rhodium in lcd screen brands

I used a different tool to separate the glass from the adhesive holding it to the aluminum on the back. I haven"t seen any of those screens your talking about. If you have some clear looking plastic that acts like a magnifying glass, it"s probably a fresnel lens. I"ve got a number here somewhere for a company that recycles and sells LCD screens. You can put some in with the circuit boards to be refined but they don"t want too many in there so they (SIPI) gave me a number but now I can"t find it, might have to call them back. So I put all the little LCD"s in with the boards like from phones games and calculators and save the large ones. That other pane of glass I just broke it up and threw it in with my other screens, I ain"t messing with it.

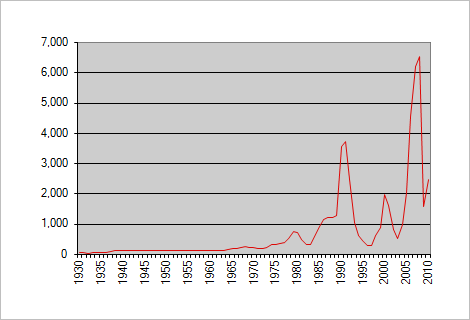

On May 19, 2011, Deutsche Bank issued db Physical Rhodium ETC securities.Johnson Matthey recently (Nov. 15, 2011) forecast that the metal will remain in surplus (by 123,000 troy ounces (one troy ounce (oz) = 31.10 grams)) in 2011, and now its price has fallen from a "stratospheric" level of over $10,000/oz in June 2008 to "languish" around $1,700 (midprice on Nov. 30, 2011), somewhat lower than that of gold. So, what"s with rhodium?

The platinum group metals, or PGMs, of which rhodium is one, are a group of six metals clumped together pretty much in the middle of the periodic table. The others are iridium, osmium, palladium, platinum and ruthenium. The metal, which is extremely difficult to separate from the other metals with which it naturally occurs (including the other PGMs), is always produced as a byproduct of the extraction of these others; no such thing as a rhodium mine exists.

The English chemist, William Hyde Wollaston discovered the metal in 1803, soon after he discovered palladium and around the same time Smithson Tennant (also English) discovered both osmium and iridium. The rarity of the metal, the fact that it is a byproduct, and the complexity of (and costs involved in) its extraction have all, historically, contributed to robust pricing over the last 80 years, and especially in the last couple of decades.

An autocatalyst, which sits inside a motor vehicle"s catalytic converter (itself placed between its engine and muffler), is a metal, or ceramic, honeycomb coated with PGMs (of which rhodium is one) and various chemicals.

In gasoline-poweredvehicles, the autocatalyst converts over 90 percent of the carbon monoxide, oxides of nitrogen and unburned hydrocarbons into carbon dioxide, nitrogen and water vapor (often appearing as drips from out of the auto"s muffler). In diesel-powered vehicles, in addition to the equivalent amounts of hydrocarbons and carbon monoxide that are converted to more harmless compounds, so too is 30-40 percent of the potentially carcinogenic diesel particulate matter.

Since the first production vehicle was fitted with a catalytic converter back in 1974, their use has flourished and now catalytic converters are fitted to over 85 percent of all the new vehicles sold each year worldwide.

To put the effects they have in context, back in 1960, a gasoline-powered vehicle would typically, for every mile driven, spew out 100 grams of carbon monoxide, hydrocarbons and oxides of nitrogen. By 2004, this had been reduced to just some 2 grams, and autocatalyst development continues today.

Rhodium, because of its hardness and both its resistance to corrosion and high melting point (higher than that of platinum), is currently used in three main types of glass manufacturing, that of: thin-film transistor liquid crystal display (TFT-LCD) panels, glass fibers and, increasingly, in solar photovoltaic (PV) panels.

In the manufacture of TFT-LCD panels (used in TVs, monitors and displays), platinum and rhodium are used to line the channels, melting tanks and stirring cells, not only because they can withstand temperatures up to 1,650ºC, but also because they are inert. This last is of particular importance, as the glass substrate cannot contain any charge-bearing particles that may interfere with the function of the TFT laid down on it.

In the manufacture of glass fibers, the molten glass is drawn through an array of many tiny, uniform, orifices or nozzles, set in what is called a bushing — essentially just a box out of which they stick. These nozzles are made of a platinum/rhodium alloy.

Finally, rhodium is also used in the manufacture of the glass used in solar panels, which are required to be as defect free as possible and "highly transmissive."

In the chemical industry, rhodium catalysts are used in the production of aldehyde, which, with hydrogenation, leads to an oxo-alcohol, and in the production of acetic acid using the Monsanto process. (According to Johnson Matthey, the rising demand for rhodium in the chemical sector is being driven "by downstream demand for paints and adhesives, particularly in China.")

It will come as no surprise that by far the largest producer of rhodium is South Africa, which, in 2011, is forecast to produce some 650,000 oz out a total global supply figure for the mined metal of an estimated 768,000 oz. Recycling of autocatalysts is anticipated to amount to some 260,000 oz in 2011.

Source: Forecast production figures from Johnson Matthey, who notes that: "Supply figures represent estimates of sales by the mines of primary pgm and are allocated to where the initial mining took place rather than the location of refining."

Since primary rhodium is produced only alongside other PGMs, on the mining front, anyway, no rhodium mining "pure play" exists. And the big rhodium producers are, therefore, necessarily, the big producers of the other PGMs.

Investors can invest directly, buying the physical metal in ingot or as sponge, and "directly" through, e.g., Deutsche Bank"s Physical Rhodium ETC, this last giving the investor an entitlement to the physical metal.

As to the rationale behind an investment in rhodium, there a number of factors that should be carefully considered. Some of the more obvious are: Rhodium is, first and foremost, an industrial metal — with all that implies

There is also one other aspect of investing in rhodium (and some other industrial metals) that should be considered. While, according to Johnson Matthey, net inflows (to late September) to the Deutsche Bank ETC accounted only for about 14,000 oz, were such inflows to become significant, then any investment decision would need to factor in such demand, in addition to that from industry. This can only add further complexity to the investment process.

LONDON, Jan 10 (Reuters) - Prices of precious metal rhodium surged to a record high of $7,025 an ounce on Thursday as consumers in the glass-making and auto industries scrambled for scarce supplies, traders said.

Dealers said rhodiumwas quoted at $7,000/$7,050 an ounce, a gain of more than 25 percent since January last year and compared with the previous record high of $7,000 seen in 1980. On Wednesday it was quoted around $6,975/$7,025 an ounce.

Most rhodium is used by car makers in catalytic converters to limit carbon emissions, where regulations have become much stricter and contributed to rising demand for the metal.

Traders say that has been a major factor behind rhodium’s price rise over the last two years. Another is growing demand from glass makers ramping up production of flat panel screens used for televisions and computers.

South Africa is the world’s biggest producer of rhodium, which is a by-product of platinum. Supply disruptions in the country in recent months also have boosted rhodium prices.

During the manufacturing process, the molten glass is fed through a trough that is made out of the alloy, which can stand extreme heat and won’t melt.

Last December Corning announced capital expenditure between $1.5 billion to $1.7 billion to build additional capacity to meet growing demand for large flat-panel televisions.

“We expect that the LCD glass market will continue to grow into the next decade,” said James B. Flaws chief financial officer at Corning said on the company’s website.

Corning has previously said that it expects the overall LCD glass market to reach 1.7 billion square feet of glass in 2007 and to grow again by at least 400 million square feet in 2008.

Back in the old days, TVs were heavier, bulkier and hotter (literally), remember? All this thanks to something called cathode ray tube or CRT. Without them, we most probably would not be able to watch our favourite movies or series the way we do today. Now that we are in a new era of display technology, CRTs have been abandoned fast. But their story does not have to end just yet because, well, recycling. In this work by SIM² KU Leuven researchers and published in the Journal Hydrometallurgy a new method is proposed to recover valuable rare earth elements from waste CRT phosphor powder. (MRO, 1/12/2018)

CRT is simply a glass vacuum tube where on one end there is a cathode creating electrons and on the other an anode screen attracting those electrons. The screen is covered with a special fluorescent powder (or CRT phosphor powder) that can light up by the electrons thereby enabling a colorful display. This powder contains a certain compound doped with a special element for production of each main color. Valuable rare earth elements (REEs) are present as yttrium and europium in the red phosphor Y2O2S:Eu3+ (YOS). For the green and blue colors, zinc sulfide (ZnS) based phosphors doped with silver and copper are used. The screen of a CRT device contains on average 7 g of luminescent powder.

CRT technology was developed several decades ago, vastly used in display units (e.g. TVs and computers) and, like everything else, reached its downfall. Especially after the early 2000s, a new era began when new and more efficient (and fancier) display technologies like liquid crystal display (LCD) or light emitting diode (LED) became popular. This development accelerated the disposal and accumulation of waste electronics containing CRTs. However, such wastes are hazardous when it comes to their landfilling due to toxic elements (e.g. cadmium and lead) present in the CRT structure. This clearly necessitated strict regulations to manage them in several countries but also allowing readily available waste stream for recycling. Even then, it is not possible to fully free the fluorescent powder from the surrounding materials such as glass and aluminium flakes.

Because of the sulfidic nature of YOS and ZnS, conventional acid leaching needs an oxidising agent, causes toxic H2S gas formation as well as co-dissolution of lead and other contaminants. In order to avoid these problems, we developed a new recycling flow sheet for these powders where we can target exclusively on YOS and ZnS with no H2S formation or any need for an oxidising agent. First, the fine-sized CRT powder is mixed with zinc sulfate monohydrate (ZnSO4.H2O or ZSMH). Next, the mixture is roasted to convert Y2O2S:Eu3+ into sulfates. Finally, europium and yttrium are dissolved by water leaching. High roasting temperatures are avoided to enable easier dissolution of valuable zinc from the zinc-rich leaching residue. ZSMH does not contaminate the system with other metals and it can be recovered by electrolysis as metallic zinc. With this methodology we recovered about 95 % of Y and Eu and minimised the total zinc dissolution to about 5 %. To further purify the solution from zinc, we tested several methods:

By using oxalate precipitation we produced a mixed rare earth oxide of 97.4 wt% purity with only 2.2 wt% ZnO. This zinc oxide can easily be washed away without losing REEs by an alkali solution increasing the purity even further.

By using a novel liquid-liquid exchange reaction, we showed that Y(III) and Eu(III) in an aqueous solution can be exchanged with Zn(II) in an organic solvent. This work seems to be promising on purification of trivalent REEs from divalent transition metals like zinc and iron.

As a future work, we also proposed hydroxide precipitation of REEs and in-situ alkali dissolution of co-precipitated zinc thereby producing a high grade mixed REE hydroxide.

M.A.R. Önal, K. Binnemans, Recovery of rare earths from waste cathode ray tube (CRT) phosphor powder by selective sulfation roasting and water leaching, Hydrometallurgy. 183 (2019) 60–70. doi:10.1016/j.hydromet.2018.11.005.

Rhodium is a rare earth metal which is a silver-white color, chemically inert, hard transition metal. It is a member of the platinum group, along with iridium, osmium, palladium, platinum, and ruthenium. Rhodium is extremely durable with a Vickers Hardness of 1246 MPa. It is resistant to corrosion, oxidation, tarnishing, and scratches, with a boiling point of 3727°C and a melting point of 1966°C. Although it is more costly than most other precious metals, it’s benefits typically are more valuable than the added cost when considering its qualities. The major benefits of rhodium include heat resistance, mechanical wear and chemical protection, electrical conductivity, and friction reduction. Industrial rhodium is particularly precious since it is typically acquired as a by-product of refining other metals, such as copper and nickel. In nature it is found with other platinum group minerals and metals. These characteristics combined with its low electrical resistance makes rhodium commonly used as an electrical contact material for electrical contacts, semiconductor wafers, printed circuit boards (PCBs), and other mission critical components.

Rhodium electroplating is more challenging to electroplate when compared to other precious metals. Additionally, costs are much higher during the plating bath operation, especially if the plating is not done currently. Due to rhodium’s inertness, once plated it cannot be chemically removed for in-process re-work, whereas most other precious metals can be chemically stripped in cases where re-work is required. In the electroplating industry rhodium has a high barrier to entry due to initial costs, with a high cost of failure. The result is a steep learning curve when developing the proper electroplating techniques. Companies looking to electroplate rhodium onto high value parts need to consider the high risk of failure, therefore finding a company experienced in rhodium electroplating is essential. For this reason, there is a shortage of rhodium platers with experience and adequate capabilities to serve the market demand for challenging electroplating projects, making it difficult for manufacturers to work on rhodium plating requirements without a trusted, capable partner.

Semiconductor electroplating typically has precise requirements such as flatness of base material wafers or precise diameters of the interconnected pins for hermetically sealed connectors, with equally tight plating tolerances for the plating thickness and uniformity deposited to the flat wafers or precise diameter electrical connector pins. Often, these wafer assemblies have miniature features such as numerous small wires and stacked chips compacted onto a small wafer diameter which requires only selective areas of the assembly plated. Other applications include contact pins, which are assembled in a hermetically sealed connector build that requires selective plating at the ends of the pins and specifies a very uniform plating deposit due to post plating hermetic sealing assembly requirements. Thus, process control is critical for plating and especially critical for rhodium plating to achieve reliable and repeatable outcomes. The plating bath and the parts being processed must be in its purest form free of dust and particles, and the bath must be frequently maintained and monitored. For this reason ProPlate employs an in-house chemistry department so that chemistries can be proactively managed whereas many electroplating companies do not have in-house chemical testing and management capabilities; which forces these plating operations to wait for weeks or months to receive bath test data that is critical to quality outcomes. ProPlate has offered customers rhodium plating services since inception in 1983, giving it a vast knowledge base of experiences to offer its customers for unique plating projects and production services.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In nature it is found with other platinum group minerals and metals. These characteristics combined with its low electrical resistance makes rhodium commonly used as an electrical contact material for electrical contacts, semiconductor wafers, printed circuit boards (PCBs), and other mission critical components.

RHODIUM. While the major use of rhodium (Rh) is in catalytic converters, 11% of production is used in glass-related applications, such as coatings for optic fibres and optical mirrors. Because it is also highly resistant to corrosion, it is used for thermocouple elements and crucibles.

Platinum, palladium, rhodium and iridium are used to coat electrodes, the tiny components in all electronic products which help to control the flow of electricity.

Rhodium is distinguished by its unique corrosion resistance, hardness, silvery-white metallic appearance and chemical inertness. It does not tarnish and is not prone to corrosion at normal room temperature.

South Africa produces over 85% of the global rhodium supply annually, with majority of this supply being generated by the mining companies listed below (rhodium production listed as a percentage of overall mining production):

Q: What cars have the most rhodium? If you"re asking, “Which catalytic converters have the most rhodium?” Some of the cars with the most rhodium in their cat converters include the Ferarri F430, Ford Mustang, Ram 2500, Ford F250, etc. This is part of the reasons why these cars are luxury automobiles in the industry.

Selling Rhodium Online. At Express Gold Cash we understand that selling your precious metals can be both sensitive and confusing. We work to make sure our customers are 100% satisfied. We accept all forms of scrap rhodium including rhodium bars, rhodium sponges, rhodium alloy wire, sheet, rods, foil, tube, mesh.

The major use of rhodium is in catalytic converters for cars (80%). It reduces nitrogen oxides in exhaust gases. Rhodium is also used as catalysts in the chemical industry, for making nitric acid, acetic acid and hydrogenation reactions.

Computer CPU"s (processors) have the most precious metal value by weight, followed by Memory (RAM) & Circuit Board Fingers / Connectors / Pins, then Circuit Boards (Motherboards), then cables / wires, with hard drives & whole computers being last.

Rhodium is used as an alloying agent for hardening and improving the corrosion resistance of platinum and palladium. These alloys are used in furnace windings, bushings for glass fiber production, thermocouple elements, electrodes for aircraft spark plugs, and laboratory crucibles.

In the manufacture of TFT-LCD panels (used in TVs, monitors and displays), platinum and rhodium are used to line the channels, melting tanks and stirring cells, not only because they can withstand temperatures up to 1,650ºC, but also because they are inert.

Palladium is often used in cell phone and laptop components, and it"s also found in ceramic capacitors having multiple layers. Due to the metal"s high level of conductivity, manufacturers commonly include it in the connector plates of a variety of electronic products.

Typically, the amount of rhodium in a catalytic converter is anywhere between 1-2 grams, while the amount of platinum ranges anywhere from 3 to 7 grams and the amount of palladium ranges anywhere from 2 to 7 grams.

Historically, Rhodium reached an all time high of 29800 in March of 2021. Rhodium - data, forecasts, historical chart - was last updated on December of 2022.

Rhodium is often used by jewelers as a coating on silver, platinum, and palladium jewelry to make the items more scratch resistant and improve luster and shine. Because of its reflexive properties, rhodium is also used in high quality glass and LCD screen production.

Rhodium is a silvery-white platinum group metal (PGM) resistant to corrosion and highly reflective. It is considered the rarest and most valuable precious metal in the world. About 88% of the global rhodium produced is used for making catalysts that reduce the release of harmful substances from vehicle exhausts.

Rhodium is an ultra-shiny, corrosion resistant metal that had become useful in many industries including the automobile, jewelry, chemical and electrical trades. According to Peterson, it"s rhodium"s scarcity and use that makes it so valuable.

Rhodium is a platinum-group metal. In 2022, the supply of rhodium in South Africa was forecast to stand at around 575,000 ounces, making South Africa the world"s largest rhodium producer.

Rhodium, a chemical element with symbol Rh, is a silvery-white, hard, corrosion-resistant, which can be used as a structuring material for glass manufacturing. It exhibits properties such as high melting point and enhanced corrosion resistance.It is naturally occurring, free metal, rarest, and most valuable precious metals. Alloys made from rhodium are used in manufacturing of LCD glass for flat panel displays and many more products.These alloy compositions are used in low-energy &low-voltage contact, thick &thin film circuits, thermocouples &furnaces, and electrodes. South Africais the largest producer of rhodium.

Owing to the lockdown implemented across various countries, national and international transport have been hampered, which has significantly impacted the supply chain of numerous industries across the globe, thereby increasing the supply–demand gap.

Increasing demand for glass manufacturing, LCD glass panels, and auto-catalyzing is driving the demand for rhodium alloys.Increasing use of rhodium by automotive industry is expected to affect the market growth. Volatility in rhodium prices is one of the major restraining factorsof the market. Rhodium alloy market is still in development stage. As rhodium is one of the rarest metals in the world, supply struggles to catch up to demand. Around more than 50% of all rhodium comes from South African mines, in which distribution is difficult, especially with mining strikes in past years.

North America is at the top position to lead rhodium alloys market in terms of market size. Asia-Pacific, being a growth-oriented country in almost every sector, is growing at a significant rate. Latin America is trying to expand its market size in coming years.

Key benefits of the report:This study presents the analytical depiction of the global rhodium alloys industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global rhodium alloysmarket share.

The report provides a detailed global rhodium alloysmarket analysis depending on competitive intensity and how the competition will take shape in coming years.

Key Market Players J and J materials, Inc., Pure tech, Merck KGaA, Rhodium ferro Alloys private ltd., American elements, Reade international corp., Nobills metals, Parekh industries, Anglo American

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

"The final result is incredible... the screens are performing without fail, look amazing in person and on camera, and provide so much more creative flexibility for visuals, than we could ever have imagined. The low latency provides a flawless IMAG experience. Vanguard LED Displays has provided incredible support. I have no doubt that our next LED project will be with Vanguard..."

Behind a nondescript Manhattan storefront, Chi-Tien Lui is stockpiling objects many people wouldn’t think twice about trashing: cathode ray tube televisions. The first floor of CTL Electronics — whose clientele includes the Museum of Modern Art, the Whitney, and other museums across the country — is lined with a rich mix of vintage TVs, from tiny boxes to big, looming screens. In his bedroom upstairs, Lui has a 1930s mechanical television, an early image transmission system that passed light through a spinning metal disc. In his workshop, there’s a grid of old screens that once sat inside the Palladium, an iconic New York nightclub that closed in 1997. “They used to have 16 of these, rotating in the club — everybody danced underneath,” Lui recalls. “When they went out of business I took all the equipment back. And right now, I’m restoring them.”

CRTs were once synonymous with television. By 1960, nearly 90 percent of American households had one. But at the turn of the millennium, their popularity rapidly decayed as LCD panels flooded the market. Even though CRTs comprised an estimated 85 percent of US television sales in 2003, analysts were already predicting the technology’s demise. In 2008, LCD panels outsold CRTs worldwide for the first time. Sony shut down its last manufacturing plants that same year, essentially abandoning its famous Trinitron CRT brand. By 2014, even stronghold markets like India were fading, with local manufacturers switching to flat-panel displays.

Despite all this, picture tube televisions continue to linger. You’ll find them in museums, arcades, video game tournaments, and the homes of dedicated fans. But as the CRT slips further into obsolescence, devotees like Lui are navigating a difficult transition between simply maintaining an aging device and preserving a piece of technological history.

The concept of television predates the electronic CRT display by decades. Scholar Alexander Magoun’s book Television: The Life Story of a Technology describes it as a natural extension of the telegram, fax machine, and telephone. In 1879, a cartoonist envisioned families communicating across continents via a wall-mounted “telephonoscope.” In the 1880s, German inventor Paul Nipkow imagined capturing slices of an image through holes in a spinning disk, then projecting the light patterns through an identical disk on the other end. Russian scientist Constantin Perskyi reported on this new theory of “television by means of electricity” at the 1900 Paris world’s fair, coining the term that we still use today.

The first actual working television, demonstrated by Scottish inventor John Baird in the mid-1920s, used Nipkow’s mechanical disk idea to show dim, fuzzy images of a ventriloquist dummy named Stookie Bill. Several similar devices followed, some backed by major companies like GE and AT&T. By 1928, Americans could pay for a mechanical “radiovision” kit from inventor Charles Jenkins, and tune in for thrice-weekly “radiomovie” pantomimes on his broadcast network. But these TVs were inherently limited by the number of holes you could put on a disk, and the incredibly bright lights that were required to capture an image.

When the Great Depression hit, support for mechanical TVs petered out, and companies began funding versions that scanned electronic lines across a screen. Over the next several years, these experiments produced a technology that would last for almost a century.

Electronic CRT TVs flourished in the years after World War II, and for the rest of its lifespan, manufacturers looked for ways to iterate on it. Perhaps the most obvious advance was color television, which took off in the 1960s after a bitter standards war between Columbia Broadcasting System and the ultimately victorious National Broadcasting Company. Once these standards were set, individual companies built loyalty with technological tweaks. Sony’s iconic Trinitron abandoned the perforated metal “shadow mask” that most color TVs used to keep their electron streams separate, for instance, using vertical wires that produced bright, clean colors and a flatter screen.

Toward the end of the CRT era, manufacturers began directly competing with the plasma and liquid-crystal displays that were threatening to overtake the market. The mid-2000s saw a brief enthusiasm for “ultra-slim” models, which touted tubes as miraculously thin as 15 inches. Some manufacturers adopted new high-definition HDMI connections. These machines maintained a tenuous advantage at first: new flat-panel TVs cost thousands of dollars, and consumers had to sort through a confusing assortment of unproven display technologies. But as these screens got cheaper, bigger, and had higher-resolutions, there was no way for the CRT to win. Its design relied on a fat glass tube, which became deeper and heavier with every added inch of screen space. Sony’s hulking 40-inch Trinitron from 2002, one of the biggest consumer CRTs ever produced, weighed over 300 pounds. A modern 40-inch Sony TV, the second-smallest option in its current lineup, weighs less than 20 pounds.

But flatscreens haven’t won everyone over. Ian Primus, an IT repair technician and CRT aficionado, has amassed a basement and storage unit full of old TVs. He has a reputation as one of the increasingly few people who will take CRTs off people’s hands. “If you let people know that you’re looking for old TVs, suddenly you’ve got three or four people calling you,” he says. He gives out his number to thrift stores that have decided the bulky sets are more trouble than they’re worth and want to direct donors elsewhere. Sometimes he simply drives around at night before garbage collection, looking for castoffs.

Primus says he doesn’t just hoard old TVs; he uses them constantly in his daily life. “I don’t have an LCD computer monitor, and I don’t have an LCD TV. Everything is CRTs,” he says. “I know I’m crazy.” Most new devices exclusively support current TVs, including one of Primus’ newer tech purchases — Nintendo’s NES Classic — which, ironically for such a retro-looking device, only features a modern HDMI adapter. But it’s still possible to use adapters with many of them. As long as that’s true, Primus says he’ll probably stick with CRTs.

“I’m not going to try to be one of those guys who says, ‘Yeah the picture on a CRT is better than the LCD,’” he says. But he likes the deep blacks and high color contrast and the sturdiness of old hardware. Primus, like Lui, is also helping keep CRTs available to the people who can’t do without them. In his case, that’s the retro gaming community.

A video game’s look and feel is often highly dependent on specific hardware setups, and for most of the medium’s history, those setups often involved a CRT. The iconic black scanlines we associate with old games, for instance, exist because consoles would tell a TV to only draw every other line — thus avoiding the flickering that interlaced video could produce, and smoothing out the overall image. (For more detail, retro gaming enthusiast Tobias Reich maintains an exhaustive guide about scanlines and other CRT rendering issues.) Old games may look torn or feel laggy on a new TV. That’s in part because LCD screens process an entire frame of an image and then display it, rather than receiving a signal and drawing it right away.

Some games are completely dependent on the display technology. One of the best-known examples is Duck Hunt, which uses Nintendo’s Zapper light gun. When players pull the trigger, the entire screen briefly flashes black, then a white square appears at the “duck’s” location. If the optical sensor detects a quick black-then-white pattern, it’s a hit. The entire Zapper system is coded for a CRT’s super fast refresh rate, and it doesn’t work on new LCD TVs without significant DIY modification.

A less extreme — but much more popular — case is Super Smash Bros. Melee, a 2001 Nintendo GameCube title that’s become one of the most beloved fighting games of all time. Originally designed for casual players at parties, Melee upends the conventions set by series like Street Fighter and Mortal Kombat: instead of memorizing combos to chip down an opponent’s health bar, players try to knock each other off the screen using careful positioning and improvised, super fast moves. Despite its age, and the increasing difficulty of finding a copy, it’s a mainstay at fighting game tournaments.

Melee’s frantic pace has kept players coming back year after year, even after Nintendo released subsequent Super Smash Bros.games in 2008 and 2014. But it also makes the game exceptionally unforgiving of lag. On CRT monitors, which were dominant when the game launched, a character will react almost instantly when you push a button. On a newer TV, the animation may start just a little later, forcing players to adjust their timing, which can put them at a disadvantage.

As with many debates in the gaming world, there’s disagreement over whether new TVs are truly unusable. Not everyone believes the lag is bad enough to justify keeping an old CRT around, especially as flat-panel displays have gotten more responsive. But for now, visiting the Melee section of an e-sports tournament is a little like stepping back in time, as sleek LCD screens give way to bulky black boxes. Some of those boxes belong to Primus. He leases them out to gatherings around his hometown of Albany, as well as larger events across the region, like the Boston-based tournament Shine.

Shi Deng, co-founder of Shine’s organizing body Big Blue Esports, estimates the tournament used about 100 CRTs last year. Some events let players bring their own displays, but Shine doesn’t; they’re a pain to set up, and there’s too much liability if someone drops a 50- or 100-pound television on the ground. (An abandoned CRT caused real panic at one Detroit tournament last year, when police shut down the surrounding block out of fear it might be a bomb.) Instead, they rent from a handful of providers, who might truck the screens in from hundreds of miles away, coordinating tournament dates so there are enough TVs to go around.

Deng has his own small CRT, a hand-me-down from his mother. But rounding up old TVs is one of the most inconvenient parts of running a tournament, he says, and he’d love to see Nintendo come out with a remake so the Melee community could move on. That may not happen anytime soon. Some Smash players have rallied around the 2014 Wii U sequel, but it’s still a sideshow. A Nintendo Switch remake was widely rumored last year, but so far, it’s proven elusive.

Even if it does come out, CRTs will have a place in gaming for years to come. Speedrunners, for instance, use them to get the absolute best reaction time on old games. And CRTs aren’t just a pragmatic consideration for experts, either. They’re also the only way to give people a sense of how a game’s original players would have experienced it.

The CRT’s slow extinction is also becoming a pressing problem for arcades, especially with the rise of arcade bars over the past decade. Establishments like San Francisco’s Brewcade, Portland’s Ground Kontrol, and Chicago’s Emporium Arcade Bar all line their walls with dozens of nostalgia-inspiring cabinets and by extension, dozens of CRT displays.

Barcade, one of the largest — and most strictly retro-focused — chains, has about 350 games spread across seven locations. It has almost an equal number in storage. The company carefully preserves original, untouched cabinets for games like Centipedeand Tetris. But it also buys a lot of sloppy “conversions” — machines that arcade operators hacked to install new games, with different paint jobs and controls. It strips these down for parts, operating out of what Barcade co-founder and CEO Paul Kermizian jokingly refers to as a “secret lair” on the outskirts of New York City. They give the cabinets to collectors for restoration, swap individual components into vintage machines, and hold onto the tubes until they can’t possibly be fixed.

Arcades generally have in-house teams of employees with varying levels of expertise. Ground Kontrol, which describes itself as a “hands-on museum,” is owned by two electrical engineers and two software specialists. They initially repaired machines themselves, until finally hiring a full-time technician. Barcade employs two dedicated repair specialists, and a number of other staff can do some work on the machines.

These places may eventually have to start installing LCD monitors in cabinets, and the results might not be disastrous. Software filters can approximate a CRT’s trademark image distortions, like scanlines or the curve of a screen, and a tinted glass panel can enhance the illusion. Not all arcades are so dependent on CRTs, either. Classic arcade series like Street Fighter switched to LCD-based cabinets years ago. A wave of indie game developers have designed a host of cabinet-based games with modern displays, ranging from weird, arty experiments to traditional-looking two-player boxes.

Barcade, for one, will hold onto CRTs as long as possible — and Kermizian thinks that will be a while. “I think there’s plenty around for at least 10 years, before anyone even stresses about it,” he says. It’s still cheaper to buy old parts than to retrofit a cabinet for LCD, a process Kermizian says would cost about $350. And paradoxically, he says fear of an impending shortage could free up more tubes, as some competitors preemptively adopt LCD displays to get ahead of the curve.

“The day maybe will come when we have to do an emulation of a CRT. We’ll be pretty sad,” he says. “But there are a lot of tubes out there. It’s not dire at this point. Not for us, anyway.”

It’s one thing to round up screens for a video game tournament, or even swap out the tube in an arcade cabinet. But what if an artist has turned a mass-market television set into something truly one-of-a-kind and that television set is about to wear out? This is the question that Chi-Tien Lui has built his life around, and one that few people are so well equipped to answer.

When Lui started CTL Electronics in 1968, he and his customers were working in the vanguard of film and video. He had learned to fix TVs as a teenager in Taiwan, and he came to America working as an electrician in the merchant marines. He opened his shop just after Sony released its first Portapak system, a comparatively tiny video camera that attracted artists like Andy Warhol and Nam June Paik, the Korean-born father of video art. Paik and others came to CTL for help with their work, and as their installations aged, shaping the future of media became less important than preserving its past.

Today, Lui specializes in maintaining pieces like Paik’s Untitled (Piano), a player piano piled high with televisions displaying closed-circuit footage of its interior workings. He’s been fixing TVs for so long that he knows exactly which brands have compatible parts, across decades’ worth of hardware, including the now-rare Korean monitors that Paik favored. That’s particularly important for the museums that hire him to help replicate the precise original look of video art installations. It’s a task that’s much easier if you can just replace a broken tube with one of the right shape and size, rather than replacing the entire set. When he eventually retires, the prospect of losing that expertise makes the future of CTL Electronics — which employs Lui’s daughter and a handful of other employees — uncertain.

CRTs are tough pieces of hardware, but as they age, plenty of things can go wrong. The electron gun can weaken, giving screens a dim, yellowish tinge. An electrical transformer can blow out. The phosphor can burn away unevenly, leaving permanent, ghostly outlines of images behind.

Lui works with a German engineer who helps refurbish tubes — by installing a new electron gun to fix yellowing, for example. Much of his work involves sifting through the vast but shrinking pool of CRT detritus. He scours eBay for old TVs and parts, snapping them up in bulk, and hopes that most of them will work when they arrive. “It’s getting harder and harder, and the price goes up and up and up,” he says. He gestures toward a sizable Sony Trinitron, one of his prize finds. “Ten years ago, I could get them under $100. Now it’s $2,000. Certain TVs, everybody wanted to grab.”

Getting rid of the broken or unwanted CRTs, though, is a nightmare. “CRTs are essentially the bane of the electronic recycling industry,” says Andrew Orben, director of business development at Tekovery, one of the companies Barcade uses to dispose of irrevocably broken hardware. The tubes contain toxic metals that could leach into a dump site, and 18 states specifically ban sending them to landfills. They’re made of raw materials that are often impossible to sell at a profit, primarily glass that’s mixed with several pounds of lead. When CRTs were still being made, that was a useful resource, but recyclers have struggled to find other uses. Companies could once export the tubes abroad, but as LCDs become more commonplace, CRTs are becoming less and less attractive.

Tekovery doesn’t dismantle the CRTs it receives, and Orben says few e-waste companies in America will handle that part of the operation. Over the past few years, several supposed CRT “recyclers” have been caught secretly abandoning their old displays in vast television graveyards. Iowa’s attorney general sued the now-defunct company Recycletronics in January for storing 4.6 million pounds of leaded CRT glass, along with other e-waste, across eight facilities in two states. A lawsuit last year targeted a former partner of Recycletronics, which kept a staggering 113 million pounds of glass in two Ohio warehouses.

The problem isn’t going away anytime soon, either. A 2011 EPA-commissioned report estimated that over 580 million CRT televisions (not counting computer monitors) had been sold in the US since 1980; the average CRT was used for 11 years and kept in storage long after that. Recyclers don’t want to deal with them, and even if TVs are dismantled correctly — and not dumped in a landfill — the dust from leaded glass can have long-term health effects on workers and their families, including birth defects in children.

“There are companies in the industry that are specifically looking for long-term solutions” to the CRT recycling question, says Orben. But they’ve faced their own difficulties. Nulife, a company that legitimately smelted down old tubes for commercial sale, was ordered to scrap its backlog of glass after failing regulatory checks. It pulled out of the US market last year.

The CRT television has had a vast impact on American culture, but it’s come at a cost — and the companies that created this crisis aren’t the ones paying it. “The manufacturers made their money on this type of stuff,” complains Orben, “and now, they’ve basically left all these private recyclers to clean up.”

The few people still using CRTs are trying to preserve the best experiences these machines made possible — to prolong the lives of objects that don’t die gracefully. “We as a society have developed this mentality where everything CRT-based is obsolete and needs to be trashed,” Primus says. “They’re a lot more robust than people think they are.”

Aging televisions will eventually stop feeling merely old and start feeling vintage. It’s unlikely that CRTs will enjoy a sudden resurgence in popularity like vinyl records have. They’re extraordinarily large and heavy, and depend on other obsolete technologies like VCRs and old gaming consoles. But people may start thinking more carefully about how to maintain or donate them, rather than just throwing them away — something that would be good for both preservationists and the environment. For now, Lui sees the bright side of our nearly century-long love affair with CRTs. “America’s a good place to collect antiques,” he says. “It’s much easier to get old equipment in this country than anywhere else.”

In the meantime, he has no intention of moving into the world of repairing flatscreens. “When the iPod, iPad came out, I quit learning new things,” he says. The new generation of electronics, he says, is fundamentally different from the old one. You could go to a factory training program and learn how to repair a CRT. “The new TVs, they don’t want you to repair.”

But when it comes to actually watching television, Lui is less nostalgic. Across from the grid of Palladium monitors, he shows off a Chinese TV station playing on a massive screen above his desk. “This is an LG, Korean TV, OLED monitor,” he says. “I think this is the best TV I’ve ever seen.”

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey