lcd panel backlight not working manufacturer

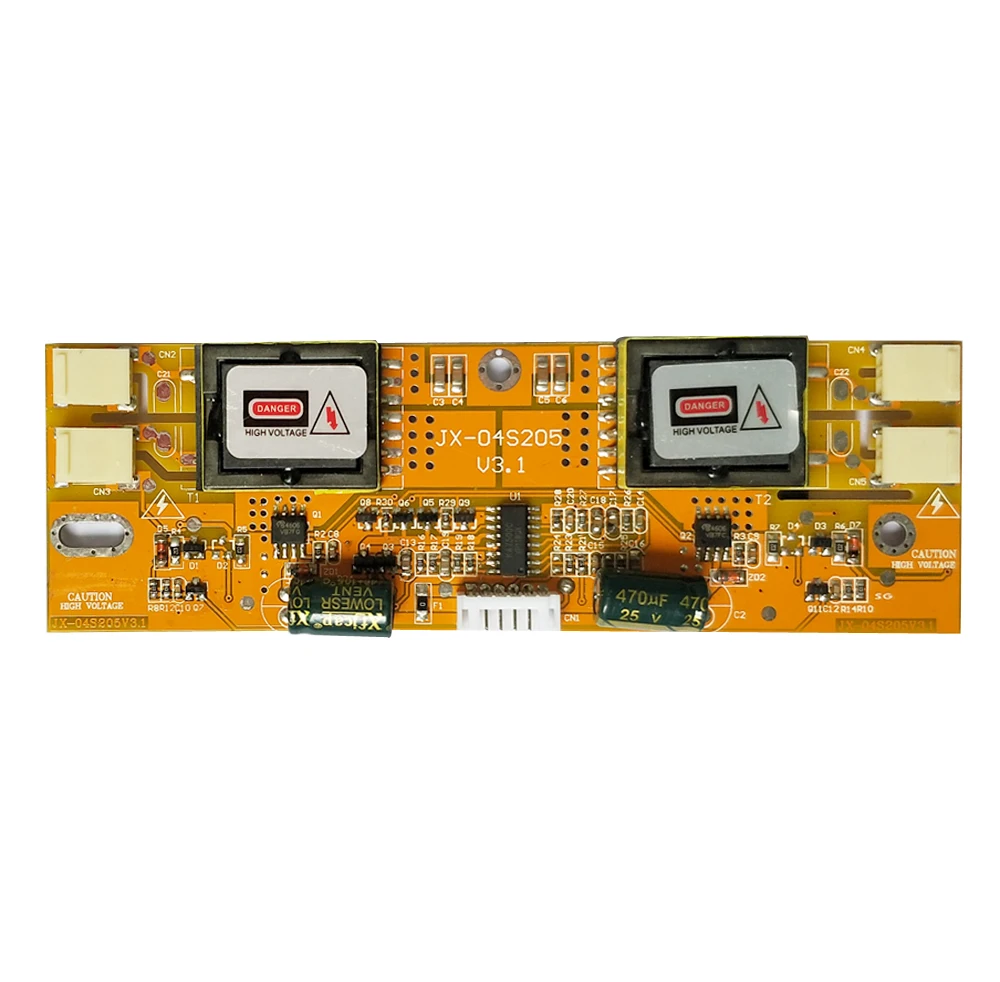

Most hardware operates at voltages between 1.8 V - 5.2 V. However, the backlight circuit operates at about 15 - 20 V. At this higher voltage, the backlight components are more prone to damage when a short circuit occurs. The high voltage backlight circuit is also prone to corrosion from water damage.

The backlight diode - Like the backlight filters, the backlight diode is a fragile component. In cases where a backlight filter is particularly burned up, you’ll often find that the diode has failed as well. Diode failure in the absence of filter damage is rare, but it can happen.

The most common cause of a self-induced short occurs from working on the device with the battery still connected. Even when the screen is dark, there is voltage in the backlight circuit. A slipped pair of tweezers or misalignment of the LCD connector can short the backlight circuit to ground. Avoid self-induced shorts by always disconnecting the battery before working on a device.

Another cause of backlight shorts is faulty assembly procedures. During device fabrication, these solder joints are protected by piece of black tape—however, during the screen refurbishing process some manufacturers neglect to replace the tape, apply it misaligned, or fail to apply it securely. As a result, the screen initially works during testing—but once the metal LCD shield is installed, the exposed solder joints touch the grounded frame, shorting the backlight circuit.

Backlight shorts can occur when the latch for the ZIF connector securing the LCD flex is missing. The LCD flex slides out an angle and the high voltage backlight pin contacts the ground pin, causing a short circuit.

Water damage is a frequent source of backlight problems. Water will corrode the LCD connector pin/pad junction, which breaks the electrical path to the connector and can damage the filter.

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

To diagnose whether your device is “dead” or just has a malfunctioning screen, try connecting it to your computer. If the computer recognizes the device, then the problem probably resides with the LCD screen or backlight circuit.

The good news is that nearly all backlight failures are repairable. Once the damaged component is identified it can simply be replaced. Follow this Samsung Television Backlight Replacement guide for more details.

This content is almost entirely sourced from Reed Danis and his iPhone/iPad Backlight Troubleshooting page. Users were finding this content when searching for TV related backlight issues so we repurposed it for TV.

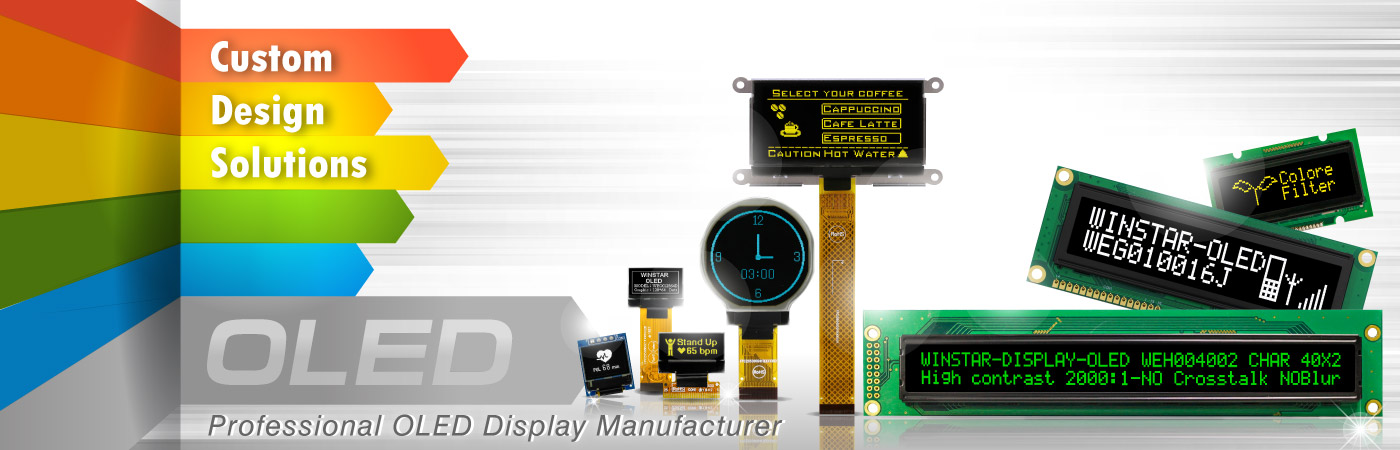

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

4. #Determine whether the gate IC is OK. There is a signal test point on the back of COG-IC, and the green paint can be scraped for measurement confirmation; If there is a gate IC problem, which IC fault can be confirmed. The confirmation of gate IC fault is only for analysis when you are interested, and this method is not recommended.

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

One LED like those ones typically needs between 2.5-3.6v input voltage to light up. By looking up this model online, I found out that the ones used on those strips need 3.6v; so as there are 9 LEDs per strip: 3.6 x 9 = 32.4v input voltage required to light a single strip. That’s the maximum voltage we do NOT want to exceed, otherwise LEDs could be damaged during testing.

So, I took 3 9v batteries that were laying in a drawer, put them in series to make a virtual 27v battery (3 x 9v). It’s less then the optimal 32.4v required but not that much lower, it might be able to light the strip a bit so we can identify which is not working. Here is a look at the set-up:

Now we simply have to test each strips individually to see if they light up or not. For each that doesn’t completly, it will mean it has at least one defective LED.

After repeating this operation on all strips, I found only 1 defective LED, the same we thought looked burnt when we first had a look at the backlight (3rd strip from the top, 6th LED from the left). For a better understanding at what a burnt LED looks like here are 2 pictures of a burnt one and an OK one. Mind the roasted color compared to the regular one.

For starters I’ll go with the third one, just to make sure there is no other issues with the TV, but afterwards it’s better to replace the LED with a new one, otherwise you might notice a darker spot on the image.

Desktop and laptop computer LCD monitors sport a long light bulb to display the video. When this bulb burns out, the screen dims to almost black. Failing backlights can also cause the picture to flicker, blink on and off or offer an odd color cast to the screen.

Troubleshooting Before assuming the backlight bulb is the issue, check to make sure the monitor is connected properly and receiving power. Watch for the power light near the On/Off switch when you plug in the monitor, and verify all cables are connected tightly and appear undamaged. If possible, connect a different monitor to your computer using the same cables to verify the computer"s video card is sending a picture. If everything else seems in good working order, the monitor could have suffered a backlight failure.

Testing, Testing Various things can cause your monitor to go dark, ranging from a burned-out backlight bulb to a monitor-killing short circuit. In most cases, a monitor with a burned-out bulb still has an image on the screen, it"s just very dim. Look closely at your screen; if you see absolutely no picture at all, the monitor itself may have gone belly up. A bad bulb can be tested, but only if you have a working replacement bulb and are comfortable opening your monitor and doing some checking.

Some Disassembly Required As you would guess, checking the backlight bulb on your monitor requires actually getting into the screen and pulling out the suspect light. Monitor disassembly varies by model; check your monitor"s manufacturer"s website for instructions. Once you have the bulb out, disconnect it from the inverter board that powers it and connect your working bulb. If the new one lights, your old one was dead. If the new one is as dark as the first, your inverter board may have failed and will need replacement.

Seek Professional Help Because cracking open your laptop or desktop monitor can leave other parts vulnerable to unintentional damage, you have to be confident in your abilities to attempt backlight testing. One wrong move could fry another component, leaving you worse off than befire. If the idea of opening up a monitor and fiddling with the insides makes you nervous, seek out the help of an experienced technician. Replacing a bad bulb or inverter board is a relatively inexpensive fix to extend the life of your equipment.

If the backlight on your Droid screen is broken, you will need to send your phone to the manufacturer or to your carrier for repair or replacement. However, if the backlight is too dim or too bright, you can fix the intensity of the light by manually adjusting the settings on the device. The Droid automatically adjusts the backlight by default, but you can turn off the automatic adjustment feature and configure the backlight brightness to suit your personal preferences.

I replaced the backlight in my ThinkPad last year some time and it"s still going strong. It"s really not that hard, just be VERY careful to take note of where everything comes apart so you can put it all back together in the right way again.

And go to extra lengths to make sure you do not have dust between the glass when reassembling! That is the only mistake I made, and now there are flecks of schmutz on my screen which I cannot get off, because they aren"t really ON it, but IN it!

I had thought my laptop was dead beyond rescue. Especially when a local repair shop told me they don"t do monitors because it"s not worth it. But it was relatively quick, easy (though intricate) and saved FAR more money than the mere $15.00 I spent to repair it. Honestly I"m not sure why repair shops DON"T do this, as it would be a procedure on which they could have a pretty high profit-margin. Whatever...

We manufacture and stock backlight assemblies for many NEC LCD panels. We produce premium quality replacements to extend the life of your flat panel screen devices. If you do not see your panel model listed here, please contact us to learn about our cost effective design and manufacturing process. Simply mail us a sample of the backlight you are looking to replace, and we can recreate and supply you with what you need to meet you needs.

We manufacture and stock backlight assemblies for many LG LCD panels. We produce premium quality replacements to extend the life of your flat panel screen devices. If you do not see your panel model listed here, please contact us to learn about our cost effective design and manufacturing process. Simply mail us a sample of the backlight you are looking to replace, and we can recreate and supply you with what you need to meet you needs.

I have two laptops, one Macbook and one Lenovo. If I press the Brightness Down button repeatedly, eventually the backlight is turned off completely. The Lenovo also has a shortcut key to turn off the backlight (Fn+F9).

Without the backlight, both monitors of the laptops are completely invisible even in a very dark room. So, I thought the monitors were turned off and laptop manufactures had put this feature to conserve energy by turning off the monitor when not needed like when listening to music.

But when I placed a flashlight near the screens, I could see the screen on both laptops. So, the LCDs were actually turned on but only the backlights were turned off.

Surely, no user would try to see the screen this way, and surely LCD would consume some power if it still animates pixels even without the backlight. So, I am wondering why the manufactures did not completely turn off the screen but just turned off the backlight instead? What advantages are there to keep the LCD on when there is no backlight?

When I used an application to turn off the monitor on the Lenovo, the LCD was completely turned off and I could not see anything on the screen even with a flashlight.

Note: If your MacBook Pro has any damage which impairs the service, that issue will need to be repaired first. In some cases, there may be a cost associated with the repair.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

NOTE: Other damages may be considered customer induced if determined by Dell Technical Support, an on-site field engineer, or at the mail-in repair center.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Dell monitors cannot be repaired by an on-site field engineer or at the mail-in repair center. If you notice any damage to the monitor, you must purchase a new monitor.

Light leak or backlight bleeding is often noticeable around the edges or the sides of a screen. Especially while it is displaying a dark background or is in a dark environment.

Ideally, light leakage must not be inspected in a dark room. All Dell monitors are inspected as per industry standard with 150-Lux ambient lighting (similar to typical office lighting). However, for gaming monitors, ambient lighting is 70 Lux. Any visual inspection must be done in the same manner to help with the troubleshooting process.

NOTE: This article provides information about common issues that are seen on LCD screens. It is not something specific to a particular Dell computer but is something that can be seen on any LCD screen by any manufacturer.

Laptops, computer screens, tablets, notebooks. Is your display not lighting up? Maybe it is getting dim or even starting to have a reddish or pinkish hue, maybe it has completely gone dark. The good news: you need a new CCFL backlight lamp and we have them. We stock LCD backlight bulbs for most LCDs. The backlight repair is actually easier than you think, and once you replace the CCFL lamp in your LCD you have essentially restored your LCD display to new condition, as bright and vibrant as it was the first day you got it. And best of all, one less old LCD panel in a landfill somewhere! Call us today, we are here to help (402) 330-2222.

Nearly every piece of Industrial equipment now made has an LCD control panel of some sort. Expensive equipment like CNC machines, heavy machinery, industrial control panels, medial and military displays, sewing machines, food processing equipment, you name it! What they also have in common is they are all heavily used and the LCD displays eventually fail. The equipment manufacturers charge exorbitant amounts for new displays, but the fact is all that is needed is new CCFL backlights. Install a new CCFL lamp assembly and your critical piece of equipment is back on line.

ATMs, amusement displays such as casino gaming, video games, juke boxes, and kiosks- these LCD displays are notorious for failure due to the 24 hour high demand usage. Again, a new CCFL lamp, and they are back up and running like new. CCFL Warehouse supplies CCFL backlights to many of the largest LCD display repair companies in the world. Our high-quality CCFL lamps are trusted for ultra long life in these demanding environments. If you do not find the exact CCFL lamp that you need on our website, drop us an email or give us a call, we will make it for you.

There is a reason all of the most respected LCD repair facilities in the country, both big and small, purchase their CCFL Backlight lamps from us, quite simply our expertise in the area of LCD backlights is simply unparalleled. Not only do we stock more cold cathode fluorescent lamps than any other company, produce the highest quality lamps, offer exceptional pricing, but we are here to help!

Quite simply, we are the experts in CCFL lamps and LCD backlighting, that is all we do and anything we can do to help you in your repair efforts we are more than happy to accommodate.

CCFLwarehouse.com is the single largest CCFL backlight supplier in North America. We specialize in CCFL lamps, producing the highest quality lamps available and stocking them in high volumes so that they are available for our customer when they need them. Our lamps are used all over the world by a wide range of clients, some just looking to get their laptop back up and running and others who operate some of the largest repair facilities in the world. Whatever your backlight repair needs, we can help.

Our CCFL lamps are designed specifically for repairs of LCD panels made by many of largest LCD panel manufacturers in the world such as: AU Optronics (AUO), Samsung, Sanyo, LG, Innolux, Torisan, Sharp, Che Mei, Chunghwa, NEC, Mitsubishi, Toshiba, Boe Hydis, Hitachi, Fujitsu, HannStar and many more.

In addition we stock LCD backlights specific for the repair of laptop and notebook computers and desktop monitors. Our CCFL lamps are used to repair LCD panels in all major computer brands such as; Acer, Asus, Gateway, Dell, Hewlett Packard (HP), Compaq, Lenova, Apple, Sony, BenQ, Alien Ware, Sager, Quanta, Clevo, and many more.

My monitor is not turning on even though it is plugged in (external power supply)First, try another device in the same outlet to determine if the outlet is working properly.

Is everything firmly plugged in? It is easy for cables to become loose and not firmly connected, especially if you are using a mobile system. Please check to ensure everything is securely plugged in.

The LED light on the power supply should be GREEN. If the LED light is not on, then either the power supply is dead or there is no power being generated from the power source. Try another power source (outlet) and if this doesn’t work, there may be an issue with the power adapter.

Amber Light: The amber light indicates the monitor is receiving power but is not receiving the video signal being fed from the signal source (camera, computer, etc). This may also signify that the monitor is currently set to the wrong video input; you may need to press the “Auto/Switch” button to select the appropriate input (VGA, HDMI, etc).

My monitor is not turning on even though it is plugged in (internal power supply)First, try another device in the same outlet to determine if the outlet is working properly.

Is everything firmly plugged in? It is easy for cables to become loose and not firmly connected, especially if you are using a mobile system. Please check to ensure everything is securely plugged in.

Amber Light: The amber light indicates the monitor is receiving power but is not receiving the video signal being fed from the signal source (camera, computer, etc). This may also signify that the monitor is currently set to the wrong video input; you may need to press the “Auto/Switch” button to select the appropriate input (VGA, HDMI, etc).

My monitor screen is completely black, even though it is powered onIs everything firmly plugged in? A loss of video signal will cause the monitor to go black and then turn off entirely. It is easy for cables to become loose and not firmly connected, especially if you are using a mobile system. Please check to make sure everything is securely plugged in.

Your monitor possibly has TRU-Vu’s Dim-To-Black feature which allows you to control the screen’s brightness and contrast by pressing the arrow keys in the menu. The reason it has gone completely black could be because the dim-to-black was turned all the way down. Press the arrow up to the right to raise the brightness again. If this does nothing, try pressing the left arrow keys.

Why does my monitor keep entering sleep mode when I turn it on?The primary cause is usually that the monitor is not receiving a video signal from the signal source (camera, computer, etc). The monitor will automatically enter sleep mode if it cannot detect a video signal.

If the LED on the monitor is amber, this means the monitor is receiving power but not receiving a video signal from your source. Ensure the monitor is set to the correct input and try swapping out sources to determine if that is the root of the problem.

Why are there black bars and/or squeezing (banding) with my monitor?If there are black bars around your signal and/or a “squeezing” effect, this means that the aspect ratio of your monitor and the incoming video signal do not match.

Make sure the monitor’s picture size setting is set to the factory default, not zoom, fit or stretch. For optimal picture quality without distortion, black bars or squeezing, it is always best to match the aspect ratio of your video signal with the aspect ratio of the monitor.

My touch screen is not working.All touch panels must be connected to a computer via USB or RS232 cable. This allows the touch panel to communicate with the computer.

If you recently downloaded a new touch panel driver, you must also delete the old driver and reboot your computer. Make sure you have deleted any old touch panel drivers and then restart your computer.

My touch screen is not registering correctlyAll non-HID compliant touch panels will need to be calibrated during the initial start-up and may need recalibrating at some other point in the future. This is accomplished via the touch panel software installed on your computer. For a detailed walk through, please contact us.

Certain touch panels are susceptible to issues due to grease/dust/water and therefore may need added care. If this is a constant problem, please contact us for further assistance.

The buttons on my monitor are lockedKeylock is a safety feature offered by TRU-Vu to prevent unauthorized personnel from changing the desired monitor settings. We do not publish the lock codes for public knowledge; please contact us for the unlock codes.

The speakers are not very loud on my monitorTRU-Vu speakers are provided for signals and alerts; these are not intended for voice or music. If quality of sound is a major concern, we advise using external speakers.

It is always recommended to spray the microfiber cloth first, then clean the screen with the moistened cloth. Do NOT spray the monitor screen directly.

For heavier duty cleaning, create a solution of 80% alcohol mixed with 20% water and use the damp, not wet, cloth to clean the screen and panel surface.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

:max_bytes(150000):strip_icc()/CloseupofredgreenandblueLEDpanel-iStock-GettyImagesPlus-caf596087c94426eb3259e4cbee526d9.jpg)

Work isn"t somewhere you go, it"s something you do. Whether working from home or in a busy office, Brother Desktop Scanners can help you streamline the process of digitizing, organizing, and sharing documents – saving you significant time and enabling immediate access to all your important documents.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey