lcd display wiring diagram quotation

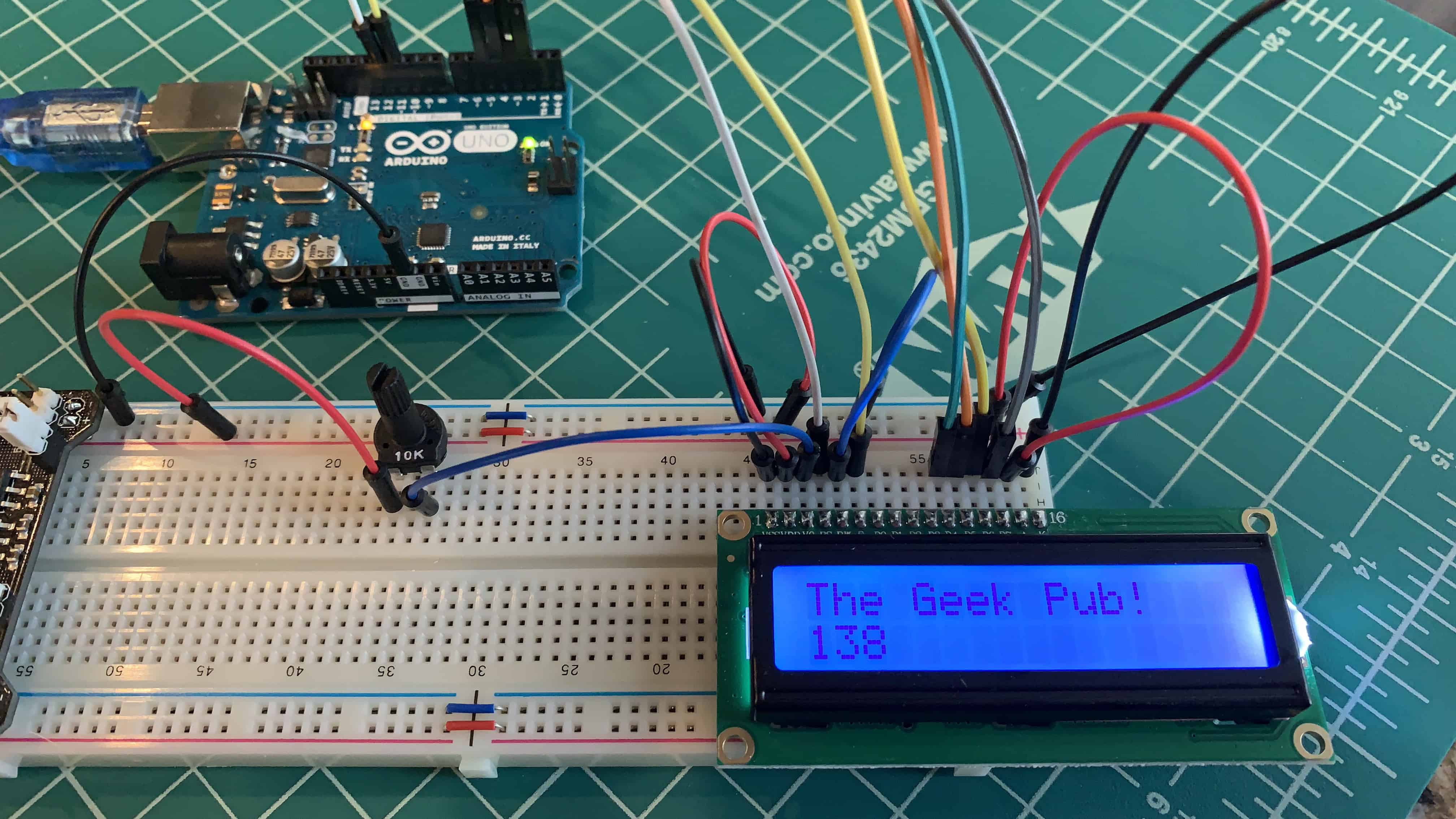

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

The 3-in-1 Smart Car and IOT Learning Kit from SunFounder has everything you need to learn how to master the Arduino. It includes all of the parts, wiring diagrams, code, and step-by-step instructions for 58 different robotics and internet of things projects that are super fun to build!

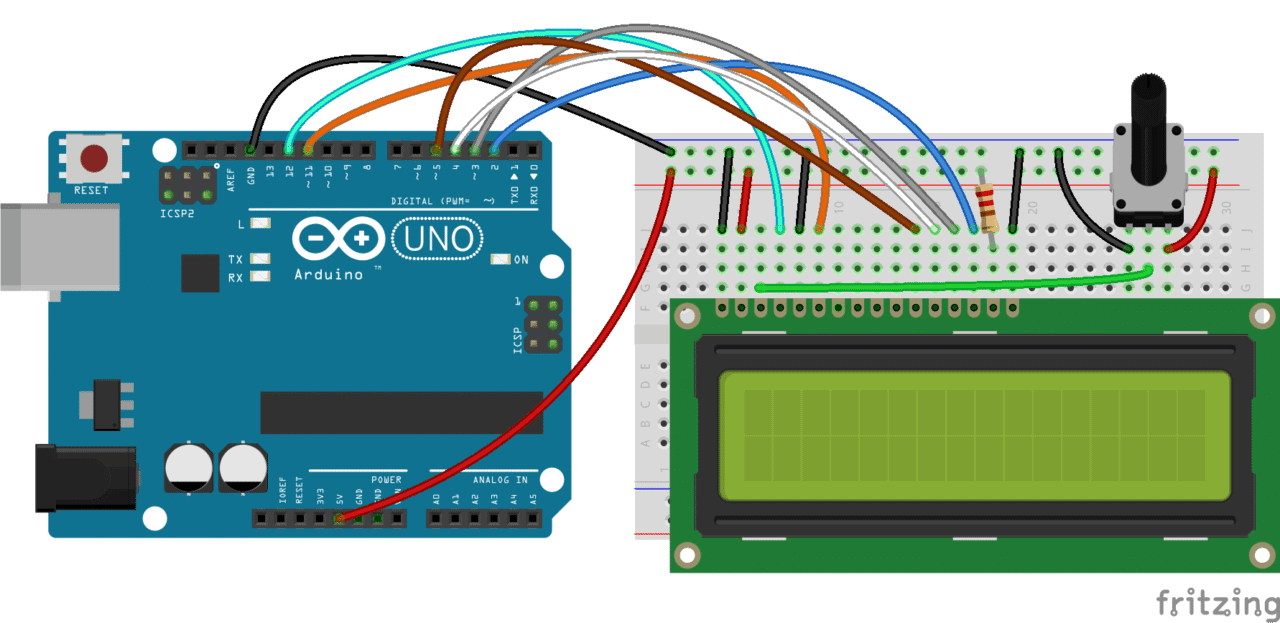

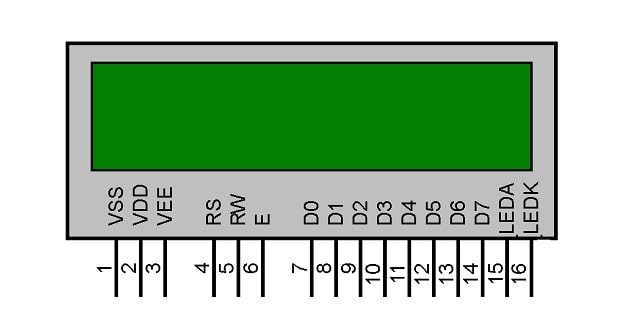

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

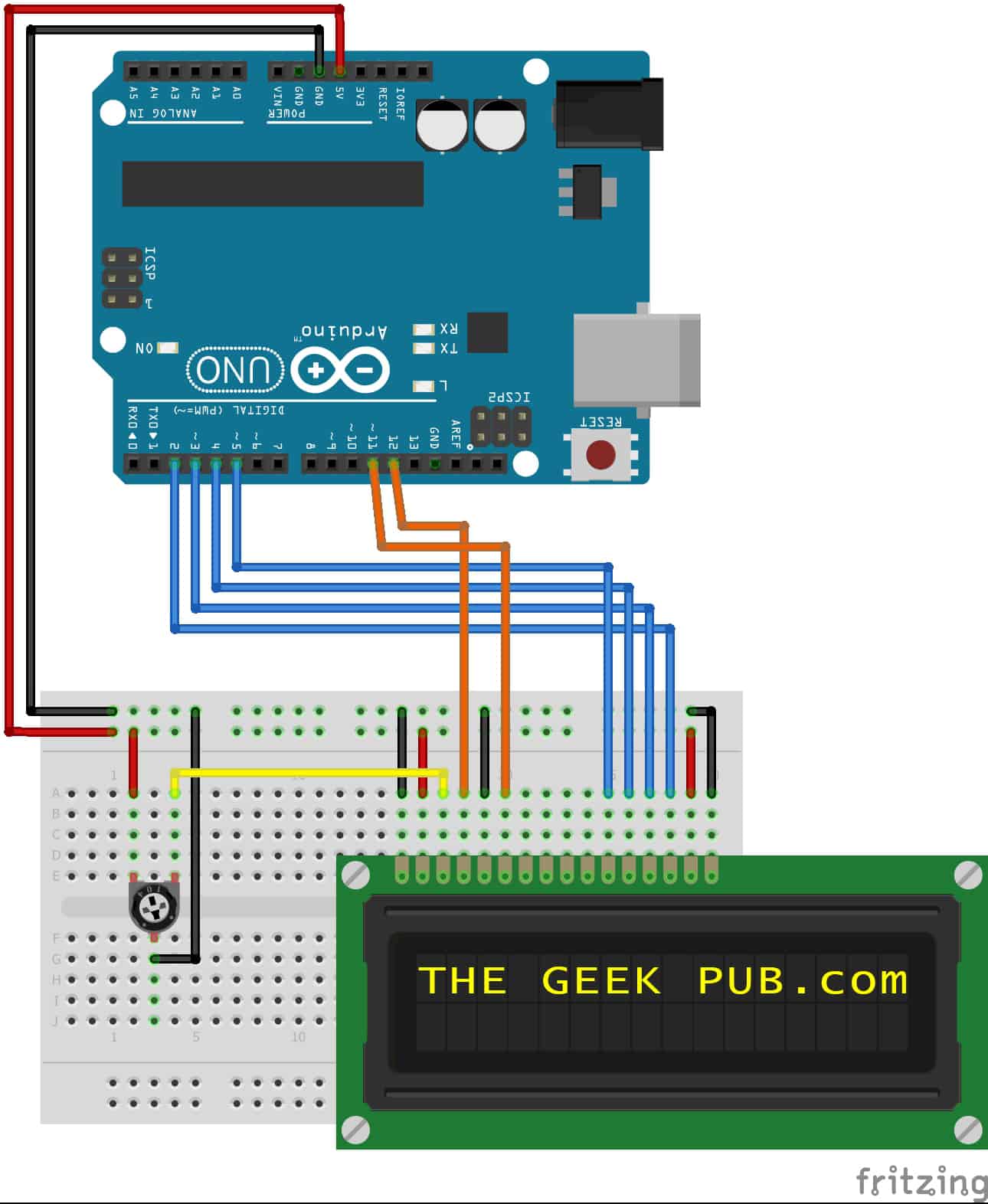

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

The resistor in the diagram above sets the backlight brightness. A typical value is 220 Ohms, but other values will work too. Smaller resistors will make the backlight brighter.

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

The Serial Monitor is a convenient way to view data from an Arduino, but what if you want to make your project portable and view sensor values without access to a computer? Liquid crystal displays (LCDs) are excellent for displaying a string of words or sensor data.

This guide will help you in getting your 16×2 character LCD up and running, as well as other character LCDs (such as 16×4, 16×1, 20×4, etc.) that use Hitachi’s LCD controller chip, the HD44780.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

Character LCDs are available in a variety of sizes and colors, including 16×1, 16×4, 20×4, white text on a blue background, black text on a green background, and many more.

One advantage of using any of these displays in your project is that they are “swappable,” meaning that you can easily replace them with another LCD of a different size or color. Your code will need to be tweaked slightly, but the wiring will remain the same!

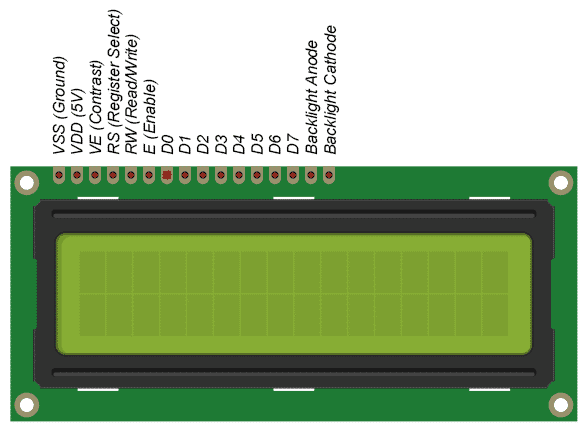

Before we get into the hookup and example code, let’s check out the pinout. A standard character LCD has 16 pins (except for an RGB LCD, which has 18 pins).

Vo (LCD Contrast) pin controls the contrast of the LCD. Using a simple voltage divider network and a potentiometer, we can make precise contrast adjustments.

RS (Register Select) pin is used to separate the commands (such as setting the cursor to a specific location, clearing the screen, etc.) from the data. The RS pin is set to LOW when sending commands to the LCD and HIGH when sending data.

R/W (Read/Write) pin allows you to read data from or write data to the LCD. Since the LCD is only used as an output device, this pin is typically held low. This forces the LCD into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD ignores activity on the R/W, RS, and data bus lines; when it is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. To see an uppercase ‘A’ character on the display, for example, we set these pins to 0100 0001 (as per the ASCII table).

The LCD has two separate power connections: one for the LCD (pins 1 and 2) and one for the LCD backlight (pins 15 and 16). Connect LCD pins 1 and 16 to GND and 2 and 15 to 5V.

Depending on the manufacturer, some LCDs include a current-limiting resistor for the backlight. It is located on the back of the LCD, close to pin 15. If your LCD does not contain this resistor or if you are unsure whether it does, you must add one between 5V and pin 15. It should be safe to use a 220 ohm resistor, although a value this high may make the backlight slightly dim. For better results, check the datasheet for the maximum backlight current and choose an appropriate resistor value.

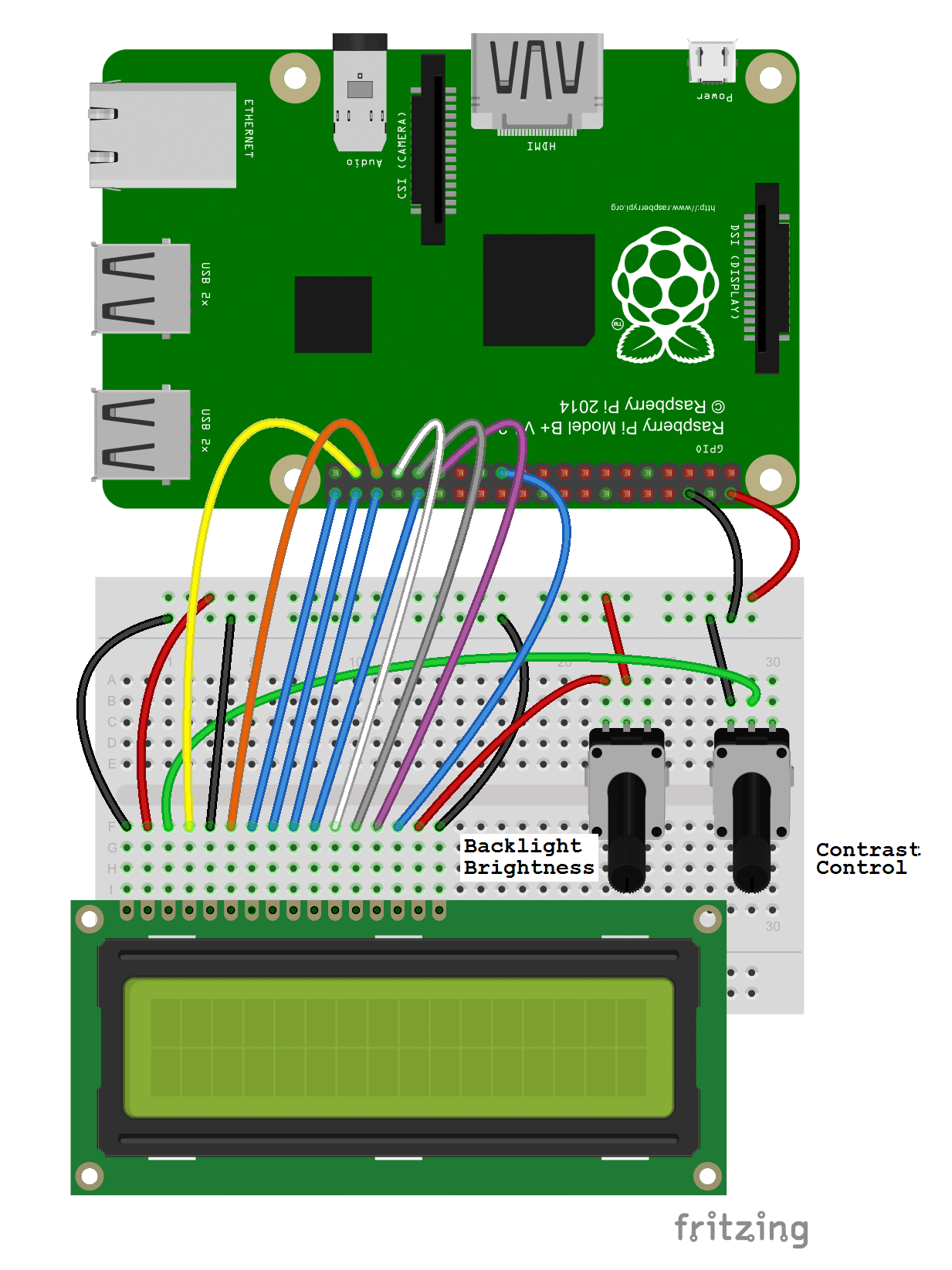

Let’s connect a potentiometer to the display. This is necessary to fine-tune the contrast of the display for best visibility. Connect one side of the 10K potentiometer to 5V and the other to Ground, and connect the middle of the pot (wiper) to LCD pin 3.

That’s all. Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, you will see the first row of rectangles appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

We know that data is sent to the LCD via eight data pins. However, HD44780-based LCDs are designed so that we can communicate with them using only four data pins (in 4-bit mode) rather than eight (in 8-bit mode). This helps us save 4 I/O pins!

The sketch begins by including the LiquidCrystal library. This library comes with the Arduino IDE and allows you to control Hitachi HD44780 driver-based LCD displays.

Next, an object of the LiquidCrystal class is created by passing as parameters the pin numbers to which the LCD’s RS, EN, and four data pins are connected.

In the setup, two functions are called. The first function is begin(). It is used to initialize the interface to the LCD screen and to specify the dimensions (columns and rows) of the display. If you’re using a 16×2 character LCD, you should pass 16 and 2; if you’re using a 20×4 LCD, you should pass 20 and 4.

In the loop, the print() function is used to print “Hello world!” to the LCD. Please remember to use quotation marks " " around the text. There is no need for quotation marks when printing numbers or variables.

The function setCursor() is then called to move the cursor to the second row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

If you find the default font uninteresting, you can create your own custom characters (glyphs) and symbols. They come in handy when you need to display a character that isn’t in the standard ASCII character set.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

This article includes everything you need to know about using acharacter I2C LCD with Arduino. I have included a wiring diagram and many example codes to help you get started.

In the second half, I will go into more detail on how to display custom characters and how you can use the other functions of the LiquidCrystal_I2C library.

Once you know how to display text and numbers on the LCD, I suggest you take a look at the articles below. In these tutorials, you will learn how to measure and display sensor data on the LCD.

Each rectangle is made up of a grid of 5×8 pixels. Later in this tutorial, I will show you how you can control the individual pixels to display custom characters on the LCD.

They all use the same HD44780 Hitachi LCD controller, so you can easily swap them. You will only need to change the size specifications in your Arduino code.

The 16×2 and 20×4 datasheets include the dimensions of the LCD and you can find more information about the Hitachi LCD driver in the HD44780 datasheet.

After you have wired up the LCD, you will need to adjust the contrast of the display. On the I2C module, you will find a potentiometer that you can turn with a small screwdriver.

Note that counting starts at 0 and the first argument specifies the column. So lcd.setCursor(2,1) sets the cursor on the third column and the second row.

Next the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text since we are printing a text string.

The example sketch above shows you the basics of displaying text on the LCD. Now we will take a look at the other functions of the LiquidCrystal_I2C library.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space.

If the current text direction is left-to-right (the default), the display scrolls to the left, if the current direction is right-to-left, the display scrolls to the right.

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions or if you think that things are missing in this tutorial, please leave a comment down below.

What is the purpose of declaring LiquidCrystal_I2C lcd(0x27, 2, 1, 0, 4, 5, 6, 7, 3, POSITIVE); if we are using pins A4 and A5? I know that 0x27 is the ic address but what is the rest for?

I am getting a error while i m going to add zip file of lcd library error id this zip file does not contains a valid library please help me to resolve this issue as soon as possible.....

Hey guys. My LCD works fine using the above instructions (when replacing the existing LCD library in the Arduino directory) but I can"t get the backlight to ever switch off. Suggestions?

Newhaven 16x2 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216HZ-FL-YBW-C display has an optimal view of 6:00 and comes with a temperature compensation circuit. This display operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Newhaven 8x1 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0108BZ-FSY-YBW-33V3 display has an optimal view of 6:00. This display operates at 3.3V supply voltage, has a built-in ST7066U controller and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Hello friends welcome back to Techno-E-solution, In previous video we see how to interface LCD 16×2 to Arduino Uno, but there are very complicated circuits, so in this tutorial, I"ll show you how to reduce circuitry by using I2C module which is very compact & easy to connection. Simply connect I2C module with LCD parallel & connect I2C modules 4 pins to Arduino. I2C module has 4 output pins which contains VCC, GND, SDA, SCL where 5V supply gives to I2C module through VCC & GND to GND of Arduino. SDA is a data pin & SCL is clock pin of I2C module. To interface LCD and I2C with Arduino we need Liquid Crystal I2C Library in Arduino IDE software.

An LCD FPC is a flexible circuit that connects an LCD to a customer’s product. A flat cable is a better choice than a round or a wire because it provides greater suppression of RFI and EMI. A flexible printed circuit is custom-built with additional circuitry and lengths to carry data signals from an LCD to the customer’s product. This type of circuit is also called a ZIF connector.

The ZIF connector for LCD FPC is a common failure point for Apple iPad 3and 4. The problem with this component is that it easily breaks during connection or disconnection. The best way to prevent this is to avoid any contact that might damage the connector.

When we talk about the LCD FPC, we talk about the connector that holds LCD screens together. This connector is flexible and can be helpful in many applications, such as mobile phones and navigation equipment. Its main characteristics include high transmission speed, small spacing, and high density. These features can help to ensure the reliability of the transmission of the signal. In addition, it can also convert electrical signals into optical signals. Hence, it is essential to know the specifications of the connector before it is helpful in an application.

Identifying the exact problem with your LCD FPC can be difficult. It may require the use of specialized tools. Therefore, it is critical to know how to perform a diagnosis before starting any repair work. In most cases, the fault is not a hardware one but rather a software issue. Sometimes, a simple FPC repair is sufficient to fix the problem. In other cases, purchasing a replacement LCD FPC may be necessary.

If you’re looking for an LCD unit, there are some key features that you should look for. Some of these factors include energy efficiency, easy connections, and easy cleaning. Other considerations include GPIO pins and GPIO bus compatibility. Then, you can begin shopping for the best LCD unit to meet your needs. Continue reading to learn more.

LCDs are an increasingly popular choice for computer systems. This is because they are energy-efficient and feature many other benefits. For example, FPC displays’ energy efficiency helps decrease energy usage. Additionally, the FPC-based units offer better connectivity than their LCD counterparts. However, they are not the only energy-efficient displays.

FPC or flat panel connectors have been used for many years to provide easy connectivity between multiple devices. These connectors use a flexible cable that adheres to the display with conductive glue. Many of these connectors consist of silicone, and we can easily clean them with a wet toothbrush. However, following the manufacturer’s cleaning instructions is essential, as some are more sensitive than others and may require special care to avoid damaging them.

You can use microfibre cloths and a spray bottle with water to clean LCD displays. You can use these clothes to remove stubborn stains and fingerprints. However, you must be careful not to get any liquid or residue on display, as this may damage the coatings. You should also avoid using liquid soaps and detergents near your display, as they can harm the LCD screen.

The efficiency of FPC/FFC cables has risen rapidly and is now used to connect LCD panels to other printed circuit boards. These cables are helpful in various applications from industrial equipment to home appliances, LCD television sets, printers, and mobile devices. The increasing usage of these cables has resulted in a growing demand for these units.

Using the GPIO pins of efficient FPC LCD FPPC units allows you to connect peripherals such as sensors to the display. The display itself has few connectors to connect peripherals, but these FFC units will enable you to hook up peripherals directly. You can also connect the display to an expandable header to connect additional boards.

Common FPC LCD modules share several common features. These include a Hitachi HD44780 compatible controller, common pins and connectors, and a standard set of communication interfaces. In addition, these common LCD modules support all eight data lines, including register-select, enable, and data. They also share a LiquidCrystal library.

FPC is the most common type of connection between LCDs. Its major function is to transmit data safely. This connection consists of a conductive strip that is malleable. The strips fit between the controller and display connection ports. To make sure the strips are securely connected, bezels are necessary. This ensures proper connection and prevents surface-to-surface reflections. In addition, this helps to produce better viewing angles and contrast.

If you have a new display, you should carefully follow the manufacturer’s instructions when cleaning it. It can damage the LCD by allowing it to come in contact with moisture or other liquids. Instead, you should use a soft cloth dampened in a mild detergent solution to remove stubborn dirt and other grime. You should avoid using abrasive pads, solvents, or scouring powders on the LCD.

Avoid using paper towels to clean the display. They leave small fibers that can compromise the accuracy of the LCD. Instead, use a lint-free microfiber cloth. This will remove most of the dirt and dust without damaging the display. The final step is to dry the display with a soft cloth.

The DT022BTFT uses the same connections as the DT022CTFT, with the exception of the backlight (which has connections shown in the Displaytech datasheet).

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function. Keep the default values for all registers in the ILI9341, unless changed by the example code provided.

Note that the WR pin becomes the D/CX signal in serial mode. CS is used to initiate a data transfer by pulling it low. At the end of the data transfer, pull the CS pin high to complete the transaction. The timing diagram indicates that you can pull the CS pin high in between the command byte and data bytes within a transfer, but it is unlikely needed if the display is the only device on the SPI bus. To keep things simple, we suggest to leave it low during the entire transaction.

The D/CX pin tells the ILI9341 that the current byte is either command or data. Pull the D/CX pin low when the current byte is a command, and pull high when it is data. The timing diagram indicates only needing to set D/CX on the last bit of a byte, but it is much simpler to just leave it high or low during the entire byte.

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function.

An LCD or liquid crystal display is a combination of two states of material ie, the solid & the liquid. These displays use a liquid crystal to produce a visible image. LCDs are super thin technology display screen that are used in cell phones, TVs, portable video games, laptops, computer screen, portable video games. Compared to CRT (cathode ray tube) technology, this technology permits displays to be much thinner. The LCD is composed of different layers which contain two electrodes and polarized panel filters. This technology is used to display the image in electronic devices. It is made up of active matrix or passive display grid. Most of the gadgets with LCD display uses active matrix display. There are various technologies used to make digital displays. But, we are discussing two different LCDs. The alphanumeric display and customized LCD.

The most common types of monochrome LCDs are called character display or alphanumeric display. Alphanumeric LCD displays are used to display alphabets and numbers. The 16×2 intelligent alphanumeric dot matrix displays are capable of displaying 224 different symbols and characters. Generally, alphanumeric LCDs are used widely in these applications: cellular phones, home appliances, meters, word processors, communication, medical instruments, etc.. These displays are widely used due to the following reasons:

Hardware designers and engineers favor alphanumeric LCD displays for fast developing products. These types of devices contain their own controller driver chip with a character map built into the IC. To integrate the software, the character map makes it easy for the design. When any designer or engineer wants to display or show a letter, all they need to do is to send a command requesting the capital. This is much easier than a graphics LCD module wherein each spot on the letter A needs to be addressed. This is a highly time consuming activity.

The most common structure of alphanumeric display is known as a chip on board (COB) where in the PCB (printed circuit board) is attached to the LCD glass. The name COB means that the controller driver chip is placed on the back of the PCB. This module handles vibration very well. And also the increasing holes placed on the PCB permit an easy and secure method to attach the LCD to the customer’s product.

Alphanumeric LCD displays are designed in standard configurations such as LCD display 16×2, 8×1 and 40×4. The identification of alphanumeric displays is broken down into the number of characters in each row and then the number of rows. The example of this is a 16×2, where there are 16 characters in each row, and there are two rows of these characters. This enables the alphanumeric displays to display 32characters at a time.

A character can be any letter: capital or small, any number,and punctuation mark, such as comma, period and backslash. The character table built into the microcontroller of the LCD display displays 255 different characters.Furthermore, there are many languages, so you can select a character table that displays English, German and French or any other language. Most of the alphanumeric LCD displays cannot display Chinese and Japanese languages without the use of a larger character size. This means that a 16×2 is built to display English characters, but not the Chinese;Chinese will require larger than 16×2 display.

The alphanumeric displays consist of LCD displays or a set of LEDs that are connected in common anode or common cathode mode. 7 segment displays are used for only numbers in decimal and hexadecimal format.For both alphabets and numbers, the 18 segment display consisting of the 5 by 7 dot matrix is used.

Alphanumeric LCD Displays are most commonly used in test and measurement equipment, process control equipment, handheld devices, PLC’s, data loggers, PCO displays energy meters, and a host of other applications. Displaying Scrolling Messages on Alpha Numeric Displays using a PC is one of the most frequently used application of alphanumeric display.

The above block diagram can be used to display scrolling message on alphanumeric LCDs by using PC. The information can be sent through a PC that is interfaced with an 8051 microcontroller through MAX232. An external memory is connected to the microcontroller which stores the information. The endless scrolling can be displayed using alphanumeric LCD display, which is connected to a microcontroller.

In present days, different types of LCDs are used in a wide range of applications from calculators, watches, games to medical and industrial applications. One of the main advantages of LCDs over other display technologies is the display content can be modified to satisfy the exact requirements of an application. In this way, the customized LCD panels can present particular user interface information that enhances the product value and performance.

Customized LCD displays are used to display a combination of numeric, alphanumeric digits, on/off indicators,messages, graphic icons, symbols, pie charts, bar graphs, etc. The content of this panel is limited only by the imagination of the product designer. There are manyfactors that should be considered in the design of a customized LCD panel. In order to design a quotation for a customized LCD panel, the following information is necessary:LCD panel, display modes, polarisers, viewing mode, backlight requirement, operating environment, drive method, connection method, and a keypad is required if applicable.

This is all about Alphanumeric and Customized LCD displays with Applications. We all know that these LCD displays play an essential role in many applications like measurement equipment, process control equipment, handheld devices, PLC’s, Measuring device, Marine equipment, Medical equipment, Automotive display etc. This article deserves readers’ feedback, suggestions and comments. Furthermore, any doubts regarding electronics projectsreaders can post their comments in the comment section below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey