how to repair lcd touch screen manufacturer

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

The main control buttons may be faulty. Clean them with a metal cleaner, or jostle to attach a loose connection. If necessary, locate the circuit board they are attached to and re-solder any broken connections.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

Touch Screens: Plazmo"s state of the art manufacturing facilities have the capabilities to produce various types of touch screens. Our customers appreciate our attention to detail and ability to produce premium quality OEM replacements for many different sizes, styles of touch screens.

Touch panels, or touch screens, have become an integral part of everyday for millions and millions of people around the world. Daily uses include Bank ATMs, ticket vending machines, car navigation, kiosks, gaming and casinos, handheld video games, industrial control panels, smartphones and tablet devices.

Depending on the application"s use and volume, touch screen panels can wear out from daily operation. Many factors come into play such as outdoor elements, oils from fingers, heavy stylus use, mineral spirits, alcohol, fuel, gasoline and other fluids. When the touch screen impacts the utility of the device or the customer experience, it"s time to look at replacement. The good news is replacing a touch screen is much more cost effective than replacing the entire LCD screen. Plazmo manufactures premium quality OEM touch panel replacements for all manufacturers and applications.

Resistive Film Touch Screens: This popular method is also called pressure sensing or analog-resistive film. These are used in a wide range of applications. With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached.

Capacitive Touch Screens: These are probably the second most widely used. There are two types: surface or projected. Surface capacitive panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover.

Projected capacitive touch screens are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover.

These panel types feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch screens.

On the other hand, these touch screens require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface Acoustic Wave (SAW) Touch Screens: these panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Weak points include compatibility with only fingers and soft objects (such as gloves) that absorb ultrasound surface elastic waves. These panels require special-purpose styluses and may react to substances like water drops or small insects on the panel.

Optical (Infrared) Touch Screens: The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

Electromagnetic Induction Touch Screens: This type differs somewhat from the above touch panels and is used primarily in specialty devices like LCD graphics tablets, tablet PCs, and photo sticker booths. Since the technology was intended for use in graphics tablets, it offers superior sensor precision. However, since a special-purpose stylus is used for input, input using a finger or a general-purpose stylus is not possible, and the method has limited applications.

“The ‘critical down’ machine tool is back up and running! Our engineers say the screen is brighter than it’s ever been! Moving forward, we’re going to keep your company very busy!”

“We’re back up and running. I’m still in shock that you were able to repair the terminal! The manufacturer kept telling us that the unit was beyond repair. The parts were not available and that we needed to purchase a new terminal. You saved us over $5500!”

“We have received and installed the repaired LCD into our system, and it’s working fine. Thank you again for your fast, courteous service. If we ever need your assistance again we’ll certainly let you know.”

“I am very impressed with the quality of work and how clean the monitors were returned (especially the new glass). Going forth, I will send all my repairs to CRC Systems!”

The touch screen is a device that integrates display and touch control. Because the touch system is a bridge for man-machine dialogue, it has a wide range of contacts with people, and it is composed of glass as the main body, which is relatively fragile, and the failure and breakage rate is relatively high compared to other devices. At this time,the problem thateveryone is most concerned about is here, what should I do when the screen encounters a malfunction during use? Can I repair it myself? What basic maintenance needs to know?

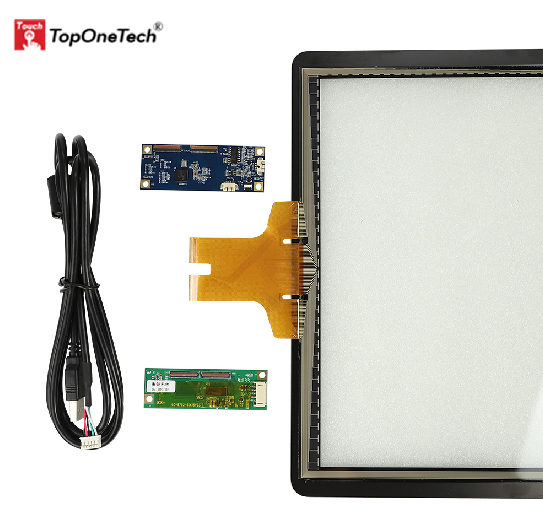

Touch screens repair needs to be equipped with advanced testing equipment and sufficient spare parts, including a large number of brands of touch lenses, LCD screens, circuit boards, and other spare parts stocks. There are various technical data, which can provide users with fast and high-quality touch screen repair skills and maintenanceservices.

The composition of the touch screen: touch detection components, touch screen controller. The touch screen detection component is installed on the front of the display screen to detect the user"s touch position and send it to the touch screen controller after acceptance. The main function of the touch screen controller is to receive touch information from the touchpoint detection device and convert it into touch point coordinates, and then send it to the CPU, and at the same time receive the signal sent by the CPU and execute it.

1. Communication failure, the communication program of the lower computer is not set correctly, the touch screen address is not set correctly, the communication line is short-circuited or not connected correctly, the communication port is burned out, poor contact etc. will cause communication failures, you can first eliminate and confirm from these aspects one by one.

2. The touch is not working. It is usually caused by the positional deviation of the LCD display and the corresponding buttons of the glass. There is also aging of the touch panel, which can be corrected according to the calibration center point function provided by the touch screen supplier. The aging on needsto replace the touch panel and some are caused by pollution. Generally, cleaning thetouch panel cansolve the problem.

3. Circuit board failure requires maintenance personnel who mastercertain circuit principles and have a certain degree of practical ability tosolve the problem. Generally, touch screens use highlyintegrated chips such as DSP as the control core. When repairing, you need to compare the touch screen and analyze the specific internal structure.

4. The LCD on the display screen has no display or incomplete display, most of which are due to the aging of the liquid crystal, which is also dealt with by replacement. Another reason is that the driver of the liquid crystal is damaged, and the circuit board needs to be repaired.

5. Touch the glass. This is the place where you have the most contact with people and the surface that is most likely to cause problems. Generally, this type of failure is caused by the user. The only way to deal with it is to replace it.

First, check whether the wiring interfaces are loose, and then check whether there is a conflict between the serial port and the interrupt number. If there is a conflict, adjust the resources to avoid the conflict. Then check whether there are cracks on the surface of the touch screen. If there are cracks, replace them in time. It is also necessary to check whether there is dirt on the surface of the touch screen. If there is, use a soft cloth to remove it. Observe and check whether the indicator light on the control box is working properly. When it is normal, the indicator light is green and flashing.

In some applications, due to poor grounding performance, the enclosure of the control box is filled with a large amount of static electricity, which affects the working electric field inside the control box and causes failure. At this time, use a wire to ground the control box shell and restart it.

When the touch screen is clicked, its work is extremely unstable, sometimes it can be clicked normally, sometimes there is no response. In view of this phenomenon, you should focus on checking whether each wiring interface is loose, whether there is a conflict between the serial port and the interrupt number.

There are many techniques for touch screen repair. Its repair method is very close to that of repairing ordinary electrical products. If you encounter a touch screen problem that cannot be judged on your own, please consult us and we will answer you. Every time Top One Tech sells a touch screen, we willprovide customers with the best after-sales service, check, analyze, and solve problems forcustomers.

If you own a smartphone, you’re very familiar with a touchscreen. You likely also understand the pain of a touchscreen which isn’t working properly. Touchscreens are sensitive & responsive by design, but keeping them in good condition can be challenging in an industrial setting. Here are common issues that crop up:

Touch screens are typically able to sense which area of the screen is being touched, and then use that input to facilitate a corresponding action. Sometimes though, a touch screen can lose its calibration and misinterpret a user’s touch, or be unable to sense user touches at all. In some cases, users can follow the screen prompts or use other peripheral tools to recalibrate the screen on their own. If that doesn’t work, then it’s time for you to call the pros at AES!

Touch screens can become scratched or worn with any sort of normal use, but those problems can be quickly compounded in a more challenging industrial environment. With enough scratches or cracks, your screen can become difficult to read. Worse still, it can develop some dead spots or other issues. Any type of impact or shock can also cause a touch screen to malfunction.

It’s not just regular contact that can wear a touch screen down. Exposure to contaminants like dirt, moisture, grease, or even oils from your skin can cause some external damage, and can even work its way inside to damage internal components, as well. Contamination is a prime cause of early failure for all sorts of electronic equipment, and that’s even more true for sensitive devices like touch screens.

Even if you try to be conscientious about taking care of your touch screen, sometimes an operating error can still occur. This can happen due to a variety of reasons, including user input error, software issues, hardware issues, glitches in the electrical circuitry, power surges, etc. If you’ve done everything you know to do on the outside, the problem may lie inside. The good news is that the AES team is trained to work on all internal components of touch screens!

Got a bad display or unresponsive touchscreen? AES can help! Just send your touchscreen display to us, and let our expert team take a look. We can diagnose any problems quickly, clearly communicate with you what the solution will require, and then we’ll get to work on making it happen!

At AES, we’ve been providing successful repairs on all sorts of electronic equipment and machinery – including industrial monitors, touchscreens, and operator interfaces – since 1992! Offering effective repairs that help to keep you running – while also benefiting your bottom line – is why we’re here! Learn more about what makes AES different:

At AES, we understand that you really need your equipment repaired and restored NOW! Well, that’s what we do! Of course, a quality touch screen repair will require some time & effort to complete it correctly. But the good news is that we work both hard and smart! We maintain a fast, standard turnaround time of 8-12 business days, but we also get it done sooner if you want to place a RUSH on your order. We’ll do our best to meet your time requirements!

Some may see it as old-fashioned, but AES is proud to say we still believe it’s worth doing right, if it’s worth doing at all. We’ll do the repair job right for you the first time, and every time! We utilize full-load testing so we can accurately diagnose any performance issues or other problems, and we’ll make sure your repair is completed correctly before we ever return your equipment back to you.

Not to overstate it, but at AES, we truly believe there’s not a better industrial electronics repair team in the business! Our technicians possess literally decades of on-the-job experience…we know what we’re doing! Plus, we go beyond what we already know, to also provide ongoing training opportunities for our team. That way, we know we’ll be well-equipped to serve your needs in the future, too.

Why pay to replace a touch screen or other expensive piece of electronic equipment, when AES can repair it and get it back to you fast, FOR LESS? We can get your touch screen back up and running correctly again, plus we’ll save you some valuable time, money, and potential frustration in the process.

And here’s one more convincing reason to entrust AES with your repair business. We don’t just say that we do good work; we actually stand behind it by offering a 24-Month Limited Warranty for ALL REPAIRS! What does that mean for you? If a problem should arise during that time period, which is deemed to be a repair workmanship issue, AES will provide follow-up repair service for you at NO additional cost! Now, that’s service!

Ready to get your touchscreen or other industrial monitors back online and back to serving your needs effectively? We can make that happen for you at AES! Reach out today at (866) 386-1001, and let’s get the conversation started! We can help!

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

When your LCD display has broken, needs replaced or simply needs a technology upgrade, and you have design/equipment elements to consider, you will want to look for a replacement part instead of replacing the unit.Problems may arise when you are sourcing the new panel from your original manufacturer.For example, by the time your panel has degraded, your LCD may be end of life, making it difficult to source;original manufacturers may be charging premium prices for their replacementLCD parts.AGDisplays offers a drop in replacement service for customers who need to replace an LCD or LCD component when their original panel/part is unavailable;this service is also for customers who are looking for a cost effective, suitable replacement or upgrade to their existing LCD. AGDisplays offers availability of standard or custom high-quality LCDs of virtually all shapes and sizes.

Replacing or upgrading the LCD component of your equipment sounds intimidating. It is rather simple if you begin your search with AGDisplays. By simply providing us with your panel part number, general specifications (if possible) and any other upgrade requirements or desires that you might have, we source these products for you or we can source an equivalent replacement, as desired. Using a replacement LCD does not compromise on quality and compatibility;we ensure functionality and performance are top priority because we know how critical the LCD interface is for your application.

You may receive notifications from your original equipment manufacturer about your LCD panel. There are a couple of announcements to pay attention to. The most important two are the end of life (EOL) announcement and the end of sale date. The end of life announcement will officialize a future cease production date for the indicated part number. It may also indicate the end of sale date, which is the last date customers are able to order the product through the manufacturer. After this date, the product will no longer be for sale. Typically end of life announcements come six to twelve months before the last time buy date. A few months later is when your last time buy will ship.

If you decide by this point that your equipment is well suited to use the LCD replacement, you may want to grab these panels when they get into the last time buy phase. If you find yourself ready to upgrade after EOL and last time buys have passed, don’t fret.A drop in replacement unit extends the lifecycle of your unit in the case of EOL or unavailability of original parts. Products are matched for compatible integration without compromising quality. AGDisplays offers a full line of compatible replacement industrial LCD display systems. When your design requires an upgrade in features but you still want to retrofit the LCD into your existing equipment, AGDisplays works together with you, discussing requirements and performance options. Our experts have an eye on the safety and longevity of your electrical components. We source alternative panel with same specifications to replace the panel in your equipment. Our drop in replacement LCD displays are selected carefully, with safe and stable compatibility in mind.

AGDisplays provides our customers with the opportunity to replace LCD or components so you can avoid having to spend big bucks to OEM companies. With AGDisplays, our customers receive unparalleled attention and support without the hefty price tag that you may get elsewhere.

There are many signs an LCD will give the user to indicate that it may be due for replacement or upgrade. Even users who are not LCD experts will be able to tell when it is time to replace.

Outwardly, your LCD will show physical signs of damage such as a cracked or scratched, foggy or contaminated screen.Mostly, these damages are quickly noticeable to the naked eye and the first obvious sign that your panel may need a replacement. These are clear indications that the outside of your LCD has been damaged and is in need of evaluation or replacement. The application environment will determine the urgency in which you’ll want to replace the LCD. Cracks in the LCD may leave the LCD vulnerable to contamination and dust, which in turn can extend damage and/or decrease visual readability of the display.

Most LED technology estimate LED lifetimes to be upwards of 100,000 hours of useful life. This works out to be about six hours of usage a day—and 45 years of service, whew! So one can assume that LCD components will fail before the LED backlighting system will degrade. However, degradation does happen with long term usage. If your LCD is looking less bright than it should be, it is possible that a component in the display’s backlighting system needs replaced or upgraded.

LCDs that are broken internally may only show a black screen, a white screen, or even show no data when turned on. Other indications will be white/grey/black discoloration spots (called mura) of the display itself when it is turned on, regardless of the data/color that is shown on screen.

Another indication of a dying LCD aredamaged pixels. If you notice a small speck of white or black on your screen that does not go away, even as the screen changes, you may have a damaged pixel or two. There are a few different types of pixel defects, hot, stuck and dead pixels. Hot pixels present themselves as always ‘on,’ they always appear white in color. Dead pixels are always ‘off,’ and look black at all times. Now a stuck pixel is either stuck ‘on’ or ‘off’ so they may appear the same as a hot or dead pixel. These (sometimes) are solved by switching from bright to dark colored screens quickly to unstick these. However, this isn’t a reliable treatment for stuck pixels.

If you’ve notice defective pixels on your LCD screen, do not panic! Some manufacturers have a standard in which it allows a certain amount of pixels in production. Overall, if the LCD in question has an increased rebellion of pixels, whether hot, dead or stuck, the LCD may be of low quality or the pixels are going bad.

Sometimes white, black or multi colored streaks appear running horizontally or vertically along the display. If this is happening on every screen, this is a likely sign that something is wrong inside the LCD.

Signs of LCD degradation include those missing pixels, the dimming of screen brightness over time, and even the loss of color and contrast in a display. If you need more assurance the LCD is the problem, consult AGDisplays to discuss our replacement options.

If your car or truck factory radio LCD with touchscreen monitor needs replaced then we provide some of the best replacement car touch LCD screen replacement parts available on the market today. As is Factory Radio Parts standard: all of our car touchscreen repair kits are developed for both ease of use and functionality – so you can get your tunes blasting again in no time!

Car touchscreen damaged? Car radio or car DVD player not working? Let us provide you with 8.4” touchscreen parts, VP3 and VP4 radio replacement touch screens, MyFord touch sync 2 radio screens, RB5 RE2 radio replacement screens from Uconnect, 439 RBZ, 430N and 730N touch screen repairs and 7 inch screens. We supply big names like Ford Lincoln Clarion Navigation replacement parts, Toyota Tundra Panasonic touch screen fixes, RAM Truck, Chevrolet, Cadillac and more!

All new parts orders are subject to a strict 14 day return for refund policy. If the 14 days have gone by since receipt of your purchase, unfortunately we can’t offer you a refund but an exchange option is available if applicable.All new parts arecovered by our FRP 90 day exchange guarantee starting from the day the customer receives their item in addition to the manufacturers stated warranty. This warranty covers new parts and accessories not damaged or damaged due to accidents not caused by human involvement. Only one warranty replacement allowed per customer within the 90 day or optional 1 year period.

FRP will not be held liable or responsible for any installation of products purchased through our site by a third party. We do not provide any recommendations for repairs outside of our own professional services. If a product purchased through our website is damaged during installation by a third party, FRP will not be held liable for replacing the damaged part. Customers assume all costs and risk associated with any installations services not done by FRP. No reimbursements will be given.

All "new parts" orders are subject to a strict 14 day return for refund policy. If the 14 days have gone by since your purchase, unfortunately we can’t offer you a refund but an exchange option is available. You must contact our Support department before the end of the 13th day after your purchase date to receive your return label. See "Shipping" section below.Absolutely no refunds will be processed after the 14th day.

To be eligible for a return for refund, your item must be unused (if new) and in the same condition that you received it. It must also be in the original packaging and be within the 14 day window.

If you are an international customer (this includes Canada, Mexico, PR, HI), our system will not generate a return label because your address is classified as International by USPS, who generates all return labels. You will be responsible for any shipping costs associated with returning your order. Shipping fees are not eligible for a refund on all International orders.

Please be advised: To be eligible for a return for refund, your item must be unused (if new) and in the same condition that you received it. It must also be in the original packaging and be within the 14 day window.

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment; typically within 7-10 business days. Absolutely no refunds after 14 days of receipt of order.

We only replace items if they are received defective or damaged. Please do not ship a broken item back to us. If you need to exchange an item for an identical item, please send us an email to sales@factoryradioparts.com.

Further instructions will be provided on how to successfully complete our simple Exchange process. Please allow up to 10 business days to receive your exchange part.

PLEASE ALWAYS SEND AN EMAIL FIRST BEFORE PLACING AN ORDER IF YOU HAVE ANY QUESTIONS OUR WEBSITE DOES NOT ANSWER FOR YOU DIRECTLY!SALES@FACTORYRADIOPARTS.COM

Once you have found the correct part number, see HP Consumer Notebook PCs - Ordering HP certified replacement parts. Use the instructions in this document to order a replacement part.

HP recommends that you only order parts from an authorized HP repair parts dealer. Parts ordered from third-party companies might not perform as expected and might cause additional

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Unlike our competitors, RO Company is not in the business of trying to sell you any ELO Monitors or equipment, as we are strictly a repair company. Our goal is to provide you and your company with a satisfactory repair of your ELO touch screen monitor. We look forward to offering you professional customer service and working with you for many years to come.

The following is a list of the models of ELO Touch screen monitor repairs we work on. We offer service for more than what is shown here. If the model number of your touch screen monitor is not shown here, it is very likely we can be of assistance. Contact usfor more information.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey