rhodium in lcd screen price

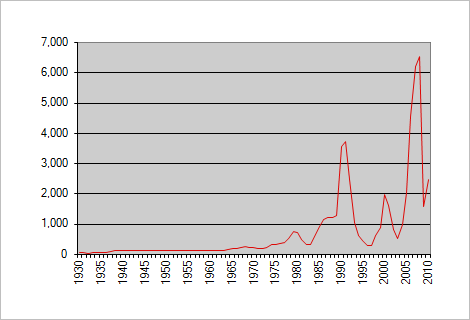

On May 19, 2011, Deutsche Bank issued db Physical Rhodium ETC securities.Johnson Matthey recently (Nov. 15, 2011) forecast that the metal will remain in surplus (by 123,000 troy ounces (one troy ounce (oz) = 31.10 grams)) in 2011, and now its price has fallen from a "stratospheric" level of over $10,000/oz in June 2008 to "languish" around $1,700 (midprice on Nov. 30, 2011), somewhat lower than that of gold. So, what"s with rhodium?

The platinum group metals, or PGMs, of which rhodium is one, are a group of six metals clumped together pretty much in the middle of the periodic table. The others are iridium, osmium, palladium, platinum and ruthenium. The metal, which is extremely difficult to separate from the other metals with which it naturally occurs (including the other PGMs), is always produced as a byproduct of the extraction of these others; no such thing as a rhodium mine exists.

The English chemist, William Hyde Wollaston discovered the metal in 1803, soon after he discovered palladium and around the same time Smithson Tennant (also English) discovered both osmium and iridium. The rarity of the metal, the fact that it is a byproduct, and the complexity of (and costs involved in) its extraction have all, historically, contributed to robust pricing over the last 80 years, and especially in the last couple of decades.

An autocatalyst, which sits inside a motor vehicle"s catalytic converter (itself placed between its engine and muffler), is a metal, or ceramic, honeycomb coated with PGMs (of which rhodium is one) and various chemicals.

In gasoline-poweredvehicles, the autocatalyst converts over 90 percent of the carbon monoxide, oxides of nitrogen and unburned hydrocarbons into carbon dioxide, nitrogen and water vapor (often appearing as drips from out of the auto"s muffler). In diesel-powered vehicles, in addition to the equivalent amounts of hydrocarbons and carbon monoxide that are converted to more harmless compounds, so too is 30-40 percent of the potentially carcinogenic diesel particulate matter.

Since the first production vehicle was fitted with a catalytic converter back in 1974, their use has flourished and now catalytic converters are fitted to over 85 percent of all the new vehicles sold each year worldwide.

To put the effects they have in context, back in 1960, a gasoline-powered vehicle would typically, for every mile driven, spew out 100 grams of carbon monoxide, hydrocarbons and oxides of nitrogen. By 2004, this had been reduced to just some 2 grams, and autocatalyst development continues today.

Rhodium, because of its hardness and both its resistance to corrosion and high melting point (higher than that of platinum), is currently used in three main types of glass manufacturing, that of: thin-film transistor liquid crystal display (TFT-LCD) panels, glass fibers and, increasingly, in solar photovoltaic (PV) panels.

In the manufacture of TFT-LCD panels (used in TVs, monitors and displays), platinum and rhodium are used to line the channels, melting tanks and stirring cells, not only because they can withstand temperatures up to 1,650ºC, but also because they are inert. This last is of particular importance, as the glass substrate cannot contain any charge-bearing particles that may interfere with the function of the TFT laid down on it.

In the manufacture of glass fibers, the molten glass is drawn through an array of many tiny, uniform, orifices or nozzles, set in what is called a bushing — essentially just a box out of which they stick. These nozzles are made of a platinum/rhodium alloy.

Finally, rhodium is also used in the manufacture of the glass used in solar panels, which are required to be as defect free as possible and "highly transmissive."

In the chemical industry, rhodium catalysts are used in the production of aldehyde, which, with hydrogenation, leads to an oxo-alcohol, and in the production of acetic acid using the Monsanto process. (According to Johnson Matthey, the rising demand for rhodium in the chemical sector is being driven "by downstream demand for paints and adhesives, particularly in China.")

It will come as no surprise that by far the largest producer of rhodium is South Africa, which, in 2011, is forecast to produce some 650,000 oz out a total global supply figure for the mined metal of an estimated 768,000 oz. Recycling of autocatalysts is anticipated to amount to some 260,000 oz in 2011.

Source: Forecast production figures from Johnson Matthey, who notes that: "Supply figures represent estimates of sales by the mines of primary pgm and are allocated to where the initial mining took place rather than the location of refining."

Since primary rhodium is produced only alongside other PGMs, on the mining front, anyway, no rhodium mining "pure play" exists. And the big rhodium producers are, therefore, necessarily, the big producers of the other PGMs.

Investors can invest directly, buying the physical metal in ingot or as sponge, and "directly" through, e.g., Deutsche Bank"s Physical Rhodium ETC, this last giving the investor an entitlement to the physical metal.

As to the rationale behind an investment in rhodium, there a number of factors that should be carefully considered. Some of the more obvious are: Rhodium is, first and foremost, an industrial metal — with all that implies

There is also one other aspect of investing in rhodium (and some other industrial metals) that should be considered. While, according to Johnson Matthey, net inflows (to late September) to the Deutsche Bank ETC accounted only for about 14,000 oz, were such inflows to become significant, then any investment decision would need to factor in such demand, in addition to that from industry. This can only add further complexity to the investment process.

I used a different tool to separate the glass from the adhesive holding it to the aluminum on the back. I haven"t seen any of those screens your talking about. If you have some clear looking plastic that acts like a magnifying glass, it"s probably a fresnel lens. I"ve got a number here somewhere for a company that recycles and sells LCD screens. You can put some in with the circuit boards to be refined but they don"t want too many in there so they (SIPI) gave me a number but now I can"t find it, might have to call them back. So I put all the little LCD"s in with the boards like from phones games and calculators and save the large ones. That other pane of glass I just broke it up and threw it in with my other screens, I ain"t messing with it.

LONDON, Jan 10 (Reuters) - Prices of precious metal rhodium surged to a record high of $7,025 an ounce on Thursday as consumers in the glass-making and auto industries scrambled for scarce supplies, traders said.

Dealers said rhodiumwas quoted at $7,000/$7,050 an ounce, a gain of more than 25 percent since January last year and compared with the previous record high of $7,000 seen in 1980. On Wednesday it was quoted around $6,975/$7,025 an ounce.

Most rhodium is used by car makers in catalytic converters to limit carbon emissions, where regulations have become much stricter and contributed to rising demand for the metal.

Traders say that has been a major factor behind rhodium’s price rise over the last two years. Another is growing demand from glass makers ramping up production of flat panel screens used for televisions and computers.

South Africa is the world’s biggest producer of rhodium, which is a by-product of platinum. Supply disruptions in the country in recent months also have boosted rhodium prices.

During the manufacturing process, the molten glass is fed through a trough that is made out of the alloy, which can stand extreme heat and won’t melt.

Last December Corning announced capital expenditure between $1.5 billion to $1.7 billion to build additional capacity to meet growing demand for large flat-panel televisions.

“We expect that the LCD glass market will continue to grow into the next decade,” said James B. Flaws chief financial officer at Corning said on the company’s website.

Corning has previously said that it expects the overall LCD glass market to reach 1.7 billion square feet of glass in 2007 and to grow again by at least 400 million square feet in 2008.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Also known as “performance cookies,” these cookies collect information about how you use a website, like which pages you visited and which links you clicked on. None of this information can be used to identify you. It is all aggregated and, therefore, anonymized. Their sole purpose is to improve website functions. This includes cookies from third-party analytics services as long as the cookies are for the exclusive use of the owner of the website visited.

However, like platinum and palladium, the majority of demand for rhodium comes from the auto industry for its usage in catalytic converters where rhodium catalyzes the reduction of nitrogen oxide to nitrogen.

Rhodium is extracted as a byproduct of platinum mining. Therefore, like platinum, the majority of the world’s rhodium supply (80%) comes from South Africa in the mining region called the Bushveld complex. Rhodium is extremely difficult and costly to extract from other elements in the earth.

The price of rhodium has been very volatile in recent years. From 2004 to 2008, it rose 2,112% from $452 per ounce to $10,000 per ounce only to fall back just below $1,000 per ounce in less than a year. Rhodium stayed near unchanged between around $1,000 per ounces from 2012 to 2016 rhodium traded between 1,800 to as low as $600 per ounce. From 2017 to 2018, the price of rhodium rose almost 150% to nearly $2,500 per ounce. At the end of 2019 rhodium surged to over $5,000 per ounce. Strong demand from China for auto manufacturing and lower supply from South Africa have made rhodium the strongest performing commodity in Q1 of 2020. Rhodium has also started 2021 with a surge to an all-time high of $21,900/oz.

People are buzzing about rhodium these days, for some very compelling reasons. One is that rhodium is trading at a very high price, currently $9,500 on the London Fix. Compare that to gold, which is trading for $1572 or even palladium, which is trading at $2181.

But even more important, the trading price of rhodium is surging. According to Bloomberg, the price of rhodium has increased 12-fold in the last four years, and also shot up 31% in January 2020 alone. That’s not a typo, it really increased by 31% in just one month.

That kind of surge in pricing is music to the ears of anyone who likes to invest in precious metals. And even though rhodium is among the scarcest of all precious metals, it is used in many applications. That means that finding rhodium scrap is not impossible at all. And if you find rhodium scrap and send it to Specialty Metals Smelters and Refiners to be processed, you and your wallet could be in for a very pleasant surprise. The way rhodium prices are headed, you might want to hold onto your scrap in the coming months and even years because prices seem to only be going up.

With rhodium trading for such high prices, even very small amounts can be worth a lot of money. How can you find out whether your scrap contains it? Simple answer, call Specialty Metals Smelters and Refiners at 800-426-2344, tell us what you have, and ask about having your scrap tested to determine whether it contains rhodium. Even if it doesn’t, it could still contain platinum, palladium and other valuable metals, so you stand to profit.

Rhodium is an incredibly popular precious metal for many reasons. Its biggest draw is arguably the fact that it is trading at an extremely high price, currently over $18,000 per troy ounce, according to Johnson Matthey prices.

We hope this infographic helped you think of a couple places you might have rhodium scrap. If you do find any, be sure to sell it to a precious metals refiner like Manhattan Gold & Silver. We offer some of the quickest and fairest payments in the industry with a thorough assay process.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

"The final result is incredible... the screens are performing without fail, look amazing in person and on camera, and provide so much more creative flexibility for visuals, than we could ever have imagined. The low latency provides a flawless IMAG experience. Vanguard LED Displays has provided incredible support. I have no doubt that our next LED project will be with Vanguard..."

Rhodium is a rare earth metal which is a silver-white color, chemically inert, hard transition metal. It is a member of the platinum group, along with iridium, osmium, palladium, platinum, and ruthenium. Rhodium is extremely durable with a Vickers Hardness of 1246 MPa. It is resistant to corrosion, oxidation, tarnishing, and scratches, with a boiling point of 3727°C and a melting point of 1966°C. Although it is more costly than most other precious metals, it’s benefits typically are more valuable than the added cost when considering its qualities. The major benefits of rhodium include heat resistance, mechanical wear and chemical protection, electrical conductivity, and friction reduction. Industrial rhodium is particularly precious since it is typically acquired as a by-product of refining other metals, such as copper and nickel. In nature it is found with other platinum group minerals and metals. These characteristics combined with its low electrical resistance makes rhodium commonly used as an electrical contact material for electrical contacts, semiconductor wafers, printed circuit boards (PCBs), and other mission critical components.

Rhodium electroplating is more challenging to electroplate when compared to other precious metals. Additionally, costs are much higher during the plating bath operation, especially if the plating is not done currently. Due to rhodium’s inertness, once plated it cannot be chemically removed for in-process re-work, whereas most other precious metals can be chemically stripped in cases where re-work is required. In the electroplating industry rhodium has a high barrier to entry due to initial costs, with a high cost of failure. The result is a steep learning curve when developing the proper electroplating techniques. Companies looking to electroplate rhodium onto high value parts need to consider the high risk of failure, therefore finding a company experienced in rhodium electroplating is essential. For this reason, there is a shortage of rhodium platers with experience and adequate capabilities to serve the market demand for challenging electroplating projects, making it difficult for manufacturers to work on rhodium plating requirements without a trusted, capable partner.

Semiconductor electroplating typically has precise requirements such as flatness of base material wafers or precise diameters of the interconnected pins for hermetically sealed connectors, with equally tight plating tolerances for the plating thickness and uniformity deposited to the flat wafers or precise diameter electrical connector pins. Often, these wafer assemblies have miniature features such as numerous small wires and stacked chips compacted onto a small wafer diameter which requires only selective areas of the assembly plated. Other applications include contact pins, which are assembled in a hermetically sealed connector build that requires selective plating at the ends of the pins and specifies a very uniform plating deposit due to post plating hermetic sealing assembly requirements. Thus, process control is critical for plating and especially critical for rhodium plating to achieve reliable and repeatable outcomes. The plating bath and the parts being processed must be in its purest form free of dust and particles, and the bath must be frequently maintained and monitored. For this reason ProPlate employs an in-house chemistry department so that chemistries can be proactively managed whereas many electroplating companies do not have in-house chemical testing and management capabilities; which forces these plating operations to wait for weeks or months to receive bath test data that is critical to quality outcomes. ProPlate has offered customers rhodium plating services since inception in 1983, giving it a vast knowledge base of experiences to offer its customers for unique plating projects and production services.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey