rhodium in lcd screen quotation

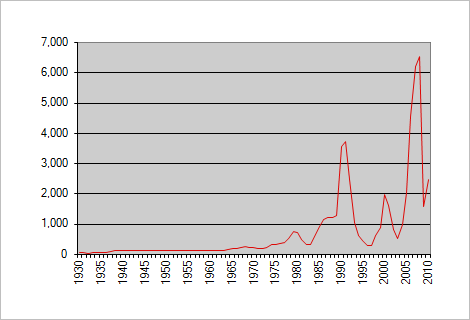

On May 19, 2011, Deutsche Bank issued db Physical Rhodium ETC securities.Johnson Matthey recently (Nov. 15, 2011) forecast that the metal will remain in surplus (by 123,000 troy ounces (one troy ounce (oz) = 31.10 grams)) in 2011, and now its price has fallen from a "stratospheric" level of over $10,000/oz in June 2008 to "languish" around $1,700 (midprice on Nov. 30, 2011), somewhat lower than that of gold. So, what"s with rhodium?

The platinum group metals, or PGMs, of which rhodium is one, are a group of six metals clumped together pretty much in the middle of the periodic table. The others are iridium, osmium, palladium, platinum and ruthenium. The metal, which is extremely difficult to separate from the other metals with which it naturally occurs (including the other PGMs), is always produced as a byproduct of the extraction of these others; no such thing as a rhodium mine exists.

The English chemist, William Hyde Wollaston discovered the metal in 1803, soon after he discovered palladium and around the same time Smithson Tennant (also English) discovered both osmium and iridium. The rarity of the metal, the fact that it is a byproduct, and the complexity of (and costs involved in) its extraction have all, historically, contributed to robust pricing over the last 80 years, and especially in the last couple of decades.

An autocatalyst, which sits inside a motor vehicle"s catalytic converter (itself placed between its engine and muffler), is a metal, or ceramic, honeycomb coated with PGMs (of which rhodium is one) and various chemicals.

In gasoline-poweredvehicles, the autocatalyst converts over 90 percent of the carbon monoxide, oxides of nitrogen and unburned hydrocarbons into carbon dioxide, nitrogen and water vapor (often appearing as drips from out of the auto"s muffler). In diesel-powered vehicles, in addition to the equivalent amounts of hydrocarbons and carbon monoxide that are converted to more harmless compounds, so too is 30-40 percent of the potentially carcinogenic diesel particulate matter.

Since the first production vehicle was fitted with a catalytic converter back in 1974, their use has flourished and now catalytic converters are fitted to over 85 percent of all the new vehicles sold each year worldwide.

To put the effects they have in context, back in 1960, a gasoline-powered vehicle would typically, for every mile driven, spew out 100 grams of carbon monoxide, hydrocarbons and oxides of nitrogen. By 2004, this had been reduced to just some 2 grams, and autocatalyst development continues today.

Rhodium, because of its hardness and both its resistance to corrosion and high melting point (higher than that of platinum), is currently used in three main types of glass manufacturing, that of: thin-film transistor liquid crystal display (TFT-LCD) panels, glass fibers and, increasingly, in solar photovoltaic (PV) panels.

In the manufacture of TFT-LCD panels (used in TVs, monitors and displays), platinum and rhodium are used to line the channels, melting tanks and stirring cells, not only because they can withstand temperatures up to 1,650ºC, but also because they are inert. This last is of particular importance, as the glass substrate cannot contain any charge-bearing particles that may interfere with the function of the TFT laid down on it.

In the manufacture of glass fibers, the molten glass is drawn through an array of many tiny, uniform, orifices or nozzles, set in what is called a bushing — essentially just a box out of which they stick. These nozzles are made of a platinum/rhodium alloy.

Finally, rhodium is also used in the manufacture of the glass used in solar panels, which are required to be as defect free as possible and "highly transmissive."

In the chemical industry, rhodium catalysts are used in the production of aldehyde, which, with hydrogenation, leads to an oxo-alcohol, and in the production of acetic acid using the Monsanto process. (According to Johnson Matthey, the rising demand for rhodium in the chemical sector is being driven "by downstream demand for paints and adhesives, particularly in China.")

It will come as no surprise that by far the largest producer of rhodium is South Africa, which, in 2011, is forecast to produce some 650,000 oz out a total global supply figure for the mined metal of an estimated 768,000 oz. Recycling of autocatalysts is anticipated to amount to some 260,000 oz in 2011.

Source: Forecast production figures from Johnson Matthey, who notes that: "Supply figures represent estimates of sales by the mines of primary pgm and are allocated to where the initial mining took place rather than the location of refining."

Since primary rhodium is produced only alongside other PGMs, on the mining front, anyway, no rhodium mining "pure play" exists. And the big rhodium producers are, therefore, necessarily, the big producers of the other PGMs.

Investors can invest directly, buying the physical metal in ingot or as sponge, and "directly" through, e.g., Deutsche Bank"s Physical Rhodium ETC, this last giving the investor an entitlement to the physical metal.

As to the rationale behind an investment in rhodium, there a number of factors that should be carefully considered. Some of the more obvious are: Rhodium is, first and foremost, an industrial metal — with all that implies

There is also one other aspect of investing in rhodium (and some other industrial metals) that should be considered. While, according to Johnson Matthey, net inflows (to late September) to the Deutsche Bank ETC accounted only for about 14,000 oz, were such inflows to become significant, then any investment decision would need to factor in such demand, in addition to that from industry. This can only add further complexity to the investment process.

I used a different tool to separate the glass from the adhesive holding it to the aluminum on the back. I haven"t seen any of those screens your talking about. If you have some clear looking plastic that acts like a magnifying glass, it"s probably a fresnel lens. I"ve got a number here somewhere for a company that recycles and sells LCD screens. You can put some in with the circuit boards to be refined but they don"t want too many in there so they (SIPI) gave me a number but now I can"t find it, might have to call them back. So I put all the little LCD"s in with the boards like from phones games and calculators and save the large ones. That other pane of glass I just broke it up and threw it in with my other screens, I ain"t messing with it.

LONDON, Jan 10 (Reuters) - Prices of precious metal rhodium surged to a record high of $7,025 an ounce on Thursday as consumers in the glass-making and auto industries scrambled for scarce supplies, traders said.

Dealers said rhodiumwas quoted at $7,000/$7,050 an ounce, a gain of more than 25 percent since January last year and compared with the previous record high of $7,000 seen in 1980. On Wednesday it was quoted around $6,975/$7,025 an ounce.

Most rhodium is used by car makers in catalytic converters to limit carbon emissions, where regulations have become much stricter and contributed to rising demand for the metal.

Traders say that has been a major factor behind rhodium’s price rise over the last two years. Another is growing demand from glass makers ramping up production of flat panel screens used for televisions and computers.

South Africa is the world’s biggest producer of rhodium, which is a by-product of platinum. Supply disruptions in the country in recent months also have boosted rhodium prices.

During the manufacturing process, the molten glass is fed through a trough that is made out of the alloy, which can stand extreme heat and won’t melt.

Last December Corning announced capital expenditure between $1.5 billion to $1.7 billion to build additional capacity to meet growing demand for large flat-panel televisions.

“We expect that the LCD glass market will continue to grow into the next decade,” said James B. Flaws chief financial officer at Corning said on the company’s website.

Corning has previously said that it expects the overall LCD glass market to reach 1.7 billion square feet of glass in 2007 and to grow again by at least 400 million square feet in 2008.

People are buzzing about rhodium these days, for some very compelling reasons. One is that rhodium is trading at a very high price, currently $9,500 on the London Fix. Compare that to gold, which is trading for $1572 or even palladium, which is trading at $2181.

But even more important, the trading price of rhodium is surging. According to Bloomberg, the price of rhodium has increased 12-fold in the last four years, and also shot up 31% in January 2020 alone. That’s not a typo, it really increased by 31% in just one month.

That kind of surge in pricing is music to the ears of anyone who likes to invest in precious metals. And even though rhodium is among the scarcest of all precious metals, it is used in many applications. That means that finding rhodium scrap is not impossible at all. And if you find rhodium scrap and send it to Specialty Metals Smelters and Refiners to be processed, you and your wallet could be in for a very pleasant surprise. The way rhodium prices are headed, you might want to hold onto your scrap in the coming months and even years because prices seem to only be going up.

With rhodium trading for such high prices, even very small amounts can be worth a lot of money. How can you find out whether your scrap contains it? Simple answer, call Specialty Metals Smelters and Refiners at 800-426-2344, tell us what you have, and ask about having your scrap tested to determine whether it contains rhodium. Even if it doesn’t, it could still contain platinum, palladium and other valuable metals, so you stand to profit.

However, like platinum and palladium, the majority of demand for rhodium comes from the auto industry for its usage in catalytic converters where rhodium catalyzes the reduction of nitrogen oxide to nitrogen.

Rhodium is extracted as a byproduct of platinum mining. Therefore, like platinum, the majority of the world’s rhodium supply (80%) comes from South Africa in the mining region called the Bushveld complex. Rhodium is extremely difficult and costly to extract from other elements in the earth.

The price of rhodium has been very volatile in recent years. From 2004 to 2008, it rose 2,112% from $452 per ounce to $10,000 per ounce only to fall back just below $1,000 per ounce in less than a year. Rhodium stayed near unchanged between around $1,000 per ounces from 2012 to 2016 rhodium traded between 1,800 to as low as $600 per ounce. From 2017 to 2018, the price of rhodium rose almost 150% to nearly $2,500 per ounce. At the end of 2019 rhodium surged to over $5,000 per ounce. Strong demand from China for auto manufacturing and lower supply from South Africa have made rhodium the strongest performing commodity in Q1 of 2020. Rhodium has also started 2021 with a surge to an all-time high of $21,900/oz.

Rhodium is an incredibly popular precious metal for many reasons. Its biggest draw is arguably the fact that it is trading at an extremely high price, currently over $18,000 per troy ounce, according to Johnson Matthey prices.

We hope this infographic helped you think of a couple places you might have rhodium scrap. If you do find any, be sure to sell it to a precious metals refiner like Manhattan Gold & Silver. We offer some of the quickest and fairest payments in the industry with a thorough assay process.

Rhodium is a precious metal that belongs to the platinum group. It is a very rare and expensive element that is extracted from native platinum. A well-known property of the metal is its ability to break down certain substances into their simplest components in a gaseous state. It is known for its high chemical stability to aggressive environments: in this respect it surpasses many other elements.

Wollaston dissolved raw platinum in aqua regia and neutralized the excess acid with caustic soda. From the neutralized solution he covered platinum with ammonium chloride and palladium with mercury cyanide. The filtrate was treated with hydrochloric acid to remove the excess mercury cyanide and evaporated to dryness. The residue treated with alcohol turned out to be a dark red rhodium-sodium salt powder. The rhodium was recovered by heating this powder in a stream of hydrogen.

The largest reserves of rhodium there are today, Mexico (43%) is the frontrunner in terms of gold deposits, as its gold sands are oversaturated with rhodium. This is followed by the South African, Colombian and US supplies.

South Africa is the largest exporter of rhodium (80% by volume). The second largest production country is Russia (11,9%), followed by Canada and Zimbabwe.

The extraction of rhodium from the obtained macro shafts is carried out in an artisanal way (mining). It is complicated by the composition of the ore: the metal is associated with gold, palladium, platinum and copper.

The next step is metallurgy. The concentrated mixture is immersed in an oven and heated to 1500 ° C. The old rock is burned and the slag is removed by blowing it out. The concentrate content rises to 1400 g / ton. -

A solution left over from the platinum refining process is used to release the rhodium. After treatment with chemicals and incineration, the result is almost pure rhodium metal.

Research is currently being carried out on several technologies in order, among other things, to recover rhodium from hazardous waste residues from nuclear power plants. These very cost-intensive new technologies enable a greater production potential of rhodium in the future than from conventional mining. Furthermore, problematic storage of nuclear waste would be reduced in this way.

Iridium or platinum alloys are contained in precision instruments that can measure temperatures of up to 2200 ° C (for example in catalytic converters).

A platinum / rhodium alloy reduces the formation of nitric acid. Such an alloy is used to manufacture exhaust gas neutralizers for motor vehicles. The automotive industry is the main user of rhodium.

They are used to coat mirror surfaces and ultra-precision instruments. This is thanks to the fact that the surface reflects 80% of the light in the visible range of the spectrum and is not clouded by Superfine.

In radio technology, it is mostly not used for the manufacture of components because it is too brittle and unstable. Radio components are simply coated with rhodium. The contacts (reed relays) of the RPS 55 (A), for example, are coated with rhodium.

Electronic engineer of computer technology. Maintenance computer cpu hardware upgrade of motherboard component. Pc repair, technician and industry support concept.

This electronics is developing into an important area of application. The metal is used in filters on LCD monitors (TVs, laptops, iPhones and other devices).

Silver band for engagement with gem for female Cropped of diamond luxury jewelery bijouterie ring from white gold or platinum with gemstone. 3D rendering on black background New collection of jewelry

It has been proven that rhodium compounds are highly toxic carcinogens. However, the amount of rhodium in certified jewelry is harmless to human health.

An alloy of rhodium and copper (or zinc), which is dissolved in hydrochloric acid, filtered and dried, results in a powder. This is because it is a compound that can detonate under normal conditions.

The global rush reached its peak at the end of 2008: At that time, up to 10.1k dollars per troy ounce were in demand on the foreign exchange market, which was ten times more than gold at the same time.

In the last period (December 2019 - December 2020) the price per gram has tripled: from $ 150 to $ 500. In other words, the price was around $ 2021 for an ounce in December 14.100. The all-time high of rhodium was recorded in May 2021 at USD 29.100 per troy ounce.

As with other precious metals, the price of rhodium fluctuates. In the long term, however, it will continue to grow. Science, manufacturing and technology will not do without this metal. However, production capacities are limited and global deposits are finite.

Rhodium is a rare earth metal which is a silver-white color, chemically inert, hard transition metal. It is a member of the platinum group, along with iridium, osmium, palladium, platinum, and ruthenium. Rhodium is extremely durable with a Vickers Hardness of 1246 MPa. It is resistant to corrosion, oxidation, tarnishing, and scratches, with a boiling point of 3727°C and a melting point of 1966°C. Although it is more costly than most other precious metals, it’s benefits typically are more valuable than the added cost when considering its qualities. The major benefits of rhodium include heat resistance, mechanical wear and chemical protection, electrical conductivity, and friction reduction. Industrial rhodium is particularly precious since it is typically acquired as a by-product of refining other metals, such as copper and nickel. In nature it is found with other platinum group minerals and metals. These characteristics combined with its low electrical resistance makes rhodium commonly used as an electrical contact material for electrical contacts, semiconductor wafers, printed circuit boards (PCBs), and other mission critical components.

Rhodium electroplating is more challenging to electroplate when compared to other precious metals. Additionally, costs are much higher during the plating bath operation, especially if the plating is not done currently. Due to rhodium’s inertness, once plated it cannot be chemically removed for in-process re-work, whereas most other precious metals can be chemically stripped in cases where re-work is required. In the electroplating industry rhodium has a high barrier to entry due to initial costs, with a high cost of failure. The result is a steep learning curve when developing the proper electroplating techniques. Companies looking to electroplate rhodium onto high value parts need to consider the high risk of failure, therefore finding a company experienced in rhodium electroplating is essential. For this reason, there is a shortage of rhodium platers with experience and adequate capabilities to serve the market demand for challenging electroplating projects, making it difficult for manufacturers to work on rhodium plating requirements without a trusted, capable partner.

Semiconductor electroplating typically has precise requirements such as flatness of base material wafers or precise diameters of the interconnected pins for hermetically sealed connectors, with equally tight plating tolerances for the plating thickness and uniformity deposited to the flat wafers or precise diameter electrical connector pins. Often, these wafer assemblies have miniature features such as numerous small wires and stacked chips compacted onto a small wafer diameter which requires only selective areas of the assembly plated. Other applications include contact pins, which are assembled in a hermetically sealed connector build that requires selective plating at the ends of the pins and specifies a very uniform plating deposit due to post plating hermetic sealing assembly requirements. Thus, process control is critical for plating and especially critical for rhodium plating to achieve reliable and repeatable outcomes. The plating bath and the parts being processed must be in its purest form free of dust and particles, and the bath must be frequently maintained and monitored. For this reason ProPlate employs an in-house chemistry department so that chemistries can be proactively managed whereas many electroplating companies do not have in-house chemical testing and management capabilities; which forces these plating operations to wait for weeks or months to receive bath test data that is critical to quality outcomes. ProPlate has offered customers rhodium plating services since inception in 1983, giving it a vast knowledge base of experiences to offer its customers for unique plating projects and production services.

Vanguard invented the industry-leading Rhodium 16:9 native aspect ratio cabinet. This cabinet eliminated the need to scale video images that are always shot in 16:9 and as a result, it has been embraced by the market.

Rhodium is our best-selling product. The cabinet can be wired internally, allowing for flush wall mounts, or with traditional external wiring. The Rhodium Series can be hung, recessed, and ground-supported. The Rhodium series is without a doubt the most unique, versatile, well-thought, LED cabinet on the market.

Every cabinet in Vanguard"s Rhodium product series has a native 16:9 aspect ratio. If a display has the same number of cabinets horizontally and vertically, the display will be in a 16:9 aspect ratio and not require scaling of the video images. The Rhodium series is available for P2.5mm and P4mm indoor pixel pitches!

"The final result is incredible... the screens are performing without fail, look amazing in person and on camera, and provide so much more creative flexibility for visuals, than we could ever have imagined. The low latency provides a flawless IMAG experience. Vanguard LED Displays has provided incredible support. I have no doubt that our next LED project will be with Vanguard..."

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The word “rhodium” originates from the Greek word “rhodon,” which represents the lovely “rose.” When the metal was discovered, the scientist thought that the beautiful rose aptly describes its pinkish red color. Later on, however, the metal was found to have a shiny silver-white color in most cases.

Rhodium (Rh) belongs to the six member noble metals group that includes palladium, ruthenium, iridium, osmium and platinum. These metals exist in common rare metallic ores and exhibit some common characteristics. Rhodium is distinguished by its unique corrosion resistance, hardness, silvery-white metallic appearance and chemical inertness. It does not tarnish and is not prone to corrosion at normal room temperature. That is the secret of its durability, and it is one of the rarest precious metals.

After discovering the rare metal palladium, W. H. Wollaston discovered rhodium while he was trying to separate pure platinum from the ore. He used platinum ore from Peru as the raw material. After separating platinum and palladium from the ore sample, he was left with the residue of a red powder, which was later recognized as sodium rhodium chloride. Research studies state that he had used aqua regia, ammonium chloride and iron to separate palladium. By using hydrogen in the reduction process of the chloride salt of rhodium, he was able to separate rhodium, which had a pinkish hue. (Interested in discovering the properties of various materials? Be sure to read How to Get Started in a Career as a Materials Scientist.)

Rhodium is a highly valued precious material. Most of the metal is used as a catalyst (along with other catalysts) for automobile catalytic converters.

Rhodium compounds should be considered as toxic and carcinogenic. These can also cause strong stains on the skin. If the aerosol of this rare metal is inhaled it can be absorbed by the body, causing the risk of toxicity.

Because it is a rare mineral, there is insufficient data related to its safety. Hence, maximum precautions must be taken while handling, processing and using this material. (For more on safety, read The Dangers of Typical Corrosion Prevention Solutions.)

Rhodium displays many of the common properties of the rare platinum group metals (PGM), which generally have good chemical stability as well as catalytic properties. Additionally, rhodium is a good conductor of heat and electricity. It is corrosion resistant and stain resistant, and is one of the most reflective metals, which makes it a superior precious metal.

Low electrical contact resistance makes rhodium an ideal material for electrical contacts. It is durable, as it generally fails to oxidize even when heated. It absorbs oxygen while melting and releases the absorbed oxygen during solidification. It dissolves in aqua regia, but not in nitric acid.

It has a high melting point of 1,966°C (3,571°F). Thermocouples made of rhodium can accurately measure temperatures up to 1,800°C (3,272°F). This metal has a boiling point of 3,695°C (6,683°F). These properties ensure that it is suitable for high temperature applications.

Most of the reserves of the platinum group of metals (PGMs) are found in South Africa. Production of these metals involves refining the base metals as well as finishing refinery of the precious metals. Steps involved include floatation, comminution, smelting and final conversion. Chrome and oxide ore content often creates challenges for the PGM metal extraction. Proprietary processes using low temperature roasting and bromine (acid) leaching process are able to maximize the yieldof oxide ores and mixed ores containing rhodium (improved to the tune of 65% for rhodium and 85% for platinum).

The normal production process of rhodium is briefly described as follows:Noble metals such as platinum, gold and palladium are first separated by precipitation from the PGM ores

The addition of hydrochloric acid to rhodium hydroxide results in H3RhCl6 (a purified acid solution of rhodium), which is further added to sodium nitrite and ammonium chloride, enabling the precipitation of rhodium

The precipitate of rhodium is allowed to dissolve in hydrochloric acid and heated to remove contaminants by burning and thus the purified rhodium metal is finally produced

Most of the market demand for rhodium is driven by the demand for automobile catalytic converters in Japan, Europe and the United States, and the glass industry demand in Asia. As it is one of the rarest metals, the price is determined by the demand. According to market research studies, increasing Asian demand for the rare metal is due to producers of flat display glass panels.

Rhodium is sometimes applied as a decorative coating on jewelry made of silver and on circuit components, making these products free from tarnish and corrosion. It is applied on decorative products and also used to obtain highly reflective shining surfaces for optical appliances. The electrodeposition process is used to create a durable rhodium coating with a presentable color on jewelry.

Rhodium is also used to produce palladium and platinum alloys that have high hardness and excellent corrosion resistance. These alloys are then used to manufacture catalytic converters and catalytic nets that catalyze chemical reactions. In 1976, three-way catalytic converters were developed by Volvo by using rhodium alloys. This breakthrough helped minimize nitrogen oxide (NOx) emissions from automobiles.

Rhodium is a noble metal, known for its unique corrosion resistance, high temperature chemical stability, durability, shiny appearance and reflectance. It is one of the six rare metals of the platinum group. Rhodium does not tarnish and is not prone to corrosion. It is one of the rarest noble metals with very good durability.

Most of this rare metal is used by the automobile industry to make vehicle catalytic converters that accelerate and catalyze the reduction of nitrogen oxides into nitrogen gas, thus enabling regulatory engine exhaust compliance.

Gold is globally respected throughout the world for its value and significant history as a part of many cultures for thousands of years. Gold has been seen as a special and valuable commodity with coins containing Gold appearing circa. 650 B.C. and the first pure Gold coins were minted during the reign of King Croesus of Lydia around 550 B.C.

People have continued to hold Gold for a variety of reasons throughout history. Societies and economies have placed a value on Gold, ensuring it’s continued worth. Gold is the metal we collectively fall back on when other currencies or monetary systems fail; and therefore it provides a legitimate and time-tested insurance against such unpredictable times of crisis. Owning gold can act as a hedge against inflation and deflation alike, as well as a good portfolio diversifier. As a global store of value, Gold can also provide financial cover during geopolitical and macroeconomic uncertainty.

Gold is an important part of a diversified investment portfolio because its price increases in response to events that cause the value of paper investments, such as stocks and bonds, to decline. Although the price of Gold can be volatile in the short term, it has always maintained its value over the long term. Through the years, it has served as a hedge against the erosion of major currencies. Gold is a unique asset in so far as it is highly liquid, yet scarce; and it is as much a luxury good as it is an investment. Physical Gold is no one’s liability and carries no counterparty risk, both very attractive attributes in times of crisis.

Unlike paper currency, coins or other assets, gold has maintained its value throughout the ages. People see gold as a way to pass on and preserve their wealth from one generation to the next. Since ancient times, people have valued the unique properties of the precious metal. Gold doesn’t corrode and can be melted over a common flame, making it easy to work with and stamp as a coin. Moreover, gold has a unique and beautiful color, unlike other elements. The atoms in gold are heavier and the electrons move faster, creating absorption of some light; a process which took Einstein’s theory of relativity to figure out.

Generally the markets seem to focus solely on the loss of purchasing power of the US dollar as one of the world’s most important reserve currencies, when the value of the dollar falls against other currencies this often prompts people to flock to the security of Gold, which causes Gold prices to rise.

This is not actually correct as the US$ in 1998 was trading at exactly the same value versus global currencies as of today in 2021 (DXY Index charts) while Gold has risen over 7 times in value in that same time frame versus US$.

What has to be taken into consideration is the global monetary aggregate expansion of sovereign currencies which gives you forward guidance in inflation or more accurately the loss of purchasing power and ongoing debasement of Fiat paper sovereign currencies.

Gold has historically been an incredible holder of purchasing power versus currencies which consistently lose value over time. The market will highlight that Gold is a reliable hedge against inflation but this is not entirely accurate. Between 1980 and 2002 we had very high compound rates of headline inflation and yet Gold fell in value against currencies for over 20 years. Gold is rather a crisis hedge and a fantastic holder of purchasing power over very long periods of time. Gold tends to rise very dramatically and corrects its under-priced situation in times of crisis and hence recognizing where we are on the macroeconomic cycle is of paramount importance. Over the past 50 years investors have seen Gold prices soar and the stock market plunge during high-inflation years. This is because when fiat currency loses its purchasing power to inflation, Gold tends to be priced in those currency units and thus tends to arise along with everything else. Gold is also seen as a good store of value so people may be encouraged to buy Gold when they believe that their home currency is losing value.

Deflation is defined as a period in which prices decrease, when business activity slows and the economy is burdened by excessive debt, which has not been seen globally since the Great Depression of the 1930s (although a small degree of deflation occurred following the 2008 financial crisis in some parts of the world). During the Depression, the relative purchasing power of Gold soared while other prices dropped sharply. This occurs when people choose to hoard cash, and the safest places to hold such cash is in Gold bars and coins.

Gold retains its value not only in times of financial uncertainty, but in times of geopolitical uncertainty. It is often called the “crisis commodity,” because people flee to its relative safety when world tensions rise; and during such times, it often outperforms other investments. For example, Gold prices experienced some major price movements this year in response to the Covid-19 crisis. Its price also often rises the most when confidence in governments is low.

Much of the supply of Gold in the market since the 1990s has come from sales of Gold bullion from the vaults of global central banks. This selling by global central banks slowed greatly in 2008 and since 2010, 22 central banks have been buying Gold in record annual amounts. At the same time, production of new Gold from mines had been declining since 2000. It can take from 5 to 10 years to bring a new mine into production. Generally speaking, a reduction in the supply of Gold increases gold prices.

Historically, increased wealth of emerging market economies boosted demand for Gold. In many of these countries, Gold is very much embedded into the culture. In China, where Gold bars are a traditional form of saving, the demand for Gold has been steadfast. India is the second largest Gold-consuming nation in the world; it has many uses there, including jewelry. The Indian wedding season in October is traditionally the time of the year that sees the highest global demand for Gold.

Demand for Gold has also grown among investors. Many are beginning to see commodities, particularly gold, as an investment class into which funds should be allocated and properly diversified. SPDR Gold Trust, became one of the largest ETFs in the U.S., as well as the world’s largest holder of Gold bullion recently.

The key to diversification is ensuring that investments that are not closely correlated to one another; Gold has historically had a negative correlation to stocks, property and other financial instruments.

Unlike Gold, the price of Silver swings between its perceived role as a store of value and its role as an industrial metal. Price fluctuations in the Silver market are more volatile than Gold.

So, while Silver will trade in approximate unison with Gold as a hoardable commodity, the industrial supply/demand picture for the metal exerts an equally strong influence on its price.

The industrial equation fluctuates with new innovations. The rise of a vast middle class in the emerging market economies created an explosive demand for electrical appliances, medical products, and other industrial items that require Silver. From bearings to electrical connections, mobile phones, digital cameras, computers and iPhones, Silver’s unique properties have made it a highly desired commodity. Silver is also used in batteries, superconductor applications and microcircuit markets.

Silver’s price is affected by its multitude of applications and is not just used in fashion or simply as a long term store of value. It is the second most-consumed commodity after oil, and there is no substitute for Silver on the periodic table given it’s highly unique properties.

This enormous industrial demand, partly responsible for pushing prices up, will not diminish as the Silver price rises because this metal is used in very small quantities in each product. Even a substantial increase in the price of Silver will not cause industrial demand to fall. Contrary to Gold (which can be recycled), Silver, once consumed, is almost entirely destroyed, at present.

If we consider the historical trend over millennia, the price of Silver should be $118/oz today (Gold price divided by 15). On January 20th, 2015, its price was $18/oz. Silver is one of the very few commodities trading at less than it did in 1980.

Silver is used extensively in the photovoltaic (solar) industry. With zero-carbon emission targets globally embraced, countries seeking to increase their renewable energy production capacities will invariably consume more Silver.

Monetary demand is added to the industrial demand: Silver has been considered a form of money for centuries, and the destruction of currencies’ purchasing power (as money printing aggressively continues) is contributing to Silver’s return as a critical element of a stable monetary system.

As the price of Gold increases, it becomes unaffordable for millions of people (especially in Asia). This is not the case with Silver. Millions of people will rush to this metal as they witness the destruction of paper currencies’ purchasing power. This global demand wasn’t present during the last major Gold and Silver boom of the 1980’s, so this could play a very important role.

One phenomenon must be taken into account to understand the potential for Silver: There are enormous short positions on the Silver market. With Silver prices going up, investors and traders holding those positions will have to cover, which will accelerate the rise in price dramatically.

As with Gold, many Silver “paper” certificates have been sold without enough physical Silver in reserve to actually satisfy eventual delivery to all holders of such “paper” certificates. This abundant “paper” offer has contributed to limiting the increase of Silver prices for years by taking attention away from the physical market itself. But this rush towards tangible assets (and physical Silver in particular) will make those paper certificates (ETFs etc.) explode, along with the price of Silver. One should only invest in and own Silver in its physical form.

Like Gold and Silver, Platinum is traded around the clock on global commodities markets. It often tends to fetch a higher price (per ounce) than Gold during routine periods of market and political stability because it is much rarer. Far less of the metal is actually extracted from the ground annually.

Platinum has seen a huge surge in popularity among investors. Unlike Gold, Platinum has not been mined for thousands of years. Thanks to its higher boiling point and the fact that it rarely occurs in its natural form, Platinum wasn’t discovered until 1735.

Over 73% of the world’s Platinum comes from mines in northern South Africa where extraction is extremely challenging, especially from super-heated magma mines deep below the earth’s surface. Platinum is rarely found in isolation, it is more usually found alongside other base metals such as nickel, copper and chrome. Therefore, deposits discovered underground must be refined before they can be considered pure and the complexity and cost of this process makes Platinum extremely rare.

Platinum has a silver appearance and it is extremely hard. While jewellers value its malleability, it’s also ductile, rigid, dense and extremely unreactive.

Like Silver, Platinum is considered an industrial metal. The greatest demand for Platinum comes from automotive catalysts (about 40%), which are used to reduce harmful emissions. Following their inclusion in catalysts, jewelry accounts for the majority of demand. Petroleum and chemical refining catalysts as well as the computer industry use up the rest, and it is also found in everything from fertilisers to pacemakers.

Because of the auto industry’s heavy reliance on metal, Platinum prices are determined in large part by auto sales and production numbers. Increasing requirements by “clean air” legislation will require automakers to install more catalytic converters, raising demand. Carmakers have started turning to recycled auto catalysts or using more of Platinum’s reliable sister group metal, Palladium. When the price of Palladium rises, substitution into Platinum will occur.

Platinum mines are heavily concentrated in only two countries, South Africa and Russia. This creates greater potential for cartel-like action that would support or even artificially raise platinum prices or indeed for geopolitical considerations in either country.

Platinum is used as the exclusive precious metal catalyst in hydrogen fuel cells, alongside Iridium. This fast-growing hydrogen-fuel-cell technology relies on Platinum, as it can withstand considerably higher temperatures than other metals. A fuel cell needs Platinum for the catalyst that separates hydrogen into protons and electrons, which then generate the electrical current, making it an alternative to battery-powered vehicles. Hydrogen fuel cells, though presently expensive in their infancy, are expected to be a massively important part of reducing global carbon emissions.

The balance of any investment portfolio depends on appetite for risk. Many investors consider a precious metal holding a safe haven – a form of protection against riskier exposure elsewhere. Demand for Platinum investment bars can increase when the price of Gold rises and the Platinum/Gold ratio increases. Platinum is however deemed to be the most volatile of the precious metals.

Lesser known than the above three metals is Palladium, which has more industrial uses. Palladium is a shiny, silvery metal used in many types of manufacturing processes, particularly for electronics and industrial products. It can also be used in dentistry, medicine, chemical applications, jewelry, and groundwater treatment. The majority of the world’s supply of this rare metal, which has the atomic number 46 on the periodic table of elements, comes from mines located in the United States, Russia, South Africa and Canada.

This is by far the number one driver for prices of Palladium around the world. The auto industry accounts for approximately three quarters of the global demand for Palladium. Palladium is a key component in the manufacturing of catalytic converters because the metal serves as a great catalyst that speeds up chemical reactions. This and the demand for vehicles in large markets like the US and China have a sizable bearing on the price of Palladium.

Metalworkers can create thin sheets of palladium down to one-two hundred fifty thousandths of an inch. Pure palladium is malleable, but it becomes stronger and harder once someone works with the metal at room temperature. The sheets are then used in applications like solar energy and fuel cells.

Much of the world’s Palladium supply (circa 80%) comes from Russia and South Africa. Any interruptions to this supply or process, be it in the form of sanctions as Russia sometimes deals with, or power supply problems (currently faced in South Africa) can cause a fluctuation in prices.

Substituting Palladium for other metals within the auto industry is coming under increasing scrutiny. This is in large part due to the high price of Palladium, and also the fact that a number of substitutes, including Platinum can be used.

The US Dollar forex market is facing numerous challenges. The weakening dollar can certainly have an impact on Palladium prices as it does on other precious metals, though the reasoning may be different. Palladium is typically purchased from suppliers in US Dollars. Any downward movement in the Dollar has the potential to act as a disincentive to suppliers. This can reduce the supply of the precious metal which in turn can lead to upward price movements.

Jewelers first incorporated Palladium into jewelry in 1939. When mixed with yellow gold, the alloy forms a metal stronger than white gold. In 1967, the government of Tonga issued circulating Palladium coins touting the coronation of King Taufa’ahau Tupou IV. This is the first recorded instance of Palladium used in coinage.

Rhodium has rarely been considered an investment precious metal like Gold, Silver, Platinum and Palladium. However, it is considerably rarer than all of these precious metals and thus merits investment consideration. Only 28 tons of Rhodium are mined annually compared to 220 tons of Platinum and over 2,300 tons of Gold.

Rhodium is a lustrous white metal that is both hard and dense. It has very high reflective properties and is an excellent conductor of both heat and electricity. Like Palladium, it is one of the six Platinum Group Metals or “Noble Metals”. Rhodium was discovered in 1803 by the British chemist and physicist William Hyde Wollaston along with his discovery of Palladium.

Engineers understand Rhodium as an alloy or coating agent that improves the corrosion resistance of both Palladium and Platinum. Rhodium is often used by jewelers as a coating on Silver, Platinum and Palladium jewelry to make the items more scratch resistant and improve luster and shine.

Like Platinum and Palladium, the majority of demand for Rhodium comes from the auto industry for its usage in catalytic converters where Rhodium catalyzes the reduction of nitrogen oxide to nitrogen.

Rhodium is extracted as a byproduct of Platinum mining. Therefore, like Platinum, the majority of the world’s Rhodium supply (80%) comes from South Africa in the mining region called the Bushveld complex. Rhodium is extremely difficult and costly to extract as compared to other elements in the earth.

The price of Rhodium has been very volatile in recent years. Rhodium traded up from US$600/oz in 2016 to a record high of US$29,800/oz in Q1, 2021. Strong demand from China for auto manufacturing due to increasingly stringent emissions regulations globally, together with the threat of lower supply amid a lack of investment in new mines over the past decades have made Rhodium the strongest performing commodity in 2020.

Rhodium is a rare platinum group metal (PGM) that is chemically stable at high temperatures, resistant to corrosion and mainly used in the production of automobile catalytic converters.

Rhodium is a hard, silver-colored metal that is very stable and has a high melting point. Rhodium metal is resistant to corrosion and, as a PGM, it shares the group’s exceptional catalytic properties.

In 1803, William Hyde Wollaston was able to isolate palladium from other PGMs and, consequently, in 1804, he isolated rhodium from the reaction products.

Wollaston dissolved platinum ore in aqua regia(a mixture of nitric and hydrochloric acids) before adding ammonium chloride and iron to obtain palladium. He then found that rhodium could be drawn from the chloride salts that remained.

Wollaston applied aqua regia then a reduction process with hydrogen gas to obtain rhodium metal. The remaining metal showed a pink hue and was named after the Greek word "rodon", meaning "rose".

Rhodium is extracted as a byproduct of platinum and nickel mining. Owing to its rarity and the complex and expensive process required to isolate the metal, there are very few naturally occurring ore bodies that provide economical sources of rhodium.

Like most PGMs, rhodium production is focused around the Bushveld complex in South Africa. The country accounts for over 80 percent of the world"s rhodium production, while other sources include the Sudbury basin in Canada and the Norilsk Complex in Russia.

The first step in extracting rhodium from the ore is precipitating precious metals such as gold, silver, palladium, and platinum. The remaining ore is treated with sodium bisulfate NaHSO4 and melted, resulting in rhodium (III) sulfate, Rh2(SO4)3.

Rhodium hydroxide is then precipitated out using sodium hydroxide, while hydrochloric acid is added to produce H3RhCl6. This compound is treated with ammonium chloride and sodium nitrite to form a precipitate of rhodium.

The precipitate is dissolved in hydrochloric acid, and the solution is heated until residual contaminants are burnt off, leaving behind the pure rhodium metal.

According to Impala Platinum, global production of rhodium is limited to only about 1 million troy ounces annually (or roughly 28 metric tons) annually, whereas, in comparison, 207 metric tons of palladium were produced in 2011.

About one-quarter of rhodium production comes from secondary sources, mainly recycled catalytic converters, while the remainder is extracted from ore.Large rhodium producers include Anglo Platinum, Norilsk Nickel, and Impala Platinum.

According to the US Geological Survey, autocatalysts accounted for 77 percent of all rhodium demand in 2010. Three-way catalytic converters for gasoline engines use rhodium to catalyze the reduction of nitrogen oxide to nitrogen.

Roughly 5 percent to 7 percent of global rhodium consumption is used by the chemical sector. Rhodium and platinum-rhodium catalysts are used in the production of oxo-alcohol manufacturing as well as to produce nitric oxide, a raw material for fertilizers, explosives, and nitric acid.

Glass production accounts for a further 3 percent to 6 percent of rhodium consumption each year. Because of their high melting points, strength and resistance to corrosion, rhodium, and platinum can be alloyed to form vessels that hold and shape molten glass. Also of importance is that alloys containing rhodium do not react with, or oxidize, the glass at high temperatures. Other rhodium uses in glass production include:

In the production of liquid crystal displays (LCDs) because of the higher temperatures required to melt raw materials and the quality of glass required.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey