tft display vs capacitive display made in china

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

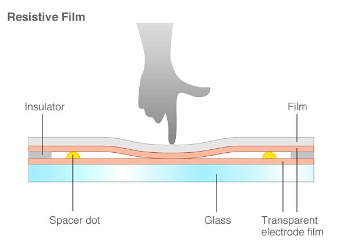

Capacitive touch screen technologyUSES the human body’s current induction to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with one layer of ITO respectively. The outermost layer is a thin layer of silica soil glass protective layer. When the finger touches the metal layer, the user and the touch screen surface form a coupling capacitor due to the electric field in the human body.

In order to realize multi-touch on a capacitive screen, it is necessary to add electrodes of mutual capacitance. In a simple words, it is to divide the screen into blocks and set a group of mutual capacitance modules in each area to work independently. Therefore, the capacitive screen can independently detect the touch situation of each area and simply realize multi-touch after processing.

Capacity Touch Panel USES the current induction of the human body to work. The capacitive screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with ITO (indium sikgold oxide nano). The outermost layer is a protective layer of silica glass with a thickness of 0.0015mm.

Whena user capacitive touch screen, the electric field due to the human body, your fingers and face form a coupling capacitance, because the working plane to have a high-frequency signal, so the fingers on a very small current, respectively from the current screen in the four corners of the electrode, and theoretically through the four electrodes with the finger to the four corners of the current is proportional to the distance, the controller through the precise calculation of the four current ratio, it is concluded that location. It can achieve 99% accuracy, with a response speed of less than 3ms.

Projective capacitive touch screens etch different ITO conductive circuit modules on two layers of ITO conductive glass coatings. The etched patterns on the two modules are perpendicular to each other and can be thought of as sliders with continuous changes in X and Y directions. As the X and Y architectures are on different surfaces, their intersection forms a capacitor node. One slider can be used as the drive wire and the other as the detection wire. When a current passes through one of the wires in the drive wire, if there is a signal of a change in the capacitance outside, it will cause a change in the capacitance node on the other layer of wire. The change in capacitance can be detected by measuring the electrical circuit connected to it, and then converted to A digital signal by A/D controller, which can be processed by A computer to obtain the (X, Y) axis position, so as to achieve the positioning target.

Commonly used is the surface capacitive touch screen, which works in simple principle, low price, simple circuit design, but difficult to achieve multi-touch.

Projective capacitive touch screens are multi-finger touch. These two capacitive touch screens have the advantages of high light transmittance, fast response speed, and long life, etc. The disadvantages are: with the change of temperature and humidity, the capacitance value will change, resulting in poor work stability, often drift phenomenon, need to frequently proofread the screen, and can not wear ordinary gloves for touch positioning.

The projected capacitive touch screen can be divided into the capacitance and mutual capacitance screen two types, one of the more common mutual capacitance screen as an example, the internal electrode and receiving electrode by the driver, drive electrode signal low voltage high frequency projected onto the receiving electrode form stable current, when human exposure to the capacitance screen, earth due to the human body, fingers and capacitance screen to form an equivalent capacitance, and the high-frequency signal by the equivalent capacitance into the ground, in this way, the receiver receives charge is reduced, when fingers near the transmitter, electric charge, the more significant, according to the receiving end receives the current strength of to determine the touchpoint.

Arrays of transverse and longitudinal electrodes are made from ITO on the surface of the glass. These transverse and longitudinal electrodes form capacitors with the ground respectively. This capacitor is commonly referred to as self-capacitance, that is, the capacitance of the electrode to the ground. When the finger touches the capacitive screen, the capacitance of the finger will be superimposed on the capacitance of the screen, thus increasing the capacitance of the screen.

During touch detection, the horizontal and longitudinal electrode arrays are respectively detected from the capacitive screen. According to the changes of capacitance before and aftertouch, the horizontal coordinates and longitudinal coordinates are determined respectively, and then the touch coordinates of the plane are combined. The scanning method of self-capacitance is equivalent to projecting the touchpoints on the touch screen to the X-axis and Y-axis directions respectively, and then calculating the coordinates in the X-axis and Y-axis directions respectively, and finally combining them into the coordinates of the touchpoints.

If it is a single touch, the projection in the X and Y direction is unique, and the combined coordinates are unique. If there are two touches on the touch screen and the two touches are not in the same X direction or the same Y direction, then there are two projections in the X and Y direction respectively, and the combined coordinates are 4.Apparently, only two of the coordinates are real, and the other two are known as ghost points. Therefore, self – the capacitive screen can not achieve true multi-touch.

The mutual capacitor screen also USES ITO to make the transverse electrode and the longitudinal electrode on the glass surface. The difference between it and the self-capacitor screen is that the place where the two groups of electrodes cross will form a capacitor, that is, the two groups of electrodes form the electrodes of the capacitor respectively. When a finger touches a capacitive screen, the coupling between two electrodes near the touchpoint is affected, thus changing the capacitance between the two electrodes.

The advantage of the mutual capacitive screen is less wiring, and can simultaneously identify and distinguish the difference between multiple contacts since the capacitive screen can also sense multiple contacts, but because the signal itself is fuzzy, so can’t distinguish. In addition, the induction scheme of the mutual capacitive screen has the advantages of fast speed and low power consumption, because it can measure all the nodes in a driveline at the same time, thus reducing the number of acquisition cycles by 50%. The dual-electrode structure has the function of self-shielding external noise and can improve signal stability at a certain power level.

• Capacitive schemes last longer because the components in the capacitive touch screen do not need to move at all. In a resistive touch screen, the top layer of the ITO film needs to be thin enough to be elastic so that it bends down and touches the bottom layer of the ITO film.

• The choice of capacitor or resistor depends largely on the object touching the screen. If it is a finger touch, the capacitive touch screen is a better choice. If a stylus is needed, whether plastic or metal, a resistive touch screen will do. A capacitive touch screen can also use a stylus but requires a special stylus to work with it.

• Capacitive technology is wear-resistant, has a long service life, and has low maintenance costs when users use it, so the overall operating costs of manufacturers can be further reduced.

• Capacitive touch screens are designed to support multi-touch technology and are less responsive and less prone to wear and tear than resistive touch screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

The reason for LCD Display flashing screen: shielding coil; Signal interference; Hardware; Refresh frequency setting; Monitor time is too long; Too high...

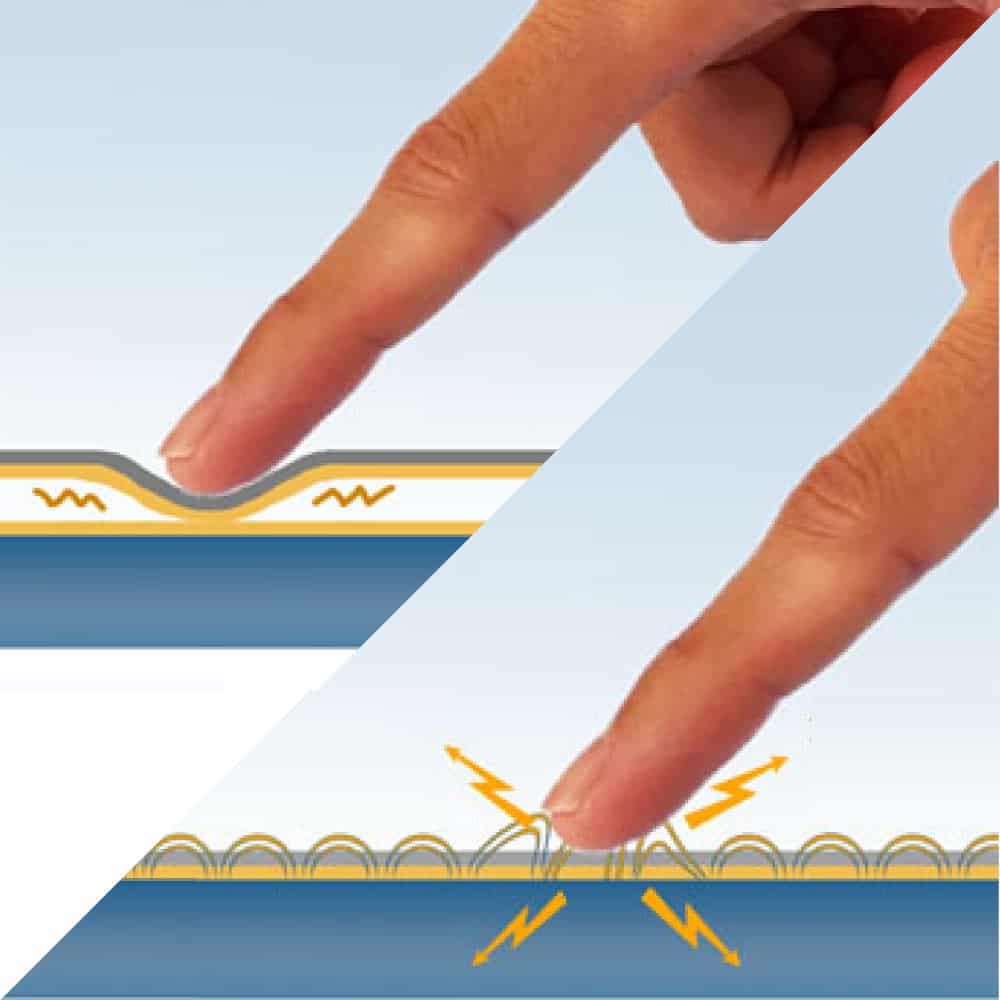

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

With this motto in mind, we"ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Meaning Of Tft Display, Serial Tft Display, Lcd Industrial Monitor, Lcd Screen Tester,Lcd Flat Panel Display. Sincere cooperation with you, altogether will create happy tomorrow! The product will supply to all over the world, such as Europe, America, Australia,Accra, Bhutan,Cairo, Belgium.On today, we"ve got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We"ve been looking forward to doing business with you!

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for Tft Lcd Display Screen With Capacitive Touch Screen, Tft Lcd Interface, Tft Touchscreens, Vehicle Touch Screen,Touch Screen Breakout. We fully welcome shoppers from all around the world to ascertain stable and mutually effective enterprise interactions, to have a dazzling long run jointly. The product will supply to all over the world, such as Europe, America, Australia,moldova, Bogota,Lithuania, Manchester.Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we"ll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

.jpg)

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

A:We provide touch screens ranging from 1 inch to 32 inches. We can produce capacitive touch screens, resistive touch screens, and infrared touch screens.

A: Please don"t worry about it. Our engineer will help you if you have any problems when you try to power on the display. We will send you the complete development documentation (data sheet, initial code, schematic, CAD drawing etc) and help you easy to get started.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick responding and are typically found on smaller devices such as iPhones, iPod touches or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes change and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Putting together a machine with a TFT LCD module requires immense accuracy and attention to detail. And this is indeed true if you’re a manufacturer of a crucial machine such as a ventilator.

Ventilators are essential medical equipment that can help save the lives of critically-ill patients. These machines are most needed nowadays, what with the increasing number of people getting sick from COVID-19 and other respiratory diseases. Hence, it’s important to use the best touch screen display module for ventilators to ensure that the machine works its best all the time.

This post is meant to raise awareness on why TFT-LCD modules are the best types of display panels for ventilators in china. We’ll also give you a brief preview of what ventilators are, how a TFT LCD display module works for a ventilator machine, and why a touch screen TFT LCD screen is the best choice for ventilator screens.

Ventilators are made up of many parts, all working together to provide life support to patients with breathing problems. Ventilators vary in designs depending on their manufacturer. However, the general parts of all ventilators include the following:Touch screen LCD display for patient monitoring and control settings

Modern ventilators in china now use TFT touch LCD display monitors. This is a big leap from the old ventilator models with minimum to no monitor displays.

A TFT color LCD display allows the ventilator to accurately display patient monitoring parameters and machine settings. This is possible because the combination of TFT-LCD technologies results in high-resolution images displayed on the screen. And since the ventilator is a critical life-saving machine, an accurate display is of tantamount importance.

Before the advent of the touch LCD module, ventilators use buttons and dials to operate various machine settings and control patient alarms. But with the use of a touch screen LCD display, it’s easier to silence alarms, adjust machine parameters, and check on a patient’s vital signs.

Now, using a TFT touch LCD display screen makes ventilator cleaning easier. This is because the screen is predominantly flat in a ventilator with a touch screen interface. Furthermore, there are fewer buttons and dials in such ventilators. A machine with plenty of buttons and dials makes for a good breeding space for harmful pathogens, as they’re harder to clean than those with flat touch screen interfaces.

As previously mentioned, a ventilator with a touch LCD display screen has fewer dials, knobs, and buttons than those who use a non-touch TFT LCD display. And this is because of a touch screen’s multifunctional nature. The screen can display content while acting as an interface device at the same time.

Machines meant to help patients breathe aren’t necessarily portable and lightweight. But using a touch TFT LCD display screen makes a full-blown ventilator significantly less bulky and more portable.

Imagine if you’d use an old display technology such as cathode ray tubes to power a ventilator’s display system. Now, that would be impractical and bulky.

TFT-LCD modules are made up of thin-film transistors built within the LCD-containing glass. Such a module makes the finished ventilator screen lightweight and thin.

A small TFT-LCD monitor with touch screen technology can also be used for ventilators that are meant to be portable. Examples of such portable breathing machines are those used on emergency vehicles and operating rooms.

There are several kinds of touch screen technologies that touch screen display suppliers and manufacturers use to power a ventilator screen. But the capacitive touch screen is the one that’s most widely used. Here’s an overview of what this touch screen technology is.

The capacitive touch screen is the most widely-used touch screen technology on medical equipment like ventilators. In this technology, electric charges from the human user pass through the screen surface, distorting the screen’s electrostatic field and prompting the device’s reaction to the touch.

In this technology, the display panel is made up of a glass sheet with transparent electrode films embedded in it. An integrated circuit chip is added to create an electrostatic field that is three-dimensional.

Lots of industries use PCT in their machine displays, including the medical field. For instance, an increasing number of ventilators now use TFT LCD capacitive touch screens with PCT technology for their displays.

Rarely will you find a modern ventilator being powered by touch screen technologies other than capacitive ones? And this is for good reason! Here are the benefits clinicians can enjoy while using a ventilator with a TFT LCD capacitive touch screen:

Capacitive touch screen panels provide significantly better image clarity than other technologies. For instance, compare the output clarity of capacitive versus resistive technology (touch screens for ATMs and supermarket kiosks). Resistive touch screens have poorer clarity because the actual image display is right behind the protective glass layer. This isn’t the case in capacitive screens.

Furthermore, pairing up a capacitive touch screen with a TFT LCD module ramps up the output’s clarity. This is extremely needed in ventilator displays to ensure that clinicians and other health care workers clearly see the patient’s vital signs and machine parameters. This will eventually aid in better evaluation of the patient’s breathing status and general condition.

Capacitive touch screens are easier to use since they don’t require pressure to detect and respond to touch. A simple gentle touch is all you need to operate the ventilator’s display! Using a projective capacitive touch screen (PCT) makes a TFT LCDscreen even more friendly to the gloved fingers of health care workers and clinicians.

Capacitive touch screens are a perfect match for life-saving devices such as ventilators. This is due to its durability and extreme resistance to liquids and surface contaminants like grease and dust. A TFT LCD capacitive touch screen is also easy to disinfect once contaminated.

Most TFT LCD module manufacturers recommend disinfectant wipes with less than 70% alcohol for disinfecting touch screen ventilator screens. However, the disinfecting agent may widely vary amongLCD screen manufacturer guidelines or hospital protocol, so be sure to double-check them first.

Nevertheless, capacitive touch screens generally withstand harsher environmental conditions and strong cleaning agents than touch screens using other technologies.

To conclude, we’ve talked about touch screen display modules and why it’s the best choice to use for medical ventilators. We also tackled some facts about ventilators to further understand why touch screen LCD display modules are often used for their screens.

TFT-LCD display modules are good for ventilators because they make the machine lightweight, portable, easily cleaned, and easy to operate. Such modules also create clear and crisp screen displays.

If you are a ventilator manufacturer in china, consider using a touch screen LCD display for your next ventilator design. Look for a reputable touch LCD display manufacturer who can provide you with high-quality TFT LCD touch screen modules for your breathing machines. Remember, your ventilators will save patient lives, so choose the best TFT LCD modules with a touch screen display now!

The TFT LCD touch screen is a crucial part of the breathing machine. As a touch solution provider, Ever Glory has served many professional ventilator manufacturers all over the world in the past. We will provide effective guarantee and support to each ventilator manufacturer, ensure the smooth process of the whole ventilator production and rapid development, and do our best to alleviate the situation of ventilator shortage.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey