5 tft display 3d case brands

After some inspiration from Raspberry Pi cases i have decided to design a more aesthetic model with smoother surfaces and easier mounting mechanisms, hence i intend to put this as the new project forward.

...You will have to buy this lcd kit for the raspberry pi. You will have to power supply the pi trough the gpio connection. https://www.aliexpress.com/item/Best-Price-Original-3-5-LCD-TFT-Touch-Screen-Display-for-Raspberry-Pi-2-Model-B/32508151978.html

This is remix of "PanelDue 7i & 5i Cases with flexible mounts" for [Waveshare 5" HDMI LCD (H) version](https://www.waveshare.com/wiki/5inch_HDMI_LCD_(H)).

I whipped up this case for my 5" touchscreen LCD for my Raspberry Pi I got off Aliexpress Ideally this is meant for OctoPrint and OctoScreen/ OctoDash but honestly it could work for anything. In my setup I tap off of the 24v PSU on the Ender 3 and...

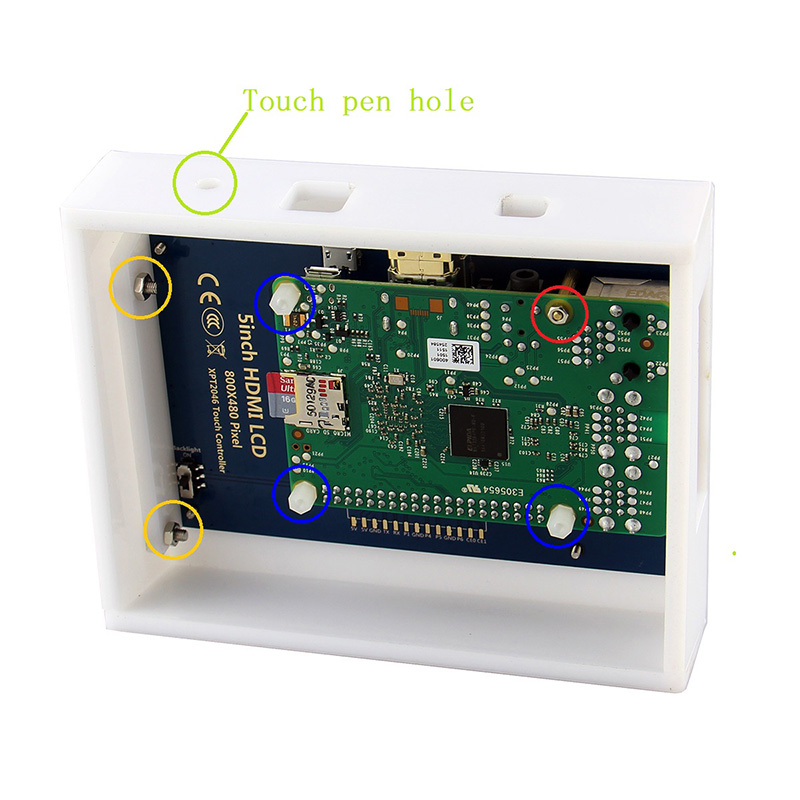

Raspberry Pi 5 inch lcd case Fits the Raspberry pi 5 inch HDMI display-B with capacitive touch LCD screen found here - https://www.aliexpress.com/item/1005002550189338.html Edit: Reprinted with a carbon effect on the front.

Raspberry Pi 5 inch lcd case Fits the Raspberry pi 5 inch HDMI display-B with capacitive touch LCD screen found here - https://www.aliexpress.com/item/1005002550189338.html Edit: Reprinted with a carbon effect on the front. Category: Gadgets

Hello, this is remix of this project (good job!): https://www.thingiverse.com/thing:3679054 My lcd had higher lcd, so i decided to change front part by adding 2mm of height.

This is the case for an independent OctoPi system suitable for my 5 inch touch LCD, Raspberry Pi 3 and stand for Pi Camera. Includes a stand where i mounted the Camera. Also i included guides for the camera cable, mounted in the arm pieces. I used...

This case is for Elecrow"s (waveshare) 5 inch lcd screen. This is part of a project to create modular components for a portable handheld gaming system. This way novices can assemble any models they want to use and essentially "snap" them together to...

it"s based on raspberry Pi and 5 inch GPIO HDMI touch screen, you can buy it from links below:http://www.52pi.com/en/lcd-display/83-5-inch-800x480-hdmi-tft-lcd-touch-screen-for-raspberry-pi-32-model-bb-ab.html and you can get the user manual from...

If you"re looking for the smallest case for Raspberry Pi with Waveshare 3.5" Touch LCD with out too much additional add-ons, this will be the ideal one to fill in both.

......If you"re looking for the smallest case for Raspberry Pi with Waveshare 3.5" Touch LCD with out too much additional add-ons, this will be the ideal one to fit in both.

This is a case and stand for the Raspberry Pi and the 5-inch Waveshare HDMI Touchscreen LCD. https://www.waveshare.com/5inch-HDMI-LCD.htm https://www.waveshare.com/wiki/5inch_HDMI_LCD ### Description The Raspberry Pi header connects directly to the...

This is a case for Raspberry Pi 4 with 3.5 inch TFT/LCD Display. It is a tight fit and may require some wriggling to fit the PI in. ...This is a very simple and a sleek case.

This is a case for a 7 inch LCD screen, this one right here: https://www.amazon.ca/gp/product/B071X8H5FB/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 There are other cases out there but I wanted something that used less material and didn"t take...

The screen itself is nice and seems to work as advertized, but the little stand/case is a nightmare to assemble, and it doesn"t actually assemble correctly without some slight modifications on your behalf. First, it"s not actually a finsihed black like they have in the picture, mine is black around the edges, but the surface sections look like it"s made out of tough cardboard. I"m assuming it"s ABS 3D printed, but I"m not sure. In either care, unless you want to spray paint it, it"s not going to be shiny black like the pic. Also, there"s no instructions for how to assemble to case. Lot"s of instructions on how to get the screen working, but none on how to assemble the case. There"s some type of video on the sellers website for something, but the video was removed so I don"t know if that was the assembly instructions or not. It took me a few tries to figure out how to assemble the case, and once I figured it out, I also figured out that some of the parts don"t fit correctly. There are 4 column spacers that attach to the back of the LCD screen that are used to secure the RPi to the screen, except the screws on the back of the LCD screen are not long enough once you put the back piece on. Only a little nub of the screw sticks out, and it"s not enough for the column spacer to get a grip. I modified it by using a dremel to sand down the hole edges and to widen the hole a little bit. If I did something wrong then it"s because of the lack of clear instructions, so Longruner, I would suggest getting some better instructions posted somewhere.

5) After the programming is completed, open the config.txt file in the root directory of the TF card, add the following code at the end of config.txt, save and eject the TF card safely.

6) Power on the Raspberry Pi and wait for a few seconds until the LCD displays normally. And the touch function can also work after the system starts.

I was rebuilding one of my 3D printers — again — and decided I needed a display upgrade. A color screen is nice, but there are some limitations. I also found there are ways around these limitations, so I wanted to share my thoughts on a dual-mode color touch screen LCD controller for your 3D printer. The screen in question is a TFT35 from BigTree Tech. It is similar to an MKS screen, but it can operate in two different modes, as you will see.

A few years ago, I picked up an Anet A8 which was very inexpensive, especially on sale. Not the best printer, though, because it has that cheap acrylic frame. No problem. A box full of aluminum extrusion later, the printer was reborn. Over time, I’ve completely reworked the extrusion system and the Y-axis, leaving only the motors, bearings, and the controller/display as the original.

There’s another way to control a printer, and it’s one you may have thought of before. Since the printer accepts commands via a serial port, you could take a computer like a Raspberry Pi with a nice LCD and just have it issue commands to the serial port. Bonus points if the board has more than one serial port so you can still hook up a PC or a Raspberry Pi running Octoprint or similar. Turns out, you don’t have to build this. The MKS touchscreen uses an ARM chip (it isn’t a Pi, though) and has a touch screen that you can use to control the printer. These come in different sizes and are usually called something like TFT35 for 3.5 inch display.

The advantage isn’t just appearance. Having a bunch of touch screen buttons makes many things easier. For example, if the printer is at (0,0) and you want to jog the head to (100,200), that ends up being a lot of button pushes in Marlin. With the touch display, you can bring up a navigation screen that makes it easy. Or, you can bring up an entire terminal and enter G-code. When you press Send, it shows the results of the command, if any. You can set a temperature with the knob, on-screen buttons, or press the number and type in what you want with a virtual keypad.

These displays are colorful and nice, but there are a few things they can’t do. Marlin has some wizards and user interaction that insist on a proper, local LCD. But the Marlin code thinks the MKS display is a remote host computer, connected over serial. Displays that can act like both types of LCDs are a sweet hack, and here’s the part that was never clear to me before: these displays can switch modes during printer operation. In other words, it is not a case of selecting a mode and rebooting everything. You can be looking at the colorful touchscreen, then switch over to the stock display while printing and then switch back any time you want. The best of both worlds.

On the face of it, the display looks like an MKS TFT. You have colorful menus and a touch screen. The connection for that is a simple two-wire serial port, along with — of course — power, ground, and an optional reset connection. They provide a cable you can use or modify to connect to your setup. There is also an EXT3 port for boards that have that connector.

If all you want is an MKS display, you are done. Since the display looks like a host computer, you don’t even have to recompile Marlin if the serial port you used was active. In my case, the second serial port wasn’t set up, so I had to recompile, but I do that often enough, anyway.

However, if you wire the normal EXT1 and EXT2 ribbon cables to your printer, the display can emulate a normal 128×64 LCD. If you are already set up to use one of these displays, you should not need to recompile Marlin to use this display. However, if you are set up for a different type of display, you’ll need to tell Marlin to use the normal “REPRAP DISCOUNT GRAPHICS CONTROLLER.”

Here’s what I never understood about the device. Looking at the write-up about it on different vendor sites like Amazon, Banggood, or AliExpress, it sounded like you could use the screen in either mode as a static configuration choice. In other words, you might wire up EXT1 and EXT2 and then use the emulated mode until you decided to switch over to serial at some future date. But that’s not how it works. You can connect all the cables and switch back and forth between display systems on the fly.

That’s huge. It means you can have a nice user interface that lets you control the printer, print from an SD card or USB stick, and even make customizations to the menu with the source code provided on GitHub or with a simple configuration file edit. (And, yes, you can add custom menu items simply.) But when you need to do something very specific to Marlin, or a new feature shows up that the LCD doesn’t know about yet, you can simply switch to the Marlin display mode. Then you can switch back.

If you use a bezel, be careful. If you tighten a case down enough to make the touch screen think you are pressing the screen, you’ll get stuck in the selection mode, which makes sense. Just don’t overtighten the LCD!

Installing the LCD was straightforward save a few problems. For some reason, the pin 1 designation for EXP1 and EXP2 are not consistent among vendors. A Geeetech display worked fine with the Spider board, but the TFT35 didn’t want to come up in Marlin mode at all. I applied power at the serial port and the board appeared hung. The answer was to snip off the alignment tabs on the ribbon cables and flip them 180 degrees.

The serial port was also a mystery. With so little documentation on anything, I just soldered the power and ground wires and then hand twisted RX and TX so I could swap them until it worked. As I expected, the cable needed a cross on those lines to work. You also have to match the display’s baud rate to the port you are using.

After that, it all worked fine. The EXP1 and EXP2 connectors do connect to the board’s reset, so you don’t need to wire the serial port’s reset pin if you have those connected. However, I did notice that switching the mainboard to DFU mode will sometimes fail with the display plugged in. Reflashing the display requires an SD card that flashes a binary file and then reboots and loads fonts and icons. If it is connected to the Spider, it sometimes hangs when trying to reboot during an update. It also works sometimes, though, so I suspect it is just loading on the reset line. In any event, popping the connectors will make it work if you don’t want to try repeatedly.

The display has a number of other ports, but you probably shouldn’t use them. For example, there’s a port for a filament runout sensor. But if you connect it there, it will only work if you are printing using an SD card or USB stick in the display. A better option is to connect it to your printer and tell Marlin to notify the host if a filament break occurs. This will work with the display or something like Octoprint.

In theory, you should be able to connect Octoprint itself through one of the extra serial ports. However, I never got this to fully work. The subordinate port seems to work pretty well, but it never sends Octoprint acknowledgments so Octoprint waits forever or until you force it to continue — use the Fake Acknowledgment button in the terminal. Since the Spider has multiple serial ports, it isn’t a big deal, but in theory, the TFT should work a little better if it can intercept and filter the data stream between the printer and the host software. In practice, I don’t really notice any problems. Some Octoprint plugins like DisplayLayer can send status information to the TFT, anyway.

Another note: Using the jog keys sets the printer to relative mode. If you are used to popping codes into a terminal, you might want to get used to issuing a G90 before you send a move because the TFT will change it to relative anytime you do a jog.

These displays are inexpensive and easy to interface and since they can still work as a classic display, there’s no reason not to do this easy upgrade. There are plenty of mounting options you can print, of course. The finished result looks great and doing things like moving in both X and Y are much easier with the new display.

The Artillery Sidewinder X2 is a large 3D printer that has some notable limitations, such as its build quality and sometimes confusing user interface. However, it is a decent machine and can be a great solution for your voluminous 3D printing needs if you are willing to look past its shortcomings.

The Artillery Sidewinder X2 also comes with several new additions that promise to improve your 3D printing, so it is time that we put it to the test and see if it is one of the best 3D printers under

These days, 3D printers are used in various applications, from education and prototyping to advanced things like bioprinting organs. In the drone hobby, many DIY enthusiasts started to print their spare parts and accessories for long time ago. Lately, Free Zillion, founder of RaceWhoop Facebook group, designed a ducted drone that is almost entirely 3D printed. The concept became quickly popular due to its durability and simplicity in build. For this project is recommended to use filaments with g

Artillery3D has been making desktop 3D printers since 2018. Based in Shenzhen China. According to their website they were ranked amongst the top 10 desktop FDM 3D printing manufacturers by 2019. Today we are reviewing their latest FDM entry into the space and also their first Bowden style 3D printer, it’s aimed at the Ender 3 market with similar features and a competitive price point. The Hornet is currently listed for $359 CAD/ 259 USD.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey