difference between digitizer and lcd screen brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Your iPod, iPhone and tabletare commonly known to have three key components: a glass panel, digitizer (aka touch screen) and LCD. What are the differences? Let’s clearly define these layers:

Digitizer –The digitizer is located just under the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer. The digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa. UEGoffers a Front Glass (Digitizer Touch Screen) Repair Service on tablets.

Touch Screen – The term touch screen is interchangeable with the term digitizer. You’ll often see the combined terms Digitizer Touch Screen offered as a repair service.

LCD – LCD is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. UEGoffers LCD repairs on tablets, iPhonesand iPods.

United Electronics Group (UEG) is the parent company of United Camera Repair, United MP3 Repair, United Mac Repair, United Tablet Repair and United Smartphone Repair.

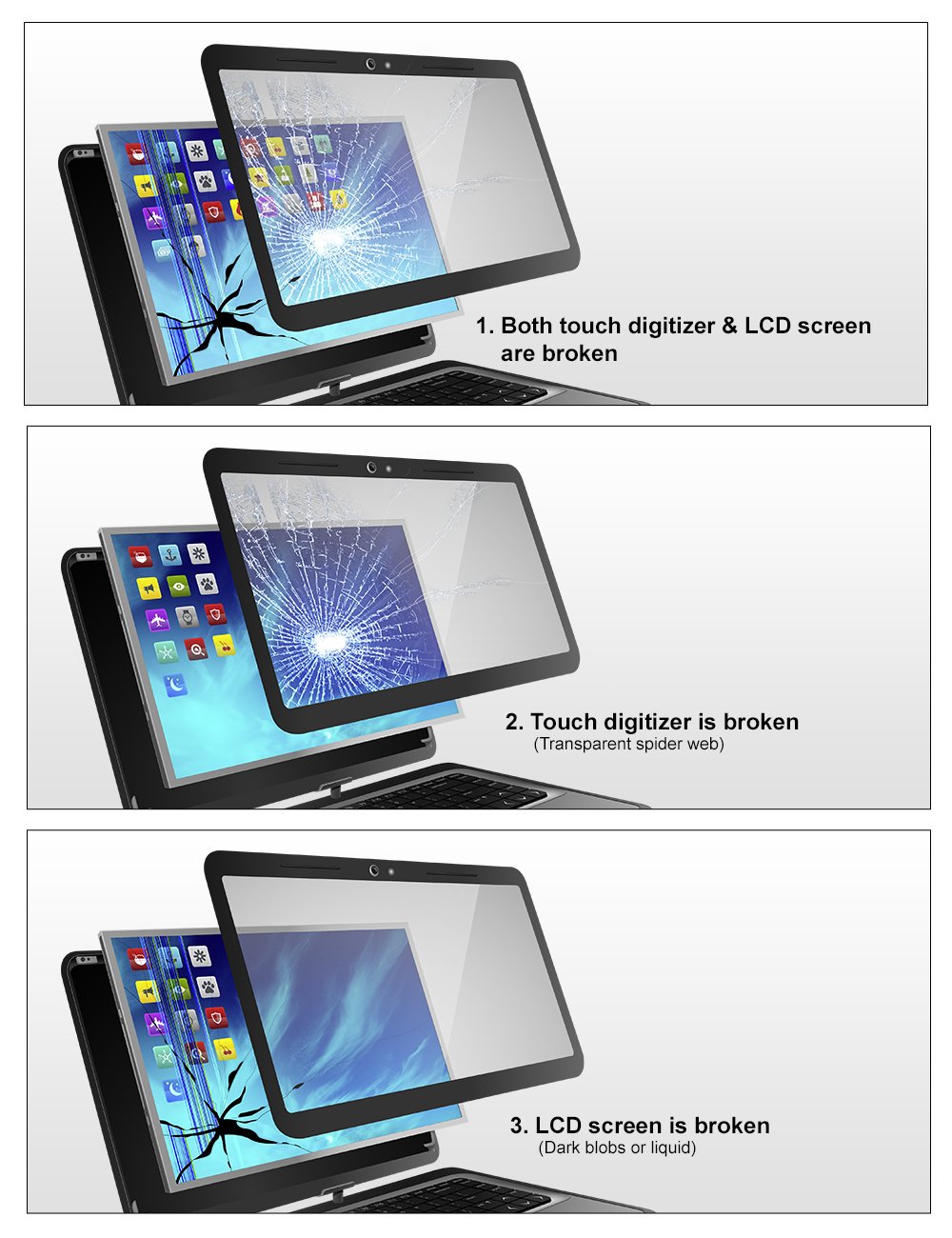

A touch screen display is usually made with three main parts. The protective glass sheet, the digitizer sheet, and the LCD. The digitizer is a thin transparent sheet that is adhered to the protective glass sheet with a transparent conductive adhesive. The digitizer is the only part of the display assembly that is responsible for sensing touch. Since the human touch is conductive it allows the screen to sense the location you touch. The LCD is only responsible for displaying the image on the screen. If the screen is not responding to touch then usually the digitizer is damaged or faulty. Usually a damaged or cracked LCD will display a distorted image or no image at all. So if the phone displays a good image but does not respond to touch then you may have the option of only replacing the digitizer. It"s not as easy of a repair as replacing the whole display but is cheaper. A new digitizer part already has the digitizer sheet adhered to a protective sheet of glass. If a person can remove the faulty digitizer from the phone without damaging the LCD then it is surely more cost effective repair. Some displays have the digitizer fused to the LCD which makes it hard not to damage the LCD if trying to remove the digitizer. If that is the case with your phone"s display it is a lot easier to just replace the whole display. Hope this information is helpful.

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

Touchscreen devices consist of numerous different components that must work cohesively together in order to make it functional. The touch sensor, controller, and the software all play important roles. But there’s one component that’s often overlooked in the equation and that’s the touchscreen digitizer. This is the component that allows users to directly interact with what’s on the screen and issue commands.

As you know, touchscreen devices consist of multiple layers each of which serve a different purpose and carry out various functions. The purpose of the touchscreen digitizer glass layer is essentially to translate or convert physical touch commands into digital signals that the device can understand and then carry out.

Commercial and industrial displays such as capacitive and resistive screens all feature touchscreen digitizers that are placed on top of and connected to the LCD layer using a flex cable. While the LCD layer is responsible for displaying sharp and crystal-clear images on the screen, the LCD touchscreen digitizer reads, understands, and translates the commands given so that the device can perform the appropriate functions.

Touchscreen digitizers are fairly common components of modern LCD displays, but not all of them are equipped with one. The sole purpose of an LCD display touchscreen digitizer is to convert touch commands on the top layer into digital data that the device can understand and perform. Once the touch commands are converted into digital data, the device can then perform the required function and change the images displayed on the screen accordingly.

Touchscreen digitizers are made of a single glass layer, which means they can be susceptible to damage if the device is dropped or comes into contact with a brute force. Although the device can still marginally function depending on the extent of the damage to the touchscreen digitizer glass, its functionality and ability to comprehend touch commands may be limited. If the glass is completely shattered, then the device won’t be able to interpret touch commands at all.

The LCD and touchscreen digitizer layers of a device display serve completely different functions, but they work in tandem to maximize user experience and device performance. Since both of these components are made of thin glass layers, they’re not impervious to damages such as cracks or scratches as a result of being dropped or coming into contact with external physical stressors.

If it’s only the touchscreen digitizer that’s broken, you’ll still be able to make out what’s being displayed on the screen by the LCD component for the most part. The only difference is that parts of the screen or the entire screen might be unresponsive to your touch commands as a result of the damages. Moreover, blobs or splotchy images may appear in certain parts of the screen.

This indicates that there’s a disconnection between the touchscreen digitizer and the LCD display, which is preventing the device from performing the desired functions issued by touch commands.

The LCD screen is responsible for the visual component of your device. Pixelation in the form of multicoloured splotches or dots throughout the screen indicates that the LCD component has sustained a certain level of damage. It can be caused by wear and tear over time or if your device sustains physical damage.

A black screen indicates that the LCD layer of the device is damaged. The device itself will most likely still turn on and function like normal, but you won’t be able to see what it’s doing on the screen itself. Typically, this just means that the LCD layer needs to be repaired or replaced. Depending on the extent of the damage, it might be more practical and cost-effective to simply purchase a new device altogether unless you’re still within the warranty period.

Nauticomp Inc. is one of the leading digital device manufacturers and distributors in North America and the UK. We deliver high-quality state-of-the-art commercial and industrial displays that can be custom-tailored according to the specific needs of our customers. Contact ustoday to learn more about our products or to place an order.

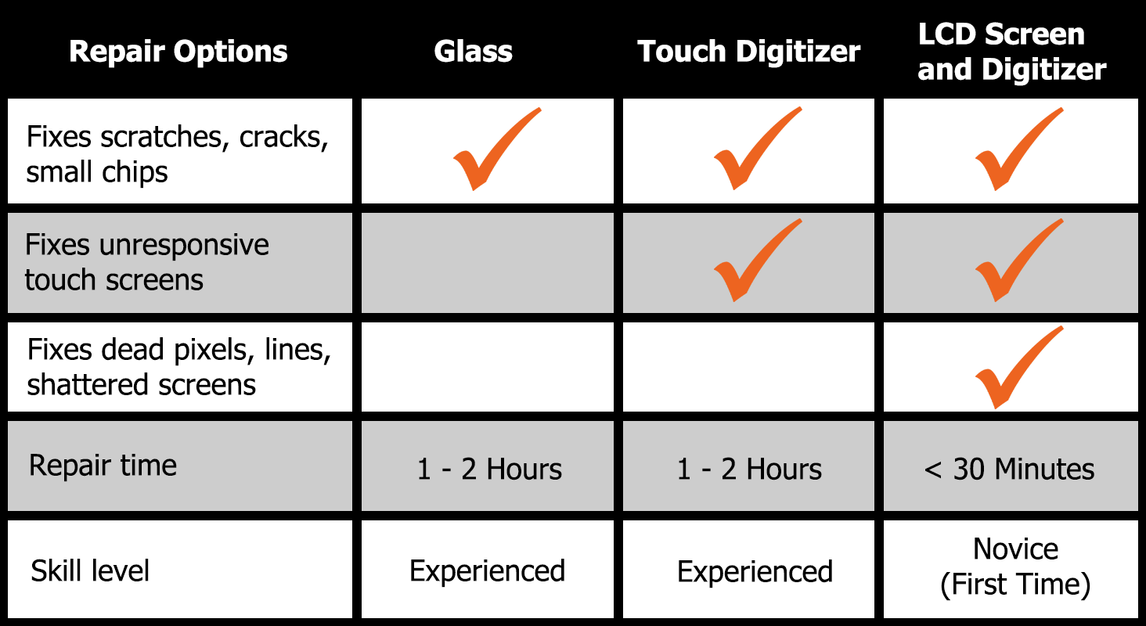

The easiest repair for mobile phones to complete is the LCD assembly replacement. This repair takes less than an hour and requires the least amount of technical ability. For some devices the LCD assembly can be replaced simply by removing a few screws and cables. Also, as the assembly includes the glass, touch screen and the LCD, you can be confident it will fix all common screen issues.

For iPad and other tablets, if the screen parts aren"t fused, then you can do a glass touch digitizer only replacement. Otherwise, the full assembly is the easiest repair. Either way, it usually takes 1-2 hours.

While it can be significantly cheaper repair, If the screen parts are fused, the screens must be heated to loosen the adhesive between the screen and LCD and you need special equipment. This includes all iPhone and most other mobile phones and some iPads or tablets. A heat gun or hair dryer can be used for this. The screen is then gently and very slowly pried apart from LCD. DIYers need to use care to insure the LCD is not damaged in the process.

Tip: Transferring the home button on an iPhone or an iPad can be the most tricky part. It takes a little patience and heat. You can purchase screens that have the home button pre-installed (along with other small parts) and this is the easiest of all repair. This can take 15-30 minutes. However, Touch ID function only works with the original home button so you have to transfer if you want to retain it. Note: some of the iPads don"t have a screen replacement option that includes the home button like the iPad Pro and newer iPad Mini. iPad 1st Gen to 9th Gen screens, have a home button pre-installed option.

However, if the digitizer or LCD is also damaged during a fall, that screen no longer carries value because it cannot be refurbished. Repair shops cannot sell broken LCDs to refurbishing companies; therefore, they cannot offset the cost of an LCD repair. That is why repair stores often charge a little extra if there is damage to the LCD or digitizer, to make up for that loss. Repair stores that don’t have an additional charge for an LCD repair typically inflate their glass repair price to make up for the loss from damaged LCDs. If they have one price, that means everyone is paying more to cover the cost of customers who have damaged LCDs and customers who only have cracked glass. This is why TCR separates the price of glass and LCD repairs for you! If you only have cracked glass, you only have to worry about paying to replace the cracked glass.

If your phone or tablet’s glass is shattered there will be cracks or chips on the screen itself. If it is just the glass that is damaged, the device may still function and you may be able to use it normally. If this is the case, it is likely that only the glass needs to be replaced. To prevent further damage to your device it is best to get it repaired quickly. For example, if liquids seep through the cracks it could cause permanent damage to the LCD.

Many people may continue to use their touchscreen with shattered glass and delay fixing the glass on their devices; however, if the touchscreen isn’t responsive, it could be a sign of more significant damage to the device’s digitizer which is integrated with the LCD screen.

A pixelated screen can indicate LCD damage. This would look like a patch of multicolored dots, a line or lines of discoloration, or a screen with rainbow colors. For many people, these colors are an easy way to know that their LCD is broken and that they should get it repaired.

Dropping your phone isn’t the only reason you’ll end up with a pixelated screen. Over time, your screen’s LCD may break down through regular use. This happens to other devices aside from your smartphone or tablet. Pixelation can happen to TVs and computers, too. People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.

A black screen or black spots on your smartphone or tablet is an indication of a damaged LCD. Often with a bad LCD, a phone may still turn on and make noises, but there is no clear picture. This does not necessarily mean any other part of the phone is damaged and a simple screen replacement will get it functioning again. Sometimes it can mean a battery or other internal component is damaged. It is best to have a highly qualified phone repair technician diagnose what is wrong so the appropriate repair can be made.

Fortunately, your mobile device is fixable whether you cracked the glass or damaged the LCD. Stop by or call TCR: Triangle Cellular Repair at (919) 263-2699 for a free diagnostic and quick, affordable cell phone repair in Chapel Hill and surrounding areas. We’re always happy to help!

As an official phone repair provider who has been in the business for almost a decade, one unique question people ask when they visit our service centres to replace their phone screen is: "what"s the difference between original and copy phone screen?"

Well, the answer is, there are many differences between these two screens, which is mostly in their quality. And while “copy” phone screens are somewhat cheaper than the originals, it doesn’t justify the difference in quality. So, before you regret replacing your phone screen with a forbidden part, the tips below will tell you the critical differences between original and copy phone screens.

Generally, phone screens manufactured from your brand"s factory are the original ones while ‘Copy’screens are the ones designed and produced by third-party manufacturers and factories that are not related to your brand.

Many people usually like to go for copy screens because of their cheaper price. However, the "real" differences between original and copy screens lie in their quality, and here’s what you need to know about them.

One of the principal issues with "copied" phone screens and why it differs from the originals is touch and digitizer problems. And that"s a big problem since you"re going to control the device with the touchscreen anyway.

As far as we could remember, phone manufacturers build the touch panel/digitizer with the LCD itself, while the copied screen manufacturer build it separately on the surface glass. Hence, there"s a difference in touch sensitivity. Additionally, copied phone screens usually drop the high touch sampling rate, meaning your screen may not respond to your touches faster.

Here"s also another major issue with the digitizer on copied phone screens. When you crack a copied screen accidentally, the touchscreen stops working, stopping you from accessing the device until you fix it again. Meanwhile, the touch on the original phone screen works perfectly, even after undergoing severe cracking.

Besides having touch problems, most copy phone screens usually have poor display properties. That means you get lower brightness, colour accuracy, sharpness, contrast, etc. And when the display isn"t great, watching movies and viewing other content becomes boring.

For instance, if the original screen is supposed to have 480 nits of brightness, but the copy screen has just 200 nits, the screen becomes unusable under bright lights. Moreso, copied phone screen seems to have more blue light, which, in return, affect your sight and disrupts your sleep at night.

Among others, copied phone screens drop higher refresh rates, and that"s a bummer since most phones come with at least 90Hz refresh rate screens. What that means is the copied screen won’t feel smooth as it’s supposed to be.

It"s not all about the display quality. A copy phone screen may also affect other parts of the phone system if its specifications don"t tally with the original one. In such a case, it could drain your battery at an alarming rate, or at worse, damage your backlight.

If you happen to have a phone with an in-display fingerprint sensor, then replacing its screen with a copied one is not an option – it’s going to mess with your fingerprint accuracy.

We know copied phone screens for their poor quality, and it also extends to the fingerprint sensor. Hence, it takes a longer time to unlock your device. And in other cases, the security of the sensor is not accurate. We"ve seen situations where phones get unlocked with many unregistered fingers after replacing the screen with a copied one.

If you care about your phone"s security and you don"t want a sluggish fingerprint sensor, then we recommend you only go for the original phone screen replacement.

That brings us to the last difference we’re going to mention between copied and original phone screens. They manufacture copied phone screens with poor glass materials. Hence, they break quicker than the originals. And when they do, you’ll be left with only one option: to replace the screen again.

The major reason for choosing the official service centre over third-party/local repair shops summarizes what we"ve said earlier. The official service centre is the reliable place to get original phone screen replacement parts.

Why? As of today, smartphone phone manufacturers/brands release genuine spare parts only to the official service centres and affiliated repair centres. That means third party repair shops get their spare parts somewhere else: usually third-party factories/companies not related to your phones brand.

Besides offering you the original screen spare parts, the official service centres also have other advantages. These include certified and well-experienced technicians to fix the screen, the use of modern tools that won"t damage your phone further, and most importantly, a reliable warranty. Local repair shops usually don"t offer these features; most especially a reliable warranty, which means you"re on your own if the replaced screen gets faulty afterwards.

As far as choosing the official service centre is concerned for genuine screen replacement, then you shouldn"t shy away from Carlcare Service if you own a TECNO, Infinix, or itel phone with a cracked screen.

We"re the official service center for these three brands to cater for your mobile repair needs. And for screen replacement, Carlcare delivers excellently. Our brand-trained technicians replace your cracked screen with genuine OEM parts at affordable rates.

We understand you have a busy schedule; and yes, we"ll replace your screen in the shortest possible time. Start by checking how much it cost to fix your cracked phone screen, then you can book an online reservation service with us to reduce your waiting time and also become a VIP customer.

Most of the time people don’t know the difference between a touchscreen and a LCD screen. When there are dark black blobs on your screen, it’s not because the display screen is damaged, it is the caused due to the damage in the LCD of your mobile phone whereas when there are cracks on your screen its mainly due to the damaged caused to your touchscreen and as compared to an LCD screen it is easier to fix as you only need to replace the display screen of you mobile phone.

An LCD is the part of a phone that displays the image we see on screen. It is the layer which produces and displays the image, therefore if the LCD is damaged you can still use the touchscreen although the panel would have either the aforementioned dark black blobs or the spider web type dark cracks on the display or both it would still function normally. To repair the LCD, a technician would have to pull apart the phone part by part to reach the LCD and assess the damage done which is not required for a touch screen. LCD, which is a liquid crystal display, is widely used in mobile phones as it uses low power and produces good quality images.

The images which are displayed in a LCD are produced through small elements which are called pixels. Pixel is a word everybody is familiar with but what exactly is a pixel? Pixel is made up of a layer of molecules lined up between two transparent electrodes and polarizing filters. There are several types of LCDs, reflective, transmissive and transflective, each has a specific function. A transmissive LCD can produce a clear and good quality image in low light while Reflective screen can produce a very good image in bright light. The transflective screen as the name indicates can produce a good quality image in both conditions, hence it is a mixture of both transmissive and reflective LCD.

Touchscreen is now a part of almost every digital gadget in the 21st century. From mobile phones and laptops to TVs and switch boards, it is now used almost everywhere your eyes fall on. But what exactly is a touchscreen? A touchscreen is basically a device which allows us to directly interact by using our fingers or a stylus. The stylus is a special kind of pen whose tip is covered with a unique coating which allows it to directly interact with the computer. We can use one finger or multiple gestures to interact with a touchscreen device. It doesn’t require a mouse or any alternative device such as a keyboard for navigation. A touchscreen can use several methods to sense our finger, it can use a grid which consists of infrared beams or it can use touch sensitive units to sense our gestures.

With touchscreen, there are several gestures that we can make which would be quite tiresome if we use a mouse or a keyboard like when we double tap the screen while using gallery or while reading a pdf file the screen tends to zoom in and when we double tap again it zooms out similarly we can easily drag different icons and swipe to scroll upwards, downwards even sideways. A touch screen is also referred to as an input device as it takes input directly from the user. The computers require a mouse which makes them hard to use but touchscreen is very simple to use as you are directly interacting with the icons, it is also cost efficient to manufacture touchscreen as it does not require buttons for each icon.

In conclusion it can be said that LCD and Touch Screen have very different functions which makes them different from each other. One deals with production of images and the other deals with receiving the input from the user directly. Although they are different, they are equally important for a digital device.

When customers visit a shop for a screen repair, some shops will give them an option to choose between an original screen and a ‘copy’ screen. Most of the time, the first question that a customer asks is “What’s the difference between the two?” Originals are manufactured for Apple while copy screens are only compatible replacements that are manufactured by third party companies. Most of the time, customers choose the relatively affordable copy rather than the original because of the price distinction, but original iPhone screens are still recommended because of its far higher quality.

One of the most noticeable differences between an original and a copy is how the touch sensor also called the digitizer is designed. Original Apple screens manufacture digitizers as part of the LCD while copy screens manufacture it on the glass.

There are some companies that manufacture bare LCDs themselves, but these LCDs are also bought by other companies, who in turn add the other parts to create a complete working screen. Because of this, it is possible that you get a great LCD screen, but the digitizer is poor quality.

, iPhones transferred the chips necessary for the digitizer to work directly on the LCD, that means that when you buy a ‘copy screen’ for these models, you are not only getting a copy of the screen but a copy of the chip.

When you buy a copy screen you are also buying a low image quality for your phone. This is because the LCD is of poor quality. The problems experienced are weak brightness, contrast and vibrancy, grainy appearance because of low image resolution and lower refresh rate.

In most cases, the performance specification of copy screens is not identical to the original ones. As a result, the battery of the phone drains faster and the OS or operating system is misled. This mismatch is also a possible cause of damage to your backlight.

Copy screens can also create damage to your phone’s touch ID fingerprint reader. The home button flexes on the copy screens design which makes it stop working, and we all know the struggle of not having a working ID fingerprint reader.

Some shops offer copy screens to remain competitive in the market since the difference in price ranges to £20-30. Still, you can get the most of your money with the original for having a better performing iPhone screen. Even though there are different qualities of copy screens, from good copies that actually work to cheaply made ones, there are several factors at play to have your iPhone be used seamlessly. Aside from the points above, one of the factors that might affect the use of your phone with a copy is the Apple updates that conflict with the low grade copy screens.

Eventually, it is your decision whether to choose an original one or not. But additional pounds for an original screen is a good investment. You can avoid all the possible damage caused by copy screens which in turn will help you save money in the long run since you won’t need to return to a shop for further repairs.

If you have any concerns and questions, don’t hesitate to call us at 01179424400 or send us a message at support@letstalktps.com. Our friendly team will be happy to help you.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

No matter what type of laptop, smartphone, or tablet you have, you can find a replacement screen for it. Whether it"s an LCD or LED screen, you can have a brand-new display and be on your way to watching your favorite movies, writing that novel you"ve been putting off, or simply surfing Facebook to keep up with family and friends.

Laptop screens and smartphones are proprietary technology, which means that the screen is made specifically for the model it fits into and most likely won"t work for other devices. Screens can vary in both the technology used and the size. A screen made for a Samsung laptop, for instance, isn"t going to work on an Apple MacBook. It is extremely important to select a replacement that is made for the exact model of your specific technology.

A digitizer is the device that sits under the glass panel on a laptop or a smartphone and controls what appears on the screen and, in the case of touch screens, reacts to your fingertip or stylus. If the unit will power on, look at the screen and see if the picture looks correct other than the cracks. If there are no burned-out spots, such as pixels that appear black or a different color than they should be, or lines that appear where they shouldn"t, your digitizer is probably fine. Some technology, however, makes it extremely difficult to remove the glass from the digitizer to replace it, so you may want to purchase a kit that has both.

LCD stands for liquid crystal display. The display is made up of a grid of tiny, light-emitting crystals, and each crystal is a pixel on the screen. These are activated by electric current in groups; this is what makes LCD screens the most energy efficient. LED stands for light-emitting diode. These displays are made up of a network of little diodes that are activated individually by an electric current.

Because the screen replacements for most units are proprietary, it means that they are made specifically for their respective units. Make sure to purchase a replacement display that matches the model you own to avoid mismatches and screens that won’t work properly on your device.

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

There’s nothing stopping any random person without training or experience opening up a smartphone repair shop. As a result, the industry is full of companies with little skill or experience who are only interested in getting hold of your money and installing the cheapest parts they can find.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Obtained or manufactured “off the clock” via the same production line that produced them for Apple- in some cases, from the stockpile of parts that didn’t meet Apple’s standards, or

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

A touchscreen or touch screen is the assembly of both an input ("touch panel") and output ("display") device. The touch panel is normally layered on the top of an electronic visual display of an information processing system. The display is often an LCD, AMOLED or OLED display while the system is usually used in a laptop, tablet, or smartphone. A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or other such devices (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as game consoles, personal computers, electronic voting machines, and point-of-sale (POS) systems. They can also be attached to computers or, as terminals, to networks. They play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers. Touchscreens are also important in educational settings such as classrooms or on college campuses.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field, heavy industry, automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display"s content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers have acknowledged the trend toward acceptance of touchscreens as a user interface component and have begun to integrate touchscreens into the fundamental design of their products.

The prototypeCERNFrank Beck, a British electronics engineer, for the control room of CERN"s accelerator SPS (Super Proton Synchrotron). This was a further development of the self-capacitance screen (right), also developed by Stumpe at CERN

One predecessor of the modern touch screen includes stylus based systems. In 1946, a patent was filed by Philco Company for a stylus designed for sports telecasting which, when placed against an intermediate cathode ray tube display (CRT) would amplify and add to the original signal. Effectively, this was used for temporarily drawing arrows or circles onto a live television broadcast, as described in US 2487641A, Denk, William E, "Electronic pointer for television images", issued 1949-11-08. Later inventions built upon this system to free telewriting styli from their mechanical bindings. By transcribing what a user draws onto a computer, it could be saved for future use. See US 3089918A, Graham, Robert E, "Telewriting apparatus", issued 1963-05-14.

The first version of a touchscreen which operated independently of the light produced from the screen was patented by AT&T Corporation US 3016421A, Harmon, Leon D, "Electrographic transmitter", issued 1962-01-09. This touchscreen utilized a matrix of collimated lights shining orthogonally across the touch surface. When a beam is interrupted by a stylus, the photodetectors which no longer are receiving a signal can be used to determine where the interruption is. Later iterations of matrix based touchscreens built upon this by adding more emitters and detectors to improve resolution, pulsing emitters to improve optical signal to noise ratio, and a nonorthogonal matrix to remove shadow readings when using multi-touch.

The first finger driven touch screen was developed by Eric Johnson, of the Royal Radar Establishment located in Malvern, England, who described his work on capacitive touchscreens in a short article published in 1965Frank Beck and Bent Stumpe, engineers from CERN (European Organization for Nuclear Research), developed a transparent touchscreen in the early 1970s,In the mid-1960s, another precursor of touchscreens, an ultrasonic-curtain-based pointing device in front of a terminal display, had been developed by a team around Rainer Mallebrein[de] at Telefunken Konstanz for an air traffic control system.Einrichtung" ("touch input facility") for the SIG 50 terminal utilizing a conductively coated glass screen in front of the display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreenMagnavox Plato IV Student Terminal and thousands were built for this purpose. These touchscreens had a crossed array of 16×16 infrared position sensors, each composed of an LED on one edge of the screen and a matched phototransistor on the other edge, all mounted in front of a monochrome plasma display panel. This arrangement could sense any fingertip-sized opaque object in close proximity to the screen. A similar touchscreen was used on the HP-150 starting in 1983. The HP 150 was one of the world"s earliest commercial touchscreen computers.infrared transmitters and receivers around the bezel of a 9-inch Sony cathode ray tube (CRT).

In 1984, Fujitsu released a touch pad for the Micro 16 to accommodate the complexity of kanji characters, which were stored as tiled graphics.Sega released the Terebi Oekaki, also known as the Sega Graphic Board, for the SG-1000 video game console and SC-3000 home computer. It consisted of a plastic pen and a plastic board with a transparent window where pen presses are detected. It was used primarily with a drawing software application.

Touch-sensitive control-display units (CDUs) were evaluated for commercial aircraft flight decks in the early 1980s. Initial research showed that a touch interface would reduce pilot workload as the crew could then select waypoints, functions and actions, rather than be "head down" typing latitudes, longitudes, and waypoint codes on a keyboard. An effective integration of this technology was aimed at helping flight crews maintain a high level of situational awareness of all major aspects of the vehicle operations including the flight path, the functioning of various aircraft systems, and moment-to-moment human interactions.

In the early 1980s, General Motors tasked its Delco Electronics division with a project aimed at replacing an automobile"s non-essential functions (i.e. other than throttle, transmission, braking, and steering) from mechanical or electro-mechanical systems with solid state alternatives wherever possible. The finished device was dubbed the ECC for "Electronic Control Center", a digital computer and software control system hardwired to various peripheral sensors, servos, solenoids, antenna and a monochrome CRT touchscreen that functioned both as display and sole method of input.stereo, fan, heater and air conditioner controls and displays, and was capable of providing very detailed and specific information about the vehicle"s cumulative and current operating status in real time. The ECC was standard equipment on the 1985–1989 Buick Riviera and later the 1988–1989 Buick Reatta, but was unpopular with consumers—partly due to the technophobia of some traditional Buick customers, but mostly because of costly technical problems suffered by the ECC"s touchscreen which would render climate control or stereo operation impossible.

The first commercially available graphical point-of-sale (POS) software was demonstrated on the 16-bit Atari 520ST color computer. It featured a color touchscreen widget-driven interface.COMDEX expo in 1986.

In 1987, Casio launched the Casio PB-1000 pocket computer with a touchscreen consisting of a 4×4 matrix, resulting in 16 touch areas in its small LCD graphic screen.

Touchscreens had a bad reputation of being imprecise until 1988. Most user-interface books would state that touchscreen selections were limited to targets larger than the average finger. At the time, selections were done in such a way that a target was selected as soon as the finger came over it, and the corresponding action was performed immediately. Errors were common, due to parallax or calibration problems, leading to user frustration. "Lift-off strategy"University of Maryland Human–Computer Interaction Lab (HCIL). As users touch the screen, feedback is provided as to what will be selected: users can adjust the position of the finger, and the action takes place only when the finger is lifted off the screen. This allowed the selection of small targets, down to a single pixel on a 640×480 Video Graphics Array (VGA) screen (a standard of that time).

Sears et al. (1990)human–computer interaction of the time, describing gestures such as rotating knobs, adjusting sliders, and swiping the screen to activate a switch (or a U-shaped gesture for a toggle switch). The HCIL team developed and studied small touchscreen keyboards (including a study that showed users could type at 25 wpm on a touchscreen keyboard), aiding their introduction on mobile devices. They also designed and implemented multi-touch gestures such as selecting a range of a line, connecting objects, and a "tap-click" gesture to select while maintaining location with another finger.

In 1990, HCIL demonstrated a touchscreen slider,lock screen patent litigation between Apple and other touchscreen mobile phone vendors (in relation to

An early attempt at a handheld game console with touchscreen controls was Sega"s intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s.

Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.Apple Watch being released with a force-sensitive display in April 2015.

In 2007, 93% of touchscreens shipped were resistive and only 4% were projected capacitance. In 2013, 3% of touchscreens shipped were resistive and 90% were projected capacitance.

A resistive touchscreen panel comprises several thin layers, the most important of which are two transparent electrically resistive layers facing each other with a thin gap between. The top layer (that which is touched) has a coating on the underside surface; just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point.voltage dividers, one axis at a time. By rapidly switching between each layer, the position of pressure on the screen can be detected.

Resistive touch is used in restaurants, factories and hospitals due to its high tolerance for liquids and contaminants. A major benefit of resistive-touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections (i.e. glare) from the layers of material placed over the screen.3DS family, and the Wii U GamePad.

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. The change in ultrasonic waves is processed by the controller to determine the position of the touch event. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.

The Casio TC500 Capacitive touch sensor watch from 1983, with angled light exposing the touch sensor pads and traces etched onto the top watch glass surface.

A capacitive touchscreen panel consists of an insulator, such as glass, coated with a transparent conductor, such as indium tin oxide (ITO).electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Touchscreens that use silver instead of ITO exist, as ITO causes several environmental problems due to the use of indium.complementary metal-oxide-semiconductor (CMOS) application-specific integrated circuit (ASIC) chip, which in turn usually sends the signals to a CMOS digital signal processor (DSP) for processing.

Unlike a resistive touchscreen, some capacitive touchscreens cannot be used to detect a finger through electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather when people may be wearing gloves. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread allowing electrical contact with the user"s fingertip.

A low-quality switching-mode power supply unit with an accordingly unstable, noisy voltage may temporarily interfere with the precision, accuracy and sensitivity of capacitive touch screens.

Some capacitive display manufacturers continue to develop thinner and more accurate touchscreens. Those for mobile devices are now being produced with "in-cell" technology, such as in Samsung"s Super AMOLED screens, that eliminates a layer by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance between the user"s finger and what the user is touching on the screen, reducing the thickness and weight of the display, which is desirable in smartphones.

A simple parallel-plate capacitor has two conductors separated by a dielectric layer. Most of the energy in this system is concentrated directly between the plates. Some of the energy spills over into the area outside the plates, and the electric field lines associated with this effect are called fringing fields. Part of the challenge of making a practical capacitive sensor is to design a set of printed circuit traces which direct fringing fields into an active sensing area accessible to a user. A parallel-plate capacitor is not a good choice for such a sensor pattern. Placing a finger near fringing electric fields adds conductive surface area to the capacitive system. The additional charge storage capacity added by the finger is known as finger capacitance, or CF. The capacitance of the sensor without a finger present is known as parasitic capacitance, or CP.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor"s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.

Although some standard capacitance detection methods are projective, in the sense that they can be used to detect a finger through a non-conductive surface, they are very sensitive to fluctuations in temperature, which expand or contract the sensing plates, causing fluctuations in the capacitance of these plates.

This diagram shows how eight inputs to a lattice touchscreen or keypad creates 28 unique intersections, as opposed to 16 intersections created using a standard x/y multiplexed touchscreen .

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology but where sensitivity to touch, accuracy, resolution and speed of touch have been greatly improved by the use of a simple form of

"Artificial Intelligence". This intelligent processing enables finger sensing to be projected, accurately and reliably, through very thick glass and even double glazing.

Some modern PCT touch screens are composed of thousands of discrete keys,etching a single conductive layer to form a grid pattern of electrodes, by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid, or by forming an x/y grid of fine, insulation coated wires in a single layer . The number of fingers that can be detected simultaneously is determined by the number of cross-over points (x * y) . However, the number of cross-over points can be almost doubled by using a diagonal lattice layout, where, instead of x elements only ever crossing y elements, each conductive element crosses every other element .

In some designs, voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid. This system is able to accurately track touches.

These environmental factors, however, are not a problem with "fine wire" based touchscreens due to the fact that wire based touchscreens have a much lower "parasitic" capacitance, and there is greater distance between neighbouring conductors.

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter, or the change in frequency of an RC oscillator.

Self-capacitive touch screen layers are used on mobile phones such as the Sony Xperia Sola,Samsung Galaxy S4, Galaxy Note 3, Galaxy S5, and Galaxy Alpha.

Self capacitance is far more sensitive than mutual capacitance and is mainly used for single touch, simple gesturing and proximity sensing where the finger does not even have to touch the glass surface.

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitive styli are now widely available for a nominal charge, and often given away free with mobile accessories. These consist of an electrically conductive shaft with a soft conductive rubber tip, thereby resistively connecting the fingers to the tip of the stylus.

Infrared sensors mounted around the display watch for a user"s touchscreen input on this PLATO V terminal in 1981. The monochromatic plasma display"s characteristic orange glow is illustrated.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any opaque object including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and POS systems that cannot rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt and dust that can interfere with the infrared beams, and suffer from parallax in curved surfaces and accidental press when the user hovers a finger over the screen while searching for the item to be selected.

A translucent acrylic sheet is used as a rear-projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user, frustrated total internal reflection results in leakage of infrared light which peaks at the points of maximum pressure, indicating the user"s touch location. Microsoft"s PixelSense tablets use this technology.

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors (such as CMOS sensors) are placed around the edges (mostly the corners) of the screen. Infrared backlights are placed in the sensor"s field of view on the opposite side of the screen. A touch blocks some lights from the sensors, and the location and size of the touching object can be calculated (see visual hull). This technology is growing in popularity due to its scalability, versatility, and affordability for larger touchscreens.

Introduced in 2002 by 3M, this system detects a touch by using sensors to measure the piezoelectricity in the glass. Complex algorithms interpret this information and provide the actual location of the touch.

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined signal as measured by three or more tiny transducers attached to the edges of the touchscreen. The digitized signal is compared to a list corresponding to every position on the surface, determining the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other sound-based technologies by using a simple look-up method rather than expensive signal-processing hardware. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in th

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey