2.4 tft lcd shield work with 3.3v free sample

With the help of this forum, and Google, I succeeded in getting different LCD shields to work, but now I seem to be out of ideas how to fix this problem.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

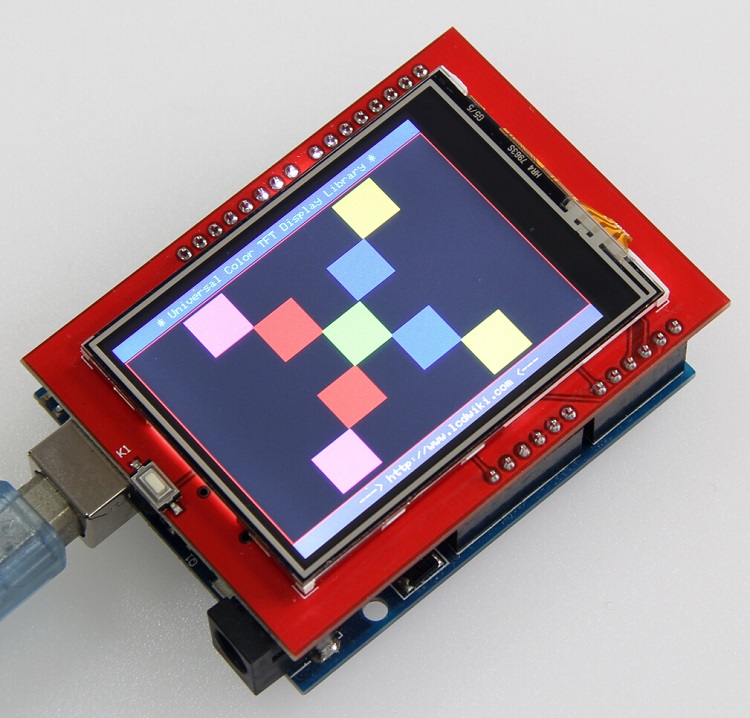

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

The ST7789 TFT module contains a display controller with the same name: ST7789. It’s a color display that uses SPI interface protocol and requires 3, 4 or 5 control pins, it’s low cost and easy to use. This display is an IPS display, it comes in different sizes (1.3″, 1.54″ …) but all of them should have the same resolution of 240×240 pixel, this means it has 57600 pixels. This module works with 3.3V only and it doesn’t support 5V (not 5V tolerant).

As mentioned above, the ST7789 TFT display controller works with 3.3V only (power supply and control lines). The display module is supplied with 3.3V (between VCC and GND) which comes from the Arduino board.

The first library is a driver for the ST7789 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “st7789” and install the one from Adafruit).

![]()

Hi community, i have Wemos Lolin32, and a TFT display recognized by id 0x4532 (mcufriend 2.4 inch TFT LCD shield). I have connected just RS to 15, CS to 33 and RST to 32, but the display is very dark. I found the wiring to be this:

my question is, do GPIO33 and GPIO34 have to be connected both to LCD_CS? Same for RST--32--36, RS--15--35. I"m worried that connecting two pins (15-35 for example) may kill my hardware (like short circuit it), if i don"t understand the comments correctly, even that is directly written. I"m new in hardware. Is it "ok" to connect all this pins together? Please help.

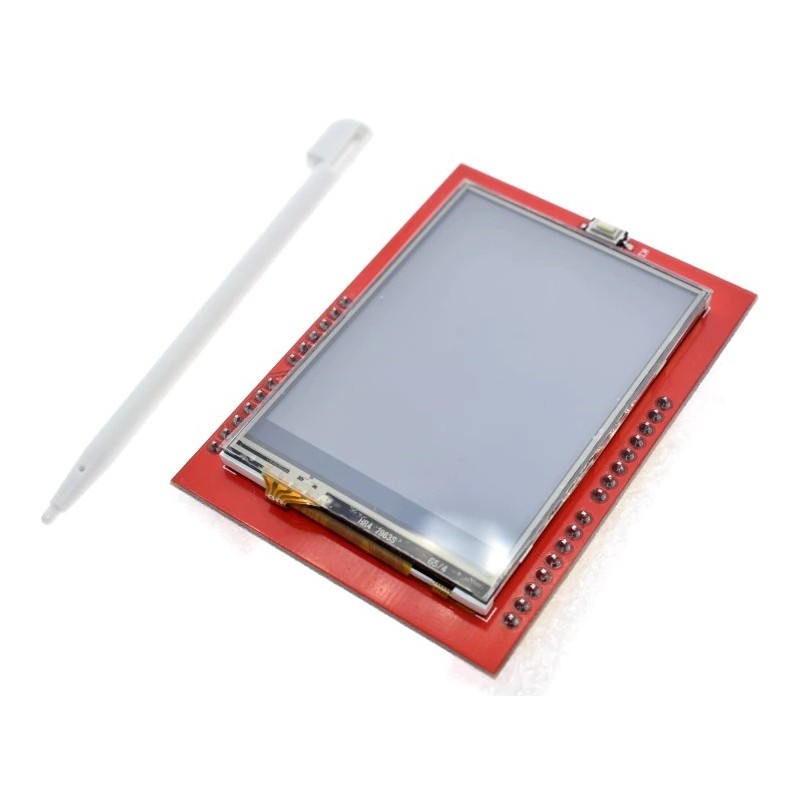

HY-TFT240 is a 2.4 inch TFT LCD Screen module, 320*240 (resolution), 65K color, 40pins interface , not just a LCD breakout, but include the Touch screen, SD card. So it’s a powerful extension module for your project.

This Screen includes a controller ILI9320, it’s 8 bit data interface, easy to drive by many MCU like STM32 ,AVR and 8051.HY-TFT240 is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 40 pins breakout. Another useful extension in this module is the SD Card socket . It use the SPI mode to operate the SD card, the SPI interface include in the 40pins breakout.

UTFT library is required to be installed to get this screen model display. This library is especially designed for TFT LCD screen using 16 bit mode. The library require the following connections.

Note: The TFT controller model needs to be declared in the initializing statement. UTFT myGLCD(38,39,40,41) needs to be modified as myGLCD(GEEE24,38,39,40,41) when using Arduino Mega2560.UTFT myGLCD(GEEE24,19,18,17,16) needs to be commented when using Aduino UNO. Otherwise it just show a blank screen. In practice, RS, WR, CS, RSET can be connected to any free pin. But the pin number must be in accord with myGLCD(RS,WR,CS,RST).

The LCD has a 2.4" 4-wire resistive touch screen lying over it. The Touch library needs to be installed to get it works. This library is designed for 2.4’’ TFT, 2.8” TFT LCD screen module.

Note:TCLK, TCS, TDIN, TDOUT, IRQ also can be connected to any free pin. But the pin number must be in accord with the touch screen initializing statement myTouch(DCLK,CS,IN,OUT,IRQ).

The default setting is not accurate for 2.4” TFT module, so you need to calibrate when using 2.4” TFT module. A program to calibrate the touch screen is included in the example. If you touch screen is inaccurate, you need to run touch_calibration. Follow the on-screen instruction to calibrate the touch screen. Better not use your finger to calibrate it, use your accessory touch pen to pressure the frontsight with stength. Then record the calibration parameters and apply them in ITDB02_Touch.cpp in your touch screen library.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big 4"(3.97" diagonal) bright (6 white-LED backlight) and colorful (18-bit 262,000 different shades)! 480x800 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 and capacitive touch panel with FT6336.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

Many Arduino projects require adequate display of what is being monitored. Think of time, temperature, humidity, pressure, sound, light, voltages, or combinations of recorded data in a weather station. With the addition of fast and capable ESP32 microcontroller boards to my personal ‘fleet’ my collection of good old Arduino Unos with their TFT display shields seemed prone to gather dust. The ESP32 combines well with TFT displays through a 4-pin SPI interface* while the Uno shields have parallel interfaces that feature 28 pins of which a minimum of 13 is necessary for the daily display business (see figure 2). A parallel interface is generally faster than a SPI interface. The prospect of a bunch of shield displays with fast parallel interface parked forever in a deep drawer was a stimulus for me to start a project to connect these shields to an ESP32. Fortunately there are several solutions available of which I selected the one proposed by Alberto Iriberri Andrés at https://www.pangodream.es/ili9341-esp32-parallel. However, the nightmarish prospect of connecting shield after shield with an ESP with unwieldy Dupont jumper wires inspired me to create a Uno-shield compatible parallel ESP32 TFTdisplay workbench for the purpose of checking all my Uno TFT shields, one by one. Here follows the design, wiring, and the results with a collection of parallel Uno shield type displays.

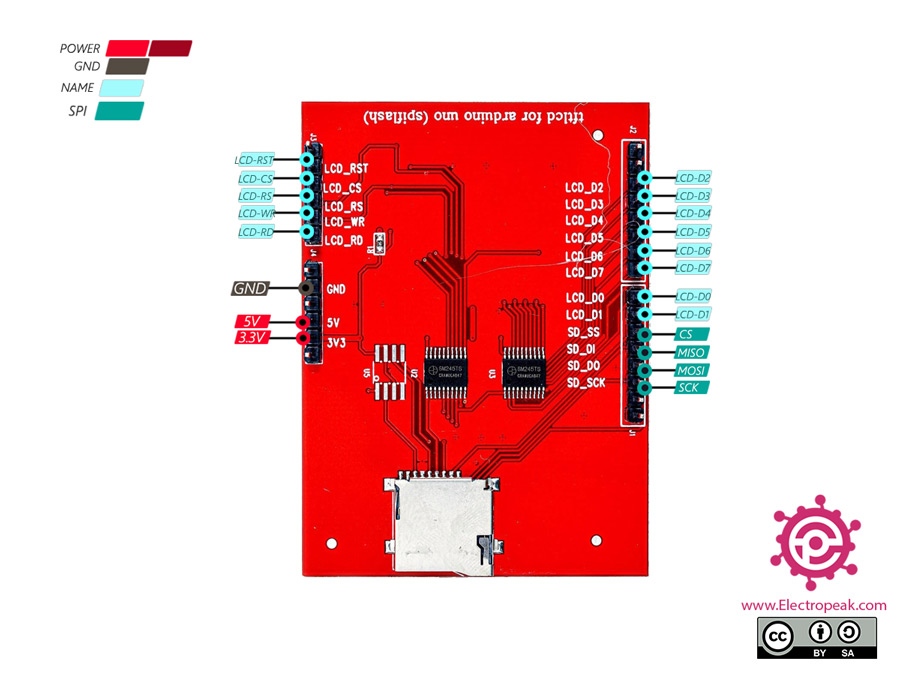

The market is swamped with TFT shields that can be placed directly on the pin sockets of an Arduino Uno. These shields feature parallel interfaces. They have in common that there are four pin header blocks through which one can stick such a shield very handy right onto a Uno (fig. 2). The displays mounted on these shields have different pixel dimensions and, more important, different controller chips. Most commonly used are ILI9341, ILI9481 and ILI 9486 chips. The best performing TFT shields are equipped with 3V-5V voltage converters (e.g. the shield shown in fig 2) but there are plenty of cheap shields available that lack a voltage regulator and therefore accept only 3V.

Controllers need their own specific driver to make the display work correctly. A major effort to supply the Arduino world with adequate drivers for ESP8266 and ESP32 microprocessors running smoothly with the above ILI controllers has been undertaken in recent years by the electronics engineer known as Bodmer: the TFT_e_SPI.h library.

So what I needed is a board that accomodates an ESP32 and that has enough space to accommodate a variety of small (2.4 inch) and large (3.95 inch) Uno TFT shields.

The base board consists of a doule-sided soldering board fastened with four nylon spacers on a piece of cardboard. Mounted on this base are two 15-pin parallel socket headers to accommodate an ESP32 microcontroller board and the four socket headers to accommodate the Arduino Uno TFT shields to be tested. As screen diagonals of TFT shields in my ‘arsenal’ vary between 2.4 inch and 3.95 inch, a 12080 mm double-sided soldering board with 4230 holes was selected for this purpose. The positioning of the socket headers is shown in figure 3. There are also two 2-pin pin headers to allow to select the proper voltage to power the display being tested (with jumpers).

12080 mm double-sided soldering board featuring 4230 holes, two 15-pin socket headers, two 6-pin socket headers, two 8-pin socket header, one 3-pin socket header, one black 2-pin socket header (black), two 2-pin headers (red), four nylon bolts, four nylon spacers and four nylon nuts, ESP32-WROOM32 microcontroller board with 30 pins, wire, two jumpers.

The positioning of pins on the original Arduino Uno does not follow the uniform 2.54 mm (0.1 inch) pitch rule. Any Uno parallel TFT shield therefore will not immediately fit a standard soldering board. On the back of each shield are jumper blocks labeled J1 through 4 (figure 2). We call J1 here the ‘SD jumper block’, J2 the ‘parallel jumper block’, J3 the ‘control jumper block’ and J4 the ‘power block’. Part of the SD jumper block is occupied by the parallel data interface. Some manoevering makes it clear trhat the J2-J3-J4 blocks fit the holes of the soldering board while the parallel jumper block (J1) is the outlier. Fortunately, the pins in all blocks follow the 2.54 mm pitch rule. It is J1 as a whole that is half a unit positioned ‘out of pitch’. Through this unorthodoxy, say asymmetry, a TFT shield fits an Arduino in only one way. Very clever. The present soldering board was adapted to this configuration by cutting a narrow sleeve where the pins of the J1 parallel jumper block should be, just wide enough to let the pins of the corresponding socket header through. Then an extra piece of soldering board was prepared and fastened with wire and solder under the sleeve, taking care that the J1 accepting socket header would exactly match jumper block J1.

The design is quite simple: two parallel rows of 15-pin socket headers serve as a mounting point for the ESP32 (figures 2,3). These sockets are positioned in the upper left corner of the board to leave as much area as possible to position the TFT shields. Here, TFT shields are oriented landscape. The bench is designed only for displaying data and graphs only, with no SD card reader support.

All Uno TFT shields have three pins that deal with power (3V3, 5V, GND), five pins that are necessary for display control and eight pins connected with the parallel data transfer interface, i.e., there is a total of 16 pins that need to be wired (figure 2). In addition I planned three ‘free’ pins of the ESP32 available via pin sockets for input-output puposes: pins D2, D5 and D15 (figure 4).

With so many wires it is necessary to bring order in the assembly of the bench. One can distinguish (1) power wires, (2) TFT control wires, (3) parallel interface wires, (4) additional wiring. One by one the groups of wires were mounted on the soldering board.

The group of control wires originates from pins D26, D27, D14, D12 and D13 and connect to the socket header that accomodates TFT shield jumper J1 (figure 5).

There are eight data pins on the TFT shields, marked LCD_D0 through LCD_D07. LCD-00 and LCD_01 are pins on jumper block J3 while the remaining LCD_nn pins can be found on jumper block J2. These pins must be connected to, respectively, pins RX2, D4, D23, D22, D21, D19, D18 and TX2 (figure 6).

Bodmer’s TFT_eSPI library is different than other libraries, e.g. Adafruit_GFX and U8G2 in the sense that there is no ‘constructor’. Pin definitions for each type of controller are in TFT_eSPI systematics stored in a separate Setup_nn.h file that is placed in a folder with the name ‘User_Setups’. In turn, the specific Setup_nn.h is called in another stetup file named User_Setup_Select.h. Consider the systematics as a kind of two-stage rocket. Both stages need to be edited befor launch. The first stage is User_Setup_Select.h and the second stage is Setup_nn.h.

An example of the specific Setup_nn.h file for one of my ILI9341 shields (the one shown in figure 1) is named ‘Setup_FW_WROOM32_ILI9341_parallel_TFT_016.h’. This is a file editable with any ASCII editor.

Figure 1 shows one of my Uno TFT shields mounted on the bench, running the example ‘TFT_graphicstest_one_lib,’ that can be found in the Arduino IDE under File, Examples, TFT_eSPI, 320×240, of course after correct installation of Bodmer’s TFT_eSPI library. With an ESP32. My own ‘ESP32_parallel_Uno_shield_TFT_radar_scope.ino’ runs fine: the downloadable demo sketch which mimics an aviation traffic controller’s radar scope with a sweeping beam. I created this sketch in 2017 as a demo for one of my first Arduino Uno TFT shields**. The body of that demo was used for the present demo sketch.

Testing my complete collection showed marked differences between shields. I tested shields with ILI341, ILI9481, ILI8486 and ILI9488 controllers, with mixed results. Best performance was achieved with ILI9341 controller equipped shields. Shields that lack a voltage regulator appeared to be dedicated 3V3 shields as they would not perform, or produce an upload error, if the 5V jumper was closed. One 3V3 shield needed the 3V3 jumper closed during upload while after upload it needed 5V to lighten up the screen. Some but not all shields accepted closed 3V3 and 5V jumpers during uploading and running sketches. One ILI9481-powered shield behaved very peculiar: only if both 3V3 and 5V jumpers were open during upload the sketch would be accepted and then be visible on screen only with the 5V jumper closed.

The experiences with the TFT shields lead to the following rule of thumb: first try to figure out the correct controller (this on an Arduino Uno with David Prentices’ ‘MCUFRIEND_kbv.h’), then checking the User_Setup_nn.h file icreated for this shield n the TFT_eSPI library system, and then try to upload first with the 3V3 jumper closed, then again (if necessary) with the 5V jumper closed, and finally with both jumpers closed.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

After reading the previous section, you should be familiar on how this sketch works, so we’ll just take a look at the newly created function: scrollText()

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

Wiring the LCD 16\u00d72 Keypad Shield on Arduino | 14core.comDFR0009 ESP32 DIYI0TArduino Touch Screen Calculator using TFT LCD Circuit Digest Calculator using arduino lcd and keypadTouch Screen TFT Shield for.

2.4 inch TFT Touch Screen LCD Module for Arduino has excellent vivid color contrast. You can Spice up your Arduino project with a beautiful large touchscreen.

I have a iteadstudio 2.4 tft touch shield that currently works with my Arduino Uno R3 board. I now want to get this shield working on the Arduino Mega 2560.

We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HCSR04 ultrasonic sensor.

I have a iteadstudio 2.4 tft touch shield that currently works with my Arduino Uno R3 board. I now want to get this shield working on the Arduino Mega 2560.

I have a iteadstudio 2.4 tft touch shield that currently works with my Arduino Uno R3 board. I now want to get this shield working on the Arduino Mega 2560.

We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HCSR04 ultrasonic sensor.

Arduino TFT LCD Touchscreen Calculator: Hi Guys in this instructables we will learn how to make a calculator using Arduino Uno with 3.5 TFT LCD Touchscreen.

Also due to the use of phosphors OLEDs suffer from screen burnin and there is currently no way to recycle OLED displays whereas LCD panels can be recycled.

If you"re just getting started with Nextion we recommend getting the 3.2 size which is the one used in the Nextion Editor examples the examples also work.

That is the reason why Uno works out of box for SD access. ArduinoUnoR3Pinouts.png. On the other hand Mega 2560 SPI takes place on 50 51 and 52 as shown.

Arduino touch screen calculator using tft lcd display Lcd Arduino Arduino Programming Diy Electronics. Choose board. Save. Saved from circuitdigest.com.

Find many great new & used options and get the best deals for 2.4 TFT LCD Display Shield Touch Panel Module 240320 for Arduino UNO Ili9341 at the best.

Oct 29 2016 Arduino Mega + 2.4 TFT LCD Shield + DHT11 Temperature and Humidity Displaying: Today I am going to show you how to use 2.4 TFT LCD shield.

ERTFT0243 is 2.4tft lcd module display in 240x320 resolution with parallel and serial spi interface.Optional touch panel.Idea for 8051arduinostm32avr.

2.4 TFT LCD Display Shield Touch Panel Module 240320 For Arduino UNO ILI9341 12.00. FOR SALE! 2.4 inch 2.4 TFT LCD Display Module with Touch Panel SD.

This is Sainsmart 2.4 inch TFT LCD module with the TFT LCD shield kit for arduino enthusiasts.It includes one piece of 2.4 inch TFT LCD display and a TFT LCD shield for Arduino MEGA2560 (R3).We will provided you the whole document including the example project of arduino due with the kit. We will supply you the technical support after your purchase.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.(Click here)

It is 100% compatible with the normal MCU like ARM AVR PIC and 8051,especially on arduino family such as arduino due and arduino mega2560(R3).The module uses the LCD controller Chip SSD1963 with 5 inch LCD including the touchscreen.

The shield defines that all the the data transmit ports are PC1-PC8 and PC12-PC19,the controll pins are PD0-PD3.The perfect design could realize that the data transmits in high speed.The SPI interface is designed in the ISP header of arduino due so that the SPI transfer with DMA could be achieved in high speed with no drag.

You have the right to revoke this contract or to return the goods within 14 (fourteen) days without giving reasons. The cancellation period is fourteen days from the day on which you or a third party named by you, who is not the carrier, has taken possession of the last goods. In order to exercise your right of withdrawal, you must inform us (company AZ-Delivery Vertriebs GmbH, Lärchenstraße 10, 94469 Deggendorf, telephone number: 0991/99927827 , e-mail address: info@az-delivery.com ) by means of a clear statement (e.g. a letter sent by post, fax or e-mail) about your decision to revoke this contract. You can use the attached model withdrawal form, but it is not mandatory. In order to comply with the withdrawal period, it is sufficient that you send the notification of the exercise of the right of withdrawal before the expiry of the withdrawal period.

If you withdraw from this contract, we have to repay all payments we have received from you, including the delivery costs (with the exception of the additional costs arising from the fact that you have chosen a different type of delivery than the cheapest standard delivery offered by us), immediately and at the latest within fourteen days from the day on which we received the notification of your cancellation of this contract. For this repayment we will use the same means of payment that you used for the original transaction, unless expressly agreed otherwise with you; in no case will you be charged fees for this repayment. We can refuse the refund until we have received the goods back or until you have provided proof that you have returned the goods, whichever is the earlier. You have received the goods immediately and in in any case, to be returned or handed over to us at the latest within fourteen days from the day on which you inform us of the revocation of this contract. The deadline is met if you send the goods before the expiry of the period of fourteen days. You bear the direct costs of returning the goods. You only have to pay for any loss in value of the goods if this loss in value is not limited to a check of the nature, properties and functionality of the goods necessary to deal with them.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey