adhesive layer, with an adhesive layer (not shown) attaching the reflecting polarizer 406 to the diffuser layer 404. An optional lower layer 482, for example a clear polymer layer, may be attached to the other side of the bottom of the diffuser layer 404. The assembly 484, comprising the reflecting polarizer 406, the diffuser layer 404, and the optional lower layer 482 if included, may be disposed with a substrate 402. The assembly 484 may be attached to the substrate 402, but need not be attached to the substrate 402.

In another exemplary embodiment, schematically illustrated in FIG. 4J, an assembly of films 485 comprises a diffuser layer 404 attached to an optional transparent lower layer 482. An intermediate layer 486 is attached to the upper side of the diffuser layer 404. The intermediate layer 486 may be, for example, a transparent layer or a reflective polarizer film. The transparent layer may have a matte surface one or both surfaces. The intermediate layer 486 may be depressed into the diffuser layer 404: for example, where the diffuser layer 404 is a foam tape, the intermediate layer 486 may be pressed into the foam tape so that the foam tape deforms, producing a depressed region in which the intermediate layer 486 is located. The lateral extent of the intermediate layer 486 may be less than that of the diffuser layer 404, so that the un-deformed portion 487 of the diffuser layer 404 acts as a support for the upper layer 488. The upper layer 488 may be a prismatic brightness enhancing film, or may be a combination of prismatic brightness enhancing film and a reflective polarizer. One example of a prismatic brightness enhancing film above a reflective polarizer is BEF-RP film manufactured by 3M Company, St. Paul, Minn. There may be a gap formed between the intermediate layer 486 and the upper layer 488.

In another exemplary embodiment, schematically illustrated in FIG. 4K, an assembly of films 490 comprises a diffuser layer 404 attached to an optional transparent lower layer 482. An intermediate layer 486 is attached to the upper side of the diffuser layer 404. The intermediate layer 486 may be a transparent layer, which may or may not have a matte surface on one or both surfaces. A prismatic brightness enhancing layer 410 is located above the intermediate layer. The intermediate layer 486 and the prismatic brightness enhancing layer 410 may be each be depressed into the diffuser layer 404 so that the diffuser layer 404 deforms with a depression where the intermediate layer 486 and the prismatic brightness enhancing layer 410 are located.

A reflective polarizer layer 406 is positioned above the prismatic brightness enhancing layer 410. The reflective polarizer layer 406 may be attached only to the un-deformed portions 487 of the diffuser layer 404, or may be attached to the prismatic brightness enhancing layer 410 in the manner described above with regard to FIGS. 4D and 4E.

In some exemplary embodiments, the lower plate of the LCD panel itself may be used as the substrate that supports the diffuser layer and other optical layers. One exemplary embodiment of such a display assembly 500 is schematically illustrated in FIG. 5A, in which an LCD panel 102 includes an LC layer 104 and upper and lower plates 106 a, 106 b. The plates 106 a, 106 bare typically made of glass, or a thick polymer, and may also include absorbing polarizers. A light management unit 502 may be attached to the lower plate 106 b. The light management unit 502 includes a diffuser layer 504 and may also include other optical layers. For example, the light management unit 502 may also include a brightness enhancing layer 506 and a reflective polarizer 508. If a brightness enhancing layer is 506 is included, then an air gap 510 may be formed at its lower surface using any of the approaches described above. For example, a layer of adhesive 512 around the edge of the light management unit 502 may be used to provide the air gap 510. The light management unit 502 may be attached to the lower plate 106 busing another adhesive layer 514. The light management unit 502 may also be provided as a unit that is not attached to the panel 102.

Other layers may also be present in the light management unit 502 attached to the LCD panel 102. For example, an additional substrate may be placed within the light management unit 502.

In another exemplary embodiment of display assembly 520, schematically illustrated in FIG. 5B, a diffuser layer 522, for example a layer of diffuse adhesive or an acrylic foam tape, is attached directly to the lower polarizer 106 b, with a reflective polarizer layer 508 attached to the lower surface of the diffuser layer 522. In this embodiment, it may be desired that the diffuser layer be polarization preserving. In another exemplary embodiment of display assembly 530, schematically illustrated in FIG. 5C, a reflective polarizer 508 may be disposed between the diffuser layer 522 and the display panel 102. Other light management films may be provided with the reflective polarizer layer 508 and the diffuser layer 522.

Some fluorescent light sources, referred to herein as a flat fluorescent lamp (FFL), provide a two dimensional plane or surface that may be used for attaching the diffuser layer and other optical layers. These types of light sources are also known by other names, such as flat discharge fluorescent lamp, and two-dimensionally integrated fluorescent lamp (TIFL). Some FFLs are based on a fluorescently converting the UV output from a mercury discharge, while other FFLs use the discharge of some other material. For example, the Planon II lamp, available from Osram GmbH, Munich, Germany, is a two dimensional fluorescent lamp based on a xenon excimer discharge.

One exemplary embodiment of a light management unit 604, comprising a diffuser layer 606 and, optionally, other optical layers, integrated on an FFL 602 is schematically illustrated in FIG. 6A. In this embodiment of integrated light source 600, the FFL 602 has a substantially flat upper surface 603. The light management unit 604 may optionally include other layers, for example, a reflective polarizer 608 and/or a brightness enhancing layer 610, one or more of which are attached to the diffuser layer 606. In the illustrated exemplary embodiment, the reflective polarizer 608 is attached to the diffuser layer 606. The diffuser layer 606 may be an adhesive layer, or an additional adhesive layer (not shown) may be used to attach the reflective polarizer 608 to the diffuser layer 606.

The brightness enhancing layer 610 may be free standing or may be attached to one or two of the other layers in the light management unit 604 using any of the approaches described above. For example, in the exemplary embodiment of integrated light source 620 schematically illustrated in FIG. 6B, the brightness enhancing layer 622 is positioned between the reflective polarizer 608 and the diffuser layer 606, and has a lower surface 624 adapted to provide air gaps 626 diffuser layer 606 and the brightness enhancing layer 622.

The FFL need not have a flat upper surface. For example, in the embodiment of integrated light source 640 schematically illustrated in FIG. 6C, the light management unit 644 is attached to an FFL 642 that has a ribbed upper surface 646. The diffuser layer 606 may be attached to the ribs of such a surface 646.

A number of sample diffuser plates manufactured according to this disclosure were prepared and their performance was compared to that of diffuser plates used in commercially available LCD-TVs. The diffuser plates were tested for single pass light transmission and reflection and for brightness and uniformity.

Light transmission and reflection measurements of the diffuser plates and substrate materials, for samples S1-S27 and control samples C-1 and C2, were made using a BYK Gardner Haze-Gard Plus instrument, catalog no. 4723 and supplied by BYK Gardner, Silver Spring, Md. The transmission and haze levels were collected according to ASTM-D1003-00, titled “Standard Test Method for Haze and Luminous Transmittance for Transparent Plastics”. The instrument was referenced against air during the measurements. In all the measurements for transmission and haze, the D1 side of the diffuser plate was positioned on the same side as the clarity port and the D2 side of the diffuser plate faced the haze port.

The measurements of brightness and uniformity, for samples S1-S27 and control samples C1 and C2, were performed on a specially designed LCD-TV experimental test bed. The test bed apparatus 700, illustrated schematically in FIG. 7 used two functioning parts: namely i) a 22″ Samsung LCD-TV, Model LTN226W, Model Code: LTN226WX/XAA and shown as element 702 in FIG. 7, and ii) a goniometer stage 704. The goniometer 704 allowed the TV 702 to be moved from a horizontal position, used for film loading and shown in dashed lines, to a vertical position for the measurements. This arrangement provided for convenient for convenient loading and testing of various diffuser panels 706. The LCD-TV 702 was located about ˜15 feet (about 4.6 m) from a Prometric CCD Camera, Model 16111 (shown as element 708 in FIG. 7), obtainable from Radiant Imaging, DuVall, Wash.). The camera was provided with a Radiant Imaging Optical Filter, 72 mm ND 2.0. The Prometric camera luminance was calibrated using a Photo Research PR 650 (Chatsworth, Calif., SSN: 60964502). For the measurements reported below, the LC panel and absorbing polarizers had been removed from the LCD-TV, and various diffuser panels were used with the LCD-TV"s backlight. The LCD-TV"s backlight included an arrangement of eight parallel CCFL lamps.

The data was averaged across one x coordinate and reported as the luminance in nits, while the standard deviation in the brightness across the diffuser plate was collected on the same data to provide a metric on the uniformity.

The structural and optical properties of each of the sample diffuser plates and the control samples are summarized in Table I below, and values of brightness uniformity are shown plotted against total brightness in FIG. 8A. In Table I, each row presents the data for a single sample. The control samples, C1 and C2, being listed first.

The “Subst.” column lists the type of substrate used. The “Thick” column shows the thickness of the substrate. The “D1” column lists the type of diffuser layer used on the side of the substrate facing away from the lamps. The “D2” column lists the type of diffuser layer used on the side of the substrate facing the lamps. When the substrate was provided with a single diffuser layer, the optical properties were measured with the diffuser layer facing away from the lamps. The “Luminance” column shows the total luminance measured for light transmitted through the diffuser plate, in Nits. The “Uniformity” column lists the standard deviation in the brightness measured across the diffuser plate, also in Nits. The column labeled “σ/x” lists the ratio of the uniformity over the luminance, in other words a relative uniformity. The “Transmit” column lists the single pass transmission through the diffuser plate. This is the value of the single pass transmission averaged across the diffuser plate. Where the plate has a uniform diffusion characteristic, the transmission at any one point is equal to the spatially averaged transmission. Where the plate has a non-uniform diffusion characteristic, i.e. as with a printed pattern diffuser, the transmission at any one point need not be the same as the spatially averaged transmission. The “Haze” column lists, as a percentage, the ratio of the diffuse light transmitted through the diffuser plate over the total light transmitted through the diffuser plate.

Control Sample 1 (C1) is the Samsung Patterned Diffuser Plate that accompanied the 22″ Samsung LCD-TV (Model: LTN226W). This diffuser plate was a 2 mm thick plate formed of PMMA, and contained CaCO3diffusing particles. In addition, the plate possesses a printed pattern that is registered to the CCFL bulbs of the Samsung LCD-TV. Control Sample 1 is taken as representing a high performance LCD-TV diffuser plate.

Control Sample 2 is the diffuser plate that accompanied a Sharp 30″ LCD-TV, model no. LC-30HV2U. This diffuser plate was formed from a 2 mm thick plate of PMMA containing 5 μm glass spheres as the diffusing particles. This diffuser plate did not possess a printed pattern. Control Sample 2 is taken as representing a standard LCD-TV diffuser plate.

Samples S1-S3 were single-sided diffuser laminates based on a 1 mm thick LCD glass substrate (Corning 1737F) and a variety of diffuser films. The glass plates were sized to fit into the Samsung 22″ LCD-TV (19.58″×11.18″ with 0.1″×1″ notches in the middle of both horizontal edges). These samples possessed the same sizes as C-1 and C-2. The glass plates of samples S1-S3 were laminated with 3M Scotchcal™ diffusing films 7725-314, 3635-70, and 3635-30 respectively, all available from 3M Company, St. Paul, Minn. The diffuser films provided a diffusion characteristic that was uniform across the width of the samples.

The brightness measured across S1-S3 diffuser plates is shown as a function of position across the plates in FIG. 8B, with the results for control sample C1 shown for comparison. The single pass transmission for the samples reduces from S1 to S3. As the plate transmission decreases the brightness values also decrease. The illumination through the plates becomes more uniform (reduced σ), however, with lower single pass transmission.

Samples S5, S8 and S10 were prepared the same way as samples S1-S3, except that diffuser films were laminated to both sides of the diffuser plate. Samples S5, S8, S10 were symmetric, in other words the diffuser layer was the same on both sides of the substrate. The diffuser films provided a diffusion characteristic that was uniform across the width of the samples.

Samples S6, S7 and S9 were asymmetric, using different diffusers on the sides of the substrate. Samples S6 and S7 were prepared the same way as S1 except that the second diffuser layer D2, was added, 3635-70 in the case of S6 and 3635-30 in the case of S7. Sample S9 was prepared the same way as S9, except that a 3635-30 diffuser layer was added as the D2 layer.

The brightness through samples S5, S8 and S10 is shown as a function of position across the plate in FIG. 9, along with the measured values for C1. The performance of S8 most closely matches to that of C1: the luminance value for S8 is 5175 nits, compared with 5422 nits for C1, and the relative uniformity is 1.7% compared with 1.3% for C1, and 4.7% for C2. These data demonstrate that, by proper design of the diffuser plate laminate, a diffuser plate fabricated according to the present disclosure can be designed to have optical properties similar to those of a patterned diffuser plate.

This set of examples demonstrates that, by proper design of the diffuser element with the enhancing layers, an optimized light management assembly can be realized. It is important to realize that the optical performance of the laminated samples S2 and S8 approaches that even of the high quality diffuser C1. C1 was provided with a patterned diffuser, which increases the cost of the diffuser plate, in order to achieve high uniformity. In contrast, laminated samples S2 and S8 used a uniform diffuser.

Samples S19, S21 and S26 were made in the same way as S2, except that S19 used a substrate of 2 mm thick Lexan polycarbonate (PC), S21 used a substrate of 2 mm thick PMMA, and S26 used a 1 mm sheet of float glass (Industrial Glass Products, Los Angeles, Calif.). The brightness measurements across the plates are presented in FIG. 10 for S19, S21, and S26, along with the corresponding measurements for S2. The uniformity levels are similar in all three samples, but the single pass transmission through the PC plate was relatively low. These results suggest that the plate material may be an important variable in designing the diffuser plate.

Samples C-1, C-2, S1-S10 S19-S22, S26 and S27 were modified by placing a layer of Vikuiti™ DBEF-440 reflective polarizer (RP) and a layer of Vikuiti™ BEF-3T prismatic brightness enhancing film (BEF) above the diffuser plate, both films available from 3M Company, St. Paul, Minn. The brightness was measured as a function of position across the display. The results some of these measurements are summarized in Table II, which shows the luminance and the brightness uniformity in terms of the standard deviation, σ, in the luminance level across the display, and the relative uniformity, σ/x. For comparison, the relative uniformity of the diffuser plate when illuminated without the brightness enhancing film and reflective polarizer is shown in the last column, marked σ/x (D). FIG. 12 shows a graph of uniformity plotted against illuminance.

A study of the illuminance uniformity was made for various values of transmission in the range of about 77%-92%. Various samples like S1 were made, but with additional layers of the Scotchcal™ ElectroCut™ Graphic Film, type 7725-314 diffusive layer. The performance of these samples, S1a-S1d is listed in Table II below. Samples S1a-S1d had 2-5 layers of the diffuser on each side of the substrate (4-10 layers total), respectively.

These results for σ/x also shown in FIG. 19 as a function of single pass transmission, T. The 7725-314 diffusive layer had an absorption of around 2%, and so the transmission for samples S1a-S1d was reduced relative to the transmission of S1. However, the value of σ/x was very good, in most cases being less than 1%, which shows that a uniform diffusing layer can provide uniformity values approaching that of a patterned diffuser.

Conventional wisdom holds that increased illumination uniformity is achieved using relatively high levels of diffusion, which means relatively lower single pass transmission, typically around 70% or lower. The results presented in FIG. 19 show that the conventional wisdom is misleading when the diffuser is used in conjunction with a brightness enhancing layer, and that high illumination uniformity can be achieved using a uniform diffuser having a single pass transmission higher than 70%. In fact, where the diffuser is uniform, the relative uniformity is maximum in the range 75%-90%. It is believed that high levels of uniformity are possible with high diffuse transmission because the brightness enhancing layer interacts preferentially with light diffused by the diffuser at certain angles. Accordingly, preferred values of single pass transmission in the diffuser plate may be greater than 75%, 80%, or 85%, and ranges of single pass transmission may lie in the range 72%-95%, more preferably in the range 75%-90%. These single pass transmission values correspond to the single pass transmission through the combination of all diffuser layers present in the set of light management layers disposed between the light source(s) and the LCD panel.

An additional example, Sample S28 was prepared with a 0.4 mm layer of acrylic foam tape (VHB 4643 tape, available from 3M Company, St. Paul, Minn.) as the diffuser layer on a 3 mm thick PMMA substrate. The diffusion characteristic of the acrylic foam tape was uniform. The performance of this sample, compared with an additional control sample, C3, is shown in Table III. The control sample was the diffuser plate taken from an SEC 40 inch LCD-TV Model No. 400W1 and was based on a 3 mm thick PMMA substrate containing diffusing particles.

The single pass transmittance and haze were made as single pass measurements, while the remaining measurements of illuminance were made with the diffuser plates in place on the SEC television, using the television"s lamps. The illuminance was measured with various configurations of diffuser plate and other light management layers. The third row shows the illuminance for the diffuser plate only. In the case of comparative example C3, the diffuser plate was the PMMA sheet that contained diffuser particles. In the case of S28, the diffuser plate was the 3 mm thick PMMA plate with an acrylic foam tape diffuser mounted on one side.

The fourth row shows the illuminance when the diffuser plate was combined with a layer of brightness enhancing film (BEF) (Vikuiti™ BEF-3T film produced by 3M Company, St. Paul, Minn.). The fifth row shows the illuminance when the diffuser plate was combined with the absorbing polarizer used in the LC panel. The sixth row shows the illuminance when the diffuser plate was combined with the BEF and the absorbing polarizer. The seventh row shows the illuminance when the diffuser plate was combined with the BEF, a reflecting polarizer (Vikuiti™ DBEF-440 MOF reflecting polarizer), and the absorbing polarizer.

The single pass transmittance of S28 is a little lower than that for C3, but has a similar level of haze. Also, the illumination performance of S28 is only a few percent lower than that for C3, which is significant because the transmittance of S28 was not optimized for this test. Conoscopic plots showing the output from S28 and C3 are shown in FIGS. 14A and 14B respectively. The acrylic foam tape diffuser plate has a nearly isotropic distribution, similar to that of C3. Thus, it is believed that, with further optimization, acceptable optical characteristics can be achieved in a diffuser plate possible using acrylic foam tape as a diffuser.

The diffuser plates of the present invention may be fabricated using different approaches. One particular approach is now discussed with reference to FIGS. 15A and 15B. In this approach, a number of flexible films, for example diffuser, reflective polarizer and/or brightness enhancing films are first laminated together. The films may be directly laminated together or may be laminated using one or more intermediate adhesive layers. In the illustrated embodiment, a first film 1502 and a second film 1504 are taken off respective rolls 1506 and 1508 and laminated in a lamination roll 1510, as schematically shown in FIG. 15A. The laminated web 1512 may then be wound on a rewinding roll 1514. The laminated web 1512 may be a laminate of more than two films.

Another approach to fabricating a diffuser plate is now discussed with reference to FIGS. 16A and 16B. In this approach, a number of flexible films, for example, a diffuser film, a reflective polarizer layer and/or a brightness enhancing film are first laminated together. The films may be directly laminated together or may be laminated using one or more intermediate adhesive layers. In the illustrated embodiment, a first film 1552 and a second film 1554 are taken off respective rolls 1556 and 1558 and laminated in a lamination roll 1560, as is schematically illustrated in FIG. 16A. The resulting laminated web 1562 is then cut by a cutting tool 1564 into prepared laminate sheets 1566 of a desired length. The prepared laminate sheets 1566 may be formed into a stack 1568.

Another approach to fabricating a diffuser plate according to the present invention is now described with reference to FIG. 17. Substrate panels 1702 are fed to a lamination stage 1704 where they are laminated with a number of films. In the illustrated embodiment, the substrate panels 1702 are laminated with two films 1706, 1708 that may be removed from respective rolls 1706 a, 1708 b. The substrate panels 1702 may optionally have a premask removed before lamination, for example by removing the premask using a removal roll 1710. Likewise, at least one of the films 1706, 1708 may have a premask removed, for example by premask removal roller 1712.

There may be one or more films laminated to the panels 1702 at the same time. The films laminated to the panels 1702 may include a diffuser layer, a reflecting polarizer and/or a brightness enhancing layer. For example, the intermediate layer 1708 may be a diffuser layer, such as an acrylic foam tape, while the upper layer 1706 is a reflective polarizer or a brightness enhancing layer, or a pre-formed combination of reflective polarizer and brightness enhancing layer.

Another approach to making a diffuser plate according to the present invention is now discussed with reference to FIGS. 18A and 18A. In this approach, a number of flexible films, for example a diffuser, reflective polarizer and/or brightness enhancing films are first laminated together, prior to lamination to the substrate. The films may be directly laminated together or may be laminated using one or more intermediate adhesive layers. This approach may be used to make, for example, the embodiments of diffuser plate illustrated in FIGS. 4F and 4G.

In the approach illustrated in FIG. 18A, a first film 1802, for example a diffuser sheet, and a second film 1804, for exa

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey