flexible lcd display technology factory

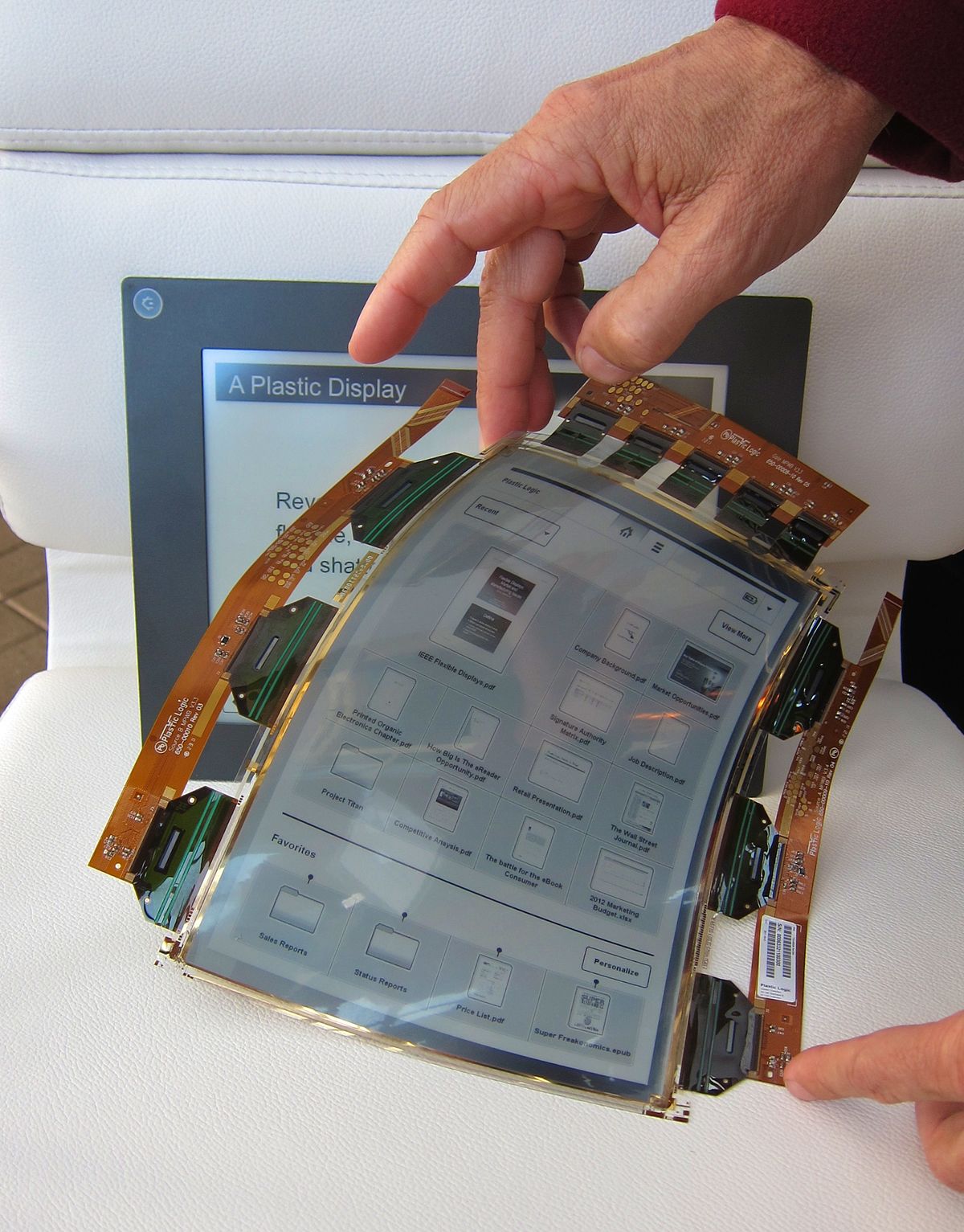

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

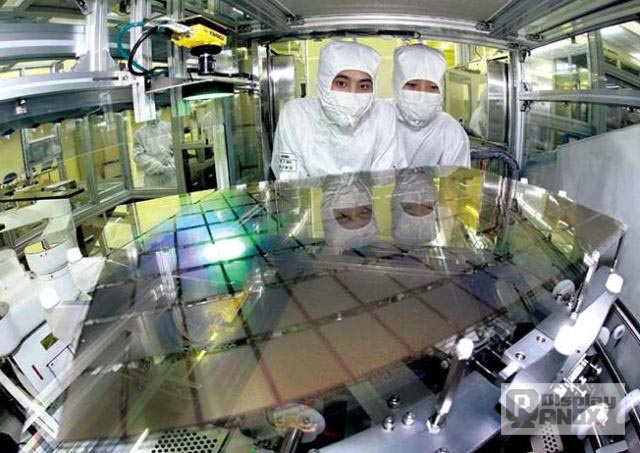

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

FlexEnable’s award-winning flexible technology platform, including our unique FlexiOM™ materials, brings transformational possibilities to products including AR and VR optics, ePrivacy screens, automotive smart windows and displays. The complete low temperature manufacturing process allows, for the first time, commonly available and optically ideal flexible bio-degradable substrates such as TAC film to be used instead of glass. This innovative technology is used to make active matrix flexible Organic Liquid Crystal Displays(OLCDs) and flexible active optical films which are thin, light and conformable to almost any surface.

Today FlexEnable has around 600 patents and patent applications globally for OTFT and Liquid Crystal (LC) Cell materials, processes and architectures. The company has technology transfer programmes underway with several leading display manufacturers in Asia as well as commercial programmes with some of the world’s biggest brands in consumer electronics.

Our OTFT platform is the most flexible array technology available and offers unique benefits to display makers. The scalable organic transistor processes have been specifically designed to be implemented on today’s flat panel display manufacturing lines and are already proven for mass production. They are the lowest cost way to produce area-scalable active-matrix flexible displays and optics. Through our Technology Transfer and Licensing programme we help manufacturing partners not only achieve product innovation, but also reduce their environmental impact by implementing sustainable manufacturing.

Our unique manufacturing approach minimises the environmental impact compared to today’s glass-based display production. We do this by reducing energy consumption, reusing equipment, and using recyclable materials. For example, in comparison to glass displays, OLCD brings huge energy savings primarily as a result of the incredibly low manufacturing temperatures used:

Reduce – At 100°C, the reduced manufacturing temperatures of organic transistors compared to 300°C-500°C of silicon TFTs reduces energy consumption in production compared to glass displays. The combined energy savings of low temperatures and CVD-free processes of OLCD reduce production energy by around 25% compared to glass LCD. With a medium-sized (Gen 6) display factory consuming around 500 GWh/year, this major energy saving also results in a carbon footprint reduction of 67,000 tonnes of CO2 per year for a single factory. If applied industry-wide the energy savings alone would be enough to power 1 million homes.

Reuse – OLCD is purposefully designed to re-use existing factories originally built to make glass displays. This prolongs the useful economic life of existing installations by giving them the capability to manufacture highly disruptive flexible display technology and then rapidly scale volume production.

Recycle – The low process temperatures allow a plastic film known as TAC (Tri acetyl cellulose) to be used as the substrate instead of glass. TAC is a widely available bioplastic made of a cellulose derived from the same raw material as paper, is highly recyclable and biodegradable, and already used in the displays supply chain. During production of the flexible displays, the TAC film is stuck to a sheet of display glass. After production is complete the flexible display is removed, and the glass is reused for the next display.

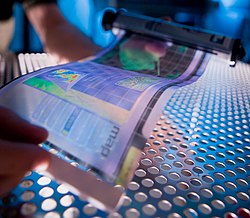

FlexEnable’s efficient manufacturing approach to making flexible electronics is unique. The conventional approach is to manufacture silicon or other ceramic-based circuits on glass with a highly engineered interlayer that is capable of coping with the extreme process temperatures, often surpassing 450°C. The removal of the finished circuit from the glass requires stressful and often expensive debonding techniques that make it difficult to scale to large sizes cost effectively.

Our approach is to use conventional adhesive technology to attach low-cost plastic films to glass and then use our low temperature organic transistor process to manufacture the same circuits. This allows us to use a very simple and efficient demount process to release the flexible device and recycle the glass carrier. In the world of flexible electronics, low temperature manufacturing is the key to low cost, scalable and sustainable.

3In contrast to the standard flat screen displays used in several electrical gadgets, a flexible display or bendable display is an electronic visual display manufactured by flexible display brands. Several consumer electronics firms have expressed enthusiasm in using this display technologies in e-readers, smart phones, and other electronic goods in recent times. Such screens may be rolled up like a scroll without distorting the image or text. Electronic ink, Gyricon, Organic LCD, and OLED are among the technologies used to create a bendable display.

With the flat panel screen having been extensively used for more than 40 years, many desirable advances in display technology have been made, with the goal of creating lighter, thinner products that are simpler to carry and store. Scientists and engineers think that flexible flat panel display innovation has a large commercial possibility in the future, thanks to recent advancements in flexible display technique.

Flexible displays offered by the flexible display brands are still somewhat costly as contrasted to their rigid equivalents, and visual quality is frequently sacrificed. When the screen is bent at a specific angle, this is extremely evident. However, in comparison to standard displays, flexible screens have a shorter lifespan.

Current models should endure a long time for the majority of users’ demands. However, most flexible display brands still require tackling this issue, particularly given the rising pricing of flexible display devices.

views itself as a supplier of intelligent vertical systems underpinned by premium display technology as an optoelectronics specialist. The company’s vast expertise, innovative skills, and corporate sustainability set it apart and set it out from the competition.

In terms of display as a networking and communication interface, AUO offers a wide range of alternatives in retail, healthcare, transport, and other industries, with the goal of forming eco-systems with partnerships across all sectors and ushering the world into a new smarter lifestyle.

is critical to advancement in both the sectors it shapes and the planet it shares. They use materials science to create life-changing technology. They are at the core of how the world communicates, performs, educates, and lives because of their technical and production competence, insatiable curiosity, and devotion to meaningful creativity.

Through its novel panel-centric and vertical integration operation style,unifies the product production supply chain and offers clients with full solutions. Innolux has a clear emphasis on handling technology and elements, as well as superior administration skills, in addition to a solid TFT-LCD basis and manufacturing quality. Innolux develops standards, sets market trends, and offers a comprehensive product portfolio and services to their suppliers’ clients in the data and electronic goods industries.

Japan Display Incorporateddevelops, designs, manufactures, and sells displays where a user interface is required to transmit a large amount of data in a short amount of time and to a worldwide market. They design engaging settings that go above and beyond the ordinary, enrich people’s lives, and stir their hearts.

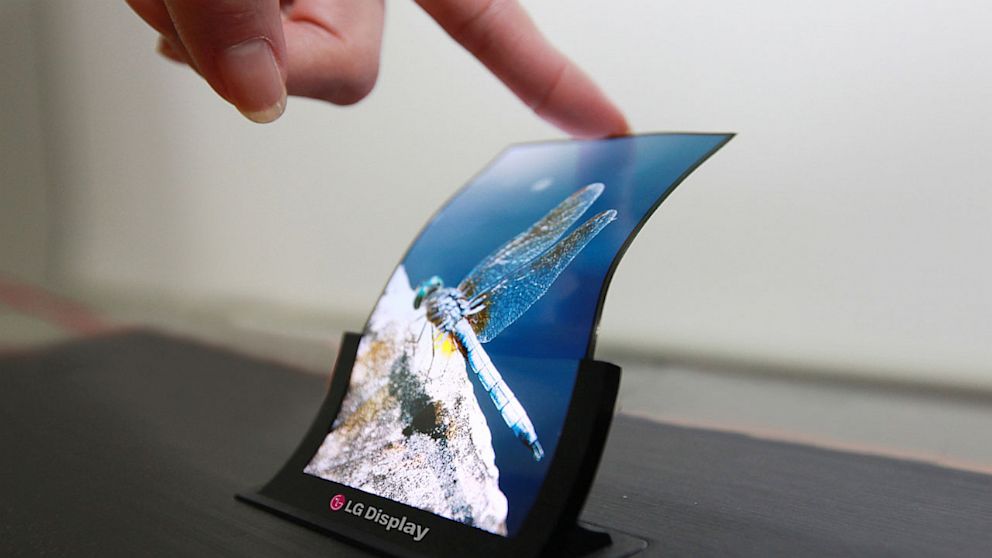

LG Displayis the world’s top inventor of display technologies, comprising TFT-LCD and OLED screens, as well as the worldwide leader in OLED lighting. The firm makes display screens in a variety of dimensions and standards for usage in televisions, laptop computers, desktop workstations, and other purposes, such as tablets and mobile phones. It also manufactures OLED light screens for the automobile and interior decorating industries.

Visionoxis the globe’s renowned provider of sophisticated display systems that are both integrated and interactive. The company’s objective is to lead China’s OLED industry via technical innovation” and its ambition is to “push limits to enrich the experience of eyesight.

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices.e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted.electronic ink, Gyricon, Organic LCD, and OLED.

Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity.pixel rollable display based on E Ink’s electrophoretic technology.flexible organic light-emitting diode displays have been demonstrated.electronic paper wristwatch. A rollable display is an important part of the development of the roll-away computer.

With the flat panel display having already been widely used more than 40 years, there have been many desired changes in the display technology, focusing on developing a lighter, thinner product that was easier to carry and store. Through the development of rollable displays in recent years, scientists and engineers agree that flexible flat panel display technology has huge market potential in the future.

Flexible electronic paper (e-paper) based displays were the first flexible displays conceptualized and prototyped. Though this form of flexible displays has a long history and were attempted by many companies, it is only recently that this technology began to see commercial implementations slated for mass production to be used in consumer electronic devices.

The concept of developing a flexible display was first put forth by Xerox PARC (Palo Alto Research Company). In 1974, Nicholas K. Sheridon, a PARC employee, made a major breakthrough in flexible display technology and produced the first flexible e-paper display. Dubbed Gyricon, this new display technology was designed to mimic the properties of paper, but married with the capacity to display dynamic digital images. Sheridon envisioned the advent of paperless offices and sought commercial applications for Gyricon.

In 2005, Arizona State University opened a 250,000 square foot facility dedicated to flexible display research named the ASU Flexible Display Center (FDC). ASU received $43.7 million from the U.S. Army Research Laboratory (ARL) towards the development of this research facility in February 2004.demonstration later that year.Hewlett Packard demonstrated a prototype flexible e-paper from the Flexible Display Center at the university.

Between 2004–2008, ASU developed its first small-scale flexible displays.U.S. Army funds ASU’s development of the flexible display, the center’s focus is on commercial applications.

This company develops and manufactures monochrome plastic flexible displays in various sizes based on its proprietary organic thin film transistor (OTFT) technology. They have also demonstrated their ability to produce colour displays with this technology, however they are currently not capable of manufacturing them on a large scale.Dresden, Germany, which was the first factory of its kind to be built – dedicated to the high volume manufacture of organic electronics.plastic and do not contain glass. They are also lighter and thinner than glass-based displays and low-power. Applications of this flexible display technology include signage,wristwatches and wearable devices

In 2004, a team led by Prof. Roel Vertegaal at Queen"s University"s Human Media Lab in Canada developed PaperWindows,Organic User Interface. Since full-colour, US Letter-sized displays were not available at the time, PaperWindows deployed a form of active projection mapping of computer windows on real paper documents that worked together as one computer through 3D tracking. At a lecture to the Gyricon and Human-Computer Interaction teams at Xerox PARC on 4 May 2007, Prof. Vertegaal publicly introduced the term Organic User Interface (OUI) as a means of describing the implications of non-flat display technologies on user interfaces of the future: paper computers, flexible form factors for computing devices, but also encompassing rigid display objects of any shape, with wrap-around, skin-like displays. The lecture was published a year later as part of a special issue on Organic User InterfacesCommunications of the ACM. In May 2010, the Human Media Lab partnered with ASU"s Flexible Display Center to produce PaperPhone,MorePhone

Research and development into flexible OLED displays largely began in the late 2000s with the main intentions of implementing this technology in mobile devices. However, this technology has recently made an appearance, to a moderate extent, in consumer television displays as well.

Nokia first conceptualized the application of flexible OLED displays in mobile phone with the Nokia Morph concept mobile phone. Released to the press in February 2008, the Morph concept was project Nokia had co-developed with the University of Cambridge.nanotechnology, it pioneered the concept of utilizing a flexible video display in a consumer electronics device.London, alongside Nokia’s new range of Windows Phone 7 devices.

Sony Electronics expressed interest for research and development towards a flexible display video display since 2005.RIKEN (the Institute of Physical and Chemical Research), Sony promised to commercialize this technology in TVs and cellphones sometime around 2010.TFT-driven OLED display.

In January 2013, Samsung exposed its brand new, unnamed product during the company"s keynote address at CES in Las Vegas. Brian Berkeley, the senior vice president of Samsung"s display lab in San Jose, California had announced the development of flexible displays. He said "the technology will let the company"s partners make bendable, rollable, and foldable displays," and he demonstrated how the new phone can be rollable and flexible during his speech.

During Samsung"s CES 2013 keynote presentation, two prototype mobile devices codenamed "Youm" that incorporated the flexible AMOLED display technology were shown to the public.OLED screen giving this phone deeper blacks and a higher overall contrast ratio with better power efficiency than traditional LCD displays.LCD displays. Samsung stated that "Youm" panels will be seen in the market in a short time and production will commence in 2013.

The Flexible Display Center (FDC) at Arizona State University announced a continued effort in forwarding flexible displays in 2012.Army Research Lab scientists, ASU announced that it has successfully manufactured the world"s largest flexible OLED display using thin-film transistor (TFTs) technology.

In January 2019, Chinese manufacturer Xiaomi showed a foldable smartphone prototype.Xiaomi demoed the device in a video on the Weibo social network. The device features a large foldable display that curves 180 degrees inwards on two sides. The tablet turns into a smartphone, with a screen diagonal of 4,5 inch, adjusting the user interface on the fly.

Flexible displays have many advantages over glass: better durability, lighter weight, thinner as plastic, and can be perfectly curved and used in many devices.glass and rollable display is that the display area of a rollable display can be bigger than the device itself; If a flexible device measuring, for example, 5 inches in diagonal and a roll of 7.5mm, it can be stored in a device smaller than the screen itself and close to 15mm in thickness.

Flexible screens can open the doors to novel and alternative authentication schemes by emphasizing the interaction between the user and the touch screen. In “Bend Passwords: Using Gestures to Authenticate on Flexible Devices,” the authors introduce a new method called Bend Passwords where users perform bending gestures and deform the touch screen to unlock the phone. Their work and research points to Bend Passwords possibly becoming a new way to keep smartphones secure alongside the popularization of flexible displays.

Flexible displays using electronic paper technology commonly use Electrophoretic or Electrowetting technologies. However, each type of flexible electronic paper vary in specification due to different implementation techniques by different companies.

The flexible electronic paper display technology co-developed by Arizona State University and HP employs a manufacturing process developed by HP Labs called Self-Aligned Imprint Lithography (SAIL).

The flexible electronic paper display announced by AUO is unique as it is the only solar powered variant. A separate rechargeable battery is also attached when solar charging is unavailable.

Many of the e-paper based flexible displays are based on OLED technology and its variants. Though this technology is relatively new in comparison with e-paper based flexible displays, implementation of OLED flexible displays saw considerable growth in the last few years.

In May 2011, Human Media Lab at Queen"s University in Canada introduced PaperPhone, the first flexible smartphone, in partnership with the Arizona State University Flexible Display Center.

At CES 2013, Samsung showcased the two handsets which incorporates AMOLED flexible display technology during its keynote presentation, the Youm and an unnamed Windows Phone 8 prototype device.Galaxy Note Edge,Samsung Galaxy S series devices.

LG Electronics and Samsung Electronics both introduced curved OLED televisions with a curved display at CES 2013 hours apart from each other.The Verge noted the subtle curve on 55" Samsung OLED TV allowed it to have a "more panoramic, more immersive viewing experience, and actually improves viewing angles from the side."

Crawford, Gregory P., ed. (2005). Flexible flat panel displays (Reprinted with corrections. ed.). Chichester, West Sussex, England: John Wiley & Sons. p. 2. ISBN 978-0470870488.

Thryft, Ann R. (7 June 2012). "All-Plastic Electronics Power Flexible Color Display". Design News. Archived from the original on 31 March 2019. Retrieved 24 April 2013.

Lahey, Byron; Girouard, Audrey; Burleson, Winslow and Vertegaal, Roel (May 2011). PaperPhone: Understanding the Use of Bend Gestures in Mobile Devices with Flexible Electronic Paper Displays, Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Pages 1303–1312.

Gomes, A., Nesbitt, A., and Vertegaal, R. (2013) MorePhone: A Study Of Actuated Shape Deformations for Flexible Thin-Film Smartphone Notifications. In Proceedings of ACM CHI’13 Conference on Human Factors in Computing. ACM Press, 2013, pp. 583–592.

Nokia Press Center (25 February 2008). "Nokia and University of Cambridge launch the Morph – a nanotechnology concept device". Nokia. Archived from the original on 27 February 2018. Retrieved 12 February 2013.

Lee, Reuben (10 January 2013). "Samsung shows off flexible display phones at CES keynote". CNET. Archived from the original on 17 February 2013. Retrieved 12 February 2013.

Sasaoka, Tatsuya; Sekiya, Mitsunobu; Yumoto, Akira; Yamada, Jiro; Hirano, Takashi; Iwase, Yuichi; Yamada, Takao; Ishibashi, Tadashi; Mori, Takao; Asano, Mitsuru; Tamura, Shinichiro; Urabe, Tetsuo (1 January 2001). "24.4L: Late-News Paper: A 13.0-inch AM-OLED Display with Top Emitting Structure and Adaptive Current Mode Programmed Pixel Circuit (TAC)". SID Symposium Digest of Technical Papers. 32 (1): 384. doi:10.1889/1.1831876. S2CID 59976823.

Drzaic, P.; Comiskey, B.; Albert, J. D.; Zhang, L.; Loxley, A.; Feeney, R.; Jacobson, J. (1 January 1998). "44.3L: A Printed and Rollable Bistable Electronic Display". SID Symposium Digest of Technical Papers. 29 (1): 1131. doi:10.1889/1.1833686. S2CID 135723096.

Lowensohn, Josh (9 January 2013). "Eyes-on: Samsung"s Youm flexible-display tech at CES 2013". CNET. Archived from the original on 26 November 2013. Retrieved 12 February 2013.

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Flexible Lcd, Tft Color Lcd Display, Custom Touch Screen Displays, Touch Screen Tft Monitor,Portable Lcd Monitor. Our mission is to allow you to create long-lasting relationships together with your consumers via the ability of marketing merchandise. The product will supply to all over the world, such as Europe, America, Australia,Cambodia, Marseille,San Diego, Rome.We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

The transistor is widely regarded as one of the most important inventions of the 20th century, and is the key enabling technology in virtually every electronic device today. From smartphones to satellites, without transistors most of today"s modern technology would not exist.

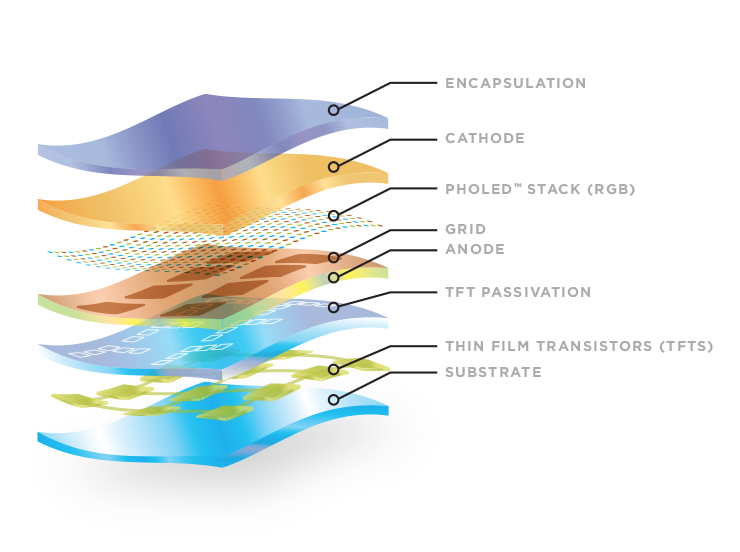

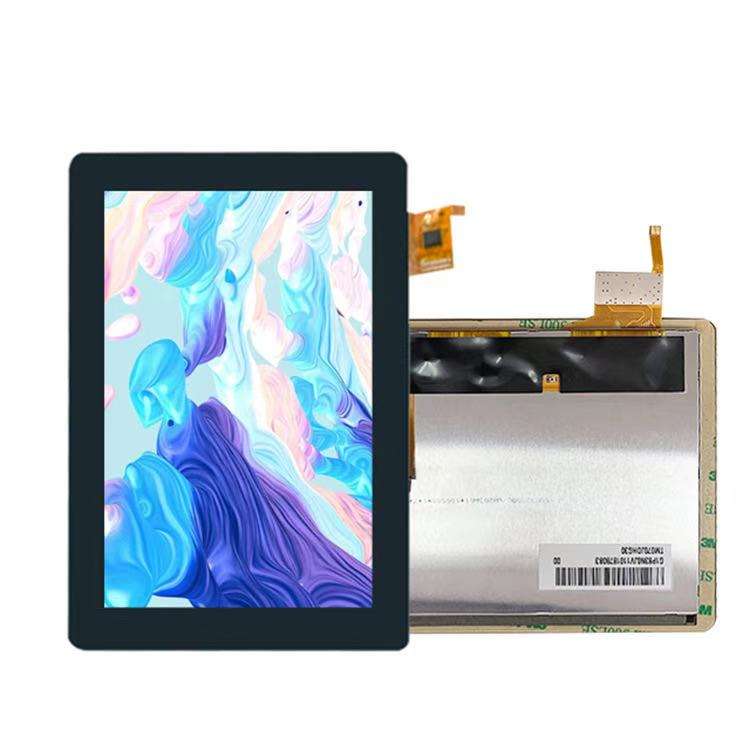

At a basic level, a display is made up of two parts: a frontplane, the layer that makes the image you see, and a backplane, an array of TFTs that control which pixels in the frontplane turn on and off. Most of the time, when you hear about displays, you hear about the frontplane technology–e.g. LCD, OLED, e-Paper, etc.–because that"s the part you see.

If you want to make a display flexible, however, you need both the frontplane and the backplane to be flexible, and you need both to be durable enough to be used in the real world. OLED and e-Paper frontplane technologies already have the required levels of flexibility and durability, however, the backplane has previously been a constraint.

![]()

Flexible display technology has the potential to revolutionize the way we interact with our devices. These displays, which can be bent, rolled, or otherwise manipulated, offer a level of flexibility that is impossible with traditional displays. Common flexible display technologies include electronic paper displays, organic LED, and LCD.

Flexible displays have the potential to offer a more immersive and interactive user experience, allowing users to manipulate the display in ways that are not possible with traditional displays. Bendable displays are an enabling technology from the perspective of new applications and human-machine interfaces, ranging from foldable smartphones to curved public information displays. Additionally, flexible displays are often more energy-efficient than conventional displays. Because they require less power to operate, they could lead to longer battery life for devices. Last but not least, flexible displays are fabricated on plastic substrates, which makes them shatterproof, unlike glass-based displays.

However, there are also challenges that need to be overcome in order for flexible displays to become widely adopted. One major concern is the durability of these displays. Most flexible displays cannot be bent for many bending cycles before they will see degradation happening. This could make them less appealing to consumers who want their technology to last.

With the exception of printed flexible displays, another issue is the cost of flexible displays. Currently, the technology used to create these displays is expensive, which means that products featuring flexible displays are often priced significantly higher than those with traditional displays. This could make them less accessible to the average consumer.

Despite these challenges, the future of flexible display technology looks bright. As flexible display technology continues to improve and become more widespread, we expect to see more devices featuring these innovative displays. Whether you are a tech-savvy individual or a business looking to stay ahead of the curve, it is worth keeping an eye on the development of flexible display technology. So, flexible display is the future of technology, and it will change the way we use our devices.

As already mentioned, one of the main challenges with implementing flexible displays has been their cost, with OLED technology being particularly expensive. However, the Ynvisible Printed E-Paper display offers a low-cost alternative based on cutting-edge printed electronics processes and organic electrochromic materials. This makes it a viable option for product developers looking for an affordable, flexible display.

Overall, the future of technology looks to be moving away from flat, rigid displays and towards more flexible and curved displays. The Ynvisible Display offers a cost-effective solution for those looking to incorporate this technology into their products. So, it is the best option for low-cost flexible displays. Read more about Ynvisible"s e-paper displays.

In July this year, FlexEnable announced partnership with Truly to bring OLCD (Organic Liquid Crystal Display) in volume production by 2018. In January, JDI (Japan Display) announced its plan for mass production of plastic Flex LCD in 2018. Flexible OLED has been in full production for some time and is playing a major role in the smartphone market gaining market share. Can LCD technology bring flexible LCD in volume production to open up new opportunities?

This licensing agreement aims to bring FlexEnable’s flexible OLCD technology into mass production on Truly’s lines within 2018. FlexEnable’s OLCD is based on flexible low temperature organic thin-film transistor (OTFT) backplane technology.

According to the company’s press release, it can be manufactured on existing TFT-LCD production lines using low cost plastic substrates such as TAC and PET. The company asserts that OLCD has better electrical performance than a-Si TFT, giving plastic LCDs the same display quality and reliability as glass-based LCDs. As it is using a plastic substrate, displays can be thinner, lighter, unbreakable (durable), shatterproof, and conformable enabling differentiated design. The FlexEnable process is compatible with existing flat panel lines. So most of the existing equipment can be reused, lowering the cost of getting into production. The use of low cost plastic substrate due to lower (less than 100º centigrade) processing temperature, contributes to lower costs and higher yield rates. Truly is the first display manufacturer to adopt OLCD and it will implement the process into its existing LCD production line in China.

According to the company‘s press release, by combining FlexEnable’s OTFT with Merck’s polymer wall LC technology, organic LCD can be curved around even more complex surface and shapes. These polymer walls can enhance cell gap control while providing excellent display performance. The organic LCD from FlexEnable can have a bend radius below 30mm.

The OLCD display can be used in applications such as smart homes, automotive, digital signage and others. The FlexEnable OLCD has been shown as a pillar display in a future concept car. The automotive display market is experiencing dynamic growth due to connected vehicle development, auto computerization and autonomous car implementation. Auto designers are hoping to move away from rigid rectangular shape displays to free form or conformable shapes with more differentiated designs.

The auto display market has stringent requirements, with a very long design cycle. The market is getting to be more competitive with a-Si LCD, LTPS LCD, OLED and now OLCD displays all now competing for market share. Companies such as LG Display are already targeting the auto market with flexible high performance OLEDs. At SID’s Display Week 2017, AUO showcased a 3.5” flexible TFT LCD using plastic substrate. To succeed in the auto market display, makers need to meet design differentiation, high quality (high resolutions, wide viewing angles, low reflection, accurate colors, high luminance, wide temperature range, high reliability) and lower costs.

AUO showcased 3.5″ plastic flexible LCDs, using a Polyimide (PI) plastic substrate. It is a bendable, unbreakable, conformable display designed for the instrument cluster auto market. The company also showed an 8.9″ free form LCD display for rearview mirrors and a 9″ curved LCD for CIDs (center information display). LCD panels are adopting curved form factors to meet future auto display requirements.

In January 2017, JDI announced the development of a “Full Active Flex” 5.5″ Full HD LC display, which uses a plastic substrate. With the Full Active Flex display, it is possible to form curved shapes by using the flexibility, which can expand the degree of freedom in smartphone design. The use of plastic also makes it shatterproof.

JDI is planning to start mass production of this display in 2018. The company is targeting this technology not only for smartphones, but also for notebook PCs, automotive applications and other products. Flexible OLED is already gaining market share in the smartphone market, mostly in the high end. But supply is constrained and the cost is high. Higher production of plastic flexible LCDs with lower cost could provide new options to smart phone brands.

The biggest differentiator between LCD and OLED display is flexibility. The shift from glass-based to plastic displays enables thinner, lighter, and flexible form factors with more design differentiation options. Smartphone, automotive, wearable and many other applications are requiring display flexibility. Flexible OLED is already meeting those needs especially in the smartphone market. The upcoming iPhone 8 products are expected to include flexible OLED display models. In future, foldable smartphones are also expected.

In spite of great advantages, there are still many challenges for flexible OLED display, especially manufacturing difficulties. Up to now, Samsung is the only maker with successful high volume manufacturing capabilities. Even though many other suppliers are planning to come to market in the 2H of 2017 and 2018, it will take time and the process is challenging.

Up to now there has been no volume production of plastic LCDs. But these recent announcements from JDI, AUO, FlexEnable, Truly, and Merck will enable volume production. Flexible LCDs are still in the phase of bendable or confirmable (due to LCD ‘s inherent structure) phase rather than truly flexible/foldable as OLED.

In conclusion, flexible LCDs will be coming to the market at last, but only with higher volume production and lower cost can it open new opportunities. – Sweta Dash, President, Dash-Insights

Sweta Dash is the founding president of Dash-Insights, a market research and consulting company specializing in the display industry. For more information, contact [email protected] or visit www.dash-insight.com

There are many different manufacturers of flexible displays. Some well-known flexible display manufacturers are Hewlett Packard, Dell, Samsung, Jitterbug, palming monochrome printer LED, and ViewSonic. The most common use for a flexible display is in product packaging. Flexible displays are often used to create 3D images by using stereo display systems and image-processing circuitry. They can be used in product packaging applications for things like watches, pens, shoes, and even electronics.

Many flexible display manufacturers have created advanced image processing circuitry with the capability to process three dimensional data. This technology allows an LCD or LED display to change the image so it appears as though it is displayed on a 2D surface. One very popular display company is Venturebeat who has developed a very unique display technique called panoramic display. A panoramic display displays an image across multiple horizontal or vertical planes. Panoramic displays can be used for a wide range of display applications including robotic surgery, electronic billboards, augmented reality, and more.

Panoramic displays are being used to display images on medical equipment such as robotic arms, and surgical robots. They are also being applied to electronic displays to create e-papers which are flat images on a thin layer of paper. These electronic displays are becoming more common and more sophisticated and we will continue to see more applications for flexible oled displays.

In addition to digital displays, flexible displays are also starting to make their way into the business world. Businesses such as hotels, restaurants, call centers, airports, and convention centers are all implementing flexible display technology in their daily operations. Flexible displays allow employees to be given clear and easy-to-read information regarding their schedules and other important information about the business. They are also making their way into the courtroom, where they are often used to display legal briefs and other legal documents.

Flexible oled screen technology is also being used to display safety and emergency signs in the workplace.As exciting as all of this technology sounds, there are still some drawbacks to flexible displays and they include some limitations to how consumers can interact with them. This may limit the ability of certain technologies to create specific types of interactions or to provide for interactive elements such as touch screens or even a keyboard.

Also, these displays do not offer you the same level of portability that a touch screen does which could be a significant disadvantage depending on the type of device you are using it on.

However, this is likely to change in the near future as display technology for smart phones becomes more affordable and becomes more like a standard item in today"s marketplace.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

Smart packaging is arguably the low-cost display application with the greatest scope for growth. Displays can be integrated into both shelf-level and item-level packaging, with the former likely to emerge first since the lower volumes enable higher unit costs. At present, electroluminescent displays are sometimes incorporated into limited edition production runs for marketing processes, but these are not regarded as an effective long-term solution due to their high power requirements.

Another application for low-cost displays is small consumer goods. This has long been the case for some premium items such as electric shavers, with small displays that show the remaining charge, for example. However, as displays get cheaper and electronic functionality/wireless capability is integrated into more devices, this could be expanded to an ever-growing range of devices and appliances. Indeed, it might not be long before bank and travel cards contain a low-cost display to show your balance and/or recent transactions.

Wearable technology is another promising application for low-cost displays. While OLED displays are widely used smart watches, they are generally too expensive at present to incorporate into clothing and skin patches for medical/fitness/therapeutic applications. The key attributes for displays in clothing and skin patches are durability, flexibility, and low power consumption. This example demonstrates that for many emerging display applications, the traditional key performance indicators of resolution, color gamut and refresh rate are no longer especially important.

OLED is an emerging display technology that enables beautiful and efficient displays and lighting panels. OLEDs are already being used in smartphones, laptops, wearables, tablets and TVs, and many of OLEDs are flexible ones.

A flexible OLED is based on a flexible substrate (usually polyimide). The first generation of OLEDs produced on these were not really flexible from the user perspective. The device maker bends the displays, or curves it - but the final user is not able to actually bend the device. These first-gen flexible OLEDs are adopted many premium smartphones, for example the Samsung edge-type Galaxy phones or Apple"s latest iPhones. A plastic-based OLED has several advantages especially in mobile devices - the displays are lighter, thinner and more durable compared to glass based displays.

Second generation flexible OLED displays can be bent by the user - these can be used for example to create foldable smartphones - the first range of which started shipping in 2019. Rollable OLEDs are also now entering the market for both TVs and smartphones.

While several companies (including Samsung, LG, BOE and others) are producing OLED displays, it is not straightforward to find a good and reliable supply of these displays.

If you are interested in buying a flexible OLED panel for your project or device, look no further. Our OLED Marketplace offers several flexible OLEDs, which can be ordered through us with ease.

When you look at a display device – your phone, your TV, your smartwatch, the screen in your car – what do you see? You see the image. A bright, vivid image on surfaces of all shapes and sizes. Flat, curved, flexible, thinner than ever before.

When you stop and think about what goes into displaying one of these amazing images, you might recognize most are protected by a glass cover. You might even be familiar with display types like LCD or OLED. Yet for many, the recognition stops there. You may see the image on the surface, but rarely think about what creates that image, how it achieves life-like, vibrant color, and the journey it makes to reach our eyes.

If we look deeper, beyond the surface and the cover glass of our devices, we would find one or more layers of ultra-thin, technical glass make such images possible. Each layer with a different purpose, all working together to deliver the beautiful, thin displays we use each and every day. Combined, these layers form what we at Corning call the “glass stack.”

It’s worth looking at the individual layers of the glass stack, since each layer is the result of breakthroughs in glass science, optical physics, and state of the art manufacturing. At the top of the stack, we have the protective cover glass of a mobile device that most consumers have heard of – Corning Gorilla Glass. This cover glass protects and maintains the appearance of the display, and also supports the use of front-facing cameras and various sensors. Often, the rear side of such devices is covered with a similar protective glass, which also allows for wireless charging.

A layer deeper, beneath the surface of the glass cover, are the substrates that serve very specific functions depending on the type of display being created.

Though each layer of the glass stack is formed with the same fusion manufacturing process, the compositions of the glass are different – allowing for different properties and benefits. LCD and OLED displays, whether on mobile devices with glass cover and back or otherwise, utilize different super-thin layers of glass specific to their applications:

Even so, the appearance of the first few flexible screens in commercial devices may be a sign of things to come. In fact, fully flexible electronic gadgets—with full-color displays that wrap around a wrist or fold up—may be just a few years away, thanks to solutions that manufacturers have already started to demonstrate.

Apple hasn’t disclosed why the Apple Watch has a flexible display. It might allow for a slight curve at the edges, and it may also simply be thinner than a conventional one (see “The Apple Watch May Solve the Usual Smart Watch Annoyances”).

In a conventional LCD display the liquid crystals within the pixels need to be perfectly positioned between two sheets of glass. These sheets cannot be bent without misaligning the pixels. According to Max McDaniel, chief marketing officer for Applied Materials, a company whose equipment is used to make displays, is also extremely difficult to make a flexible backlight—the component needed to illuminate LCD pixels.

So the screen in the Apple Watch is almost certainly an OLED display. Rather than the pixels being illuminated by a backlight, each pixel glows on its own, like a minuscule light bulb. Manufacturers can already make OLED displays flexible. They first laminate a sheet of plastic to glass and then deposit the materials for the pixels and the electronics on top of both. The glass stabilizes the manufacturing process, and afterwards the plastic, together with display and electronic components, is lifted off the glass.

Manufacturers have known how to do this for years. Samsung showed off a fully flexible OLED display in 2013. The tricky part is making sure the devices are durable. OLED pixels can be destroyed by even trace amounts of water vapor and oxygen, so you have to seal the display within robust, high-quality, flexible materials. This is costly, and there are challenges with ensuring that the seal survives being bent hundreds or thousands of times over the lifetime of a device.

The parts within a flexible display also need to survive being bent. This is tricky because different layers—the battery, the electronics, and the touch components—tend to be stacked, and the innermost layers have to bend more than the outermost ones. The outer layers also stretch while the inner ones compress.

Some researchers have developed stretchable electronics, which might help accommodate stresses (see “Stretchable Displays” and “Making Stretchable Electronics”). Novel materials for touch screens that use flexible nanomaterials could also help. One patent application suggests Apple is already looking at this issue. It describes measures such as varying the thickness of materials in a device to allow it to bend while keeping the electronics lined up properly with the pixels they control.

Making a flexible battery is another challenge. While the lithium-polymer batteries used in smartphones today are somewhat flexible, they can’t survive being bent many times. One option is to make a segmented battery, like a segmented watch band, says Kevin Chen, general manager for energy storage solutions at Applied Materials. His company is developing solid-state batteries, which could easily be cut up into small pieces for flexible devices, and which also have the potential to store much more energy than conventional lithium-ion batteries (see “Longer-Lasting Battery Is Being Tested for Wearable Devices”). Apple outlines a similar battery design in another recent patent application.

Steady progress means fully flexible devices could be available in just a few years. Meanwhile, we have flexible displays that are fixed in place—as in the Apple Watch.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey