10 x 10 Backlit Displays - backlit led display

HDI PCBs rely on several types of vias to achieve their high-density interconnections. Each type of via has its specific role in the design and manufacturing process.

The main advantage of the HDI board is its high-density interconnect design, through the use of micro lines and highly compact layout, can achieve higher interconnection density, thereby accommodating more electronic components in a limited space, improving the performance and function of the board. This design makes HDI boards particularly suitable for applications requiring high performance and high functional density, such as high performance computing, data centers, and mobile communication equipment, to support high-speed data transmission and processing.

The terms “connect” and “interconnect” may seem similar but serve distinct functions in electronics. “Connect” typically refers to the linking of two points, components, or circuits. This could be as simple as joining a wire to a terminal.

Dissipate and neutralize by grounding, ionization, and the use of conductive and dissipative static control materials. Protect products from ESD with proper ...

Plated Through Hole (PTH) technology is commonly used in traditional PCBs and involves drilling holes through the entire board to connect different layers. This method, while reliable, is limited in terms of design flexibility and component density.

For further information about access to desk space please contact Rory Clifford, Interactive Manager. Queries will be dealt with on a rolling basis and is again dependent on space available in The Pixel Mill.

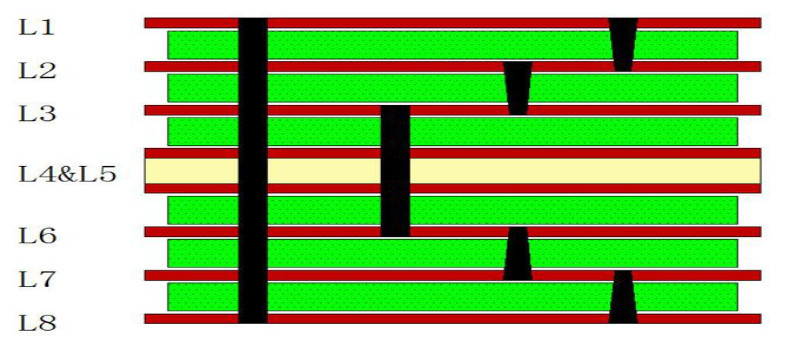

The stackup in HDI PCBs refers to how the multiple layers of the board are arranged. Stackups are critical in determining the board’s performance, particularly when it comes to signal integrity, power delivery, and heat dissipation. HDI stackups often involve intricate configurations that vary depending on the design’s complexity and purpose. Here are the most common types:

2-56 screws (2 gauge diameter, 56 threads per inch) · 1/4" length · Pan head · 100 screws per box ...

The key difference between a traditional PCB and an HDI PCB lies in the design and manufacturing process. Traditional PCBs use through-hole technology and thicker traces, limiting the board’s ability to accommodate high-density components. HDI PCBs, by contrast, use finer lines, smaller vias, and advanced interconnect techniques to maximize component density. Here are some key differences between them:

HDI PCBs, on the other hand, use smaller vias such as microvias, blind vias, and buried vias. These allow for more efficient use of space, making HDI technology the go-to solution for high-density, multi-layer designs.

GooglePixeldisplay color

ELIC takes HDI technology to the next level. In this configuration, every layer of the PCB can interconnect directly with any other layer. This is the most advanced form of HDI stackup, offering unparalleled design flexibility and performance. However, it is also the most complex and expensive option. ELIC is often used in cutting-edge technology applications such as aerospace and military equipment.

On the other hand, “interconnect” deals with more complex connections, usually involving the linking of multiple circuits or components within a system. In the context of HDI PCBs, interconnectivity is crucial because it defines how different layers and components of the board communicate. HDI technology optimizes these interconnections to make the board more efficient in terms of space and performance.

10ft Braided USB-A to Micro USB/Lightning/USB-C Cable - Fast Charging & High-Speed Data Transfer - White Jacket, Aluminum Connector. Find My Store. for ...

Deadpixeltest

For nearly 20 years, Best Technology have always been committed to providing overseas customers High Mixed, Low Volume products with Reliable Quality and Quick Delivery, and are determined to become one of most trusted partners in the field of printed circuit boards and PCBA. As an expert of HDI PCB manufacturer, we are so confident that we can provide the highest quality product that highly meet your specifications.

In this configuration, there are two HDI layers on each side of the N traditional layers. This setup allows for greater flexibility in routing, especially for complex designs requiring more components. The additional HDI layers enhance the board’s ability to manage signal transmission efficiently, making it suitable for high-performance applications.

High density Interconnect (HDI) PCB is a printed circuit board designed to meet the growing needs of modern electronic products. It allows for higher component density due to the use of thinner lines, smaller through-holes, and precise component placement. These boards are particularly popular in industries where miniaturization is key, such as smartphones, medical devices, and military equipment.

TFT display technologies is just another variation of LCD displays that offer greater color, contrast, and response times as opposed to available passive ...

Though not exclusive to HDI designs, through-hole vias extend through the entire PCB, connecting all layers. While these vias occupy more space, they are sometimes necessary for power connections or when working with thicker boards.

The design of the HDI board also focuses on improving the anti-interference ability and reliability of the circuit board, by using better signal integrity and power management technology, effectively reduce the impact of electromagnetic interference and power noise on the circuit.

The embedded via and blind via technologies used in the manufacturing process of HDI (High-Density Interconnect) boards allow for the addition of more layers without increasing the thickness of the board, thereby improving space utilization. In contrast, the drilling process for standard PCBs is relatively simple, but as the number of layers increases, the board thickness also increases accordingly. This difference means that HDI boards require more advanced equipment and higher technical requirements during production.

Blind vias connect an outer layer of the PCB to one or more inner layers but do not extend through the entire board. These vias allow for complex routing without using unnecessary space on the PCB’s inner layers.

29 Dec 2020 — One Nit represents more light than 1 ANSI lumen. The mathematical difference between Nits and Lumens is complex. However, for the consumer ...

DeadpixelTest Android

OLED TV displays use organic carbon molecules to create the best picture quality and viewing angles, thinnest profiles, and excellent brightness.

For high-end electronic products that require high-speed signal processing and complex circuit designs, HDI boards offer better performance. Due to their high density and efficiency, HDI boards can meet the high-performance demands of modern electronic devices. Standard PCBs, on the other hand, may not be suitable for these applications because of their lower signal transmission quality and higher latency.

HDI PCBs use a combination of advanced technologies such as laser drilling and sequential lamination to enable denser wiring without compromising performance. By integrating smaller, more efficient through-holes, HDI boards offer greater functionality on a smaller footprint than traditional PCBs.

Deadpixel

![]()

HDI boards are created through continuous stacking and lamination, resulting in advantages such as being “light, thin, short, and small.” Electrical interconnections between layers are achieved through conductive vias, embedded vias, and blind vias, making the structure different from standard multilayer boards. Most HDI boards are laminated two or more times (except for special structures), while standard boards are typically laminated once.

ProgrammablePixelDisplay

Please note that there is no guarantee of funding for companies using The Pixel Mill in this capacity. Companies will have to apply for funding via the normal application process.

The Pixel Mill Trainee 2022 Programme is an industry-led new entrant paid training programme (NMW/NLW) that seeks to find and develop the best new and emerging talent within the video game and immersive industries, providing them with training and live project experience. APPLICATIONS ARE NOW CLOSED.

Platform is a business accelerator programme for video game companies in Northern Ireland aimed at supporting companies to self-publish a new game based on an original IP within 12 months. Working out of The Pixel Mill based at the Ormeau Baths in Belfast, companies will have access to facilities, mentors, training and funding as well as the opportunity to attend markets to build their business network and meet consumers. APPLICATIONS ARE NOW CLOSED.

202443 — 1. What is a TFT? TFT stands for 'Thin Film Transistor' – it is a type of LCD that gives higher resolution and better image quality than ...

2024611 — The most common forms of measuring brightness are cd/m2, Nits, and ANSI lumens. There are many tools and devices that you can use to measure ...

However, HDI boards also have some limitations. First of all, compared with other advanced boards, the cost of HDI boards is usually lower, because HDI manufacturing technology helps to use advanced packaging technology, but its processing is more difficult, higher requirements for technology and equipment, which may increase a certain cost. In addition, the material choice of HDI board will also affect its performance and cost, such as FR4, PI and BT materials have advantages and disadvantages, need to be weighed according to the specific application needs.

Buried vias are located entirely within the board, connecting internal layers without appearing on the outer surfaces. This is ideal for designs where surface area needs to be preserved for components, while still allowing inter-layer connectivity.

Screen pixelapp

The smart OLED Self-Lit 4K B36LA, 65 inch LG TV offers you true 4K resolution. Immerse yourself in an enriched color experience with Quantum Dot NanoCell ...

Microvias are tiny vias, typically created using laser drilling, that connect adjacent layers of the PCB. These are essential for HDI designs as they save space while maintaining high-density connections. They can be used in stacked or staggered configurations to optimize space and signal flow.

In space-constrained devices, such as smartphones and portable electronics, HDI boards are the ideal choice because they can integrate more functions within a smaller size. HDI boards can achieve a line width of 2/2 mil and a 10-layer board thickness of below 0.8mm. Standard PCBs, due to their larger size and lower integration, may not be suitable for these applications. The line width and spacing of regular PCBs are generally limited to 3/3 mil, and their thickness also has certain restrictions.

Deadpixelfix

This is one of the simplest forms of HDI stackups, where “1+N+1” means there are two layers of high-density interconnect (one on each side) sandwiching N layers of traditional PCB. This structure is often used in applications where moderate complexity is required, providing a balance between performance and cost.

Computerscreensize pixels

The Pixel Mill is a collaborative and accessible co-working space in the Ormeau Baths Innovation Centre for Northern Ireland’s interactive sector. Its mission is to encourage company and talent pool growth by providing office space which complements the funding, skills and talent development support funded by Northern Ireland Screen with support from the Department for the Economy.

The resources and facilities at The Pixel Mill are open to all of Northern Ireland’s interactive sector depending on availability. This includes:

Staggered vias are microvias that are offset from each other across layers. This design allows for more flexibility in routing and avoids overlapping, making it a popular choice for HDI PCBs that require complex routing.

Best Technology is the professional manufacturer of Metal Core PCB, ceramic PCB, FR4 PCB esp heavy copper PCB, 0.15-0.30mm extra thin PCB, Rigid-flex and PCBA (SMT), full turn-key service in China, with more than 18 years of experience, always reply within 12 hours, with best service at good price.

Browse Encyclopedia ... Also called "screen fade" or "phosphor burn," it refers to a permanent disfiguring of areas on a computer or TV screen when menu bars or ...

The Pixel Mill offers co-working desk space for companies and freelancers working within Northern Ireland’s interactive sector. Companies and/or freelancers can use The Pixel Mill for short periods of time depending on availability of space.

The HDI board uses the micro-blind hole technology to realize the circuit board design with high line distribution density, which is especially suitable for applications requiring high performance and high reliability. Compared with traditional PCBs, HDI boards have significant advantages in terms of volume, weight, wiring density and electrical performance, which can meet the electrical requirements of high-speed signals, provide impedance control of alternating current characteristics, high-frequency transmission capacity and reduce unnecessary radiation (EMI).

This entry was posted on Friday, September 27th, 2024 at 7:07 pm and is filed under best pcb, bestpcb, HDI PCB. You can follow any responses to this entry through the RSS 2.0 feed. You can leave a response, or trackback from your own site.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey