eizo lcd monitors manufacturer

Take a close look at an EIZO monitor and you"ll see that you can"t buy a monitor like this anywhere else. Our products are unique because we are a unique company in the monitor industry; we still design, manufacture, and quality control test our products in house. As more desktop LCD monitor brands outsource development and production to third parties, we remain convinced that the best way to deliver the quality that our customers expect is to retain control over our manufacturing and quality control processes. In fact, EIZO is the only remaining Japanese brand of desktop LCD monitors that still manufactures its products in Japan.

In this article, we take you on a step-by-step tour of how our FlexScan monitors are made – from assembly to packaging – at our global headquarters in Hakusan, Japan. FlexScan is our family of general use monitors for back offices, trading floors, SOHO, CAD/CAM, graphic design and amateur photography. FlexScan is the core of our monitor lineup. By volume, it accounts for more than 50% of our desktop LCD monitor sales. The design and feature sets of FlexScan monitors serve as the basis for some of our other product families such as RadiForce medical monitors, ColorEdge color management monitors, and FORIS home entertainment monitors.

With the acquisition of the medical monitor business from Siemens Automation and Drives in 2007 and the monitor business from eg-electronic GmbH in 2009, EIZO now also has manufacturing facilities in Germany.

EIZO manufacturers a wide variety of high-end monitors and display systems, including the industry-leading RadiForce, ColorEdge, FlexScan and DuraVision product lines.

When LCD monitors first became widely available in the late 1990"s, their bezel widths rivaled those of CRT monitors. EIZO changed all that with the release of the FlexScan L675, the world"s first thin-bezel desktop LCD monitor. With a bezel width of what at the time was a revolutionary18.5 mm, the L675 was an instant hit in trading rooms and back offices.

To commemorate five years of manufacturing LCD monitors, EIZO released "Placeo", a 17-inch model with an aluminum cabinet. Only 3,000 pieces of this limited edition monitor were manufactured.

The company established "EIZO Eco Products" as an eco logo with the purpose of ensuring its products meet an internal set of criteria for environmental consciousness. EIZO has since updated EIZO Eco Products three times.

Although the migration to LCD technology in the corporate world was well underway, professionals in color-critical fields such as pre-press and photography were still clinging to their aging CRTs. EIZO made it safe for them to finally make the switch when it introduced its ColorEdge series – the world"s first line of LCD monitors specifically targeted at graphics professionals.

Building on the initial success of its ColorEdge monitors, EIZO introduced the ColorEdge CG220, the world"s first LCD monitor capable of reproducing the Adobe RGB color space.

EIZO became the first stand-alone monitor manufacturer to receive ISO 13485 certification for the quality management system for its medical display devices.

EIZO acquired graphics board developer and manufacturer, Tech Source, Inc. of Florida, USA. With this acquisition, EIZO entered the air traffic control, military and defense, and command and control markets.

Later this year, EIZO acquired the medical monitor business of Germany"s Siemens A&D and established a new subsidiary, EIZO GmbH, in Karlsruhe, Germany. Through this acquisition, EIZO expanded its presence in the medical market, strengthened its R&D expertise, and now had production capability in Germany.

EIZO entered into a definitive agreement with eg-electronic GmbH of Wolfratshausen, Germany to acquire the latter"s business units for industrial monitors, air traffic control monitors, and monitor control boards. The acquisition was finalized in February 2009 and a new subsidiary, EIZO Technologies GmbH, in Wolfratshausen, Germany, officially began operations.

Previously only available in Japan, EIZO expanded its FORIS line of TVs to include PC monitors for home entertainment and released FORIS monitors worldwide.

Anticipating rapid growth in China for medical services and medical devices, EIZO established a wholly-owned subsidiary in China, EIZO Display Technologies (Suzhou) Co. Ltd., to manufacture medical monitors for the Chinese market.

EIZO established two wholly-owned subsidiaries, Europe GmbH (Germany) and EIZO Limited (United Kingdom), to expand its sales and marketing activities in Europe.

Take a close look at an EIZO monitor and you will see that you cannot buy a monitor like this anywhere else. Our products are unique because we are a unique company; we still design, manufacture, and quality control test our products in house. As more companies outsource development and production to third parties, we remain convinced that the best way to deliver the quality that our customers expect is to retain control over our manufacturing and quality control processes. In fact, EIZO is the only remaining Japanese brand of desktop LCD monitors that still manufactures its products in Japan.

In this article, we take you on a step-by-step tour of how our FlexScan EV-Series monitors are made – from assembly to packaging – at our global headquarters in Hakusan, Japan. FlexScan is our family of general use monitors for schools and offices, trading rooms, control rooms, CAD and more, and is the core of our monitor lineup. The design and feature sets of FlexScan monitors serve as the basis for some of our other product families such as RadiForce medical monitors, and ColorEdge color management monitors.

Our FlexScan monitor manufacturing process combines manual operations with automated ones to ensure high quality products made as efficiently as possible. Manual operations are performed for assembly tasks that cannot be automated or for verifying image quality to ensure it looks right to the human eye. Automated operations take advantage of robotic, CCD (charge coupled device) camera, and AI (artificial intelligence) technologies to more efficiently perform mechanical tasks such as the transportation of monitors across conveyors and image adjustment.

With the acquisition of the medical monitor business from Siemens Automation and Drives in 2007 and the monitor business from eg-electronic GmbH in 2009, EIZO now also has manufacturing facilities in Germany.

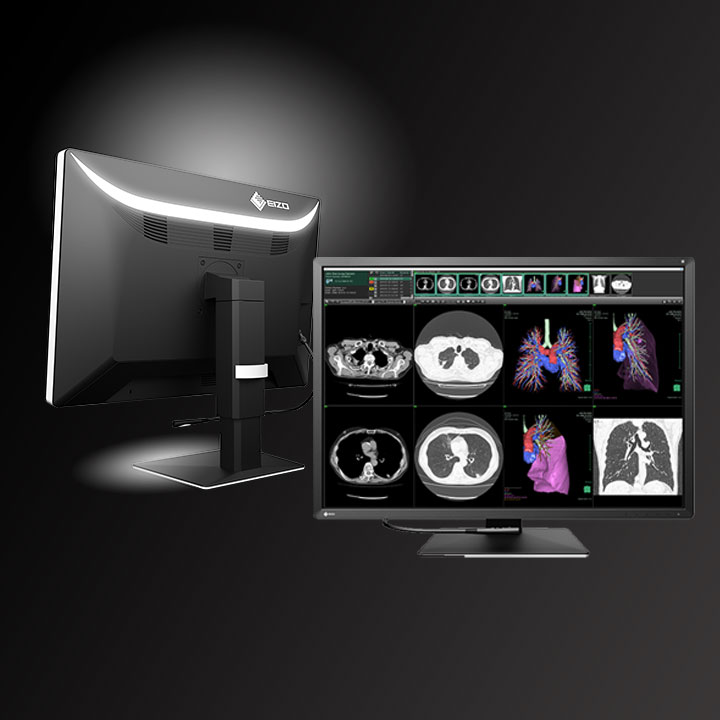

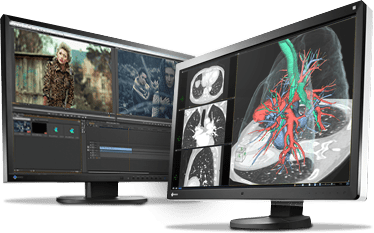

EIZO RadiForce medical imaging monitors have been at the forefront of the medical industry, helping professionals run effective diagnostics for x-rays, cross-sectional imaging, sonography, and endoscopy, to name a few.

The EIZO ColorEdge monitor range delivers extraordinary image quality with exact colour rendering and absolute colour fidelity to meet the demands of those working in graphics & print, photography, video content creation and other digital arts.

To meet the demands of today’s discerning customer, EIZO FlexScan monitors are divided in to 4 sub-categories - Traditional Square - Premium (USB-C docking and LAN Port) - Standard (USB-C & 4K options) - Basic (no USB-C & a "cost performance" price).

Eizo monitors last longer*, consume less energy and help eliminate eye strain and headaches from long days of monitor viewing. With excellent OH&S friendly ergonomics and a minimalist frame design (choose from black or white), FlexScan monitors seamlessly fit in with the decor of any home, office or studio.

The beginning of EIZO (the group) dates back to 1967. Nanao Electric Co., Ltd. was founded in Nanao City, Ishikawa Prefecture, and started by subcontracting production of a 14-inch monochrome TV the following year. Through the production of this monochrome television, the company gained a thorough quality control and mass production technique, and the starting point for its adherence to high-quality manufacturing was established.

In 1978, we began OEM (original equipment manufacturer) production for the smash hit arcade game Space Invaders. This game was originally in black and white, but did you know that it"s EIZO that colorized it? This was a demonstration of the development capabilities we had cultivated in TVs and other products.

In 1981, we built a factory in Hakusan City, Ishikawa Prefecture, where EIZO Corporation is now located. We expanded our production scale including our factory in Nanao, and started OEM production of video cassette recorders (VCRs) and radio cassette TVs in addition to CRT monitors for video games.

In the 1980s, PC use began to spread. In 1981, EIZO began OEM production of computer monitors, but as time passed our desire grew to release them to the world using our own brand name. Finally in 1985 we did just that with the release of a 12-inch CRT monitor called the "7030."

The first market we chose for the EIZO brand of CRT monitors was Europe because it is a culture that recognizes good quality. We decided to name our brand "EIZO" which is the Japanese word for "image." With the imaging technology we had cultivated as our foundation, we were determined to produce superb imaging products from then on.

In 1984, prior to completing our own brand of products, we went looking for distributors in Europe who would sell EIZO products. The most important consideration was whether or not they embraced the idea of selling "a good product at a reasonable price." We first signed contracts with distributors in Germany, Switzerland, Denmark, and the Netherlands. We then expanded our sales network into Austria, Sweden and Greece. A part of these distributors form the base of our current group companies and continue to sell EIZO products today.

In 1985, we expanded into the US by opening an office in California. Balancing quality and price in such a large country proved difficult, which made selling a challenge. But selling graphics boards with monitors that could display high resolutions proved to be a winning strategy and sales gradually improved.

The EIZO Group currently consists of 7 companies in Japan and 10 outside of Japan. Once every year, representatives from all EIZO group companies and sales distributors gather at the EIZO headquarters in Japan for an event called "EIZO United" where they can deepen their understanding of EIZO by seeing the latest products under development and having face-to-face meetings. In 2017, 86 people from 29 countries attended.

At EIZO Europe GmbH, one of our group companies in Germany, meeting rooms are named after cities in Japan. These cities include Hakusan (where the EIZO home office is located) and more well-known cities like Kyoto and Osaka.

By the end of the 1980s, EIZO CRT monitors had become highly regarded overseas and began to appear in Japan as reverse imports. Since the image quality of CRT monitors is affected by geomagnetism, we set up an area at our factory in Japan that reproduces the geomagnetism of the region the monitors were to be shipped to, and adjusted the image quality of each monitor individually. If used outside the intended area, color would not be displayed correctly which meant the EIZO monitors imported back to Japan may not have worked as intended. In 1991, we began the manufacture and sales of monitors for Japan under the brand name "NANAO" which was also the name of our company at the time.

In the early 1990s, CRT monitors reigned supreme. The transition to LCDs was anticipated, but commercialization was still a ways off in terms of technology and cost. However, EIZO got a head start by developing and producing the FA-1020 LCD monitor in 1993. The price at the time was one million Japanese yen (about 8,900 in today"s US dollars), and the product was a commercial flop, but our penchant for actively embracing the latest technology was embedded in our DNA 25 years ago with this product.

In the 1990s, we were engulfed in intense price competition due to the influence that the introduction of the Euro had on exchange rates and to the entry of major PC makers into the monitor market. In addition, shifting production to Southeast Asia where personnel expenses were lower was common. Prices declined worldwide and our business suffered. As a countermeasure, we decided to design a manufacturing line and train local workers as part of a plan to outsource production of monitors to Singapore. But then something happened. (To be continued next week.)

(Continued from last week.) We decided to cancel our plan to outsource production to Singapore just before implementation. The reason was that a company that emphasizes cost and shifts production overseas is one that will come to rely on simple cost reduction measures in the future. We feared this would destroy the corporate culture we had built up from pursuing high quality and high reliability. Instead of changing our production base, we switched to a policy of reducing costs by fundamentally changing the design. As a result of this incident in 1994, we succeeded in greatly lowering the price of our monitors while maintaining the quality and being chosen by even more customers.

In 1996, we unified our brand worldwide as EIZO after being known as EIZO in Europe and NANAO in Japan and North America. This brand unification led to further global expansion.

The color of the EIZO logo used since 1996 represents RGB (Red, Green, Blue) constituting the three primary colors of light. In addition, various meanings and thoughts were included in the design. Take a detailed look here.

In addition to renewing the EIZO brand logo in 1996, we also changed the product design. We changed not only the appearance, but also reviewed the internal design of the monitor from the ground up. In order to give it a more "human friendly" design* we incorporated the idea of ergonomics. This CRT monitor design received the Good Design Award"s "Long Life Design Award" in 2007 from the Japan Institute of Design Promotion.

In March 1997 we launched full-scale marketing of LCD monitors. The first model, the 13.8-inch FlexScan L23, had a standard price of about $3500 in today"s US dollars. In November of the same year, we released the 15-inch FlexScan L34. Because LCD monitors at the time had low resolutions and high prices compared to CRTs, initial sales were sluggish but they were gradually adopted for use in dealing rooms of financial institutions. Because one user used multiple monitors, adopting LCD monitors was much more effective in reducing installation space and power consumption compared to CRT monitors.

In 2001, we released the 18.1-inch FlexScan L675 which realized the world"s narrowest bezel width at the time of just 19 mm. It became a hit product with financial institutions. In addition to the narrow bezel width, it realized a height adjustable stand and screen rotation mechanism. In terms of image quality, it used an IPS panel with a wide viewing angle, so it had specifications that could be considered as a prototype of today"s LCD monitor.

We achieved a bezel width of 19 mm in 2001, then we achieved 11 mm in 2004, 6.9 mm in 2006, and finally 1 mm in 2015. Changing the structure of the liquid crystal panel as well as the evolution of the mechanical design of the monitor made it possible to narrow the frame to this point. The immersive feeling on the screen increases, and when you arrange multiple monitors side by side the non-display area between the screens becomes smaller allowing for use without any discomfort.

In commemoration of our fifth anniversary of the full-scale introduction of LCD monitors in 1997, we released 3,000 units worldwide of a limited edition 17-inch monitor called the FlexScan PLACEO in 2002. We overcame many challenges with the cabinet and surface such as making it from aluminum, with hair-line processing, shot blasting, and diamond cut processing.

Based on the trend of transferring X-rays and other medical images from film to data, we developed LCD monitors for medical image display and began selling them in 2002. Doing so required accurately expressing the subtle shading of X-ray images. In order to learn the basics of medical imaging we did things such as invite radiologists to give lectures to our employees.

Also, on Pink Ribbon Day in October, not only Japan but EIZO employees from around the world wear pink and conduct educational activities for breast cancer screening.

In 2003 we began developing and marketing LCD monitors for creative work markets such as photography and printing. At the time, it was still commonly recognized that the image quality of LCD monitors was inferior to that of CRT monitors, so we developed advanced functions such as hardware calibration to realize excellent image quality.

In the camera industry there are three major camera awards - TIPA and EISA in Europe and the Camera Grand Prix (DGP) in Japan. EIZO ColorEdge monitors have won all three - TIPA in 2005/2007/2009/2010, EISA in 2017, and the Grand Prix in 2008.

EIZO introduced a "working casual" (smart casual) dress code in 2003 in Japan. At the time, most companies in Japan had an informal dress code where suits were the norm. The idea behind this new dress code was to promote a work environment with more free thought.

In 2004, we began the development, production and sale of home LCD TVs in Japan with the aim of enhancing our video display technology. From this, FORIS.TV was born, with a fixation on "natural image," "natural sound," and "functional design with presence". The blue body color was based on the azure blue used in an important cultural asset called the "Seisonkaku Villa" in the city of Kanazawa which is next to the city of Hakusan where the EIZO headquarters is located.

In 2007, we acquired Tech Source (currently EIZO Rugged Solutions Inc.) in the USA. At the time, the company primarily developed graphics boards for air traffic control. With this acquisition, we made a full-fledged entry into the air traffic control market.

In 2007 we acquired the medical monitor business from Siemens AG in Germany and founded EIZO GmbH. The company has strengths in the field of medical image devices and operating rooms. By combining them with the expertise in reference viewing of diagnostic images we had at that time, it became possible to further strengthen our position in the healthcare market.

In 2009, we acquired the monitor and controller board business from eg-electronic of Germany. This company was engaged in the development, production, and sales of industrial monitors and air traffic control (ATC) monitors. This acquisition and the acquisition of Tech Source (developer of graphics boards for ATC) in 2007, allowed us to further strengthen our business in the ATC market.

On April 1, 2013, we changed our company name from EIZO Nanao Corporation to EIZO Corporation. The purpose of matching the brand name and the company name was to increase our global name recognition and achieve further growth. It was also a commitment to continue to respond to market expectations with video technology at our core.

In October of 2015, we acquired Imation Corporation"s medical system integration business in Japan through EIZO Medical Solutions Inc. The goal was to create a strong synergy by taking the hardware and software technology from our monitors and combining it with our expertise in quality control.

In 2016, we acquired the endoscopy monitor business from Panasonic Healthcare Co., Ltd. In 2017, we developed and began selling our first 3D surgical monitors under the EIZO brand.

EIZO offers products and services to various markets today which are loved by customers around the world. We introduce a small number of them on our case studies page so please have a look and see how customers around the world use EIZO.

EIZO MS Corporation in Hakui City, Ishikawa Prefecture, manufactures circuit boards used for EIZO monitors. Hundreds of tiny electronic parts such as capacitors are attached to the printed circuit boards and various inspections are carried out. The manufacturing of this circuit board is actually a very important point for the high reliability of EIZO monitors, so we undertake it ourselves within our company. The EIZO mark is stamped firmly on the board.

More than 80% of EIZO products are produced at the head office factory in Hakusan, Japan. In order to produce a wide range of products ranging from mass produced models to models produced in small quantities such as custom-made products, multiple types of production environments are used. One of them is an assembly process with a conveyor belt. It is suitable for mass production of the same model, mainly producing FlexScan monitors.

After the aging process, we adjust each monitor and then inspect them one by one. Through this survey and inspection process, the variation between products mentioned in last week"s post are removed. Even when using multiple EIZO monitors side by side, the difference in color and brightness between each screen is small, so you can use it with little discomfort.

Another one of the multiple production methods is cell production, which involves the aging, adjustment, and inspection of each unit. This is a production method suitable for high-variety, low-volume production, and what we use to produce RadiForce monitors for the healthcare market and ColorEdge for creative work. Color and brightness adjustments are much more detailed than for FlexScan and take more time. A special adjustment process to eliminate differences in brightness across the screen is also part of this production method.

In a new factory which began operation in July 2016 at our headquarters in Japan, we employ a hybrid production method which adopts the good points of the conveyor belt method and the cell production method. After the assembly process, the monitor is automatically transported to a 3-story adjustment rack, where a movable adjustment camera system adjusts each monitor individually. By using this system, we can produce various types of monitors more flexibly.

We have introduced various processes for producing our monitors. Many of these processes are automated, but the last one is a visual check conducted by our employees. Only experienced workers may conduct this check.

To meet the requirements of the maritime market and the healthcare market, we have processing facilities for optical bonding in our company. Optical bonding is a technique that fills the gap between an LCD module and panel with a layer of resin to adhere them together. By minimizing the refractive index of light, you can improve visibility, and reduce glare caused by the reflection of external light on the screen. Please check this out for details. http://www.eizoglobal.com/library/basics/eizo_optical_bonding/index.html

We also conduct various tests at the product development stage. One is an electromagnetic compatibility (EMC) test to examine the resistance to radio waves from the outside of the product and the magnitude of interference emitted from the product. Previously, we asked an external specialty agency to conduct this test, but in 2001 we set up our own facility at EIZO. In this facility, called an anechoic chamber, we take measurements by shielding out radio waves from the outside. You won"t be receiving any mobile phone calls in this room!

Well, this is the 50th and final episode about EIZO. Have you enjoyed learning about the evolution of EIZO"s business that started with OEM black and white TVs 50th Anniversary ago, and various traits that make EIZO what it is today?

Fulfill your dream PC setup with our wide range ofrefurbished computer monitors. Shop items from leading technology brands like Dell, HP, Samsung, Lenovo, Acer, LG, and more. Whether you’re building a PC or need an extra screen to help you complete tasks more efficiently, there’s always one for you at PC Liquidations. Bulk discounts for quantity purchases available online, take a look at our LCD monitors that have quantity discounts.

Our used monitors have been professionally refurbished. This means that although they have been used before, qualified technicians have tested and restored them to a fully functional state. With our LED monitors, you get crisp color and brand-new display quality at a fraction of the price.

The competition in technology has never been tighter, but it is our goal to deliver top-notch performance without the hefty price. Here at PC Liquidations, we aim to offer the best gaming or viewing displays for your home or office. Save up to 70% on our latest selections when you connect your computer with monitors from our store.

There are two types of monitors you can use: Liquid Crystal Display (LCD) or Light Emitting Diode (LED). The difference between the two is that LCD uses fluorescent lights as backlight while LED uses light-emitting diodes, which allows it to deliver superior image quality.

If you have a computer with a monitor, you can use it as a TV at home. Otherwise, you can purchase one here at PC Liquidations. We feature an extensive selection of monitors from the leading screen manufacturers, such as Dell, Sony, and Samsung.

Refurbished PC monitors come at a low price compared to brand-new ones. Here at PCLiquidations, you can often purchase one in as low as $35 depending on our inventory. This will depend on the screen size as well as the brand you’re getting. Whatever your price preference, you’re always assured of outstanding resolution and excellent performance.

The Eizo RX560 is the world’s first medical monitor to use low temperature polysilicon (LTPS) liquid crystal display. Because of this, the color monitor can reach a brightness of up to 1100 cd/m2, similar to that of monochrome monitors. Due to this high brightness, the Eizo RX560 can display high-definition monochrome breast tomosynthesis and mammography images with deep blacks and no washout in addition to color images such as ultrasound and pathology.

EIZO with an earned reputation in the industry has nearly 50 years of experience producing the highest quality visual technology and is well trusted amongst top professionals. With ultra-high 4K resolution you’re ensuring exact consistency in your production. Let your imagination soar and your creativity blossom. Your passion will guide you and the EIZO ColorEdge will ensure that you can express your ideas precisely as you have imagined. EIZO’s expertise in developing visual image displays for professional applications now extends to a diverse lineup of 4K monitors.

Automatic color calibration technology allows for improved accuracy despite complex arrangements. With an EIZO LCD monitor, you’re investing in the highest caliber of design capabilities. These professional-grade tools are what industry leaders depend on to protect their brands. Eizo Monitors define the frontier of digital imaging and provide designers the space to push their work to the edge while maintaining unwavering quality.

EIZO Rugged Solutions offers a wide range of commercial off-the-shelf (COTS) electronic hardware products targeted at video capture, processing, display, compression, streaming, recording, video format conversion, GPGPU computing, Artificial Intelligence (AI), and data archiving. The graphics and video products are based on our own GPU technology as well as that from NVIDIA® and AMD®. All of EIZO’s rugged products, including displays, are developed in-house by EIZO to ensure complete control of product quality as well as extended product life cycles.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey