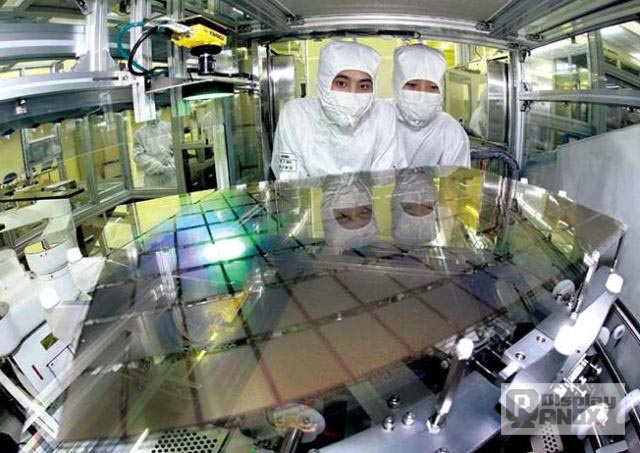

lcd panel venture factory

Japan"s Sharp said Thursday it will team with a large Chinese manufacturer to build a factory in Nanjing and mass-produce LCD screens for TVs, computers and tablets.

Sharp said it will form a joint venture with China Electronics Corp. (CEC) to manage the project, and aims to begin production in June 2015. The plant will eventually handle 60,000 LCD panels per month, each measuring 2.2 x 2.5 meters, which can then be divided into smaller sizes for consumer products.

Although Sharp is struggling with massive losses and going through a major restructuring to rebuild its finances, the company is still one of the largest LCD display makers in the world and possesses cutting-edge technology. Japan"s Nikkei newspaper reported that as part of the deal, Sharp will transfer its technology for producing IGZO (Indium Gallium Zinc Oxide) screens to the venture and will receive payment in the "tens of billions of yen" in return, part of which it will use to fund the new investment.

IGZO allows for higher resolutions and lower power drain than traditional LCD screens, and devices that use the technology are beginning to appear on the market. Sharp has launched smartphones and tablets with IGZO screens, and Samsung Electronics, Asustek Computer and Fujitsu are all releasing laptops that use the technology.

The new venture will be called Nanjing CEC-Panda LCD Technology and will be funded by a 17.5 billion yuan (US$2.8 billion) investment, 92 percent from CEC Group and 8 percent from Sharp. It will be officially established in March of next year.

Sharp said the Chinese plant will allow production at lower costs than its current factories, and it will retain the right to buy the panels produced at the new facility.

As a result of a deal announced in August 2009, Sharp and CEC already operate a Chinese joint venture producing smaller LCD panels, to which Sharp transferred some of its older technology. They said at the time they would negotiate a deal to build larger panels in the future.

![]()

Panasonic said Tuesday it will sell one of its main domestic TV panel factories to a new joint venture focused on producing smaller screens, as Japan"s big-name manufacturers continue to seek relief from deep losses in their display businesses.

Japan Display, the new venture that will acquire the factory, will be comprised of the small display subsidiaries of Hitachi, Sony and Toshiba, backed by a US$2.6 billion investment from a government-funded investment firm, Innovation Network Corporation of Japan (INCJ). The companies said Tuesday they had finalized plans to launch the new company in Spring of next year, as earlier announced.

Panasonic said it will sell its LCD TV factory located in Chiba, east of Tokyo to Japan Display for an undisclosed sum. INCJ said the new venture will build a new production line for small displays at the factory, it said Tuesday.

Japan"s prominent electronics companies are struggling to revive their TV and panel businesses, under pressure from recent record highs in the yen and foreign competition from rivals like Samsung and Vizio. Sony said earlier this month it now expects over a billion-dollar loss for the current fiscal year, after early predicting a profit, due in large part to its television woes.

With panels largely commoditized, domestic manufacturers have attempted to increase profits through technologies that offer glasses-free 3D and super high resolution, but have had little success so far.

Sharp is revamping some of its large-screen TV lines to make smaller panels for phones and tablets, a transformation similar to that planned at the Panasonic plant, although Sharp is making its changes internally.

SEOUL, Korea-Samsung Electronics Co. and Sony Corp. (Tokyo) have signed a letter of intent to form a joint venture company dedicated to developing state-of-the-art LCD television panels.

Together Samsung and Sony plan to invest approximately $2 billion in the new company, to be named S-LCD Corp. As part of the effort, S-LCD Corp. will upgrade an existing LCD television factory in Tangjeong, Korea. Samsung and Sony hope the company will be able to build 50,000 "8th-generation" panels per month by late 2007.

BEIJING (Reuters) - A joint venture between Hon Hai Precision Industry Co, known as Foxconn, and Sharp Corpplans to build a 61 billion yuan ($8.8 billion) factory in China to produce liquid-crystal displays (LCDs).

Sakai Display Products Corp’s plant will be a so-called Gen-10.5 facility specializing in large-screen LCDs and will be operational by 2019, the company said at a signing event with local officials in Guangzhou on Friday. It said the plant will have capacity equating to 92 billion yuan a year.

Global LCD output was hit this year by the closure of a Samsungfactory that accounted for 3 percent of the market, as well as factory stoppages in Taiwan after an earthquake in March.

China’s largest LCD panel maker, BOE Technology Group, began construction on its own Gen-10.5 plant in Hefei in December last year, with production scheduled to begin in 2018.

In May Shenzhen China Optoelectronics Technology Co, asubsidiary of TCL Corp, announced that it would begin construction on a 50 billion yuan LCD plant in Shenzhen.

Sakai Display Products Corp’s plans for the Guangzhou plant come as Hon Hai seeks to turn the joint venture into a subsidiary, investing a total of 15.1 billion yuan in the company.

The venture will also sell 436,000 shares for 17.1 billion yuan to an investment co-owned by Hon Hai Chairman Terry Gou, giving Hon Hai a 53 percent interest in the business and lowering Sharp’s stake from to 26 percent from 40 percent.

TOKYO (MarketWatch) -- Sony Corp. (6758.TO) said Thursday it will pull out of its liquid crystal display joint venture with Sharp Corp. (6753.TO) by selling its entire stake in Sharp Display Products Corp., less than three years after its state-of-the-art factory opened.

Separately, Sharp said SDP will merge its business operations with the LCD color filter businesses of two Japanese partners--Toppan Printing Co. (7911.TO) and Dai Nippon Printing Co. (7912.TO) in what will bring Sharp"s stake in the LCD business down to the same percentage as Taiwan"s Hon Hai Precision Industry Co. (2317.TW).

In return for selling the stock in the joint venture, whose Sakai factory in western Japan only opened in October 2009, Sony will receive Y10 billion--the same amount it spent at the time of the initial investment. The payment is due by the end of June.

The Nikkei reported that Sharp will provide advanced technology for producing liquid-crystal display panels to Hon Hai for the latter"s new plant in China, kicking off joint business operations between the two companies in line with their recent capital alliance.

In March, Sharp said it sold a 10% stake to Hon Hai and its affiliate companies, collectively known as Foxconn, in exchange for about $800 million in cash to help shore up its core business of LCD panels for televisions--an operation largely responsible for the multibillion-dollar losses Sharp expects to post this fiscal year.

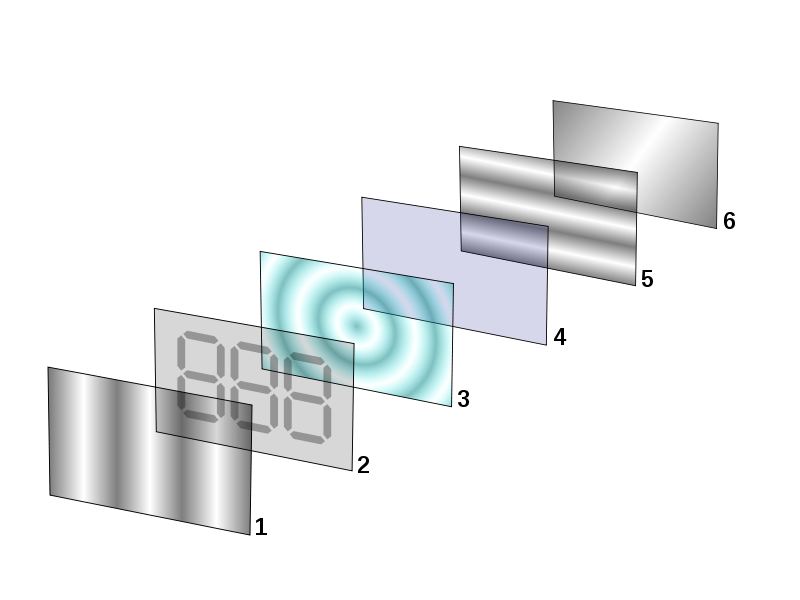

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

"Television is a key product category for Sony," Ken Kutaragi, executive deputy president of Sony, said in a statement. "S-LCD panels will be at the core of our flat-panel TV strategy, further strengthening our overall vision for television."

LCD technology allows for thinner and lighter televisions and monitors than traditional cathode-ray tube products. The market for LCD televisions is particularly promising, according to research firm iSuppli. The share of worldwide TV shipments that are LCD models will grow from 5 percent this year to 18 percent in 2008, iSuppli said. The total TV market is expected to jump from about 168 million units to roughly 203 million units during that period.

The new S-LCD plant is optimized for big panels that can fit into televisions, said iSuppli analyst Riddhi Patel. "It"s going to make the large-size LCDs available at a more reasonable rate," she said. Partly because of the new factory, the average price for LCD televisions that are 40 inches or larger should fall from about $8,000 to $1,500 by 2008, Patel said.

Sony and Samsung are vying with other LCD panel manufacturers such as LG.Philips LCD, a joint venture between Royal Philips Electronics of the Netherlands and Korea"s LG Electronics.

LCD technology is competing against plasma display technology, which also allows for thin televisions. Other display methods are emerging, including so-called liquid crystal on silicon rear-projection technology, which has been championed by

Sony and Samsung inked their joint venture in April, with each company contributing roughly half of $1.8 billion in capital. The deal, which places a Samsung executive as the CEO of the joint venture, is a sign of Samsung"s growing strength and

The giant LCD panel manufacturing plant built by Sharp Corp. and now a joint venture between Sharp and Hon Hai Precision Industry Co., Foxconn’s parent company, has reported that it generated a net loss of ¥7.4 billion ($75.7 million) for the April-December fiscal period. The news is another indicator of the degree of desperation that Sharp is facing in trying to turn around its financial condition which, like many Japanese manufacturers has struggled as a result of the global slowdown and declining profitability.

The plant, located in Sakai, Osaka Prefecture, Japan, was once the pride of Sharp who built it several years ago to create the largest world-class LCD panel manufacturing facility with the latest generation LCD panel production technology to gain a cost advantage over competitors. However, shortly after launching this plant, the industry fell into a protracted period of intensifying competition from powerful Korean companies like Samsung and LG. This competition caused a price war that deflated profits from their television division – and at the same time, a global recession caused a drop-off in consumer demand.

As Sharp’s fortunes declined, they began a campaign to find a partner to share the load of this plant for mutual opportunity. Eventually, they worked out a deal with Hon Hai who was looking for direct access to a supply of LCD production. This is the first financial report since that partnership was completed last year.

According to a report by the Japan Times, the loss was primarily due to low levels of factory utilization early in the reporting period. During the April-June quarter, this large factory was only operating at a 30% level due to sluggish demand for LCD TVs.

However, panel sales picked up in the wake of the partnership with Hon Hai in July and carried forward through December. Unfortunately, the pick up was not enough to offset the losses generated during that fiscal first quarter.

TOKYO -- Sharp will take the lead in the joint construction of a liquid crystal display panel plant in the U.S. with Taiwan"s Foxconn Technology Group, an executive at the Japanese electronics maker said Wednesday.

Under the plan, either Sharp or its TV panel venture with Foxconn, also known as Hon Hai Precision Industry, will invest in a panel maker that will operate the plant, the executive said.

Sakai Display Products Corp’s plant will be a so-called Gen-10.5 facility specialising in large-screen LCDs and will be operational by 2019, the company said at a signing event with local officials in Guangzhou on Friday. It said the plant will have capacity equating to 92 billion yuan a year.

Global LCD output was hit this year by the closure of a Samsung factory that accounted for 3 percent of the market, as well as factory stoppages in Taiwan after an earthquake in March.

China’s largest LCD panel maker, BOE Technology Group, began construction on its own Gen-10.5 plant in Hefei in December last year, with production scheduled to begin in 2018.

In May Shenzhen China Optoelectronics Technology Co, asubsidiary of TCL Corp, announced that it would begin construction on a 50 billion yuan LCD plant in Shenzhen.

Sakai Display Products Corp’s plans for the Guangzhou plant come as Hon Hai seeks to turn the joint venture into a subsidiary, investing a total of 15.1 billion yuan in the company.

The venture will also sell 436,000 shares for 17.1 billion yuan to an investment co-owned by Hon Hai Chairman Terry Gou, giving Hon Hai a 53 percent interest in the business and lowering Sharp’s stake from to 26 percent from 40 percent.

SEOUL, South Korea (AP) — Samsung Electronics Co. and Sony Corp. on Tuesday began shipping panels for large-sized flat screen televisions from the newest production line at their liquid crystal display joint venture.

""Our sights are now on LCD TVs in the 50-inch class, and we aim to lead that segment,"" Chang Won-kie said in a statement. The first panels shipped were 52-inch ones.

Samsung and Sony founded S-LCD in 2004 to produce panels to meet demand for flat screen televisions, which has soared in recent years as consumers give up bulky cathode-ray tube sets for the sleeker versions.

Succeeding generation of plants use larger glass substrates to cut LCD panels, thereby boosting output and eventually helping LCD makers cut manufacturing costs.

Sony and Samsung have built the factory that will make the bulk of their LCD displays over the next three years, and held an opening ceremony for it this week.

The join venture deal was done originally because Sony had been holding out for its own key screen technology, thought to be Grating Light valve, when it realized that it wasn’t going to arrive in time for the huge uplift expected in flat TV screens.

As Sony’s top end TV model sales began sliding it made the financial commitment with Samsung to build this 32,000 square meter factory as the world’s largest 7th generation amorphous TFT LCD panel production unit in Tangjung, South Korea.

On February 26, 2008, Sharp Corporation (�Sharp�) and Sony Corporation (�Sony�) signed a non-binding memorandum of intent regarding the establishment of a joint venture to produce and sell large-sized LCD panels and LCD modules using the world�s first 10th generation mother glass substrates (the �MOI�), and since then the two companies have been negotiating to enter into legally binding joint venture documentation.

Faced with changes in the world economy, today Sharp and Sony amended and extended the non-binding MOI to confirm their mutual intent to postpone the targeted establishment of a joint venture until March 2010, approximately one year later than originally scheduled. Sharp and Sony will, through continued discussions of how the two companies can best deploy their resources and expertise, continue to negotiate in good faith and have set June 30, 2009 as the target date by which to enter into a definitive agreement to establish a joint venture that will be mutually beneficial for both companies.

Sharp plans to start operating its new LCD panel factory in Sakai City, Osaka Prefecture (currently under construction) by March 2010 as originally scheduled.

Sony said Monday it will sell off its entire stake in an LCD (liquid crystal display) manufacturing joint venture with Samsung Electronics for 1.08 trillion won (US$934 million).

The two companies signed a contract under which Samsung will turn the company, S-LCD, into a fully-owned subsidiary that will still provide panels for Sony televisions. The Korean-based LCD manufacturer was established in April of 2004, with Sony holding just below a 50 percent share.

“This deal will allow Sony to acquire LCD panels from Samsung Electronics in a stable way based on market prices, without the responsibility or costs that come with operating a factory,” Sony said in a press release.

Like domestic peers, Sony has long struggled to make its TV business profitable against foreign rivals like Samsung and Vizio in the U.S., but executives have repeatedly said they won’t abandon the product. The firm’s latest plan calls for a focus on profitability over the number of units sold, and shifting to acquiring panels from outside manufacturers.

The iconic Japanese company has said it is focused on a “four-screen strategy,” which aims to offer content and interconnect smartphones, laptops, tablets, and televisions. It announced in October it would acquire Ericsson’s 50 percent stake in their Sony Ericsson mobile phone joint venture, allowing it to better integrate smartphones into its overall product lineup.

When talks started in January 2009, it was stated they would be completed by June 30th. Sony has had a joint LCD manufacturing operation with Samsung since 2004, and Sony is also said to be in talks with LG Display over the supply of panels.

When Sony and Sharp originally announced their co-operation on LCD manufacturing in February 2008, it was envisaged that they would jointly build the world’s most advanced LCD plant, capable of handling 2.8m x 3m glass sheets at a cost of nearly $4bn and due to start production in April 2009.

Japan created liquid crystal display (LCD) industry and has grown up it. South Korea and Taiwan entered into it and are passing over Japan. Recently, the driving product of LCD industry has changed to LCD-TV. Although Sony had the 1st place in the world TV market, it did not have its flat display. Therefore, Sony established a joint venture with Samsung. Then, Sony could keep high share in the TV market. On the other hand, Sharp Corporation make LCD panel and assemble into LCD-TV by vertical integration in one factory. Sharp has 40% share in Japan, but about 15% in the world market. Thus, Sharp has changed the global strategy. Sharp produces LCD panels in Japan. They are assembled into TVs in Japan for Japanese market. Also, they are shipped and assembled in overseas factories for global market. Sony and Sharp have top class share of the world LCD-TV market. However, their global strategies are different. Yves L. Doz etc. proposed "metanational management" concept which combined and leveraged the globally dispersed knowledge. Sony took the "metanational management". However, Sharp took the other strategy based on the "core knowledge" in Japan. Therefore, the author would like to propose "core national management."

Since its establishment in 2008, GSD Co., Ltd., has been manufacturing and providing customized display solutions like a professional resized LCD and high brightness LCD all over the world for Casino/arcade Gaming, Transportation, Public information, Advertising, ATM, Outdoor KIOSK, Medical display, Marine display and so on.

We are now achieving new custom display solutions with unique design and supreme image quality to meet your various needs. With extensive experiences in LCD displays. GSD also provides P-Cap touch solutions with various glass design support and high quality optical bonding services.

“After a shutdown, it typically takes 12 to 24 hours before production can be restarted at an LCD manufacturing fab.” said iSuppli researcher Sweta Dash in a press release. “However, if there is damage to the equipment, the shutdown will last for a longer period of time.”

VentureBeat"s mission is to be a digital town square for technical decision-makers to gain knowledge about transformative enterprise technology and transact. Discover our Briefings.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey