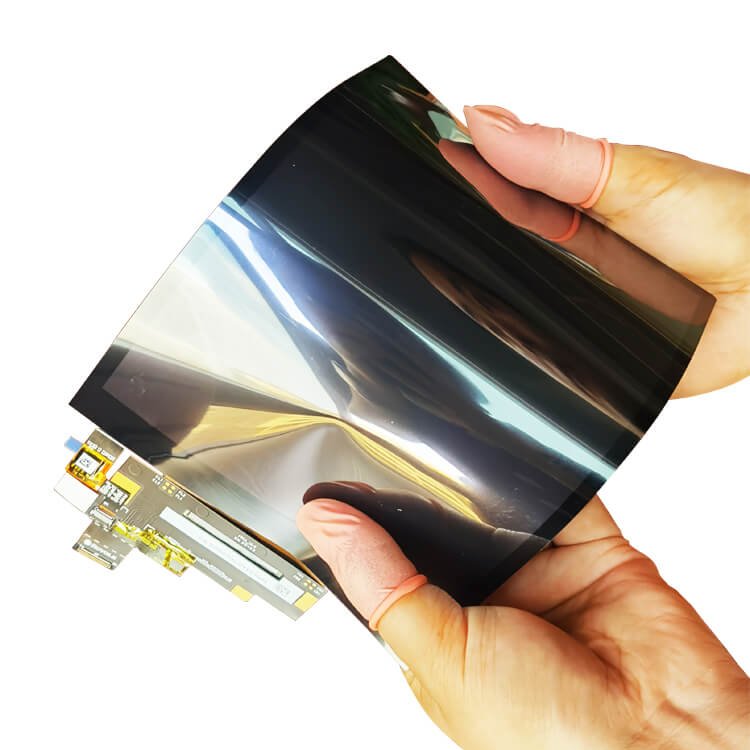

flexible lcd display technology free sample

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

Flexible OLCDs can conform to surfaces almost anywhere, uniquely combining the strengths of LCD – scalable, low cost, bright with long lifetime – with the flexible freedom of organic electronics.

OLCD is a glass-free display technology that combines the benefits of LCD with the inherent flexibility of a high-performance organic-thin-film transistor (OTFT) backplane (which replaces the amorphous-silicon backplane used in glass displays). It enables conformable and shapeable displays that can be cost-effectively scaled to large area sizes in the same way glass LCD is scaled.

The dominant active-matrix display technology in vehicles today is LCD made on glass. These glass LCDs are often the only flat surfaces left in the vehicle, disrupting the form and flow of the interior space and limiting ergonomic options for designers. Replacing these flat panel displays with OLCD screens that can conform to the vehicle interior shape and curves will allow for their seamless integration and improved aesthetics of the car interior.

Curved displays can also be used as "digital" side-view mirrors (in combination with cameras) - they can increase safety by widening the field of view as well as contributing to fuel efficiency in comparison with the external side-view mirrors. Novares showed an example of a "digital" side-mirror in Nova Car 2 using a curved display by FlexEnable - the display is integrated into the corner between the A-pillar, the instrument panel and the door panel.

The extreme thinness of OLCD cells, built onto TAC films that are ten times thinner than display glass, brings major optical advantages to so-called dual-cell LCDs, increasing the contrast to one million to one at the single pixel level, giving blacks as deep as OLED but with the higher brightness of LCD.

Equally OLCD can be combined with miniLED backlights with local dimming to give the thinnest ever miniLED displays, whilst benefitting from all the parallel innovations in backlight performance such as quantum dot colour enhancement, resulting in brighter more colourful TVs.

Flexible LCD provides all of the benefits of LCD for advertising in terms of brightness, colour performance, video-rate capability and cost, but with the clear advantage of being glass-free, thin, light and conformable. It can be scaled to large sizes allowing even large digital signage displays to be conformed to pillars, street furniture, vehicle exteriors and retail interiors.

FlexEnable is already working with leading consumer electronics brands across many exciting application areas that redefine where and how displays are used in our everyday lives.

It is generally thought that the development of flexible display technologies will soon substantially broaden the possibilities for displays. The specific characteristics of the flexible technologies (in addition to their excellent flexibility, they can be easily handled and stored) mean that flexible displays could find several applications in everyday life (e.g., for posters and calendars, roll-screen TVs and signboards, large maps and design charts, wearable costumes and seals, as well as for packaging and painting materials). To realize these flexible displays, however, it is necessary for the display panel to be made sufficiently thin, light, and flexible for easy handling.

In our work, we have therefore previously shown that liquid crystal (LC) and plastic substrates1–3 are good options for achieving the desired (i.e., improved) properties for flexible displays. For example, flexible LCDs have excellent storability, portability, and designability and can thus be used to create new viewing methods and human interfaces. Low-cost fabrication of large-area panels with flexible LCDs is also possible. The strongest benefit of flexible LCDs, however, is their excellent stability and reliability for the passage of moisture and oxygen through their substrates. Although LCDs exhibit these many attractive features (compared with ultraslim displays that include organic LEDs), the bending tolerance of flexible LCDs is limited. Indeed, we have previously fabricated a slightly curved LC device from polycarbonate substrates and conventional etched spacers (see Figure 1). As we increase the bending degree of this device, however, the substrate gap decreases at the curving center (see Figure 2), which causes the displayed image quality to be seriously degraded. Moreover, for devices with smaller radius of curvatures, the structural deformation can be even more severe.

Figure 1.A slightly curved liquid crystal (LC) device fabricated from polycarbonate substrates and conventional etched spacers. As the degree of bending increases, the substrate gap decreases at the curving center. This causes degradation of the displayed image (see Figure 2).

In our more recent work, we have thus developed polymer wall spacers4,5 to rigidly bond two substrates and to increase the bending tolerance of LCDs. We construct these spacers from a molecular-aligned solution of a liquid crystalline photoreactive monomer and a nematic LC, and we control the molecular alignment of the solution by coating the two substrates with polyimide alignment layers. Specifically, we conduct the fabrication of our bonding wall spacers under UV radiation that is patterned with an orthogonal-latticed photomask. During this process (see Figure 3), molecules of the drifted monomers move toward the UV-irradiated regions of the solution. This photopolymerization-induced phase separation phenomenon causes the networking polymers to be segregated into the UV-exposed areas. The aligned polymer aggregation then forms a condensed wall spacer that creates the bond between the two substrates. Furthermore, the orthogonal-lattice-shaped walls have large bonding areas and therefore a good LC-confining effect. As a result, the molecular-aligned polymer wall surfaces prevent LC material flow (even during large amounts of bending) and do not suffer from disordered LC alignment in high-contrast displays. We have also investigated the use of several different monomers and found that the polymer aggregation efficiency depends on the molecular structural features of the monomers (e.g., their skeleton flexibility and motility).

With our bonding polymer wall spacers we can therefore maintain a constant substrate gap and enable the use of extremely thin plastic substrates in LCDs (i.e., when the use of the spacers becomes even more beneficial). We have thus also designed an LCD-fabrication process in which we use ultrathin plastic substrates (formed via coat-debonding). We have demonstrated that our 10μm-thick coat-debond polyimide substrates exhibit excellent heat resistance, high light transmittance, and low optical anisotropy.6, 7 In addition, the final super-flexible LC device we fabricated (see Figure 4) has an excellent bending tolerance (curvature radius of several millimeters). With the use of our polymer wall spacers it is therefore possible to make any LC-mode display highly flexible. To date, we have realized nematic systems of twisted or guest-host LCs, cholesteric systems of cholesteric-to-nematic phase change or blue-phase (BP) LCs, and a smectic system of ferroelectric LCs.

Figure 4.Left: Photograph of an ultrathin (10μm) polyimide substrate formed by a coat-debond process. Right: A super-flexible LCD, without polarizers, formed from the polyimide substrate. The device is shown rolled up during a bending tolerance test.

We have also recently fabricated flexible BP LC devices that have optical isotropy and exhibit a wide range of viewing angles.8, 9 To obtain a high contrast ratio and a wide viewing angle with our devices, however, it is necessary to perform optical compensation. We have therefore developed a number of total compensation techniques10, 11 for the LC substrates in commonly used vertically aligned (VA) and in-plane switching LCDs. Our optical techniques are based on precise ellipsometry measurements for various plastic substrates. For example, the positive-c-plate optical anisotropy of a VA-LC and the negative-c-plate property of a polycarbonate substrate compensate each other. We obliquely observed the black states for a VA-LC device with and without optical compensation (see Figure 5) and found that even with the use of a plastic substrate, a wide viewing angle (160°) and a high contrast ratio (650:1) can be obtained. With our results we have thus, for the first time, confirmed that flexible LCDs can be used to display high-quality images (at a similar level to conventional glass-based LCDs).

Figure 5.Measurement of the black states of a flexible polycarbonate-substrate vertically aligned LCD with (bottom) and without (top) optical compensation. Even with the use of a plastic substrate, a wide viewing angle and high contrast ratio is achieved in both cases.

To enhance the displayed image quality of LCDs even further, a flexible backlight (including LED chips) is an important component. We have therefore developed a direct-illumination backlight sheet and a transparent rubber light-guide plate for this purpose.12, 13 Although recently available light-guide plastic plates are flexible (because of thickness reduction), local dimming control of the backlight is essential for achieving higher contrast ratios and lower power consumption (i.e., so that they are suitable for mobile terminals and large TVs). In our more recent work, we have thus proposed a flexible light-guide backlight system that includes an alignment-controlled polymer-dispersed LC (PDLC) cell with high transparency.14, 15 In this PDLC light-guide plate the light-illumination area (generated by light scattering) is selected with the use of segmented transparent electrodes that are driven according to the displayed images.

In summary, we have investigated and developed a number of polymer technologies to improve LC devices for use in flexible displays. For instance,15, 16 our polymer wall spacers enable the use of extremely thin plastic substrates and make any LC-mode display highly flexible. In addition, we have implemented optical compensation techniques to increase the contrast ratio and viewing angle of LCDs, as well as flexible light-guide backlight systems to increase image quality even further. In the next stage of our research we will form small image pixels with thin-film transistors on a flexible plastic substrate. With our various techniques for flexible LCDs it is therefore possible to achieve low-cost and high-resolution large-screen displays (i.e., that are difficult to realize with more-conventional organic LED displays). We believe that flexible LCDs will therefore have a substantial impact in image-information service technologies in the coming years.

Hideo Fujikake is a professor whose current interests involve liquid crystals, polymers, and organic semiconductors for flexible displays. He has won the Electronics Society Award from the Institute of Electronics, Information, and Communication Engineers of Japan (IEICE), and he has received fellowships from IEICE and the Institute of Image Information and Television Engineers.

1. H. Fujikake, T. Murashige, J. Yonai, H. Sato, Y. Tsuchiya, H. Kikuchi, Y. Iino, M. Kawakita, K. Takizawa, Flexible ferroelectric liquid crystal devices with polymer fiber network supporting plastic substrates, Proc. Int"l Display Res. Conf. 3.3, p. 68-71, 2000.

4. H. Sato, H. Fujikake, Y. Iino, M. Kawakita, H. Kikuchi, Flexible grayscale ferroelectric liquid crystal device containing polymer walls and networks, Jpn. J. Appl. Phys. 41, p. 5302-5306, 2002.

5. J.-W. Jung, S.-J. Jang, M. Y. Jin, Y.-J. Lee, H.-R. Kim, J.-H. Kim, Pixel-isolated liquid crystal mode for plastic liquid crystal displays, Soc. Inform. Display Int"l Symp. Digest Tech. Papers 37, p. 1732-1736, 2006.

6. Y. Obonai, T. Ishinabe, H. Fujikake, Fabrication of flexible ultra-thin liquid crystal devices using coat-debond plastic substrates with etched post spacers, Proc. Int"l Display Workshops LCTp5-12L, p. 161-162, 2015.

7. T. Ishinabe, Y. Obonai, H. Fujikake, A foldable ultra-thin LCD using a coat-debond polyimide substrate and polymer walls, Soc. Inform. Display Int"l Symp. Digest Tech. Papers 47, p. 83-86, 2016.

8. H. Sakai, T. Ishinabe, H. Fujikake, Fabrication and evaluation of flexible blue phase LC devices with polymer walls, Proc. Int"l Display Workshops LCTp2-9L, p. 115-116, 2014.

9. T. Ishinabe, H. Sakai, H. Fujikake, High contrast flexible blue phase LCD with polymer walls, Soc. Inform. Display Int"l Symp. Digest Tech. Papers 46, p. 553-556, 2015.

10. A. Sato, T. Ishinabe, H. Fujikake, Fabrication and evaluation of IPS-mode flexible LCDs using uniaxial polycarbonate substrates, Proc. Int"l Display Workshops FLXp1-14L, p. 1508-1509, 2014.

11. T. Ishinabe, A. Sato, H. Fujikake, Wide-viewing-angle flexible liquid crystal displays with optical compensation of polycarbonate substrates, Appl. Phys. Express 7, p. 111701, 2014.

12. H. Sato, H. Fujikake, Y. Fujisaki, S. Suzuki, D. Nakayama, T. Furukawa, H. Kikuchi, T. Kurita, A4-sized liquid crystal displays with flexible light guide plate, Proc. Int"l Display Workshops LCT4-2, p. 605-608, 2006.

13. H. Fujikake, H. Sato, Flexible display technologies using ferroelectric liquid crystal: low driving-voltage panel fabrication, Ferroelectrics 364, p. 86-94, 2008.

14. E. Uchida, T. Ishinabe, H. Fujikake, Fast switching alignment-controlled polymer-dispersed LCs for local dimming backlight, Proc. Int"l Display Workshops LCTp1-5L, p. 88-89, 2014.

15. H Fujikake, H. Sakai, A. Sato, E. Uchida, D. Sasaki, Y. Obonai, Y. Isomae, T. Ishinabe, Advanced polymer and LC technologies for high quality flexible displays, Proc. Int"l Display Workshops FLX2/LCT5-1, p. 1356-1359, 2015.

16. H. Fujikake, Y. Shibata, T. Ishinabe, Structural and optical technologies of polymers for flexible LCD, Proc. 16th Int"l Meet. Inform. Display, p. 175, 2016.

Flexible displays open up new dimension of design opportunities that aren’t possible with rigid glass-based displays. Nowadays, users have come to expect touch capability from almost any display-enabled device, but, many devices still need certain buttons or knobs – for example in cars. This becomes a limitation when using rigid glass displays - designers need to allow for additional space for knobs or buttons outside the display area. This can waste space, compromise aesthetics and result in a bulky non-optimised design.

Recently, some display makers have introduced glass displays with through-holes for the camera in smartphone screens. For example, Tianma has recently announced a 6.4” LCD with a through-hole that will be used in Huawei’s nova 4 device. It becomes more challenging and more expensive if the holes or the displays are larger, or if there are multiple holes required, when the displays are made from glass

In order to make displays flexible, the transistor backplane technology used needs to be flexible. This is currently made possible using conventional silicon technology or metal oxides on bespoke polyimide substrates. Flexible displays need to be mounted onto glass in order to keep them flat during fabrication. At the end of the process the flexible displays need to be demounted from the glass carrier by using a laser de-bonding process. Holes can be cut through the displays before or after the de-bonding process. If the demounting process is aggressive, like in the case of laser de-bonding for the polyimide-based displays, it can generate unwanted stresses which will cause the edges of the holes to be concentrated stress relief areas and hence impact yield and cost.

FlexEnable has developed a different approach for flexible displays. By using low temperature processing of organic thin-film transistors (OTFTs) on low cost plastics like triacetyl cellulose (TAC), no laser de-bonding processes are required. Instead a mild heat or UV treatment is used to separate the flexible displays from the glass. Holes through the displays are laser profiled while the displays are still mounted onto the glass. Unlike polyimide-based displays, OTFT displays have a simple high yielding demounting process.

There will continue to be applications that require the use of knobs and buttons even if they feature touch-enabled displays. Imagine a car’s central console which is a touch–enabled display, but the volume dials and gear stick protrude through the display. As kitchen appliances become smarter with the use of displays, they may still require physical dials to control certain functions. Wearables like smart watches can combine the digital look of a smart watch with the mechanical dials of a conventional arm watch.

As the landscape for flexible displays evolves with new use cases, the ability to cut holes through the displays unlocks even more design freedom and enables bolder product designs to meet growing consumer expectations.

Backplanes are the most essential component of electronics because they can connect in parallel with each other and control the electrical signals of devices. As opposed to the passive-matrix form, the active-matrix backplane allows selective access to each component with a rapid response while maintaining a high-circuit density by sharing electrode lines. Despite many advantages of active-matrix backplanes, the realization of deformable active-matrix backplanes with reliable operation is very challenging. This is because three electrodes (gate, source, drain) of each component are connected to different word and bit lines and grounds, and the failure of only one single component can lead to the failure of the whole backplane. Therefore, it is important to minimize stress during deformations of thin-film transistor (TFT)-based electronics. The deformability of backplanes is commonly obtained by modifying device materials and structures to accommodate most of the strains induced by bending, folding, and even stretching. These modifications can be classified into two approaches: one uses intrinsically flexible materials (e.g., ultrathin or elastomeric materials) and the other uses an engineered substrate.

The most basic method of obtaining flexibility or bendability is the adoption of ultrathin materials as the TFT backplane components.2a, b. In addition, no fracture was found on the oxide semiconductor TFT regions due to the thin thickness of the backplane (~2 µm) and the improved flexibility of the TFT regions. Javey and coworkers have demonstrated a flexible display that is composed of a flexible carbon nanotube (CNT)-based backplane and flexible organic light-emitting diode (OLED) pixels as depicted in Fig. 2c, d (ref. 3). The flexible display was fabricated on a 24-µm-thick PI film, and the total thickness of the devices (excluding the substrate) was <2 µm. Therefore, the flexible backplane showed stable electrical characteristics even during the bending states (where the bending radius was 4.2 mm), and the OLED pixels also performed with negligible degradation from the deformations (where the bending radius was 4.7 mm). Consequently, this fabricated display also demonstrated flexibility because of the deformability of the devices.

Flexible backplane for display fabricated by a thin-film process. a Photo (left) of the TFT array sample made by graphene–AuNT hybrid electrodes on a transparent polyimide substrate. Scale bar: 1 cm. A schematic diagram (right) of the TFT layout. b Photos of the TFT arrays transferred onto: a leaf, eyeglasses, and the skin of human hand. All scale bars: 1 cm. a–b Reproduced with permission from ref. 8. Copyright 2014, American Chemical Society. c Photo (left), optical micrograph (middle), and scanning electron micrographs (right) of flexible backplane. d Photos of operating flexible display combined with backplane and OLED pixels. c–d Reproduced with permission from ref. 3. Copyright 2013, Nature Publishing Group

Many studies have demonstrated flexible electronics with various methodologies. However, in the case of the aforementioned methods, mechanical stresses continue to be induced on the brittle electronic materials, even though the stresses are relieved. Therefore, the mechanical stresses generate fatigue on the electronics during repetitive or constant deformations, and the accumulated fatigue causes severe problems that deteriorate the performance and reliability of flexible TFT backplanes. Consequently, reducing fatigue becomes a key challenge to realizing highly flexible and stable backplanes or electronics. The typical method of reducing mechanical fatigue on the TFT backplane is the adoption of device islands-interconnect designs. These designs are based on engineered substrates that are composed of materials with different values of elastic modulus.3a.1 summarizes the recent advances in stretchable interconnect technology.3b). The stretchable conductors showed high stretchability at over 200% strain as plotted in Fig. 3c. Based on these systems, the stretchable backplane also demonstrated superb stretchability up to the strain of 110% (Fig. 3d). In addition, Kim et al. have also demonstrated a reversibly foldable TFT backplane based on the oxide semiconductor (indium oxide (In2O3)), which shows high performance and is used in the conventional backplane.3e). The designed stretchable conductors exhibited stretchability up to the strain of 100% and also exhibited stability against cyclic tests (10,000 times with the 80% strain), as shown in Fig. 3f. Because of these superior interconnects and engineered substrates, the oxide semiconductor TFT backplane also showed high stability during the folding states without any degradation (Fig. 3g). In addition, Park and his team have also studied stretchable TFT backplanes based on these two systems Fig. 3h. Their TFT backplanes also provided reproducible performances up to the strain of 25%, as shown in Fig. 3i, and showed high stability against fatigue (5000 times with the 20% strain), as shown in Fig. 3j. The reliability of the stretchable TFT backplane is affected by the strain isolation effect of engineered substrates and the high stability of stretchable interconnects (Au film on AgNWs-embedded elastomer).

Device islands-interconnect design for highly flexible TFT backplane. a Simulation of strain manipulation at the top surface of the engineered substrate. Reproduced with permission from ref. 9. Copyright 2013, American Institute of Physics. b Schematic illustrations of OTFT backplane on engineered substrate. c Conductivity dependence on tensile strain in printed elastic conductors with and without surfactant. d Transfer characteristics of OTFT according to the tensile strain. b–d Reproduced with permission from ref. 12. Copyright 2015, Nature Publishing Group. e Schematic images (top) and scanning electron micrographs (bottom) of stretchable conductor (Au film on AgNWs-embedded elastomer) before and after stretching. Scale bars: 5 μm. f Resistance dependence on tensile strain (left) and cyclic numbers (right) of the stretchable conductor (Au film on AgNWs-embedded elastomer). g Images (top) and output characteristics (bottom) of foldable TFT backplane on engineered substrate before and after folding. Scale bars: 5 mm (black) and 100 μm (red). e–g Reproduced with permission from ref. 13. Copyright 2016, Royal Society of Chemistry. h Illustration and photograph (inset) of stretchable TFT backplane on engineered substrate. i Electrical properties of device in h according to the mechanical strain (up to a strain of 25%). j Electrical properties of device in h according to the number of cycles

The research activities for developing TSP technologies at UNIST have been devoted mainly to exploring new materials, device structures, and device fabrication processes for multi-functional flexible and stretchable TSPs. One noticeable achievement is the development of the highly flexible capacitive TSP with AgNW diamond-pattern electrodes and transparent bridge structures formed on a polycarbonate film.4 shows the structure and touch-sensing capability of the fabricated TSP. As shown in the Fig. 4, the bridge structure is composed of an epoxy polymer (SU-8)-based bridge insulator and an Al-doped zinc oxide (AZO) bridge electrode. In order to secure the stable and robust connection between the AZO bridge electrode and the AgNW diamond-pattern electrodes over the bridge insulator, the side-wall slope of the bridge insulator is made as low as possible with our unique photolithography process, in which the exposure time is extended beyond the optimized value for forming vertical side-walls. With the extended exposure time, the lower part of the SU-8 layer immediately adjacent to the direct exposure region can be sufficiently exposed to the stray ultraviolet (UV) light scattered from the substrate, leading to the formation of a bridge insulator with a low side-wall slope. The fabricated TSP sample was found to be highly flexible and transparent and also showed good touch-sensing performance. The measured capacitance changes by ~22.7% with the finger touch.

Based on their superb operational performances and functionalities, the flexible and stretchable TSP devices developed at UNIST, including the two introduced above, are expected to significantly enrich the information communicated between humans and machines. Thus, it is quite probable that these devices will be used extensively in various future information technology applications.

Flexible light sources are important parts in flexible display applications because they determine long-term stability and commercial value of practical flexible displays under continuous mechanical stress. Thus, flexible light sources should have sufficient light-emission efficiency and mechanical stability. Generally, OLEDs have been mostly spotlighted candidates for flexible light sources because OLEDs consisted of organic materials and they have outstanding mechanical flexibility compared with inorganic LEDs.

Following constituent materials of flexible OLEDs, there are four major research issues (substrates, electrodes, light-emissive materials, and encapsulation) to be perfectly developed for practical future applications; flexible substrates, electrodes, light-emissive materials, and encapsulation. Here, we briefly introduce technical research issues with four sections and suggest future research directions of flexible OLEDs.

Almost all of the macroscopic flexibility of flexible OLEDs comes from substrates. The important properties of flexible substrates are mechanical flexibility, thermal stability, optical transparency, and gas barrier properties.

Highly conductive poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) have been investigated for flexible electrodes with highly smooth surface, optical transparency, easy processes, and enhanced electrical conductivity up to 4380 S/cm by doping with polar solvents or concentrated sulfuric acid.6. In addition, hybrid flexible electrodes composed of PEDOT:PSS and AgNWs were said to be mechanically durable and robust OLED characteristics were said to be obtained.

a Schematic illustration of thermal annealing and LPEB irradiation of AgNWs. b Schematic illustration of fabrication process for AgNW/PEDOT:PSS composite electrode and the PLED structure, and photograph of light-emitting flexible PLEDs with AgNW/PEDOT:PSS electrode

Most components of flexible OLEDs are organic materials that can easily react with oxygen and moisture because plastic substrates and other components have low gas barriers. The water vapor transmission rate (WVTR) is strongly related to the long-term stability and feasibility of practical flexible OLEDs. OLEDs generally require a WVTR of approximately 10−6 g/m2∙per day, which is a very low value compared to inorganic LEDs.−3 g/m2∙day, as shown in Fig. 8.

For next-generation displays, flexible and light-weight OLEDs are an appropriate candidate because of their excellent light emission, and mechanical flexibility. Currently available components of flexible OLEDs including substrates, electrodes, emissive materials and encapsulation layers, are still insufficient to achieve practical flexible OLEDs with stable performance under mechanical deformation. Consequently, achieving reliable components of flexible OLEDs such as (1) flexible substrates and encapsulation layers with good barrier properties, (2) transparent electrodes that are mechanically robust under deformation and have low sheet resistance, and (3) flexible materials that emit light efficiently, remains to be solved for commercial applications.

Recently, flexible display devices have attracted widespread attention as an alternative to rigid devices because of their portability and comfort for long time wearing. For the relevant applications, when the devices undergo mechanical deformations such as bending and stretching, the thicknesses of the constituent materials usually decreases and all layers suffer a tensile stress at the outside of each layer.

Flexible display devices contain many laminated structures composed of sub-micrometer-scale thin films. At UNIST, we evaluated the mechanical properties of one of these components using modified hole-nanoindentation. PDY-132 (Merck, Germany, commercially sold as “Super Yellow”) is a ‘‘high-performance polymer’’ that emits yellow light. In our evaluation, PDY-132 was spin-coated on a clean glass substrate. The sacrificial layer was selectively dissolved to fabricate free-standing films with the same dimensions as the actual devices. We fabricated hole-patterned Si wafers using the deep reactive ion etching method. The patterned hole size was proportional to each film thickness, so that the diameter of a hole was less than 1% of the film thickness.11. The elastic modulus of the hole-indentation was found to be 4.89 GPa, and its fracture strength was 1.19 GPa.

Uchic et al.12. Tensile testing is the most fundamental method of evaluating a material’s inherent mechanical properties, such as yield strength, strain-hardening exponent, ultimate tensile strength, etc. As mentioned above, in-situ testing enables precise observations of sample deformations in real time, with simultaneous imaging during testing. Various indenters are also expected to enable stretching and bending tests of constituent materials in flexible display devices.

Flexible display devices contain many organic materials, such as polymer films, active materials, and electrodes. However, mechanical tests of organic materials in high vacuum conditions in SEM and transmission electron microscopy are limiting in that organic materials are (in real environments) highly affected by surrounding environmental conditions such as humidity and temperature; it is important to measure mechanical properties in actual operating environments. A nano-UTM can be used to control environmental conditions using a controlled humidity chamber and heating block because the machine is based on an optical microscope, as shown in Fig. 13. Images of gauge sections during tensile tests are observed by a charge-coupled device camera in real time, and strain is analyzed from the images based on digital image correlation. Constituent materials in flexible display devices are macroscopically visible and their thicknesses are generally in the nanometer-scale range. PEDOT:PSS is widely used for organic transparent conducting electrodes, and PEDOT:PSS thin films are fabricated by natural drying after drop casting on a substrate. A tensile sample was fabricated by a mechanical press, and the gauge length and gauge width were 4 and 1 mm, respectively, as in the standard ASTM E8 test. We performed tensile tests of PEDOT:PSS in three different humidity conditions by nano-UTM, and the results are summarized in Fig. 13. The yield strengths of the samples tested in the lowest humidity environment were greater than those of other samples, and the fracture strain decreased as humidity increased.

In recent years, fingerprint mutual capacitive TSPs with flexible displays fabricated from flexible plastic materials have attracted much attention because of the development of transparent fingerprint sensors embedded in flexible displays that are also thin and impact-resistant. As security protections for electronic devices such as smart phones become increasingly important, a fingerprint sensor has been integrated on the device’s home button because the fingerprint sensor is not transparent. However, a mutual capacitive transparent fingerprint TSP must be developed on the display itself because a wearable device does not have a home button, and the screen sizes of smart devices must otherwise be enlarged.

To make a flexible TSP, a flexible and transparent material must be used for the TSP electrode. However, variation in load becomes a concern when the flexible electrodes of the fingerprint TSP are bent or stretched, which can interfere with capturing the fingerprint image. Because the capacitance difference of the mutual capacitive fingerprint TSP from the ridge to the valley is several hundred atto-farads, the effect of the load variation due to a bent or stretched TSP will be very critical.

Both the flexible fingerprint TSP and post-processing are required to capture the fingerprint image in the fingerprint TSP on the flexible display. A readout IC for the flexible fingerprint TSP is required to distinguish the atto-farad capacitance difference in the fingerprint TSP noise environment on the flexible display. Post-processing is also necessary to compensate for the load variation due to the bent or stretched display.

When the thickness of the covered glass of the flexible display is almost 0.2–0.3 mm, the mutual capacitance difference from the valley to the ridge is almost 50–150 atto-farad. As the thickness of the display panel increases, the mutual capacitance difference is reduced. The thickness of the rigid glass is larger than that of the flexible display panel, which induces a capacitance difference between the valley and the ridge of only several atto-farad.

A low-noise, low-offset, and fast-response receiver is required to acquire a fingerprint image in the mutual capacitive fingerprint TSP on the flexible display. In addition, the post-processing is also required to compensate for the load variation issues that occur because of the flexible TSP’s unique characteristics. A readout IC with high accuracy and a fast response and an effective algorithm for cancelling the offset due to the load variation are both required to achieve an effective fingerprint TSP on the flexible display.

Display products are frequently used for the purposes of task efficiency or leisure. Because long-term and/or frequent use of visual display terminals (VDT) is harmful to our health, ergonomic interventions including ergonomic displays are essential. Users of VDTs suffer from headaches, nausea, visual fatigue, and/or musculoskeletal disorders, which are comprehensively called VDT syndrome or computer vision syndrome. Recently, curved displays have been adopted as a new form of display for several types of commercialized visual display products (smartphones, smart watches, smart bands, TV, and computer monitors). Visual display products that adopt bendable, foldable, or rollable displays are expected in the near future. Existing guidelines for performing visual tasks on flat or convex displays (e.g., ISO 9241) require that characteristics of new displays be evaluated from the perspective of the health of the human user. New types of display are different from conventional displays in terms of optical characteristics, and ergonomic investigations should thus be more focused on visual perception, comfort, and fatigue, among other factors in the ergonomics field.

Visual ergonomics is one prominent research area in terms of ergonomics related to display and visual perception. Visual ergonomics is defined as the multidisciplinary science concerned with understanding human visual processes and the interactions between humans and other elements of a system. Visual ergonomics applies theories, knowledge and methods to the design and assessment of systems, optimizing human well-being and overall system performance. Relevant topics include, among others: the visual environment, such as lighting; visually demanding work and other tasks; visual function and performance; visual comfort and safety; optical corrections and other assistive tools.

New forms of display are characterized by optically different properties, which consequently affect visual perception (Fig. 17). Curved displays have been reported to have advantages

When determining ergonomic display curvatures, several factors should be considered, including the viewer, media content, task, and environment. Regarding the viewer, general characteristics of visual perception as well as age-related factors should be considered. It is also important to consider the effects of media content (static, dynamic, 2D, or three-dimensional) on the viewer’s perception and ocular health. Task duration and the work-rest schedule are also important to promote ergonomic conditions during VDT tasks. Finally, the viewing environment is important in terms of its illumination, light reflection, humidity, viewing distance, viewing angle, and lateral viewing position.

When evaluating visual displays, the following measures can be used. Many diverse subjective rating scales are available to assess perceived visual comfort or discomfort, visual fatigue, and cyber-sickness (e.g., ECQ, SSQ). In addition, the concept of presence, or immersive feeling, has become more important as an essential element of a satisfactory viewing experience through any media. Objective measures related to the viewing experience include critical fusion frequency to assess mental stress and visual fatigue, change in pupil size, and eye blink frequency and duration.

It is also important to understand how our visual perception operates to better inform our visual display designs. Related concepts include the just noticeable difference (JND), horopter, and depth perception. For example, JND values for display curvature can be used to determine a specific display curvature within the JND range, within which our perception is regarded equal. The horopter concept contributes significantly to the advantages offered by curved displays in comparison with flat displays. Horopter is “the locus of points in space which project images onto corresponding points in each retina”.

To summarize, it is necessary to consider human factors, task factors, and environmental factors all together during the display research and development process. Otherwise, the resulting visual display product may be technologically feasible, but adversely affect our health.

OLED is an emerging display technology that enables beautiful and efficient displays and lighting panels. OLEDs are already being used in smartphones, laptops, wearables, tablets and TVs, and many of OLEDs are flexible ones.

A flexible OLED is based on a flexible substrate (usually polyimide). The first generation of OLEDs produced on these were not really flexible from the user perspective. The device maker bends the displays, or curves it - but the final user is not able to actually bend the device. These first-gen flexible OLEDs are adopted many premium smartphones, for example the Samsung edge-type Galaxy phones or Apple"s latest iPhones. A plastic-based OLED has several advantages especially in mobile devices - the displays are lighter, thinner and more durable compared to glass based displays.

Second generation flexible OLED displays can be bent by the user - these can be used for example to create foldable smartphones - the first range of which started shipping in 2019. Rollable OLEDs are also now entering the market for both TVs and smartphones.

While several companies (including Samsung, LG, BOE and others) are producing OLED displays, it is not straightforward to find a good and reliable supply of these displays.

If you are interested in buying a flexible OLED panel for your project or device, look no further. Our OLED Marketplace offers several flexible OLEDs, which can be ordered through us with ease.

Next, we will describe applications that utilize the properties of flexible displaysFigure 7 shows a summary of flexible display shape examples. These can be divided into two fixed shape classes (Fig. 7 (a) to (c)) and a case where the shape is actively changed (Fig. 7 (d) and (e)).

Even when used in a flat state, as shown in Fig. 7 (a), if a plastic film that is thinner and lighter than a conventional glass substrate can be employed, it provides the significant advantages of a thinner, more lightweight display that is difficult to break even when subject to impact. These are important properties for mobile devices that demand reduced weight and improved impact resistance. Furthermore, for large applications such as televisions, such displays can be easily attached to a wall like a poster, as described earlier, which increases the amount of freedom when considering installation locations.

A curved display with a constant curvature across the entire screen, as shown in Fig. 7 (b), can prevent viewing distance differences and viewing angle differences between the center and edges of the screen when curved in a concave shape. These factors are expected to increase the image quality and sense of immersion. Furthermore, if curved in a convex shape, such devices can be expected to find applications such as wristwatch design improvements, wearable devices wrapped around a person’s arm, and signage when installed on cylindrical-shaped pillars.

Displays have also been proposed that provide a mechanism for switching between flat and curved shapes and even for freely changing the panel curvature radius depending on the viewing style. In particular, there are demands for applications used in vehicle-mounted displays that have a variety of curved areas, and the adoption of curved shape panels is expected to grow in the future. Locally curved shapes like those shown in Fig. 7 (c) are employed in smartphones. By folding the edges of the panel, the bezel can be made as narrow as possible when viewed from the front, and the area occupied by the screen can be increased. Furthermore, images can be displayed continuously not only on the front but also on the sides.

When the display is used in a fixed shape, as shown in Fig. 7 (a) to (c), it can be covered by a hard material such as glass even after formation on a plastic film, which makes it easy to obtain good sealing properties. In contrast, when used in variable shapes like those shown in Fig. 7 (d) and 7 (e), there is a need for better sealing and durability against repeated bending. Although this feature drastically increases the technical difficulties, it has the major advantage of improving device storability. Foldable type displays, which can be folded up like the one shown in Fig. 7 (d), have already been applied commercially to smartphones.

However, since it is difficult to avoid damage to the TFT, light-emitting elements, and plastic film if the display is completely folded up like origami, a mechanism is generally employed to limit the curvature of the bendable parts. Since this curvature has an effect on the overall device thickness when it is folded up, it is preferable to fold with a smaller curvature, and the required curvature radius will differ depending on whether or not the display folds at the front or at the back. Furthermore, since bending applies stress to the devices and wiring inside the display, research is ongoing into display structure designs, thinner displays, and stress dispersion methods.

The rollable format shown in Fig. 7 (e) is designed to be rolled up and stored when the display is not being viewed and spread out when it is being viewed. In the case of rollable displays, one problem is the strain that occurs due to the difference between the inner and outer diameters when the two substrates that make up the display are rolled up. This indicates that it is important to create thinner displays and design their structures to minimize such stress.

There is also active R&D into stretchable displays that use substrates that are not only flexible and bendable, but also stretchable. Stretchable displays can also be divided into the two cases of using a fixed shape (Fig. 8 (a)) and actively changing the shape (Fig. 8 (b)). If a highly stretchable material can be used as the substrate, it is expected that 3D shape displays that can be bent in multiple directions, like the spherical shape shown in Fig. 8 (a), could be realized. A method that uses a thermoplastic resin as the substrate for realizing 3D shapes has been proposed. In this case, after the display is fabricated, the resin is softened by heating the substrate, and the shape is formed by pressing it into a die in a vacuum.

However, to actively change the shape, as shown in Fig. 8 (b), the shape of not only the video but also the display itself must be freely changeable, and this is expected to produce a representation as if the object was actually there (free shape). Furthermore, this feature is expected to stimulate applications in wearable displays that can support the motion of muscles and joints due to their high stretchability, even when the devices are attached to the user’s skin. Although stretchable displays face numerous technical challenges, from the display structure to the development of the stretchable material, they offer even more appealing characteristics than flexible displays and will become the focus of future research trends.

OLED is an emerging display technology that enables beautiful and efficient displays and lighting panels. OLEDs are already being used in smartphones, laptops, wearables, tablets and TVs, and many of OLEDs are flexible ones.

A flexible OLED is based on a flexible substrate (usually polyimide). The first generation of OLEDs produced on these were not really flexible from the user perspective. The device maker bends the displays, or curves it - but the final user is not able to actually bend the device. These first-gen flexible OLEDs are adopted many premium smartphones, for example the Samsung edge-type Galaxy phones or Apple"s latest iPhones. A plastic-based OLED has several advantages especially in mobile devices - the displays are lighter, thinner and more durable compared to glass based displays.

Second generation flexible OLED displays can be bent by the user - these can be used for example to create foldable smartphones - the first range of which started shipping in 2019. Rollable OLEDs are also now entering the market for both TVs and smartphones.

While several companies (including Samsung, LG, BOE and others) are producing OLED displays, it is not straightforward to find a good and reliable supply of these displays.

If you are interested in buying a flexible OLED panel for your project or device, look no further. Our OLED Marketplace offers several flexible OLEDs, which can be ordered through us with ease.

High contrast and wide viewing angle: The monochromatic bistable LCD’s contrast ratio is as high as 25:1, viewing angle about 80 degree in all directions.

The finished product design should incorporate a transparent cover such as acrylic, polycarbonate etc. to protect the viewing area of the display. Place the protective cover as close to the display bistable module as possible. The protective cover should be sufficient thickness to resist bending.

The power used for screen refreshing is pretty high. So, it will not worthwhile for an application if the screen has to be refreshed more than 20 to 50 times depending on the battery used. Bistable display technology has been used for shelf label and E-reader. Bi-stable LCDs requires the use of a voltage booster. Designing into some environments needs to be cautious, examples: explosive gas. Bistable LCDs are limited to one color of character and one color of background.

Bistable LCDs are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light. If the lighting has to be used, it can only use front light instead of backlight. It can be expensive and lose its key advantage of low power.

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices.e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted.electronic ink, Gyricon, Organic LCD, and OLED.

Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity.pixel rollable display based on E Ink’s electrophoretic technology.flexible organic light-emitting diode displays have been demonstrated.electronic paper wristwatch. A rollable display is an important part of the development of the roll-away computer.

With the flat panel display having already been widely used more than 40 years, there have been many desired changes in the display technology, focusing on developing a lighter, thinner product that was easier to carry and store. Through the development of rollable displays in recent years, scientists and engineers agree that flexible flat panel display technology has huge market potential in the future.

Flexible electronic paper (e-paper) based displays were the first flexible displays conceptualized and prototyped. Though this form of flexible displays has a long history and were attempted by many companies, it is only recently that this technology began to see commercial implementations slated for mass production to be used in consumer electronic devices.

The concept of developing a flexible display was first put forth by Xerox PARC (Palo Alto Research Company). In 1974, Nicholas K. Sheridon, a PARC employee, made a major breakthrough in flexible display technology and produced the first flexible e-paper display. Dubbed Gyricon, this new display technology was designed to mimic the properties of paper, but married with the capacity to display dynamic digital images. Sheridon envisioned the advent of paperless offices and sought commercial applications for Gyricon.

In 2005, Arizona State University opened a 250,000 square foot facility dedicated to flexible display research named the ASU Flexible Display Center (FDC). ASU received $43.7 million from the U.S. Army Research Laboratory (ARL) towards the development of this research facility in February 2004.demonstration later that year.Hewlett Packard demonstrated a prototype flexible e-paper from the Flexible Display Center at the university.

Between 2004–2008, ASU developed its first small-scale flexible displays.U.S. Army funds ASU’s development of the flexible display, the center’s focus is on commercial applications.

This company develops and manufactures monochrome plastic flexible displays in various sizes based on its proprietary organic thin film transistor (OTFT) technology. They have also demonstrated their ability to produce colour displays with this technology, however they are currently not capable of manufacturing them on a large scale.Dresden, Germany, which was the first factory of its kind to be built – dedicated to the high volume manufacture of organic electronics.plastic and do not contain glass. They are also lighter and thinner than glass-based displays and low-power. Applications of this flexible display technology include signage,wristwatches and wearable devices

In 2004, a team led by Prof. Roel Vertegaal at Queen"s University"s Human Media Lab in Canada developed PaperWindows,Organic User Interface. Since full-colour, US Letter-sized displays were not available at the time, PaperWindows deployed a form of active projection mapping of computer windows on real paper documents that worked together as one computer through 3D tracking. At a lecture to the Gyricon and Human-Computer Interaction teams at Xerox PARC on 4 May 2007, Prof. Vertegaal publicly introduced the term Organic User Interface (OUI) as a means of describing the implications of non-flat display technologies on user interfaces of the future: paper computers, flexible form factors for computing devices, but also encompassing rigid display objects of any shape, with wrap-around, skin-like displays. The lecture was published a year later as part of a special issue on Organic User InterfacesCommunications of the ACM. In May 2010, the Human Media Lab partnered with ASU"s Flexible Display Center to produce PaperPhone,MorePhone

Research and development into flexible OLED displays largely began in the late 2000s with the main intentions of implementing this technology in mobile devices. However, this technology has recently made an appearance, to a moderate extent, in consumer television displays as well.

Nokia first conceptualized the application of flexible OLED displays in mobile phone with the Nokia Morph concept mobile phone. Released to the press in February 2008, the Morph concept was project Nokia had co-developed with the University of Cambridge.nanotechnology, it pioneered the concept of utilizing a flexible video display in a consumer electronics device.London, alongside Nokia’s new range of Windows Phone 7 devices.

Sony Electronics expressed interest for research and development towards a flexible display video display since 2005.RIKEN (the Institute of Physical and Chemical Research), Sony promised to commercialize this technology in TVs and cellphones sometime around 2010.TFT-driven OLED display.

In January 2013, Samsung exposed its brand new, unnamed product during the company"s keynote address at CES in Las Vegas. Brian Berkeley, the senior vice president of Samsung"s display lab in San Jose, California had announced the development of flexible displays. He said "the technology will let the company"s partners make bendable, rollable, and foldable displays," and he demonstrated how the new phone can be rollable and flexible during his speech.

During Samsung"s CES 2013 keynote presentation, two prototype mobile devices codenamed "Youm" that incorporated the flexible AMOLED display technology were shown to the public.OLED screen giving this phone deeper blacks and a higher overall contrast ratio with better power efficiency than traditional LCD displays.LCD displays. Samsung stated that "Youm" panels will be seen in the market in a short time and production will commence in 2013.

The Flexible Display Center (FDC) at Arizona State University announced a continued effort in forwarding flexible displays in 2012.Army Research Lab scientists, ASU announced that it has successfully manufactured the world"s largest flexible OLED display using thin-film transistor (TFTs) technology.

In January 2019, Chinese manufacturer Xiaomi showed a foldable smartphone prototype.Xiaomi demoed the device in a video on the Weibo social network. The device features a large foldable display that curves 180 degrees inwards on two sides. The tablet turns into a smartphone, with a screen diagonal of 4,5 inch, adjusting the user interface on the fly.

Flexible displays have many advantages over glass: better durability, lighter weight, thinner as plastic, and can be perfectly curved and used in many devices.glass and rollable display is that the display area of a rollable display can be bigger than the device itself; If a flexible device measuring, for example, 5 inches in diagonal and a roll of 7.5mm, it can be stored in a device smaller than the screen itself and close to 15mm in thickness.

Flexible screens can open the doors to novel and alternative authentication schemes by emphasizing the interaction between the user and the touch screen. In “Bend Passwords: Using Gestures to Authenticate on Flexible Devices,” the authors introduce a new method called Bend Passwords where users perform bending gestures and deform the touch screen to unlock the phone. Their work and research points to Bend Passwords possibly becoming a new way to keep smartphones secure alongside the popularization of flexible displays.

Flexible displays using electronic paper technology commonly use Electrophoretic or Electrowetting technologies. However, each type of flexible electronic paper vary in specification due to different implementation techniques by different companies.

The flexible electronic paper display technology co-developed by Arizona State University and HP employs a manufacturing process developed by HP Labs called Self-Aligned Imprint Lithography (SAIL).

The flexible electronic paper display announced by AUO is unique as it is the only solar powered variant. A separate rechargeable battery is also attached when solar charging is unavailable.

Many of the e-paper based flexible displays are based on OLED technology and its variants. Though this technology is relatively new in comparison with e-paper based flexible displays, implementation of OLED flexible displays saw considerable growth in the last few years.

In May 2011, Human Media Lab at Queen"s University in Canada introduced PaperPhone, the first flexible smartphone, in partnership with the Arizona State University Flexible Display Center.

At CES 2013, Samsung showcased the two handsets which incorporates AMOLED flexible display technology during its keynote presentation, the Youm and an unnamed Windows Phone 8 prototype device.Galaxy Note Edge,Samsung Galaxy S series devices.

LG Electronics and Samsung Electronics both introduced curved OLED televisions with a curved display at CES 2013 hours apart from each other.The Verge noted the subtle curve on 55" Samsung OLED TV allowed it to have a "more panoramic, more immersive viewing experience, and actually improves viewing angles from the side."

Crawford, Gregory P., ed. (2005). Flexible flat panel displays (Reprinted with corrections. ed.). Chichester, West Sussex, England: John Wiley & Sons. p. 2. ISBN 978-0470870488.

Thryft, Ann R. (7 June 2012). "All-Plastic Electronics Power Flexible Color Display". Design News. Archived from the original on 31 March 2019. Retrieved 24 April 2013.

Lahey, Byron; Girouard, Audrey; Burleson, Winslow and Vertegaal, Roel (May 2011). PaperPhone: Understanding the Use of Bend Gestures in Mobile Devices with Flexible Electronic Paper Displays, Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Pages 1303–1312.

Gomes, A., Nesbitt, A., and Vertegaal, R. (2013) MorePhone: A Study Of Actuated Shape Deformations for Flexible Thin-Film Smartphone Notifications. In Proceedings of ACM CHI’13 Conference on Human Factors in Computing. ACM Press, 2013, pp. 583–592.

Nokia Press Center (25 February 2008). "Nokia and University of Cambridge launch the Morph – a nanotechnology concept device". Nokia. Archived from the original on 27 February 2018. Retrieved 12 February 2013.

Lee, Reuben (10 January 2013). "Samsung shows off flexible display phones at CES keynote". CNET. Archived from the original on 17 February 2013. Retrieved 12 February 2013.

Sasaoka, Tatsuya; Sekiya, Mits

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey