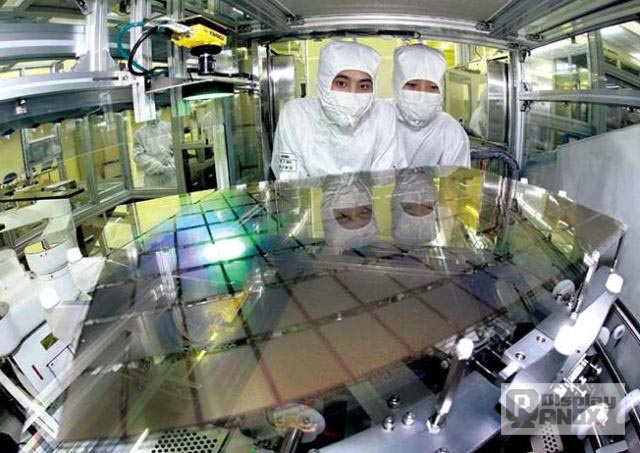

lcd panel venture manufacturer

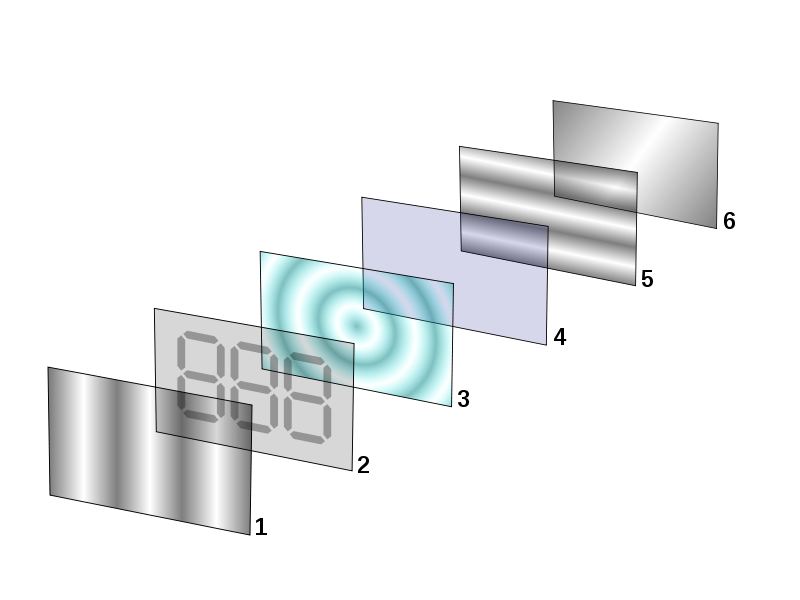

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

There has been a significant shift in the global display industry lately. Apart from new display technologies, the display world is now dominated by players in Asian countries such as China, Korea, and Japan. And rightly so, the world’s best famous LCD module manufacturers come from all these countries.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a Cortex A8 1GHz Standard 256MB. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

In this post, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the reputable LCD module manufacturers in the world.

Samsung is the world’s largest semiconductor and consumer electronics manufacturer by revenue. The electronics giant is well-known for its smartphones and home appliances, but the company also manufactures LCD, LED, and OLED panels.

Probably the most in-demand and popular display panel product for Samsung is their OLED technology. Most of its current smartphones use their trademark Super AMOLED displays. The technology allowed Samsung’s smartphones to be ultra-thin, with better image brightness, and less energy consumption.

Samsung now produces panels for smart TVs. With their ever-evolving technological expertise and high-quality products, the company shows no signs of slowing down as one of the world’s best famous LCD module manufacturers.

Stone provides a professional product line that includes intelligent TFT-LCD modules for civil, advanced, and industrial use. Furthermore, Stone also creates embedded-type industrial PCs. The company’s products are all highly-reliable and stable even when used with humidity, vibration, and high temperatures.

Stone Technologies caters to a wide range of clients and industries, being among the world’s best famous LCD module manufacturers. The company’s products are used in the following industries:

Originally, LG Display was a joint venture of mother company LG Electronics and the Dutch company Phillips. They dedicated the company to creating active-matrix LCD panels. Another joint venture called LG. Phillips Displays was created to manufacture deflection yokes and cathode ray tubes.

LG Display has risen above the rest because of its world-class module products. Because of this, the company caters to a massive range of famous clients including Hewlett Packard, Apple, Sony, Dell, Acer, and Lenovo. LG Display also creates LCD modules and similar display panels for the company’s television product range.

Innolux Corporation is another famous LCD module manufacturer. This company was established in 2003 and is currently based in Zhunan, Miaoli County, Taiwan.

The company is a well-known manufacturer of display panels in Taiwan. Innolux supplies TFT-LCD and LED panels, open cells, and touch modules for the following products:

What makes Innolux stand out from other LCD module manufacturers is the company’s commitment to its humanistic qualities. Innolux believes that they are in the business to contribute to the well-being and prosperity of their customers. This is then achieved by creating world-class products that satisfy its clients.

Sharp is a Japanese company founded in 1912. It is now based in Sakai, Osaka Prefecture. The company produces various kinds of electronic products including mobile phones, LCD panels, calculators, PV solar cells, and consumer electronics. Sharp has produced TFT-LCD products as early as the 1980s.

For the regular public consumers, Sharp produces a variety of smart TVs and LCD TVs marketed under the Aquos brand. The company’s television line-up boasts of impressively high-quality technology. The TVs are equipped with technologies that support 4K and 8K UHD display, allowing for a great high-resolution viewing experience.

BOE Display is among the leading display manufacturers in the world. The company started in 1993 and is currently based in Beijing, China. Apart from display panels, BOE also manufactures smart systems using IoT technology.

The company proudly utilizes high-end technologies to create world-class display solutions. For instance, AU’s production lines can manufacture a variety of display applications in a full panel size range. The manufacturing lines also support:

Sustainability is among the ultimate goals of AU Optronics. The company takes steps to integrate green solutions into their products for more sustainable development. This commitment to sustainability, among other strong qualities, makes AU Optronics one of the best LCD manufacturers in the world.

Most of these products use TFT-LCD panels alongside other technologies to create ultra-high-definition images. Also, modern Toshiba display products incorporate IoT and artificial intelligence for a smarter product experience.

Kyocera is a Japanese LCD manufacturer. The company started in 1959 as a fine technical ceramics manufacturer but gradually added consumer electronics products to its offerings.

The Japanese company acquired Optrex Corporation in 2012. The acquisition paved the way for creating an R&D center and more production, sales, and marketing bases. Hence, Kyocera’s global LCD business boomed even more.

The company also operates factories, R&D centers, and marketing facilities in Asia, the Middle East, Europe, Africa, North and South America, and Oceania continents. Kyocera has a vast worldwide reach that makes it one of the world’s best famous LCD module manufacturers.

To wrap all this up, we listed 10 of the world’s best famous LCD module manufacturers. These are all highly-respected companies that built their reputations and climbed up the ladder of LCD module manufacturing. Their quality products, dedication to their craft, and excellent customer service truly make them among the world’s best display solutions providers.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

The Toshiba building in central Tokyo. Japan"s Toshiba Corp. said Wednesday it will buy out its liquid crystal display (LCD) joint venture with Panasonic Corp. for about 20 million dollars in a bid to overhaul the struggling business.

Japan"s Toshiba Corp. said Wednesday it will buy out its liquid crystal display (LCD) joint venture with Panasonic Corp. for about 20 million dollars in a bid to overhaul the struggling business.

The business, set up in 2002 to produce small- and medium-sized LCDs for mobile phones, portable computers and car navigation displays, is the number two producer in that market after Epson.

Toshiba aims to overhaul the loss-making business by shifting focus to polycrystalline silicon panels that provide better quality images for high-end products, the company official said.

The company said it would report a further write-down of 66 billion yen, or about $845 million, for the final three months of 2011 because of its exit from the Samsung joint venture. But it expected to cut costs in its LCD business by 50 billion yen a year as a result of the departure, Sony said.

Sony “aims to secure a flexible and steady supply of LCD panels from Samsung, based on market prices and without the responsibility and costs of operating a manufacturing facility,” it said in the statement.

Meanwhile, Samsung Electronics, the world leader in flat-panel televisions, would gain freer rein in producing its next-generation displays by taking control of S-LCD. Samsung said in a regulatory filing that its board had approved the plan Monday.

"Television is a key product category for Sony," Ken Kutaragi, executive deputy president of Sony, said in a statement. "S-LCD panels will be at the core of our flat-panel TV strategy, further strengthening our overall vision for television."

LCD technology allows for thinner and lighter televisions and monitors than traditional cathode-ray tube products. The market for LCD televisions is particularly promising, according to research firm iSuppli. The share of worldwide TV shipments that are LCD models will grow from 5 percent this year to 18 percent in 2008, iSuppli said. The total TV market is expected to jump from about 168 million units to roughly 203 million units during that period.

The new S-LCD plant is optimized for big panels that can fit into televisions, said iSuppli analyst Riddhi Patel. "It"s going to make the large-size LCDs available at a more reasonable rate," she said. Partly because of the new factory, the average price for LCD televisions that are 40 inches or larger should fall from about $8,000 to $1,500 by 2008, Patel said.

Sony and Samsung are vying with other LCD panel manufacturers such as LG.Philips LCD, a joint venture between Royal Philips Electronics of the Netherlands and Korea"s LG Electronics.

LCD technology is competing against plasma display technology, which also allows for thin televisions. Other display methods are emerging, including so-called liquid crystal on silicon rear-projection technology, which has been championed by

Sony and Samsung inked their joint venture in April, with each company contributing roughly half of $1.8 billion in capital. The deal, which places a Samsung executive as the CEO of the joint venture, is a sign of Samsung"s growing strength and

Panasonic said Tuesday it will sell one of its main domestic TV panel factories to a new joint venture focused on producing smaller screens, as Japan"s big-name manufacturers continue to seek relief from deep losses in their display businesses.

Japan Display, the new venture that will acquire the factory, will be comprised of the small display subsidiaries of Hitachi, Sony and Toshiba, backed by a US$2.6 billion investment from a government-funded investment firm, Innovation Network Corporation of Japan (INCJ). The companies said Tuesday they had finalized plans to launch the new company in Spring of next year, as earlier announced.

Panasonic said it will sell its LCD TV factory located in Chiba, east of Tokyo to Japan Display for an undisclosed sum. INCJ said the new venture will build a new production line for small displays at the factory, it said Tuesday.

Japan"s prominent electronics companies are struggling to revive their TV and panel businesses, under pressure from recent record highs in the yen and foreign competition from rivals like Samsung and Vizio. Sony said earlier this month it now expects over a billion-dollar loss for the current fiscal year, after early predicting a profit, due in large part to its television woes.

With panels largely commoditized, domestic manufacturers have attempted to increase profits through technologies that offer glasses-free 3D and super high resolution, but have had little success so far.

Sharp is revamping some of its large-screen TV lines to make smaller panels for phones and tablets, a transformation similar to that planned at the Panasonic plant, although Sharp is making its changes internally.

A few India-based enterprises have decided or plan to set up display panel plants in India, but this is unlikely to have substantially impact on the existing global display supply chain in the foreseeable future, as the total panel production capacity in India will be much smaller than that in China, South Korea, Taiwan and Japan.

India-based oil, gas and metal producer Vedanta has acquired Japan-based LCD glass substrate maker AvanStrate and applied to the India government for setting up a 8.6G TFT-LCD plant in India. Vedanta in February 2022 signed an MoU with Taiwan-based Foxconn Electronics to establish a joint-venture maker of semiconductors. As Taiwan-based LCD panel maker Innolux is AvanStrate"s client and has a 8.6G LCD plant in southern Taiwan, Vedanta could cooperate with Innolux via AvanStrate.

With subsidies under India government"s PLI scheme and UP Electronics Manufacturing Policy 2017 set by the state government of Uttar Pradesh, northern India, Samsung Display (SDC) invested US$654 million to set up a panel module factory in the state and started production in April 2021.

China-based panel maker China Star Optoelectronics Technology (CSOT) has invested INR18.3 billion to set up a factory to produce 5- to 65-inch LCD modules in Andhra Pradseh, southeastern India. With annual production capacity of 8.0 million LCD modules, the factory is intended to mainly support TCL, CSOT"s parent company, to sell LCD TVs in the India market. TCL expects to sell 10 million LCD TVs for a market share of 7% in India in 2022. TCL currently ranks fourth in the India TV market and aims to surpass Sony, ranking third with a market share of 12% at present, by the end of 2022.

Taiwan-based LCD panel maker AU Optronics (AUO) has evaluated the feasibility of investing in India. There are problems concerning culture and government efficiency in India, AUO chairman Paul Peng has said.

There are many factors that need to be considered in setting up overseas factories, including ecosystem support, infrastructure and local talent, Peng said. India is not ideal in terms of these three factors, and exiting panel makers are quite unlikely to set up panel lines in India for the time being, Peng noted.

China-based panel makers had kept expanding production capacities for nearly 10 years and, as a result they together occupied over 60% of global production capacity for LCD panels as of 2021, followed by Taiwanese makers with 20%, South Korean ones with 10% and Japanese ones with 6%.

Since major Chinese makers are still expanding LCD panel production capacities, China"s combined share of global total will reach 70% in the mid- to long-term.

In view of diminishing competitiveness in LCD, SDC terminated LCD panel production in June 2022 and has shifted focus to AMOLED. Taiwanese LCD panel makers are expected to benefit from SDC"s exit but are still far less competitive against Chinese fellow makers in production capacity. Therefore, they have chosen not to expand production capacities and have focused on high value-added LCD panels.

2 Min ReadAn employee of LG Electronics" home appliances store walks past its LCD televisions displayed for customers at a store in Seoul July 21, 2008. REUTERS/Jo Yong-Hak

SEOUL (Reuters) - South Korea"s LG Display Co Ltdand Taiwan"s Amtran Technologyagreed on Monday to set up a joint venture in China to produce flat screen modules and manufacture TV sets for brand makers.

LG Display, the world’s second-biggest maker of liquid crystal display (LCD) panels, has sought alliances with Asian TV makers to strengthen its client base and reduce costs.

The LG-Amtran joint venture will be set up in Amtran’s existing production base in Suzhou, China, with initial funding of $20 million. LG Display will own 51 percent of the new company and Amtran, maker of Vizio brand LCD TVs, will hold the remaining 49 percent.

The joint venture will produce 3 million LCD modules and 5 million LCD TV sets a year, with operations set to start early next year, LG said. It did not disclose the value of any additional investments to be made.

Leading LCD makers, including No. 1 Samsung Electronics Co Ltd, LG Display and third-ranked AU Optronics Corpface a slowing global economy that has hit demand for new flat-screen TVs and personal computers.

![]()

TOKYO - In a bid to streamline its money-losing television business, Sony said Monday it would sell its stake in its flat-panel joint venture with Samsung Electronics, letting go of more of its production capacity at a time when outsourcing has become the norm in the world of manufacturing.

Sony, the Tokyo-based technology and entertainment giant, which makes the Bravia liquid-crystal display televisions, said in a statement that it would sell its nearly 50 percent stake in the jointly owned manufacturer, S-LCD, to Samsung of South Korea for $939 million.

Sony"s exit from the joint venture, set up in Tanjeong, South Korea, in 2004, would allow it to switch to less expensive outsourcing options that might allow it to resuscitate its struggling TV business. The only other LCD panels Sony manufactures are at its joint venture with Sharp, in which Sony owns a 7 percent stake.

TOKYO (MarketWatch) -- Sony Corp. (6758.TO) said Thursday it will pull out of its liquid crystal display joint venture with Sharp Corp. (6753.TO) by selling its entire stake in Sharp Display Products Corp., less than three years after its state-of-the-art factory opened.

Separately, Sharp said SDP will merge its business operations with the LCD color filter businesses of two Japanese partners--Toppan Printing Co. (7911.TO) and Dai Nippon Printing Co. (7912.TO) in what will bring Sharp"s stake in the LCD business down to the same percentage as Taiwan"s Hon Hai Precision Industry Co. (2317.TW).

In return for selling the stock in the joint venture, whose Sakai factory in western Japan only opened in October 2009, Sony will receive Y10 billion--the same amount it spent at the time of the initial investment. The payment is due by the end of June.

The Nikkei reported that Sharp will provide advanced technology for producing liquid-crystal display panels to Hon Hai for the latter"s new plant in China, kicking off joint business operations between the two companies in line with their recent capital alliance.

In March, Sharp said it sold a 10% stake to Hon Hai and its affiliate companies, collectively known as Foxconn, in exchange for about $800 million in cash to help shore up its core business of LCD panels for televisions--an operation largely responsible for the multibillion-dollar losses Sharp expects to post this fiscal year.

Since its establishment in 2008, GSD Co., Ltd., has been manufacturing and providing customized display solutions like a professional resized LCD and high brightness LCD all over the world for Casino/arcade Gaming, Transportation, Public information, Advertising, ATM, Outdoor KIOSK, Medical display, Marine display and so on.

We are now achieving new custom display solutions with unique design and supreme image quality to meet your various needs. With extensive experiences in LCD displays. GSD also provides P-Cap touch solutions with various glass design support and high quality optical bonding services.

Japan"s leading consumer electronics manufacturer Sony Corp and rival Samsung Electronics launched a joint venture yesterday for flat-panel televisions even as the South Korean company warned of possibly lower screen prices.

The 50-50 joint venture, S-LCD Corp., opened in Tangjeong, 100km south of Seoul, to produce large, seventh-generation liquid crystal display (LCD) panels.

Major LCD makers have been increasing capacity to meet booming demand for flat-screen TVs and computer monitors as the traditional cathode-ray-tube screens are dropped.

Samsung said that sales prices for LCD panels are expected to fall about 10 percent in the second half due to oversupply, which will be resolved from September.

The decision to close the LCD business, by Samsung Display, will be completed by June of 2022 as the company faces tough competition from its Chinese and Taiwanese counterparts, reports GizmoChina. / Representative image | Photo credit: IANS

The decision to close the LCD business, by Samsung Display, will be completed by June of 2022 as the company faces tough competition from its Chinese and Taiwanese counterparts, reports GizmoChina.

The company has decided to focus on manufacturing organic light-emitting diode (OLED) and quantum dot (QD) displays, as OLED panels have started to become the norm in the smartphone market.

A recent Display Supply Chain Consultants (DSCC) revealed that the price of an LCD is 36.6 per cent of what it used to be in January 2014, the component"s peak production period.

No investment plan details have since been announced, and the employees of the LCD business are expected to be transferred to the QD business, the report said.

Samsung Display had decided to close its LCD business in late 2020, but the plans were delayed at Samsung Electronics" request due to a sudden increase in the prices of LCD panels during the COVID-19 pandemic.

Back in 2004, Samsung and Sony formed a joint partnership named S-LCD to manufacture flat-panel LCD displays, splitting the costs of rolling out manufacturing facilities for large flat panel displays so both companies could better compete with the likes of Sharp. As recently as 2008 the companies committed $1.8 billion to the venture to build a new manufacturing facility, but now Sony has thrown in the towel: Samsung is buying out Sony’s 50 percent stake in S-LCD for a little over 1.08 trillion Korean won, or about US$935 million.

The move comes as Sony looks to cut costs as it faces the possibility of eight straight years of losses in its television business. Sony is banking that it will be able to better compete against the likes of Sharp, Samsung, Toshiba, and other flat-panel manufacturers buy buying panels for its own TVs at going rates rather than sinking massive amounts of money into production facilities. Sony will buy panels from Samsung as well as from other manufacturers.

Electronics giants Sony and Samsung have signed an agreement to transition the current business relationship with respect to LCD panels. Under the agreement, Samsung will acquire all of Sony’s shares of S-LCD, the two companies’ venture in TV and monitor panel manufacturing, making S-LCD a wholly-owned subsidiary of Samsung.

Under the terms of the share transfer, Samsung will pay Sony approximately $940 million (£607m). Concurrently, the two companies have entered into a new strategic agreement for the supply and purchase of LCD panels, with a goal of enhancing their competitiveness.

Established in April 2004, S-LCD manufactures LCD panels for both its parent companies, contributing to the expansion of the respective parties’ TV businesses, and the large-sized LCD TV market overall. However, the companies determined that LCD panel and TV market conditions have changed since they forged the deal.

In order to respond to such challenging conditions and to strengthen their respective market competitiveness, the two companies have agreed to shift to a new LCD panel business alliance. The share transfer and payment are targeted to close by the end of January 2012, subject to necessary approvals from regulatory authorities.

As a result of the transaction, Sony expects to incur a non-cash impairment loss of approximately $845 million (£546m) in the third quarter of the fiscal year ending March 31, 2012, due to the re-evaluation of its S-LCD shares. Despite this one-time loss, Sony estimated that the transaction would result in substantial savings on and after January 1, 2012, with respect to costs associated with its procurement of LCD panels.

The current estimate of the yearly savings with respect to such costs is approximately $640 million (£414m), compared with LCD panel procurement costs estimated for the fiscal year ending March 31, 2012.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey