lcd module light bleed price

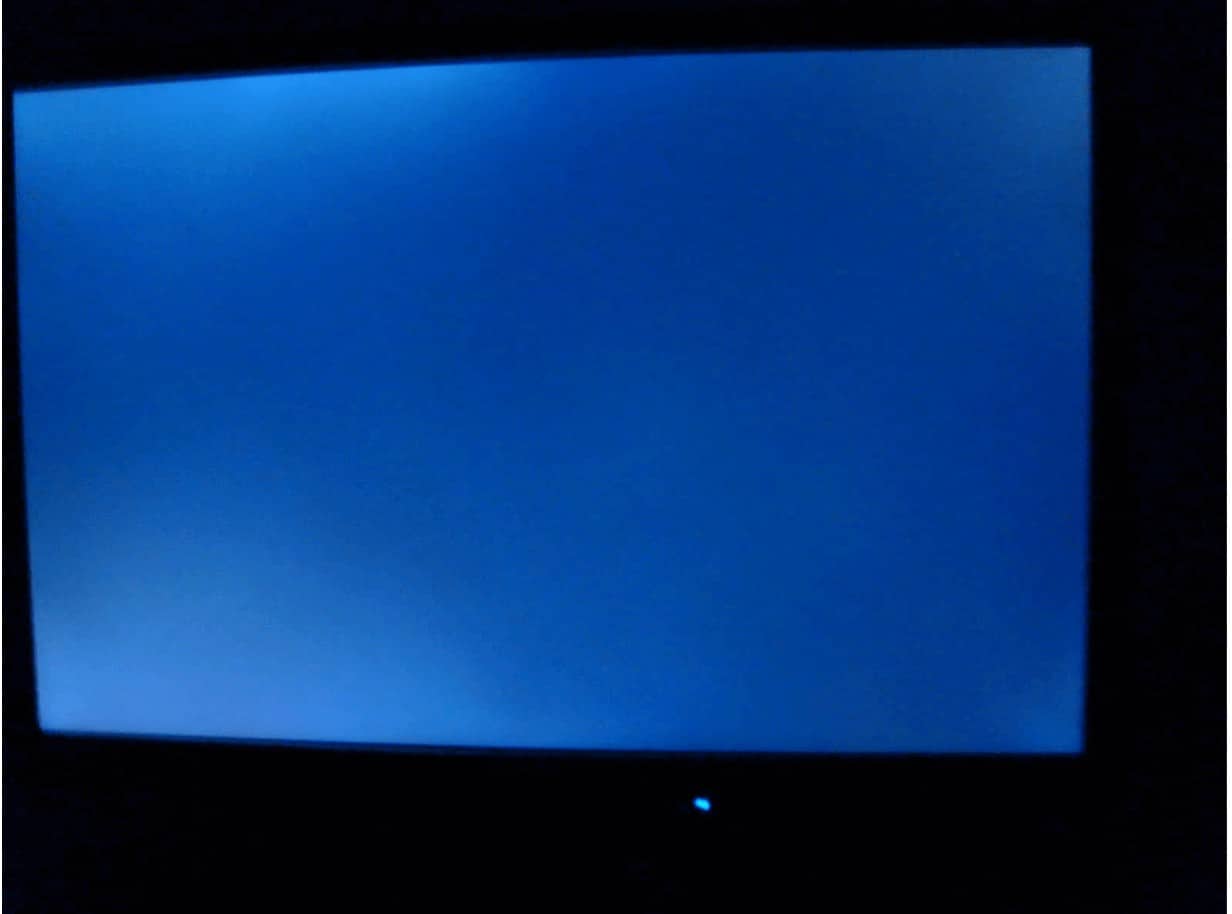

Backlight bleed is characterized as light leaking around the edges or corners of an LCD. This is due to the way these displays work; they use a light behind the panel that faces the display.

Backlight bleeding is simply some of the backlight leaking through. There are no ways to completely remove this, though it can be reduced in some scenarios. If you have too much backlight bleeding, you might be able to RMA your display.

Your LED LCD, whether it’s a TV or a monitor, uses a LED backlight to create the image through the liquid crystal display panel. Some of that light might not get entirely blocked around the display’s bezels, which results in backlight bleeding.

Generally, some minor backlight bleeding is expected due to the nature of the display technology, and it is entirely tolerable given you won’t even notice it most of the time.

However, sometimes the backlight bleeding can be rather eye-searing and, in this case, you may be able to return your display and get a new model or a refund depending on the manufacturer’s RMA policy.

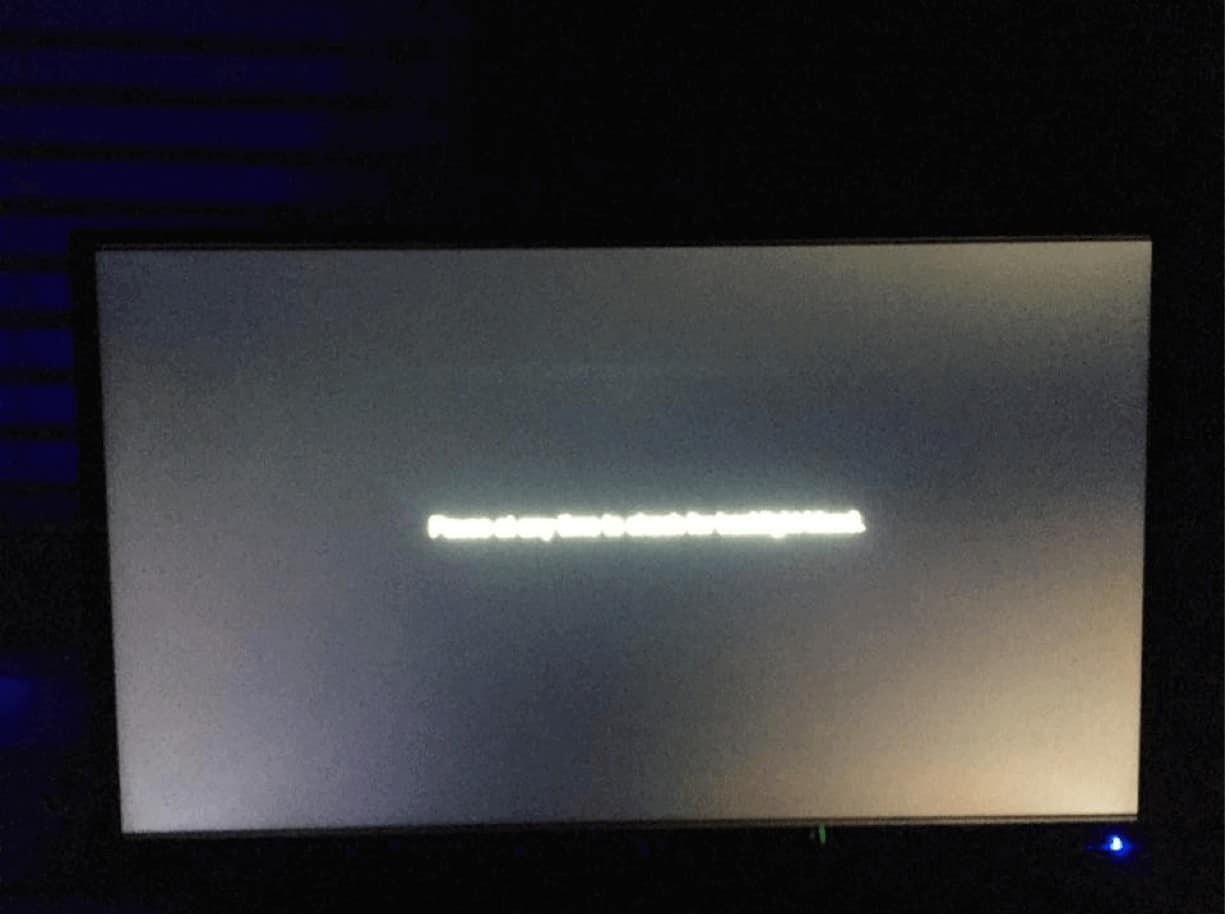

The flashlighting issue, as the name suggests, looks as if someone’s pointing a flashlight at the screen, thus creating bright patches at the corners of the screen.

In short, if you are experiencing too much backlight bleeding, you should try to RMA your display. In case the display manufacturer won’t accept it, you will have to get a new monitor/TV, preferably with an OLED panel that doesn’t suffer from these issues (but has other drawbacks).

In case the backlight bleeding doesn’t bother you in real use, it’s not worth returning or replacing the display as another unit might have even worse backlight bleeding or other defects, such as dead or stuck pixels.

Unlike backlight bleeding, the intensity of IPS glow can be reduced by changing the angle or the distance you’re looking at the screen or by decreasing screen brightness and adding bias lighting behind the screen.

tanay229 wrote:HeyI dropped a mac from a very small height, and it got a dent on back of the display which has caused very minimal backlight bleed on one corner. My MacBook pro is in warranty period, but I am guessing the repair is still pretty expensive. I am a college student and cant afford such expensive repair again. Is there any advice on how to deal with this? I can honestly manage with the current backlight bleed if it doesn"t get worse. Can it get worse? If the dent is only on one corner, then how could the backlight bleed spread?

In this post I’ll talk about pressure stains and light leaks and if you’d like it will be a pleasure for me to tell about other defects in the next post!

Light leak/ bleed is backlight shining through where it is not supposed to. Most often it can be seen on edges of the screen and in some cases as smaller spots in various areas.

Backlight is at the back of the screen and it allows you to see the actual picture as otherwise you would have to use a flashlight to see anything:) if one of the layers is slightly misaligned from the edge it creates light leakage in that area.

looks like a small bright spot or some times similar to a normal light leak and are caused by some internal components like screws or sharp board edges in the monitor/tablet/phone pressing against some of the panel layers causing them to stretch and letting more light to go through. In some cases pressure applied at the factory by workers during assembly can cause a pressure stain.

Electronic/structural function is not achieved, such as display isabnormal, speaker output sound distorted, battery cannot be charged,the expansion interface /UI no function, buttons no function, LED indicator lights’ status is incorrect, imperfect paintwork etc.There is bias on electronic/structural function, such as the display brightness is not up to the standard, speaker volume is soft, structure gap exceeds the standard etc.

from 1,00,000 screens 50% have no visually identifiable light leak from a typical end user viewing distance. 25% have minor light leak that can be seen. 20% have average light leak that most people would find annoying. 5% have SEVERE light leak.

*Some of you might think that calculation above is unfair as it does not include RMA (consumer return) costs. While it’s true! In the end of the day not so many people go for service and often times light leak is a grey zone in warranty of the product. *

Immediately upon receiving it I noticed some prominent backlight bleed but it’s not anything major. Though, major to me is different than it is to a lot of people. The bleed bugs me quite a bit, even though it’s just a little bit in the corner.

After seeing mine, my grandfather decided to order the same monitor and holy crap does it make mine look perfect. The backlight bleed on it is terrible in comparison, not to mention even more noticeable glow and a red stuck pixel right in the center of the screen.

I realize we’re talking about bargain basement monitors at this price. Should I stop being a baby and just live with the little bit of bleed I have, or send it back and play the LCD lottery again to try to get something just a bit better...even though getting something like the abomination my grandfather received is a definite possibility.

I think you need to understand that there are LCD monitors, and there are LCD monitors ! I have seen "so called " professional monitors where the issues with the backlight and the bleeding of colour , meant that the delta E variances were huge from area to area.

So if you are trying to output professional material and almost pre press proof onscreen, then there is little choice but to shell out the larger wedge required. I have to say that this has become an adventure for me over the last couple of years . I have had a few monitors stand on my desk for a week or two, and in some cases three replacements from the manufacturer. The last of which was sent to their agents in the UK for checking prior to delivery ..... and the answer, after testing it , was NO THANKS ! The screen suffered from a fundamental error in design, and huff and puff all you like, the backlight error was incurable. However I would suggest that you interview a few candidates of your own . Not when they are running the software that fakes the game, but spoils the best Delta E"s , and not when they are set up with a "show" image on a display.... but on your table being worked with, calibrated and run through their paces. I have to say that I would suggest that somewhere in that parade of suitors you allow an Eizo space to entertain.

If you produce lighting systems for products, you may be wondering how to fix backlight bleed on an overlay. Backlight bleed can be a frustrating issue, but there are some things you can do to reduce it. Read on to learn more about light guide design, backlight bleed and ways to reduce it.

Think of backlight bleed as an annoying leak. When you add graphic overlays to devices, every icon within the overlay is individually lit by an LED bulb behind it. Ideally, when a user touches a single icon, it lights up but the rest of the screen remains dark.

The issue is that light naturally wants to go everywhere. When a user pushes one icon on the screen, other icons will brighten because the LED light is spilling over into other sections of the screen.

Backlight bleed is more common in capacitive touch applications. Many of these devices contain graphic overlays that have multiple icons or buttons. Given the thinness of these applications and the minimal space between the icons and LEDs behind them, uncontrolled light leaks across the overlay.

While some minor backlight bleed is expected and even tolerable, it can also be too apparent. It even leads users to assume their devices are malfunctioning or broken.

We’ve helped our clients minimize backlight bleed with years of experimentation and finetuning. Our innovative light guide design adds different design features for better backlight control.

Cutout design – A cost-effective option to decrease light bleed is to make cuts with our in-house lasers directly into the light guides. These cutouts allow for better light blockage and control. While some light escapes the guide, it won’t spill over into unintended areas of the overlay.

Housing (with ribs) design – We’ve developed another solution that leverages white plastic housing with “ribs” or raised features that slide into the cutouts of the light guide. The housing ribs reflect light back into the light guide instead of letting it pass through any air gaps and into the neighboring section. The downside to this option is that the plastic housing adds more weight to the light guide, so it’s not always ideal for ultra-thin applications.

Foam design – Instead of housing ribs, we insert black foam to absorb escaping light. While this design is similar to a light guide with housing, the foam isn’t bulky and you can maintain a thin assembly.

Overmold design – Our overmold design is multiple small light guides with cutouts, fused together with a plastic molding to block backlight bleed. This process allows for no additional components (housings or foam) to be added to the assembly while still blocking light bleed. While this option is highly effective, it does require additional mold tooling and design, which makes it more expensive.

The right light guide design depends on your project requirements, volume and budget. However, it can be difficult to make the smartest decision without a B2B custom light guide partner on your side.

Our lighting experts help determine which option will deliver the absolute best results. We use our optical software to simulate where backlight bleed may occur within a given graphic overlay. This is just one way we work closely with you during a light guide design engagement.

![]()

The problem you are facing is moisture has gotten trapped between the defuser sheets that spread the backlight out across the screen and the polarizer sheet. While heat can cause the moisture to evaporate out, the solids and minerals within the liquid or water will leave a stain which could be pronounced or very faint.

If you do attempt to do this you will need to be mindful these sheets can be easily wrinkled which will cause the light to be distorted and will require a clean dust free work area as any dust left behind will be noticeable.

I know if I wait long enough it will get way worse. However, I want to prevent what I had a while ago: due to another issue my tablet got some physical damage. I wasn"t happy with that damage, but I was able to live with it. However, the light bleed is really

That is the key point, these Alienware laptops are not cheap. They are premium products so how does a company like Dell not have better quality control on laptops that sell for upwards of $4000? I love everything about the m17 R3 but I"m not going accept a laptop with this much backlight bleed. I"m now going to try my luck with another brand.

here. I took a few photos. In my case, if there is any backlight unevenness it appears to be mostly on the right side…? or bottom left corner perhaps? I don’t know, but I don’t notice it in real use scenarios.

This article is about backlights in liquid crystal displays. For the rear window of an automobile, see Car glass. For the lighting design practice, see Backlighting (lighting design). For other uses, see Backlight (disambiguation).

A backlight is a form of illumination used in liquid crystal displays (LCDs). As LCDs do not produce light by themselves—unlike, for example, cathode ray tube (CRT), plasma (PDP) or OLED displays—they need illumination (ambient light or a special light source) to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches,smart phones, computer displays and LCD televisions to produce light in a manner similar to a CRT display. A review of some early backlighting schemes for LCDs is given in a report Engineering and Technology History by Peter J. Wild.

Simple types of LCDs such as in pocket calculators are built without an internal light source, requiring external light sources to convey the display image to the user. Most LCD screens, however, are built with an internal light source. Such screens consist of several layers. The backlight is usually the first layer from the back. Light valves then vary the amount of light reaching the eye, by blocking its passage in some way. Most use a fixed polarizing filter and a switching one, to block the undesired light.

An ELP gives off uniform light over its entire surface, but other backlights frequently employ a diffuser to provide even lighting from an uneven source.

Backlights come in many colors. Monochrome LCDs typically have yellow, green, blue, or white backlights, while color displays use white backlights that cover most of the color spectrum.

Colored LED backlighting is most commonly used in small, inexpensive LCD panels. White LED backlighting is becoming dominant. ELP backlighting is often used for larger displays or when even backlighting is important; it can also be either colored or white. An ELP must be driven by relatively highAC power, which is provided by an inverter circuit. CCFL backlights are used on larger displays such as computer monitors, and are typically white in color; these also require the use of an inverter and diffuser. Incandescent backlighting was used by early LCD panels to achieve high brightness, but the limited life and excess heat produced by incandescent bulbs were severe limitations. The heat generated by incandescent bulbs typically requires the bulbs to be mounted away from the display to prevent damage.

For several years (until about 2010), the preferred backlight for matrix-addressed large LCD panels such as in monitors and TVs was based on a cold-cathode fluorescent lamp (CCFL) by using two CCFLs at opposite edges of the LCD or by an array of CCFLs behind the LCD (see picture of an array with 18 CCFLs for a 40-inch LCD TV). Due to the disadvantages in comparison with LED illumination (higher voltage and power needed, thicker panel design, no high-speed switching, faster aging), LED backlighting is becoming more popular.

LED backlighting in color screens comes in two varieties: white LED backlights and RGB LED backlights.blue LED with broad spectrum yellow phosphor to result in the emission of white light. However, because the spectral curve peaks at yellow, it is a poor match to the transmission peaks of the red and green color filters of the LCD. This causes the red and green primaries to shift toward yellow, reducing the color gamut of the display.a red, a blue, and a green LED and can be controlled to produce different color temperatures of white. RGB LEDs for backlighting are found in high end color proofing displays such as the HP DreamColor LP2480zx monitor or selected HP EliteBook notebooks, as well as more recent consumer-grade displays such as Dell"s Studio series laptops which have an optional RGB LED display.

RGB LEDs can deliver an enormous color gamut to screens.additive color) the backlight can produce a color spectrum that closely matches the color filters in the LCD pixels themselves. In this way, the filter passband can be narrowed so that each color component lets only a very narrow band of spectrum through the LCD. This improves the efficiency of the display since less light is blocked when white is displayed. Also, the actual red, green, and blue points can be moved farther out so that the display is capable of reproducing more vivid colors.

A newNanosys, claims that the color output of the dots can be tuned precisely by controlling the size of the nanocrystals. Other companies pursuing this method are Nanoco Group PLC (UK), QD Vision, 3M a licensee of Nanosys and Avantama of Switzerland.Sony has adapted Quantum Dot technology from the US company QD Visionedge-lit LED backlight marketed under the term Triluminos in 2013. With a blue LED and optimized nanocrystals for green and red colors in front of it, the resulting combined white light allows for an equivalent or better color gamut than that emitted by a more expensive set of three RGB LEDs. At the Consumer Electronics Show 2015, Samsung Electronics, LG Electronics, the Chinese TCL Corporation and Sony showed QD-enhanced LED-backlighting of LCD TVs.

CCFL backlighting has also improved in this respect. Many LCD models, from cheap TN-displays to color proofing S-IPS or S-PVA panels, have wide gamut CCFLs representing more than 95% of the NTSC color specification.

There are several challenges with LED backlights. Uniformity is hard to achieve, especially as the LEDs age, with each LED aging at a different rate. Also, the use of three separate light sources for red, green, and blue means that the white point of the display can move as the LEDs age at different rates; white LEDs are also affected by this phenomenon, with changes of several hundred kelvins being recorded. White LEDs also suffer from blue shifts at higher temperatures varying from 3141K to 3222K for 10 °C to 80 °C respectively.Benq G2420HDB consumer display has a 49W consumption compared to the 24W of the LED version of the same display (G2420HDBL).

To overcome the aforementioned challenges with RGB and white LED backlights an "advanced remote phosphor" cockpit displays,Air Traffic Control displays and medical displays. This technology uses blue pump LEDs in combination with a sheet on which phosphorous luminescent materials are printed for colour conversion. The principle is similar to Quantum Dots, but the phosphors applied are much more robust than the quantum dot nano-particles for applications that require long lifetime in more demanding operational conditions. Because the phosphor sheet is placed at a distance (remote) of the LED it experiences much less temperature stress than phosphors in white LEDs. As a result, the white point is less dependent on individual LEDs, and degrading of individual LEDs over lifetime, leading to a more homogenous backlight with improved colour consistency and lower lumen depreciation.

The use of LED backlights in notebook computers has been growing. Sony has used LED backlights in some of its higher-end slim VAIO notebooks since 2005, and Fujitsu introduced notebooks with LED backlights in 2006. In 2007, Asus, Dell, and Apple introduced LED backlights into some of their notebook models. As of 2008Lenovo has also announced LED-backlit notebooks. In October 2008, Apple announced that it would be using LED backlights for all of its notebooks and new 24-inch Apple Cinema Display, and one year later it introduced a new LED iMac, meaning all of Apple"s new computer screens are now LED. Almost every laptop with a 16:9 display introduced since September 2009 uses LED-backlit panels. This is also the case for most LCD television sets, which are marketed in some countries under the misleading name LED TV, although the image is still generated by an LCD panel.

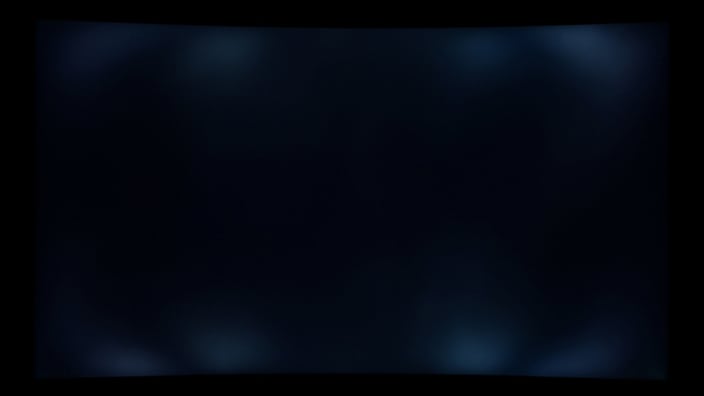

Most LED backlights for LCDs are edge-lit, i.e. several LEDs are placed at the edges of a lightguide (Light guide plate, LGP), which distributes the light behind the LC panel. Advantages of this technique are the very thin flat-panel construction and low cost. A more expensive version is called full-array or direct LED and consists of many LEDs placed behind the LC panel (an array of LEDs), such that large panels can be evenly illuminated. This arrangement allows for local dimming to obtain darker black pixels depending on the image displayed.

Using PWM (pulse-width modulation, a technology where the intensity of the LEDs are kept constant, but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources

For a non-ELP backlight to produce even lighting, which is critical for displays, the light is first passed through a lightguide (Light guide plate, LGP) - a specially designed layer of plastic that diffuses the light through a series of unevenly spaced bumps. The density of bumps increases further away from the light source according to a diffusion equation. The diffused light then travels to either side of the diffuser; the front faces the actual LCD panel, the back has a reflector to guide otherwise wasted light back toward the LCD panel. The reflector is sometimes made of aluminum foil or a simple white-pigmented surface.

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

The evolution of energy standards and the increasing public expectations regarding power consumption have made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

The Evolution of LED Backlights; Adam Simmons; PCM PC monitors, Monitor articles, 12 November 2017; "The Evolution of LED Backlights | PC Monitors". Archived from the original on 1 December 2017. Retrieved 27 November 2017.

Dimming options for LCD brightness; J. Moronski; Electronicproducts.com; 3 Januari 2004; "Dimming options for LCD brightness control". March 2004. Archived from the original on 28 July 2017. Retrieved 20 November 2017.

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; "Archived copy" (PDF). Archived from the original (PDF) on 1 August 2017. Retrieved 20 November 2017.link)

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; Mantel, Claire; Burini, Nino; Nadernejad, Ehsan; Korhonen, Jari; Forchhammer, Soren; Pedersen, Jesper Meldgaard (2013). "Controlling Power Consumption for Displays with Backlight Dimming". Journal of Display Technology. 9 (12): 933–941. Bibcode:2013JDisT...9..933M. doi:10.1109/JDT.2013.2260131. S2CID 24082090.

Thanks for your help MiguelD. I did check for blown pixels with several YouTube RGB videos and they seem ok as far as I can tell. I was really looking forward to the 32" display size, but even ignoring the bleeding on dark images, you can"t use the left and right 2-3 inches of the screen without shifting my body to look at that area straight on and eliminate the bronzing / orange coloration. Defeats the purpose of the size.

It"s amazing how bad it looks as soon as you look at a darker or low key image. After I started this thread, I made my wife sit in front of the BenQ screen and look at the corners. She thought I was doing my usual complain about everything / perfectionist thing, but the bronzing in the corners and bleed was immediately obvious to her. I really just want / need a new display that looks decent without obvious problems anyone would notice.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey