controlling leds with tft display manufacturer

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

LCDs without lighting are hard to imagine these days. However, since there are basically four different types of lighting, the type selected depends very much on the application. Here is a brief overview to clarify the situation:LED

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT-display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT-display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

FES4335U1 is a low cost, high efficiency and smart of TFT-LCD display control module which can provide characters or 2D graphics application within an embedded 768KB of display RAM.

... large range of functions. The displays can be operated up to 18 hours daily or turned on and off via a time switch function. The displays also support animations and video files.

A 17-inch touch display kit has a higher light transmittance and low light reflection, which can improve the brightness of the picture and clearly see the picture in the sun. With optical bonding technology, ...

The digi 400plus – compact display and control unit – is equipped with a 7″ colour display and touchscreen function, which allows the easy configuration of the device due to its icon ...

The Embedded OS Based display board FE1000 is a very evolved platform, with great aesthetic impact and "user friendly", particularly suitable in complex user interfaces development and able to exploit the full potential ...

... microprocessor based instrument panel that can be customized to monitor, display and control numerous machine or vehicle functions in a single integrated tool.

Parker"s IQAN-MD4 display controller is a family of master display units for IQAN control systems. The IQAN-MD4 is fully programmable for use in any machine application as a master controller. ...

... Panametrics TMO2D is an optional display and control module that enhances the performance and operation of transmitters such as the XMO2, XMTC, or oxy.IQ.

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

The reason for LCD Display flashing screen: shielding coil; Signal interference; Hardware; Refresh frequency setting; Monitor time is too long; Too high...

I have bought a 2.5" TFT shield online, which is equipped with the ILI9341 controller. I need to dim the intensity of the background LEDs to match ambient light.

This particular shield does not provide a pin to control the intensity of the LEDs with PWM via a separate input, so I need to dim the background LEDs of this display via software.

I wrote a new function to set the display"s brightness by controlling the background LEDs, but something is missing as I can seem to be writing correctly to the display. So I"m trying to get the display to answer to a known command first, like 0x28 (Display Off).

Then I call the function in my main loop. To make sure, I first write some rectangles on screen, wait 5 seconds, then fill the screen with blue, call the new function and enter an endless loop so no other commands can interfere:

I can get the display to react to the Display Off command (0x28), but only when I issue it in the begin(..) function. So, the original code in Adafruit_TFTLCD.cpp is like this:

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 2.4" TFT LCD, 2.8" TFT LCD, 3.2" TFT LCD, 3.5" TFT Display, 4.3 inch TFT LCD, 5 TFT LCD, 5.6 TFT LCD, 5.7 inch Display, 7 " TFT LCD, 8" TFT, 9" TFT, 10.1" TFT LCD, 10.2" TFT LCD, 12.1" TFT LCD , 12.3" TFT LCD (diagonal size of the active area) and so on . There are more than 250 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers" requirement.

Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

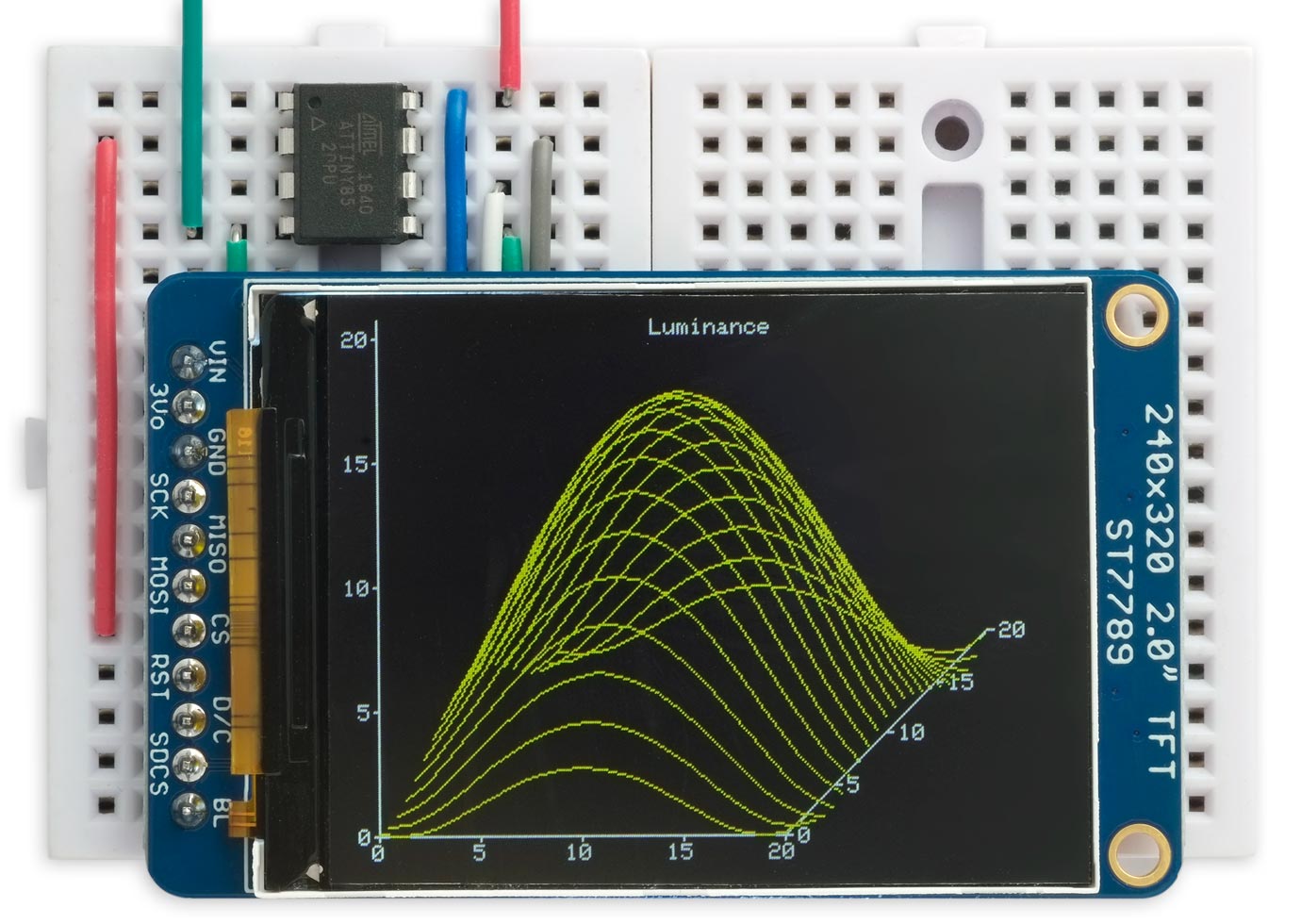

There are a number of different kinds of displays that can be driven by a microcontroller. This repository contains examples for many of them, along with information about display technologies and some of the more popular libraries for controlling them.

Multi-Segment LED display - There are many models of multi-segment LED displays, including the classic 7-segment LEDs, alphanumeric displays, dot-matrix diplays, bar graph displays, RGB LEDs, and others. What these share in common is that they will have either a common-cathode or common-anode structure. Common cathode LEDs have multiple anodes, one for each LED segment, and one cathode for all. common anode LEDs have a single anode and multiple cathode for all the segments. Driving these displays requires a control pin for each LED segment. They are usually driven by a multiplexer or LED driver, which can provide both a common interface for all the LEDs (such as an SPI or I2C interface), and a controlled current supply for all the LEDs.

Broadcom/Avago’s HCMS-29xx display is multi-segment LED display that has several 5-7 LED matrices with a synchronous serial interface. It has the smallest visibly discrete LEDs in its display that I have encountered.

LCD - Liquid crystal display. LCDs are made up of long-chain molecules in a state between crystal and liquid. When a charge is applied, the molecules align, acting as a polarizer. When paired with a second polarizer, they can either block light or allow it to pass through, appearing either light or dark. A grid of these can form a single-color display. Liquid crystals do not emit light, so a backlight is required to light them up. They come im low-resolution, passive-matrix displays which are usually monochrome or higher-resolution, active-matrix screens which have higher resolution and are usually full color.

OLED - an OLED screen replaces the liquid crystal with a matrix of organic LEDs. This eliminates the need for a backlight, since each pixel generates its own light. For more on OLEDs, see this introduction from ehergy.gov. CNET provides this comparison of LCD vs OLED displays.

ePaper - ePaper displays use a matrix of tiny capsules which are black or colored on one side, and white on the other. Applying a charge to each capsule causes it to turn one way or the other. Unlike LCD or LED displays, ePaper displays maintain their state when powered off. ePaper displays cannot be refreshed as fast as LCD or LED, however. ePaper displays are typically not backlit, and require external lighting. eInk, the primary maker of ePaper displays, has a good FAQ on the technology. Visionect.com has a helpful illustrated explanation as well.

LCD and OLED screens drive their pixels in one of two ways. A passive matrix uses a grid of wires which control each pixel using a row-column scanning method. Voltage is applied to each column in sequence. Then the rows are scanned. If the pixel on that column at a given row should be on, then the row wire voltage is taken low to create a voltage difference, and the pixel turns on. An active matrix uses a grid of thin film transistors (TFT) instead of a row-column scanning apparatus. TFTs allow for greater pixel density and therefore sharper image quality and better response time for each pixel. Jameco offers a good explanation of passive vs. active matrix driver technology.

The oldest form of LCD display, patented in the 1980’s, is known as Twisted Nematic (TN) LCD, and has limits to its viewing angle. Newer LCD technologies such as in-plane switching (IPS) or plane-to-line switching (PLS) afford wider viewing angles and brighter screens.

There are a number of common display driver ICs on the market. Typically a driver IC will be capable of controlling many different sizes and shapes of display, if they are of the same class. For example, you’ll see many TFT displays that use Sitronix’ driver ICs, notably the ST7735 and ST7789. Ilitek’s ILI9225 chip is also common in TFTs. This means that libraries written for one vendor’s display are likely to work for displays from another vendor, if they use the same chipset. This can be convenient, as it means you can sometimes choose the library whose API you find easiest to work with.

Recently, drivers for LEDs have reduced in size to the point where a driver can drive a single pixel. Usually made of three to four LEDs and a single driver, these are very popular with electronics hobbyists. For more on these, see this repository.

Displays for microcontrollers use a variety of control interfaces. The most common are the ones you see for other electronic modules as well: synchronous serial interfaces like I2C and SPI, or asynchronous serial interfaces. also feature parallel interface, requires a large number of I/O pins from your controller.

BUSY - an output pin to indicate that the display controller is busy. connects to whicheve pin the microcontroller has assigned for this function. This pin is less common on TFT displays than on ePaper displays.

Backlight - most TFT screens have a pin which enables or disables the backlight of the screen. The naming for this is not standardized: BLK, LITE, TE are all in use. Read the module’s datasheet for details.

Note: the electronics industry has used the terms “master/slave” to refer to controller devices and peripheral devices for decades without regard for the historical context of, and offense caused by, those terms. As a result, you will see the terms MOSI/MISO/SS in data sheets to refer to the pins of an SPI device While a modern standard naming scheme has not yet emerged to replace these, there are proposals in discussion. The Open Source Hardware Association has this proposal, for example. Make Magazine has this proposal. The debate is not resolved, and you will likely see some variations on the terms. The SDO, SDI, and SCK terms are the most widely accepted terms with the least historical baggage, but unfortunately, it’s still necessary to be aware of the other possible terms for pins in SPI.

Hitachi HD44780 LCD display. See the Arduino LiquidCrystal library. These 2x16 character LCD displays are ubiquitous in the hobbyist market and come in many starter kits for the Uno. They are a passive-matrix LCD with a parallel interface (6 pins) that runs on 5 volts. They will typically not run on 3.3 volts. Each character is a 5x7 pixel matrix, so these are very low-resolution displays. They can usually be foung for $10-$15, which was a bargain in the early Arduino days. Nowadays, if you need an inexpensive 2-line display, some of the OLED displays like the SSD1306 are a better bargain.

There are some display modules which have an asynchronous serial (UART) interfaces. These typically have a microcontroller on the display module itself, which is interfacing with one of the types of interfaces above. These modules typically have a communications protocol that is unique to the vendor. They are convenient, but more expensive than their synchronous serial or parallel counterparts.

Finding the right display library for your Arduino or Arduino-compatible display can be challenging. Vendors who design and sell their own breakout boards tend to publish libraries that are compatible with their own boards. Smaller vendors may not make their own libraries, relying on third-party libraries instead. The Arduino site lists over 300 display-related libraries. The ease-of-use and adaptability of those libraries varies widely. The ones I’ve found most useful are Adafruit’s GFX library and Oli Kraus’ U8g2 library.

Since there is a relatively small number of driver chip manufacturers (Hitachi, Ilitek, Solomon-Systech, and Sitronix among them), different vendors’ boards often use the same driver hardware. This means that the libraries from one vendor can support the hardware from another. When you shop for displays, it’s worthwhile to check what the driver is for each one, and see if there’s a compatible library from your favorite library writer.

Adafruit_GFX is a hardware-independent graphics library written to work with all the Arduino-compatible displays that Adafruit sells. They complement this with display specific libraries like Adafruit_SSD1306 for SSD1306 OLED libraries, Adafruit_EPD for ePaper displays, Adafruit_ST7735 for some TFT libraries, and others. The advantage of the GFX library is that you get a common drawing API regardless of which display you’re using. It uses the Arduino Printable interface too, so commands like print() and println() work with this library just like they do in the serial monitor. There’s a good guide to the GFX library as well. Sparkfun’s got their own complement to the GFX library, Hyperdisplay.

u8g2 is designed as a universal library for many different displays. It supports a wider range of displays than any other I’ve used so far. It has its own graphics API which is more or less similar to Adafruit’s, and a wide font set as well. There’s also U8g2_for_Adafruit_GFX, a library which allows you to add U8g2 fonts to any Adafruit_GFX-based library.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

Full Array Local Dimming (FALD) is a process of locally controlling LED light levels in a segmented backlight unit to enhance contrast in images, while decreasing the ‘halo’ effect around bright areas on black backgrounds. FALD delivers perfect contrast ratio making the image appear sharper for the same pixel resolution. It requires thousands of mini-LEDs to deliver the intended picture quality and consequently this increases the manufacturing cost of the backlight unit. Fortunately, this is where OTFT technology from SmartKem can make a difference. SmartKem’s performance OTFTs can be used to generate an active matrix backplane driving arrays of thousands of individual miniLEDs on a glass substrate, thereby delivering impressive high resolution images with perfect black levels. The ability to locally dim the backlight to only the areas that require it can also help to save energy, making FALD LED TVs more efficient in operation.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey