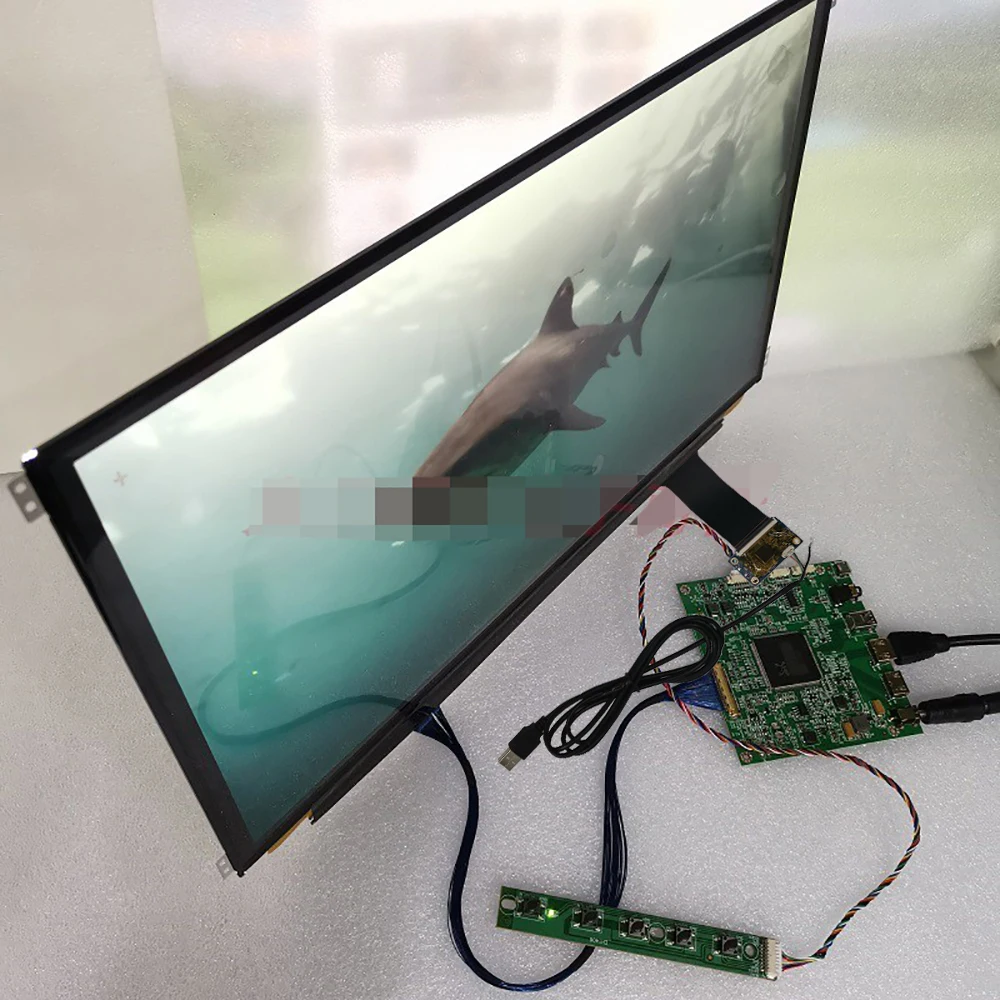

15.6 el lcd panel free sample

WINMATE industrial multi touch display screen screens as well as industrial LCD check screens offer commercial OEMs, equipment and also kiosk manufacturers, along with automation control and procedure systems with very reliable and durable products providing a large choice of touch display innovations and installing services that assist streamline all aspects of maker to equipment interface applications. WINMATE commercial LCD present monitors series with HMI interface features the latest in TFT-LCD flat panel and multi-touch capacitive touch display modern technologies, broad temperature level range, high brightness, sunlight-readable, widescreen LCD flat panel, energy saving LED backlighting, scratch-resistant, as well as anti-reflective mineral glass screen capabilities, commercial TFT-LCD modules with ahead compatibility, reduced EMI modern technology, long-life and very easy replacement lamp/LED. Numerous mounting options consist of: level panel installing with IP65/NEMA 4/4X Ingress defense score, flat panel wall place, open framework flush mounting surface, and flush framework place designed particularly to cater to interactive display and also visualization applications. These industrial displays are ideally designed for industrial automation control, manufacture of equipment, touch display stand, rental kiosk, shopping mall stand, repayment booth, retail stand, exterior stand, interactive electronic signs, and also custom-made device to maker interface applications. WINMATE full-range option of industrial monitor LCD displays are from 8.4" to 22" display sizes.

Technical assistance for vehicle drivers: setting up, removing, and supporting data; hardware: screens, controllers, peripherals; consisting of troubleshooting as well as general system concerns

Our Android Displays are commercial models, specially designed and to use in a retail environment, online digital signage screens, info touch kiosk, etcetera.

We can also provide and help you with some retail app solutions, to help you to start your project. Find more about these apps at the software section.

- 3G-4G connection via USB SIM dongle (optional, not included)This desk-model shape is available in: 10.1 / 13.3 / 14 / 15.6 / 18.5 / 21.5 / 24 / 27 / 32 / 43 / 55 inch sizes.

-First off, I have to say it was larger than I was expecting, which in my case was a good thing. I was able to straight up replace my old computer monitor with it. The display is pretty vibrant and can be adjusted using the tablet software and the buttons on the back (I just use the standard defaults, they work fine for me), and the monitor itself can be adjusted to different angles.

-Some people talk about the pen"s weight, I think it"s just fine personally. It has two buttons, the low button acts as the right click, and the high button toggles between the Pen and Erase tools. It also came with at least three of hard nubs and soft nubs each, along with a circular nub remover in the case. I just use the default hard nub that was in the pen, it works just fine for me, I don"t like the feeling of the soft nub on the display personally. There is a little place on the monitor you can put the pen when not in use, where I have it. If you travel with this monitor, I"d probably suggest putting the pen in its case so you don"t lose it, you"re not gonna be able to really use this thing for anything other than a standard PC monitor without a pen.

-The hotkeys and dial on the left hand side are pretty cool and can be mapped via the VEIKK software that can be gotten from the website. I currently have them to the defaults, so they are as followed (assuming you have the Photoshop etc hotkeys set to their defaults): From top to bottom, K1 is F5 which hides/shows the brush panel (which I don"t really use), K2 is the I key which is the Eyedropper Tool (useful when coloring), K3 is the Space Bar which uses the hand tool (again, I don"t really use), K4 is CTRL+C which is copy, K5 is CTRL+V which is paste, K6 is CTRL+S which saves your project (you are doing this frequently, right?), K7 is CTRL+Z which is the undo command (probably the one you"ll be using most), and K8 is the dial button and by default toggles between Zoom, Wheel to scroll up/down (you can hold the CTRL key to scroll left/right), and Brush Zoom to change the size of your brush. There is also a fourth option you can add to the dial button if you want to.

-The monitor also came with a drawing glove that you wear on your pen hand to keep your hand from leaving marks on the screen, as well as a cleaning cloth. Keep this display clean and free of debris or spots, otherwise it will affect your drawing.

That"s about the jist of it. For the price, this thing is really amazing and I would definitely recommend it, whether you"re a new artist looking to get into digital art like me, or a professional looking for a low cost high value solution compared to the more high end tablets which can range into the thousands price wise. My only regret is that I should"ve waited a little longer to buy it, very recently the price dropped by around $50 so I could"ve saved some money, but that"s just me, what"s done is done and I really have no major grips with my purchase. If I ever have to buy another graphics monitor for whatever reason, this will probably be my first choice. Excellent value, an absolute steal at its price.

Anything a smart speaker can do, a smart display can (usually) do better. The screens and cameras (on some models) are a step above a cheap speaker or expensive tablet.

Available on iPhone with A12 Bionic and later. Requires download of speech models. Available in Cantonese (Hong Kong), English (Australia, Canada, India, UK, U.S.), French (France), German (Germany), Japanese (Japan), Mandarin Chinese (China mainland, Taiwan), and Spanish (Mexico, Spain, U.S.).

Available on iPhone with A12 Bionic and later. Requires download of speech models. Available in Arabic (Saudi Arabia), Cantonese (China mainland, Hong Kong), English (Australia, Canada, India, Singapore, UK, U.S.), French (France), German (Germany), Italian (Italy), Japanese (Japan), Korean (South Korea), Mandarin Chinese (China mainland, Taiwan), Russian (Russia), Spanish (Mexico, Spain, U.S.), and Turkish (Türkiye).

The Medications feature should be not used as a substitute for professional medical judgment. Additional information is available on the labels of your medications, but please consult your healthcare provider prior to making any decisions related to your health.

The 15.6-inch Gateway Ultra Slim Notebook features a 1080p screen that brings a crystal-clear picture for any and all of your tasks. AMD Ryzen™ Mobile Processors deliver premium performance for productivity, entertainment, gaming, and content creation in thin and light laptops. Tuned by THX™ audio products enable listeners to get the best audio quality possible by providing custom fidelity improvements, balanced reproduction, and optimal frequency response. It is the ideal way to get the best audio for on-the-go entertainment.

1Device comes with Windows 10 and a free Windows 11 upgrade or may be preloaded with Windows 11. The Windows 11 upgrade will be delivered to qualifying devices late 2021 into 2022. Timing will vary by device. Certain features require specific hardware

when i start the session it all works perfectly, i can change tools from the program (im using the brush, then i click on the eraser tool and it works as an eraser, then i click on the selection tool and i use the pen to select etc.)

The characteristics of an OLED display can eventually change over long periods of use, leading to visible changes. This is completely normal, and can cause behavior such as image burn-in or persistence: this means that a faint ghost of an image remains visible even when it’s replaced by a new image. These effects are more likely to occur if a non-moving (static) high-contrast image is displayed for an excessively long time. ASUS laptops with an OLED display minimize this risk by setting Windows’s Dark mode as default, as well as shortening the idle time before the screen is turned off — both on mains (AC) and battery (DC) power. This dual approach minimizes the potential for burn-in to maximize the lifespan of your OLED display lifespan, and also reduces unnecessary power draw for optimal battery life. We also recommended adjusting the brightness of your OLED display to complement the ambient lighting in your environment, rather than keeping the screen at maximum brightness at all times. You should also ensure that you have an animated, dark-background screensaver enabled in the Windows Settings tool.

{"backgroundColor":"#e6f4fa","sideMsg":{"t_id":"","language":{"en_us":"","en":""},"id":""},"data":[{"bannerInfo":{"t_id":"Paged3082219-60ba-46fe-a847-05442a084c3a","language":{"en_us":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%26nbsp%3BSave%20up%20to%20%7BsavingPercent%7D%20during%20the%20Annual%20Sale.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22%2Fd%2Fdeals%2Fdoorbusters%2F%3FIPromoID%3DLEN944203%22%20target%3D%22_self%22%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20text-decoration%3A%20underline%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%3Cstrong%3EShop%20Now%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E","en":""},"id":"Paged3082219-60ba-46fe-a847-05442a084c3a"},"gInfo":{"t_id":"","language":{},"id":""}},{"pcInfo":"","mAndTabInfo":"","bannerInfo":{"t_id":"Page05093cd0-3ccb-4d93-8205-b7190c8e9d90","language":{"en_us":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3ENeed%20it%20today%3F%20Buy%20online%2C%20pick%20up%20select%20products%20at%20Best%20Buy.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22https%3A%2F%2Fadmin.lenovo.com%2Fd%2Fbopis%2F%3FIPromoID%3DLEN775727%22%20target%3D%22_self%22%20style%3D%22text-decoration%3A%20underline%3B%20color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%3Cstrong%3EShop%20Pick%20Up%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E","en":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(255%2C%20255%2C%20255)%3B%22%3ENeed%20it%20today%3F%20Buy%20online%2C%20pick%20up%20select%20products%20at%20Best%20Buy.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22https%3A%2F%2Fadmin.lenovo.com%2Fd%2Fbopis%2F%3FIPromoID%3DLEN775727%22%20target%3D%22_self%22%20style%3D%22color%3A%20rgb(255%2C%20255%2C%20255)%3B%20text-decoration%3A%20underline%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(255%2C%20255%2C%20255)%3B%22%3E%3Cstrong%3EShop%20Pick%20Up%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E"},"id":"Page05093cd0-3ccb-4d93-8205-b7190c8e9d90"},"gInfo":{"t_id":"","language":{},"id":""}},{"pcInfo":"","mAndTabInfo":"","bannerInfo":{"t_id":"Pageb95da39c-0ebc-4283-9376-914be6c2f250","language":{"en_us":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3EEarn%203%25-9%25%20in%20rewards%20and%20get%20free%20expedited%20delivery%20on%20select%20products%20when%20joining%20MyLenovo%20Rewards.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22%2Frewards%2F%3FIPromoID%3DLEN775755%22%20target%3D%22_self%22%20textvalue%3D%22Join%20for%20Free%20%26gt%3B%22%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20text-decoration%3A%20underline%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%3Cstrong%3EJoin%20for%20Free%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E","en":""},"id":"Pageb95da39c-0ebc-4283-9376-914be6c2f250"},"gInfo":{"t_id":"","language":{},"id":""}},{"pcInfo":"","mAndTabInfo":"","bannerInfo":{"t_id":"Pagee09691d5-db0a-467c-963a-43b0d729acd1","language":{"en_us":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E6%2C%2012%20%26amp%3B%2024%20Months%20Special%20Financing%20on%20qualifying%20purchases%20with%20our%20Lenovo%20Financing%20Credit%20Card.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22%2Flandingpage%2Flenovo-financing-options%2F%3FIPromoID%3DLEN771093%22%20target%3D%22_self%22%20textvalue%3D%22See%20if%20you%20Prequalify%20%26gt%3B%22%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20text-decoration%3A%20underline%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3E%3Cstrong%3ESee%20if%20you%20Prequalify%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E","en":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(255%2C%20255%2C%20255)%3B%22%3E6%2C%2012%20%26amp%3B%2024%20Months%20Special%20Financing%20on%20qualifying%20purchases%20with%20our%20Lenovo%20Financing%20Credit%20Card.%26nbsp%3B%3C%2Fspan%3E%3Ca%20href%3D%22https%3A%2F%2Fadmin.lenovo.com%2Flandingpage%2Flenovo-financing-options%2F%3FIPromoID%3DLEN771093%22%20target%3D%22_self%22%20style%3D%22white-space%3A%20normal%3B%20color%3A%20rgb(255%2C%20255%2C%20255)%3B%20text-decoration%3A%20underline%3B%22%3E%3Cspan%20style%3D%22color%3A%20rgb(255%2C%20255%2C%20255)%3B%22%3E%3Cstrong%3ESee%20if%20you%20Prequalify%20%26gt%3B%3C%2Fstrong%3E%3C%2Fspan%3E%3C%2Fa%3E%3C%2Fp%3E"},"id":"Pagee09691d5-db0a-467c-963a-43b0d729acd1"},"gInfo":{"t_id":"","language":{},"id":""}},{"pcInfo":"","mAndTabInfo":"","bannerInfo":{"t_id":"Pagef3260b23-c609-41d4-949d-e6c0516bea0e","language":{"en_us":"%3Cp%3E%3Cspan%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%22%3EFree%20shipping%20sitewide%2C%20no%20minimum.%20MyLenovo%20Rewards%20members%20receive%20free%20expedited%20delivery*%20with%20their%20free%20membership.%3C%2Fspan%3E%3C%2Fp%3E","en":""},"id":"Pagef3260b23-c609-41d4-949d-e6c0516bea0e"},"gInfo":{"t_id":"","language":{},"id":""}}],"autoRun":true}

List Price is Lenovo’s estimate of product value based on the industry data, including the prices at which first and third-party retailers and etailers have offered or valued the same or comparable products. Third-party reseller data may not be based on actual sales.

If you would like to earn rewards, you will need to check the join Rewards checkbox above. To create an account without earning Rewards, register below.

Crystalline quartz melts between 1670 °C (tridymite) and 1713 °C (cristobalite), and because quartz is pervasive and easily identified, melted grains serve as an important temperature indicator. At TeH, we observed that unmelted potsherds displayed no melted quartz grains, indicating exposure to low temperatures. On the other hand, most quartz grains on the surfaces of pottery, mudbricks, and roofing clay exhibited some degree of melting, and unmelted quartz grains were rare. Nearly all quartz grains found on broken, unmelted surfaces of potsherds were also unmelted. On melted pottery and mudbricks, melted quartz has an estimated density of 1 grain per 5 mm2.

Melted quartz grains at TeH exhibit a wide range of morphologies. Some show evidence of partial melting that only melted grain edges and not the rest of the grain (Figs. 22, 23). Others displayed nearly complete melting with diffusion into the melted Ca–Al–Si matrix of pottery or mudbrick (Fig. 22). Melted quartz grains commonly exhibit vesiculation caused by outgassing (Figs. 22, 23), suggesting that those grains rose above quartz’s melting point of ~ 1713 °C.

SEM images of melted quartz grains on melted potsherd from the palace. (a) Highly melted quartz grain from the upper surface of melted pottery; shows flow lines of molten quartz in darker ‘neck’ at upper right; (b) manually constructed EDS-based phase map showing 100% quartz grain (green) embedded in Ca–Al–Si matrix of melted pottery (red); blue marks mixing zone between SiO2 and matrix at approximately > 1713 °C, the melting point of quartz. Yellow arrow points to area depleted in oxygen, indicating high-temperature transformation to elemental Si mixed with melted SiO2. (c) Highly melted quartz grain; (d) manually constructed EDS-based phase map showing diffusion/mixing zone in blue with arrow pointing to bubble, indicating outgassing as grain reached temperatures above its melting point. (e) Quartz grain that has almost completely melted; (f) manually constructed EDS-based phase map showing the small remnant of a melted quartz grain (green) with a wide mixing zone (blue).

SEM images of melted quartz grains on melted mudbrick from the palace. (a) Highly melted quartz grain; (b) manually constructed EDS-based phase map indicates center is pure SiO2 surrounded by melted mudbrick. Arrow points to vesicles indicating outgassing as grain temperature rose above ~ 1713 °C, the melting point of quartz. (c) The surface of a flattened quartz grain showing flow marks toward the upper right. High temperatures are required to lower the viscosity sufficiently for quartz to flow. (d) Manually constructed EDS-based phase map with an arrow pointing to vesicles indicating outgassing at high temperatures. (e) Close up of grain in panel ‘c’ showing flow marks (schlieren) at arrows. (f) Shattered, melted quartz splattered onto mudbrick meltglass; (g) manually constructed EDS-based phase map indicating that the blue area is SiO2; the yellow area is a shattered, thermally altered Fe-oxide grain.

An SEM–EDS elemental map of one melted grain showed that the quartz had begun to dissociate into elemental Si (Fig. 22b). Another grain (Fig. 23c–e) displayed flow marks consistent with exposure to temperatures above 1713 °C where the viscosity of quartz falls low enough for it to flow easily. Another SEM–EDS analysis confirmed that one agglutinated mass of material is 100 wt.% SiO2 (Fig. 23f, g), suggesting that this polycrystalline quartz grain shattered, melted, and partially fused again.

The presence of melted spherulitic objects (“spherules”) has commonly been used to help identify and investigate high-temperature airburst/impact events in the sedimentary record. Although these objects are referred to here as “spherules,” they display a wide range of other impact-related morphologies that include rounded, sub-rounded, ovate, oblate, elongated, teardrop, dumbbell, and/or broken formsS7), rounded detrital magnetite, and volcanic spherules.

Spherules in TeH sediment were investigated from stratigraphic sequences that include the MB II destruction layer at four locations: palace, temple, ring road, and wadi (Fig. 24). For the palace (Field UA, Square 7GG), the sequence spanned 28 cm with 5 contiguous samples of sediment ranging from 3-cm thick for the MB II destruction layer to 13-cm thick for some outlying samples. In the palace, 310 spherules/kg (Fig. 24d) were observed in the destruction layer with none found in samples above and below this layer. For the temple (Field LS, Square 42J), 5 continuous samples spanned 43 cm and ranged in thickness from 6 to 16 cm; the MB II layer contained ~ 2345 Fe- and Si-rich spherules/kg with 782/kg in the sample immediately below and none at other levels (Fig. 24c). Six contiguous samples from the ring road (Field LA, Square 28 M) spanned 30 cm with all 5 cm thick; the MB II destruction layer at this location contains 2150 spherules/kg with none detected in younger or older samples (Fig. 24b). Five discontinuous samples from the wadi spanned 170 cm, ranging from 10-cm thick for the destruction layer up to 20-cm thick for other samples; the MB II destruction layer at this location contained 2780 spherules/kg with none in samples from other levels (Fig. 24a, Supporting Information, Table S3). Notably, when melted mudbrick from the ring road was being mounted for SEM analysis, numerous loose spherules were observed within vesicles of the sample, confirming a close association between the spherules and meltglass. At all four locations, the peaks in high-temperature spherule abundances occur in the MB II destruction layer dating to ~ 1650 BCE.

Spherule abundances. (a)–(d). Number per kg for Fe- and S-rich spherules from 4 locations. Depths are in cm above or below the bottom of the destruction layer.

SEM images of spherules are shown in Figs. 25, 26, 27 and 28, and compositions are listed in Supporting Information, Table S4. The average spherule diameter was 40.5 µm with a range of 7 to 72 µm. The dominant minerals were Fe oxides averaging 40.2 wt.%, with a range of up to 84.1 wt.%; elemental Fe with a range of up to 80.3 wt.%; SiO2 averaging 20.9 wt.%, ranging from 1.0 to 45.2 wt.%; Al2O3 averaging 7.8 wt.% with a range of up to 15.6 wt.%; and TiO2 averaging 7.1 wt.% with a range of up to 53.1 wt.%. Fourteen spherules had compositions > 48 wt.% of oxidized Fe, elemental Fe, and TiO2; five spherules contained < 48 wt.% Fe and Ti; and two had > 75 wt.% Fe with no Ti. Eight of 23 spherules analyzed contained detectable levels of Ti at up to 53.1 wt.%.

SEM image of rare-earth (REE) spherule. (a) REE-rich 72-µm-wide spherule from the palace, dominantly composed of Fe, La, Ce, and O. (b) Close up of REE blebs found on the spherule. (c)–(f) SEM–EDS elemental maps showing composition. La = 15.6 wt.% and Ce = 21.0 wt.%. Ce is enriched over Fe and La in the middle part of the spherule, as seen in panels ‘d’ through ‘f’.

SEM images of a spherule mainly composed of Fe and Si. (a) Fe–Ti-rich 54-µm-wide spherule from the palace. Spherule displays a protrusion to the left, suggesting aerodynamic shaping when molten, after which the tail detached. (b) A focused ion beam (FIB) was used to section the spherule, revealing inclusions of wassonite or titanium sulfide (TiS; yellow arrows) that are lighter-colored than the matrix. (c)–(f) Color-coded SEM–EDS elemental maps, showing the distribution of Ti, S, Si, and Fe and the location of the TiS grains. The spherule is dominantly composed of Fe and Si with minor amounts of Ti and S found in TiS inclusions.

Fe-rich spherules embedded in meltglass. (a) Optical photomicrograph of a 167-µm-wide piece of meltglass with embedded Fe-rich spherules. (b) SEM image of same grain as in panel ‘a’. Melted quartz grain (Qtz) is embedded in Ca–Al–Si-rich matrix, which has the same composition as melted mudbrick. (c) SEM close-up image of the boxed area and panel ‘b’, showing splattered Fe-rich spherule.

Two unusual spherules from the palace contain anomalously high percentages of rare-earth elements (REEs) at > 37 wt.% of combined lanthanum (La), and cerium (Ce) (Fig. 26), as determined by preliminary measurements using SEM–EDS. Minor oxides account for the rest of the spherules’ bulk composition (Table S1).

One 54-µm-wide sectioned spherule contains titanium sulfide (TiS) with a melting point of ~ 1780° C. TiS, known as wassonite, was first identified in meteorites (Fig. 27) and has been reported in impact-related material

One unusual piece of 167-µm-wide Ca–Al–Si meltglass contains nearly two dozen iron oxide spherules on its surface (Fig. 28). The meltglass contains a completely melted quartz grain as part of the matrix (Fig. 28b). Most of the spherules appear to have been flattened or crushed by collision with the meltglass while they were still partially molten (Fig. 28c).

Melted materials from non-impact-related combustion have been reported in multiple studies. Consequently, we investigated whether Ca-, Fe-, and Si-rich spherules and meltglass (mudbrick, pottery, plaster, and roofing clay) may have formed normally, rather than from a cosmic impact event. For example, (i) glassy spherules and meltglass are known to form when carbon-rich biomass smolders below ground at ~ 1000° to 1300 °C, such as in midden mounds

For the melted materials, there is a definitive difference: high-temperature minerals are embedded in meltglass at TeH but none are present at these other sites (except for Tell Leilan). To explore this difference, Moore et al.

At the sites with non-impact meltglass, estimated temperatures were consistently less than 1300 °C, too low to melt magnetite into Fe-rich spherules, e.g., with compositions of > 97% wt.% FeO, as are found at TeH. Nor can these low temperatures produce meltglass and spherules embedded with melted zircon (melting point = 1687 °C), chromite (2190 °C), quartz (1713 °C), platinum (1768 °C), and iridium (2466 °C). Moore et al.

This evidence demonstrates that although the matrix of the spherules and meltglass at TeH likely experienced incipient melting at temperatures lower than ~ 1300 °C, this value represents only the minimum temperature of exposure, because the high-temperature minerals embedded in them do not melt at such low temperatures. Instead, the spherules and meltglass at TeH must have reached temperatures greater than ~ 1300 °C, most likely involving brief exposure to ambient temperatures of ~ 2500 °C, the melting point of iridium. These temperatures far exceed those characteristic of city fires and other types of biomass burning. In summary, all of this evidence is consistent with very high temperatures known during cosmic impacts but inconsistent with other known natural causes.

In sediments of the destruction layer, we observed amber-to-off-white-colored spherules (Fig. 29) at high concentrations of ~ 240,000/kg in the palace, ~ 420/kg in the temple, ~ 60/kg on the ring road, and ~ 910/kg in the wadi (Supporting information, Table S2). In all four profiles, the spherules peak in the destruction layer with few to none above or below. Peak abundances of calcium carbonate spherules are closely associated with peak abundances of plaster fragments, which are the same color. By far the most spherules (~ 250× more) occurred in the destruction layer of the palace, where excavations showed that nearly every room and ceiling was surfaced with off-white lime-based plaster. Excavators uncovered high-quality lime plaster fragments still adhering to mudbricks inside the MB II palace complex, and in one palace room, we uncovered fragments of melted plaster (Fig. 29e). In contrast, lime plaster was very rarely used in buildings on the lower tall, including those near the temple.

Images of calcium carbonate spherules and melted plaster from TeH. (a) Photomicrographs of translucent, amber-colored CaCO3 spherules from the destruction layer in the palace. (b) SEM image of 83-µm carbonate spherule with impact or outgassing crater at arrow. (c) Photomicrograph of ~ 2-mm-wide piece of partially melted palace plaster from oxygen/propylene torch test, showing incipient melting at 1500 °C. Arrows point to hemispheric droplets emerging as spherules. (d) 142-µm cluster of 8 carbonate spherules with apparent impact or outgassing crater at arrow. (e) 64 × 30 mm piece of melted plaster that broke off the palace wall and became melted. It is composed only of calcium, carbon, and oxygen.

To explore a potential connection between plaster and spherules, we performed SEM–EDS on samples of the palace plaster. Comparison of SEM–EDS analyses shows that the plaster composition has a > 96% similarity to the spherule composition: CaCO3 = 71.4 wt.% in plaster versus 68.7 wt.% in the spherules; elemental C = 23.6 versus 26.3 wt.%; SiO2 = 2.4 versus 1.8 wt.%; MgO = 1.7 versus 2.0 wt.%; and SO3 = 0.94 versus 1.2 wt.%. The high carbon percentage and low sulfur content indicate that the plaster was made from calcium carbonate and not gypsum (CaSO4·2H2O). SEM imaging revealed that the plaster contains small plant parts, commonly used in plaster as a binder, and is likely the source of the high abundance of elemental C in the plaster. Inspection showed no evidence of microfossils, such as coccoliths, brachiopods, and foraminifera. The morphology of the spherules indicates that they are not authigenic or biological in origin.

At TeH, fragments of CaCO3-based plaster are intermixed in covarying abundances with CaCO3-based spherules with both compositions matching to within 96%. This similarity suggests that the carbonate spherules are derived from the plaster. We infer that the high-temperature blast wave from the impact event stripped some plaster from the interior walls of the palace and melted some into spherules. However, it is difficult to directly melt CaCO3, which gives off CO2 at high temperatures and decomposes into lime powder. We investigated this cycle in a heating experiment with an oxygen/propylene torch and found that we could decompose the plaster at ~ 1500 °C, the upper limit of the heating test, and begin incipient melting of the plaster. The heated plaster produced emergent droplets at that temperature but did not transform into free spherules (Supporting Information, Text S2).

Similar spherules have been reported from Meteor Crater, where spherules up to ~ 200 μm in diameter are composed entirely of CaCO3 formed from a cosmic impact into limestone

According to the previous investigations1). Because of the presence of magnetite (Fe3O4) in the REE spherule, its melting point is inferred to be > 1590 °C (Table 1). The Si-rich spherules are similar in composition to TeH sediment and mudbrick, and thus, we propose that they were derived from the melting of these materials at > 1250 °C. The carbonate-rich spherules likely formed at > 1500 °C.

To more accurately determine the maximum temperatures of the destruction layer, we used SEM–EDS to comprehensively investigate melted minerals on the outer surfaces of melted pottery and mudbricks. We searched for and analyzed zircon (melting point: ~ 1687 °C), chromite (~ 2190 °C), and quartz (~ 1713 °C)

Melted zircons in pottery and mudbricks were observed (Fig. 30) at an estimated density of 1 grain per 20 mm2. On highly melted surfaces, nearly all zircons showed some degree of melting. In contrast, nearly all zircons found on broken interior surfaces were unmelted (Fig. 30d), except those within ~ 1 mm of melted surfaces. This implies that the temperature of the surrounding atmosphere was higher than the internal temperatures of the melting objects. Unmelted potsherds displayed only unmelted minerals.

SEM images of melted zircon grains. (a) Melted TeH zircon grain with bubbles at yellow arrow due to high-temperature dissociation and/or entrapped porosity. (b) Melted TeH zircon grain decorated with bubbles along the fracture line at upper arrow; arrows labeled “Bd” point to bright granular baddeleyite, ZrO2, formed during the high-temperature dissociation of zircon. (c) Almost fully melted TeH zircon grain mixing into the Ca–Al–Si matrix. (d) A typical unmelted zircon grain from TeH with straight, euhedral edges. Grain shows cracks on the top surface from possible thermal or mechanical damage. (e) For comparison, from cosmic airburst/impact at Dakhleh Oasis in Egypt: melted zircon decorated with lines of bubbles (arrow).

The melted zircons in TeH materials exhibit a wide range of morphologies. Most showed evidence of sufficient melting to alter or destroy the original distinctive, euhedral shape of the grains. Also, the grains were often decorated with vesicles that were associated with fractures (Fig. 30a, c).

Stoichiometric zircon contains 67.2 wt.% and 32.8 wt.% ZrO2 and SiO2 respectively, but in several TeH samples, we observed a reduction in the SiO2 concentration due to a loss of volatile SiO from the dissociation of SiO2. This alteration has been found to occur at 1676 °C, slightly below zircon’s melting point of 1687 °C2:SiO2 ratios and to the formation of distinctive granular textures of pure ZrO2, also known as baddeleyite30, 31, 32). With increasing time at temperature, zircon will eventually convert partially or completely to ZrO2. Nearly all zircons observed on the surfaces of melted materials were either melted or showed some conversion to baddeleyite. We observed one zircon grain (Fig. 32d–e) displaying granular ZrO2 associated with three phases that span a wide range of SiO2 concentrations, likely formed at temperatures above 1687 °C. This extreme temperature and competing loss of SiO over an inferred duration of only several seconds led to complex microstructures, where grains melted, outgassed, and diffused into the surrounding matrix.

SEM images of other melted zircon grains in palace potsherd. (a) Two melted zircon grains adjacent to a previously discussed melted quartz grain; (b) close-up of same zircon grains; (c) manually constructed EDS-based phase map showing baddeleyite grains in green. The blue area represents melted zircon, while the red background represents the Ca–Al–Si matrix of the melted pottery. (d) Manually constructed EDS-based phase map of zircon grain showing small baddeleyite grains in green at the top.

SEM images of melted zircon grains in mudbrick meltglass from the palace. (a) Thermally distorted zircon grain with a “hook” that resulted from the flow of molten material at > 1687 °C; the darker area represents unrelated debris on top of zircon. (b) Manually constructed EDS-based phase map showing baddeleyite grains (Bd = ZrO2) in green, zircon in blue, and melted mudbrick in red. (c) Zircon grain showing limited thermal alteration, yet sufficient to cause dissociation into bright baddeleyite grains at ~ 1676 °C. (d) Zircon grain exhibiting three phases of thermal alteration, as shown in detail in (e), where a manually constructed EDS-based phase map demonstrates that high temperatures caused bubbling in the center band of zircon (purple = Hi) producing sub-micron-sized grains of baddeleyite (e.g., at arrow). Medium temperatures caused zircon to melt and flow (blue = Lo), and lower temperatures at the left end of grain produced thermal cracks (medium blue = Med). The green area marks the high-Si diffusion zone resulting from the dissociation of zircon. (f) Zircon grain from TeH has been fully converted to granular baddeleyite.

Bohor et al.30e). The presence of bubbles indicates that temperatures reached at least 1676 °C, where the zircon began to dissociate and outgas. Similar dissociated zircon grains also have been found in tektite glass and distal fallback ejecta (deposited from hot vapor clouds). Granular baddeleyite-zircon has been found in the ~ 150-km-wide K-Pg impact crater

Examples of melted chromite, another mineral that melts at high temperatures, were also observed. Thermally-altered chromite grains were observed in melted pottery, melted mudbricks, and melted roofing clay from the palace. Their estimated density was 1 grain per 100 mm2, making them rarer than melted zircon grains. The morphologies of chromite grains range from thermally altered (Fig. 33a) to fully melted (Fig. 33b, d). One chromite grain from the palace displays unusual octahedral cleavage or shock-induced planar fractures (Fig. 33b). The typical chemical composition for chromite is 25.0 wt.% Fe, 28.6 wt.% O, and 46.5 wt.% Cr, although the Cr content can vary from low values to ~ 68 wt.%. SEM images reveal that, as chromite grains melted, some Cr-rich molten material migrated into and mixed with the host melt, causing an increase in Cr and Fe, and corresponding depletion of Si. The ratio of Cr to Fe in chromite affects its equilibrium melting point, which varies from ~ 1590 °C for a negligible amount of Cr up to ~ 2265 °C for ~ 46.5 wt.% Cr as in chromite or chromian magnetite ((Fe)Cr2O4), placing the melting point of TeH chromite at close to 2265 °C.

SEM images of melted chromite grains found on a melted potsherd from the palace. (a) Shattered, polycrystalline chromite grain that appears to have become agglutinated while molten. (b) Melted chromite grain, displaying cleavage (lamellae) suggestive of thermal and/or mechanical shock metamorphism at ~ 12 GPa; (c) close-up image showing angles between three sets of crystalline cleavage; (d) manually constructed EDS-based phase map showing chromite (purple) embedded in Ca–Al–Si matrix. The lines mark three sets of cleavage extending across the entire grain. A melt tail merging with the matrix is observed to trail off to the upper right of the grain at arrow.

Chromite grains theoretically melt at ~ 2190 °C. Moore et al.S8). At temperatures of ~ 1600 °C and ~ 1700 °C, the shapes of chromite grains were intact but exhibited limited melting of grain edges. These results establish a range of ~ 1600° to 1700 °C for melting chromite grains.

Because chromite typically does not exhibit cleavage, the grain exhibiting this feature is highly unusual. Its origin is unclear but there are several possibilities. The cleavage may have resulted from exsolution while cooling in the source magma. Alternately, the lamellae may have resulted from mechanical shock during a cosmic impact, under the same conditions that produced the shocked quartz, as reported by Chen et al.

Using SEM–EDS, we investigated abundances and potential origins (terrestrial versus extraterrestrial) of platinum-group elements (PGEs) embedded in TeH meltglass, in addition to Ni, Au, and Ag. Samples studied include melted pottery (n = 3); melted mudbrick (n = 6); melted roofing clay (n = 1), and melted lime-based building plaster (n = 1). On the surfaces of all four types of meltglass, we observed melted metal-rich nuggets and irregularly shaped metallic splatter, some with high concentrations of PGEs (ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum (Pt)) and some nuggets enriched in silver (Ag), gold (Au), chromium (Cr), copper (Cu), and nickel (Ni) with no PGEs (Figs. 34, 35). Importantly, these metal-rich nuggets were observed only on the top surfaces of meltglass and not inside vesicles or on broken interior surfaces.

SEM images of nuggets of melted metals in mudbrick meltglass from the palace. (a)–(c) Pt-dominant TeH nuggets enriched in ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum (Pt). (d)–(f) Fe-dominant TeH splatter is also enriched in PGEs. (g)–(i) Nuggets enriched in varying percentages and combinations of nickel (Ni), chromium (Cr), copper (Cu), and silver (Ag).

Average composition of selected metal-rich nuggets from the palace. (a-h) Silver (Ag), gold (Au), chromium (Cr), copper (Cu), iridium (Ir), nickel (Ni), platinum (Pt), and ruthenium (Ru), showing wt.% in selected nuggets from the destruction layer of the palace (7GG).

Using SEM–EDS, we identified variable concentrations and assemblages of PGEs. The metallic particles appear to have melted at high temperatures based on the minimum melting points of the elements: iridium at 2466 °C; platinum = 1768 °C; and ruthenium = 2334 °C, indicating a temperature range of between approximately 1768° and 2466 °C. Our investigations also identified two PGE groups, one with nuggets in which Pt dominates Fe and the other with metallic splatter in which Fe dominates Pt.

We conducted 21 measurements on Pt-dominant TeH nuggets on meltglass (Fig. 34a–c). The nuggets average ~ 5 µm in length (range 1–12 µm) with an estimated concentration of 1 nugget per 10 mm2. For these nuggets, Fe concentrations average 1.0 wt.%, Ir = 6.0 wt.%, and Pt = 44.9 wt.% (Supporting Information, Tables S6, S7). The presence of PGEs was confirmed by two SEM–EDS instruments that verified the accurate identification of PGEs through analyses of several blanks that showed no PGE content. Some concentrations are low (< 1 wt.%) with high uncertainties (± 100 wt.%), and elemental concentrations greater than 10 wt.% have certainties of approximately ± 10 wt.%, making these results preliminary and indicating the need for further analyses. However, even though uncertainties are high, the relative elemental relationships of Fe > Pt or Pt > Fe were found to be consistent between the two instruments.

To determine the source of TeH nuggets and splatter, we constructed ternary diagrams. Terrestrial PGE nuggets are commonly found in ore bodies that when eroded, can become concentrated in riverine placer deposits, including those of the Jordan River floodplain. To compare Fe–Ir–Pt relationships among the TeH nuggets, we compiled data from nearby placer deposits in GreeceS6, S7). The ternary diagrams reveal that the values for Pt-dominant TeH nuggets overlap with Pt-dominant terrestrial placer nuggets but the Fe-dominant splatter is dissimilar (Fig. 36a).

Ternary diagrams for PGE-rich grains. Comparison of Fe–Ir–Pt ratios of PGE-rich nuggets fused into the surfaces of TeH meltglass. There are two populations of TeH nuggets (red diamonds): Pt-dominant at #1 (top) and Fe-dominant at #2 (bottom left). (a) TeH Pt-dominant nugget group #1 (red diamonds) overlaps Pt-dominant but not Ir-dominant nuggets (blue circles) from placers and ophiolite deposits in Greece, Turkey, Iraq, Russia, Canada, and the USA. The Fe-dominant TeH nugget group #2 is geochemically dissimilar to all known placer nuggets, suggesting that these nuggets are not placer-derived. (b) TeH nuggets (red diamonds) compared to nuggets in carbonaceous chondrites (light gray circles) and nuggets in cosmic spherules (dark gray circles). Pt-dominant TeH nuggets in group #1 are a poor match, but Fe-dominant TeH splatter is an excellent match with chondritic meteorites and cosmic spherules, suggesting that they may be extraterrestrial in origin and that the impactor may have been a chondrite. (c) TeH nuggets (red diamonds) are a poor match for most nuggets in iron meteorites (purple circles), but an excellent match for nuggets found in comets (green circles). These data suggest that Fe-dominant PGE nuggets at TeH may have originated from cometary material. (d) Semi-log comparison of PGEs ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum (Pt), normalized to CI chondrites. TeH Fe-dominant splatter (red line) is an excellent match for PGE nuggets in carbonaceous chondrites (blue line), cosmic spherules (purple line), micrometeorites (dark blue line), and iron meteorites (gray line). In contrast, TeH PGE nuggets are a poor match for bulk material from CI-normalized CV-type chondrites (e.g., Allende; orange line) and CM-type chondrites (e.g., Murchison; brown line).

We explored a potential extraterrestrial origin by constructing ternary diagrams for comparison of TeH Fe-dominant splatter with known meteorites and comets (Fig. 36b, c). We compiled data for 164 nuggets extracted from carbonaceous chondritic meteorites (e.g., Allende, Murchison, Leoville, and Adelaide)S6, S7. The Fe-dominant TeH splatter (Fig. 36b) closely matches nuggets from carbonaceous chondrites and cosmic spherules but is a weak match for most iron meteorites (Fig. 36c). In addition, the TeH nuggets are similar to four cometary particles, two of which were collected during the Stardust flyby mission of Comet Wild 2 in 2004S6, S7.

The TeH Fe-dominant splatter closely matches all types of extraterrestrial material with a similar pattern among all data sets: Pd has the lowest normalized values and Os and/or Ir have the highest, closely followed by Pt. The TeH splatter was also compared to the CI-normalized wt.% of bulk meteoritic material from CV- and CM-type chondrites (Fig. 36d). The composition of TeH splatter shows poor correlation with bulk chondritic materials, although the splatter is an excellent geochemical match with the PGE nuggets inside them. In summary, the CI normalization of PGEs suggests an extraterrestrial origin for the Fe-dominant TeH splatter, just as the ternary diagrams also suggest an extraterrestrial source. The correspondence of these two independent results suggests that the quantification of PGEs is sufficiently accurate in this study.

Another unusually abundant element, Mo, is also associated with Fe-dominant splatter but not with Pt-dominant nuggets. Mo averages 0.3 wt.% with up to 1.1 wt.% detected in Fe-dominant splatter but with none detected in TeH Pt-dominant nuggets. Mo also is not reported in any terrestrial placer nuggets and occurs in low concentrations (less than ~ 0.02 wt.%) in iron meteorites. In contrast, Mo is reported at high concentrations in PGE nuggets from carbonaceous chondrites (~ 11.5 wt.%), cosmic spherules (0.6 wt.%), and cometary material (5.8 wt.%). Thus, the Mo content of TeH splatter appears dissimilar to terrestrial material but overlaps values of known cosmic material, suggesting an extraterrestrial origin.

Based on the volume and weight of the meltglass, we estimate that the extraterrestrial-like metallic TeH Fe-dominant splatter represents < 1 wt.% of the total mass of meltglass. This low concentration is typical of low impactor content in impact ejecta (< 1 wt.%)

We also investigated nuggets that lack PGEs. The geochemistry of these nuggets shows two distinct populations, one Ni-dominant and one Fe-dominant (Fig. 34g–i). Twelve measurements of TeH samples show enrichments in Ag averaging 5.7 wt.%, Au = 0.6 wt.%, Cr = 2.2 wt.%, Cu = 2.8 wt.%, and Ni = 3.7 wt.%. All particles appear to have been melted at high temperatures: silver at ~ 961 °C; gold at 1064 °C; chromium at 1907 °C; copper at 1085 °C; and nickel at 1455 °C.

Importantly, the PGE-rich nuggets and splatter were observed embedded only on melted surfaces of the TeH meltglass but not inside the vesicles or within the meltglass. This suggests that the nuggets and splatter were not contained in the original sedimentary matrix but were fused onto the TeH glass while still molten. Geochemical analyses suggest a dual origin. The Pt-dominant nuggets do not match known extraterrestrial material and instead appear to be of terrestrial origin, possibly from placer deposits and regional mines. It is unclear exactly how they became embedded onto but not inside TeH meltglass, but one possibility is that they were originally buried as river-laid, PGE-rich placer deposits. If so, we propose that they were ejected during the impact event and distributed across the molten glass by the impact blast wave. Another possibility is that they derive from jewelry and raw precious metals in the palace complex that were pulverized and dispersed during the high-velocity destruction of the palace.

In contrast, the Fe-dominant nuggets fused into the surfaces of TeH meltglass closely match the composition of nuggets from chondritic meteorites, cosmic spherules, and comets, consistent with an extraterrestrial origin. The data suggest that a carbonaceous chondrite or a comet detonated in the air near TeH, pulverized PGE-rich nuggets within the bolide, accreted terrestrial placer nuggets, and dusted both terrestrial and extraterrestrial material across the surfaces of molten mudbricks, pottery, and building plaster at low concentrations of < 1 wt.%.

For TeH bulk sediment, neutron activation analyses show Pt abundance peaks in the destruction layer of all profiles tested (Fig. 37a–d) at ~ 2× to 8× an average crustal abundance of 0.5 ppb. Sedimentary Ir was below detection at < 0.1 ppb for the palace, temple, and ring road, but unusually high in the wadi, where values peaked at 1.0 ppb, ~ 50× larger than a crustal abundance of 0.02 ppb (Supporting Information, Table S3). Also, Pt/Pd ratios in bulk sediment from the destruction layers are anomalously higher than background layers by ~ 4× to 14× (Fig. 37e–h).

Plots for sedimentary Platinum and Palladium. (a)–(d) Platinum (Pt) concentrations. (e)–(h) Platinum/palladium ratios (Pt/Pd). Depths are in cm above or below the bottom of the destruction layer. Sample locations are labeled. Crustal abundance values (orange dashed lines) are ~ 0.5 ppb for Pt.

Abundances of Pt, Ir, and the Pt/Pd ratios all peak in sediment at or near the top of the destruction layer, suggesting an influx of those elements at 1650 BCE, most likely from both extraterrestrial and terrestrial sources. Sedimentary concentrations of Ir only peak in the wadi samples and were not detectable at the other three sites for unknown reasons.

The interior portions of many melted pieces of mudbrick, roofing clay, and pottery are highly vesicular, and the walls of these vesicles nearly always display an array of metal-rich crystals (Fig. 38). These include elemental iron and iron oxides, labeled as FeO, but is actually oxidized as hematite (Fe2O3) with a melting point of ~ 1565 °C; magnetite (Fe3O4) that melts at ~ 1590 °C; and/or elemental iron (Fe) melting at ~ 1538 °C (Fig. 38a, b, d, f, g). Also observed on vesicle walls were crystals of Fe phosphide (Fe2P) that melts at ~ 1100 °C (Fig. 38c, g), manganese oxide (MnO) at ~ 1945 °C (Fig. 38d), calcium phosphate (Ca3(PO4)2) at ~ 1670 °C (Fig. 38e), and calcium silicate (CaSiO2) at ~ 2130 °C (Fig. 38e).

SEM images of gas vesicles in melted material from the palace. (a), (b) Vesicles in melted pottery are lined with crystals of iron and iron oxide (elemental Fe, Fe2O3, and/or Fe3O4). (c)–(g) Vesicles in melted mudbrick and roofing clay often are lined with a variety of crystals including elemental Fe, iron oxide, Fe phosphide (Fe2P), manganese oxide (MnO), calcium phosphate (Ca3(PO4)2), and calcium silicate (CaSiO3). These crystals are consistent with vapor deposition at high temperatures.

SEM inspection of the palace mudbrick meltglass revealed partially melted grains of magnetite (Fe3O4) with a melting point of ~ 1590 °C (Fig. 39a, b) and titanomagnetite (TiFe2O4) with a melting point of ~ 1550 °C (Fig. 39c, d). The latter is an oxyspinel that commonly occurs as discrete grains or as an exsolution product within magnetite. The chemical composition of magnetite at equilibrium is 72.36 wt.% Fe and 27.64 wt.% O. Titanomagnetite is 21.42 wt.% Ti, 49.96 wt.% Fe, and 28.63 wt.% O. SEM–EDS analysis confirms similar compositions for the observed TeH grains.

SEM images of melted iron and titanomagnetite in mudbrick meltglass from the palace. (a) Shattered elemental Fe grain containing < 0.1 wt.% oxygen as determined by SEM–EDS; (b) close-up showing surface porosity. (c) Titanomagnetite grain showing surface porosity; (d) close-up showing aligned porosity possibly along former grain boundaries. The cause of the porosity is uncertain, but because these grains are associated with other high-temperature melted minerals, we propose that this porosity resulted from exposure to high temperatures.

These grains display bubble-rich features that are commonly associated with grain fractures. There are several possibilities. (i) Approximately 20% of the time, magnetite grains are reported to be naturally overprinted by porous magnetite as a precipitation product, creating a bubble-like texture

Sulfide and phosphide grains were found attached to the walls of the vesicles within mudbrick meltglass. SEM–EDS analyses of palace mudbrick meltglass identified melted Fe sulfide (FeS), also known as troilite (Figs. 40, 41), with a composition of 63.53 wt.% Fe and 36.47 wt.% S and a melting point of ~ 1194 °C. Commonly found associated with the Fe sulfide, Fe phosphide (Fe2P; Fig. 40b, e) is a nickel-poor variety of barringerite, a mineral first identified at Meteor Crater in Arizona. Another variant of Fe phosphide, Fe3P, was also identified in melted mudbrick from the palace. Both phosphide variants melt at ~ 1100 °C. Fe phosphide is common in meteorites, but although terrestrially rare, Fe2P is found in pyrometamorphic rocks, such as are found in the Hatrurim Formation in nearby Israel2P grains from Israel, the TeH grains lack detectable Ni, Co, and Cr.

SEM images of Fe-S-P-enriched nugget in vesicle of mudbrick meltglass from the palace. (a) Chemically complex nugget inside a vesicle; contains Fe, S, and P. (b) Manually constructed EDS-based phase map showing that nugget is dominantly composed of Fe oxides, S as FeS, and P as Fe2P. (c)–(f) SEM–EDS elemental maps showing the composition of nugget by regions.

SEM images of Fe–S–Ca–P-rich grains in mudbrick meltglass from the palace. (a) Melted Fe-rich grain is chemically complex, containing Fe, S, Ca, and P. (b) Manually constructed EDS-based phase map marking areas of Fe oxides (purple, labeled as FeO), FeS (blue), and Ca3P2, calcium phosphide (green). (c) High-temperature melted Fe-rich grain; (d) manually constructed EDS-based phase map showing the area that is predominantly Fe oxide, bordered by a thin rim of FeS.

Visual inspection indicated that the sulfide and phosphide grains were attached to the inner surfaces of vesicles, and therefore, most likely formed by vapor deposition at > 1100 °C, rather than by crystallization from the melted matrix. Troilite (FeS) is very rare terrestrially but common in meteoritic material

SEM–EDS analyses also show that vesicles in melted mudbrick from the palace contain calcium phosphide (Ca3P2) (Fig. 42). This mineral has a stoichiometric composition of ~ 66.0 wt.% Ca and ~ 34.0 wt.% P and melts at ~ 1600 °C (Table 1). Unlike Fe sulfide and Fe phosphide discussed above that appear to have formed by vapor deposition, these examples most likely crystallized from the molten Ca–Al–Si matrix material.

SEM images of calcium phosphide crystals in vesicles of mudbrick meltglass from the palace. (a) and (c) Crystals of calcium phosphide, Ca3P2, lining the inside wall of meltglass vesicles; (b) and (d) manually constructed EDS-based phase map of Ca3P2 (green) crystals embedded in typical Ca–Al–Si melted matrix.

SEM–EDS analyses of palace mudbrick meltglass (Fig. 43a, b) and melted pottery (Fig. 43c) reveal the presence of Ca silicate, also known as wollastonite (CaSiO3), with a composition of 48.3 wt.% CaO and 51.7 wt.% SiO2 and a melting point ~ 1540 °C (Table 1). These crystals are mostly found on broken surfaces of the matrix but also are sometimes observed inside vesicles. Unlike Fe sulfide and Fe phosphide above, which appear to have formed by vapor deposition, these crystals appear to have condensed from the molten matrix as it cooled.

SEM images of wollastonite crystals in palace melted pottery and mudbricks. (a) Spindle-like crystals of wollastonite (CaSiO4) on the broken face of mudbrick meltglass. Crystals of iron oxide line the vesicle. (b) Wollastonite crystal within the meltglass matrix. (c) Wollastonite crystals within a vesicle of melted pottery.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey