working of tft display manufacturer

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

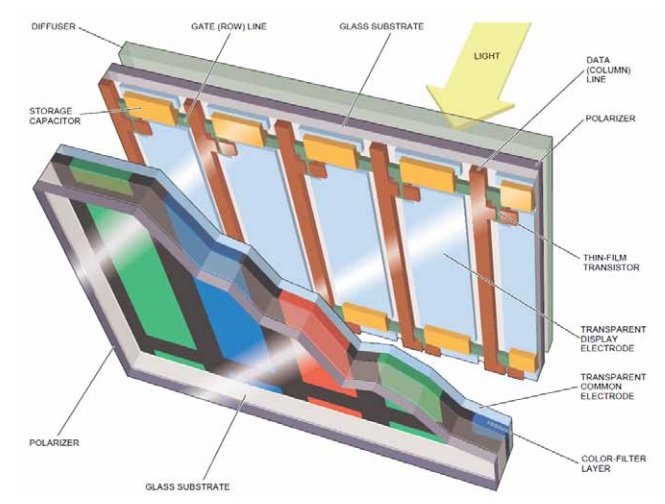

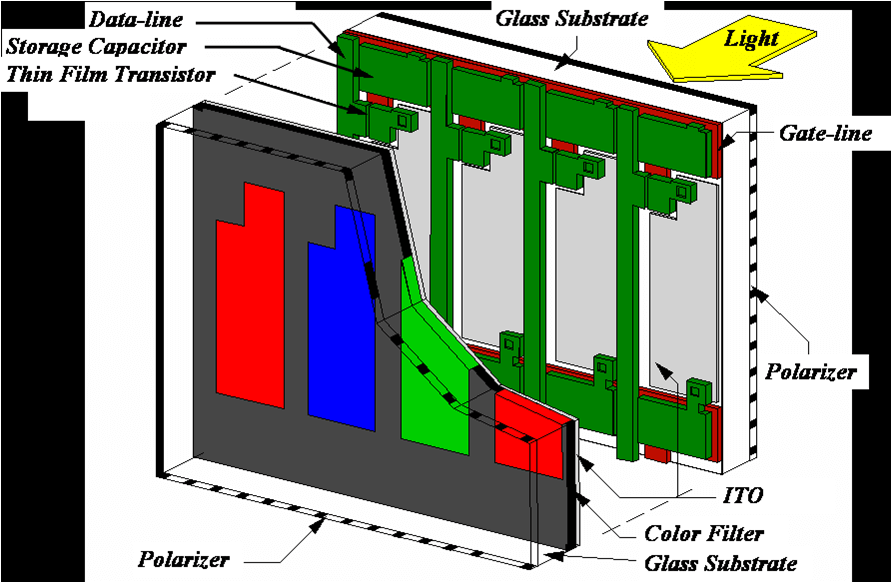

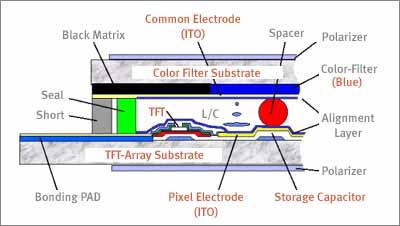

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

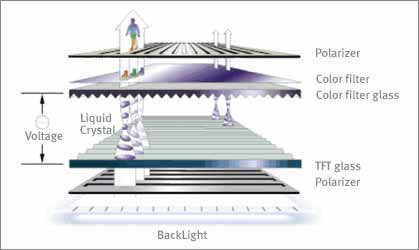

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

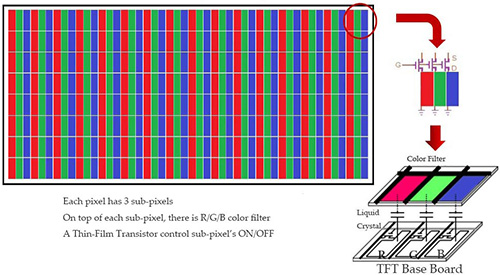

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

![]()

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

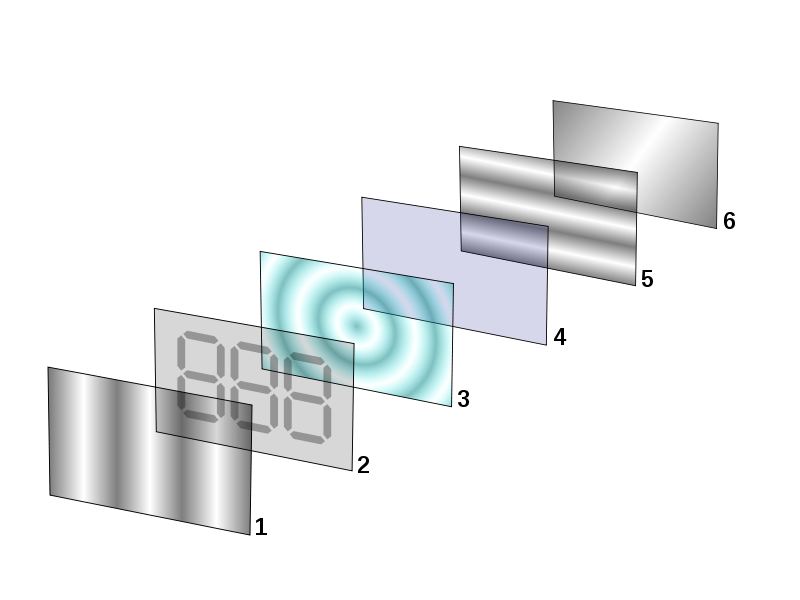

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

In order to enhance productivity, in this step we’ll do a series of procedure on a large glass, which will be cut into smaller pieces in the following step.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

◇ Use glue to build a boundary for LC on both glass. And on CF glass, apply one more layer of conductive adhesive. This enable LC molecule link to the control circuit.

The TFT LCD screen display, for the general masses, is no longer a difficult noun. And it is another after semiconductor could create a large number of emerging technology products of the business turnover, more because of its features, thin so it than using the application scope of the cathode ray tube (CRT, cathode ray tube) display made by wider. Today, I’m going to talk about how the TFT LCD Touch Screen Display Works.

As I mentioned earlier, liquid-crystal displays (LCDs) refer to a bunch produced by using the TFT screen LCD display. Now for LCD displays the name is directed mostly used in notebook computers, or desktop computer applications display. Is the thin film transistor TFT LCD display. Abbreviation of TFT LCD. This kind of display form has two main characteristics, one is a thin film transistor, the other is TFT LCD itself. Let’s talk about the TFT screen itself.

We usually think of substances like water as three states, solid-liquid, and gas. The three states of material actually are for water, for different materials, a different state may exist.

As we want to talk about liquid crystal state is concerned, it is a state between solid and liquid, actually, this kind of state is only part of the material of a kind of phase change process (see figure 1), as long as the material has the above process, namely the state exists between solid and liquid, a physicist called liquid crystal.

This type of TFT LCD screen was first discovered, had been spent more than one hundred years ago. In 1888 AD, the Austrian botanist Friedrich Reinitzer, found in the observation from the plant refined out of benzoic acid cholesterol (cholesteryl benzoate) found that when the melting behavior of the compound heated to 145.5 ℃, Solid can melt, presents a kind of solid phase and liquid phase between the half gonorrhea melt flow of the liquid. This situation will always maintain ℃ temperature rise to 178.5 degrees, to form a clear isotropic liquid (isotropic liquid).

The next year, in 1889, the study of thermodynamic equilibrium and the phase transfer German physicist O.L Ehmann, compounds for a more detailed analysis of this. He found that under the polarizing microscope, half of the viscous liquid gonorrhea liquid compounds with different parts peculiar to the crystal birefringence (birefringence) of the optical properties, namely, optical interphase (optically anisotropic). It will be a name to this as the liquid crystal. Since then, scientists will be the nature of this new discovery, known as the fourth state material – LCD (liquid crystal). It at a specific temperature range can have the characteristics of the liquid and solid at the same time.

General with water, solid lattice in heating because it is over, began to heat and destroy the lattice, when the temperature exceeds melting point will be dissolved into a liquid. And cause the type of liquid crystal is different (see figure 2), when the solid heat does not directly into the liquid, will be dissolved to form a liquid crystal state. When you continue heating, it will only then dissolve into a liquid (isotropic liquid). This is called the secondary dissolution phenomenon.

The liquid crystal state, as the name implies, will be a solid lattice and the liquid. When the liquid crystal was found, because of a lot of more phyletic, In 1922, the results observed by g. Friedel with a polarizing microscope divided liquid crystals into Nematic Smectic and Cholesteric categories. However, if they were classified according to the order of molecular arrangement (see figure 3), they could be divided into the following four categories:

Its structure is composed of TFT LCD molecules stick together, forming a layer structure. It’s every layer of the molecular long axis direction parallel to each other. And the long axis direction for each layer plane is vertical or a tilt Angle. Due to its structure is very similar to crystals, so they are called phase. The order parameter S (the order parameter) tend to be 1. Type in layered crystal layer and interlayer bonding can fracture because of temperature, so the layer and interlayer sliding more easily. But each layer within the molecular bonding is stronger, so it is not easy to be interrupted. Therefore in the context of the monolayer, Its arranged orderly and viscosity is bigger. If we use the macroscopic phenomenon to describe the physical properties of liquid crystal, we can make a group of regional average points as the liquid crystal molecules are pointing in the direction of the arrow (director), which is the direction of a group of liquid crystal molecules regional average. And with lamellar liquid crystal, because of its structure, the TFT LCD molecules will cambium-like so can point to a vector of different classification of the different lamellar liquid crystal again. When the long axis of the liquid crystal molecules are vertical stand, Call it “Sematic A phase.” if stand long axis direction of the TFT LCD molecules have some Angle of tilt (tilt), call it “Sematic C phase”. In A, C and other letters to name, which was discovered in accordance with the order to address, and so on, there should be A “Semantic phase B is.” but later found A deformation phase B is C phase, And the liquid crystal molecules in the structure layer by layer, in addition to each layer of TFT LCD molecules have tilt Angle, the tilt Angle between layer by layer will form a helical structure.

Nematic is a Greek word, the word mean in the thread is the same as in English. Mainly because with the naked eye to observe the liquid crystal, it looks like a silk pattern. The LCD screen molecules on the space of the regular arrangement of one dimension, all rod long axis of the liquid crystal molecules will choose a particular direction (that is, pointing vector) as the main shaft and arranged parallel to each other. And don’t like lamellar liquid crystal has a layered structure. Compared with the layer column type liquid crystal alignment is no order, That is to say, its order parameter S is smaller than the lamellar liquid crystal, and its viscosity is smaller, so it is easier to flow (its flow mainly comes from the free movement of molecules in the long axis direction). Linear liquid crystal is the common TFT LCD display screen TN(Twisted nematic) type liquid crystal.

Most of the sources of the name, because are generated by the derivative of the cholesterol. But some without cholesterol structure of LCD screen with this liquid crystal phase. This kind of liquid crystal as shown in figure 5, if it is a layer of a layer to separate, would very much like a linear LCD screen. But look at the Z-axis, may find it pointing in the direction of the arrow will with layers and layers of different distribution, like a spiraling when the pointing vector rotate 360 degrees for molecular layer thickness is called a pitch. Because of its every layer like linear LCD, so also known as Chiral nematic phase. In terms of cholesterol crystal, and pointing in the direction vector of the vertical distribution of LCD screen molecules, due to the different point to vector, will have the different optical or electrical differences, thus has produced different features.

If we are according to the molecular weight of high and low points can be divided into liquid crystal polymer (polymer liquid crystal, the polymer in many of the liquid crystal molecules) and low molecular liquid crystal. This kind of classification of TFT LCD belongs to the application of the low molecular liquid crystal. If the reasons for the formation of liquid crystal state, because it can be divided into type temperature formation of liquid crystal state to a liquid crystal (thermotropic), and because of the concentration and the formation of a liquid crystal state type lyotropic liquid crystal (lyotropic).

In the classification of the mentioned before, Lamellar liquid crystal and liquid crystal of the linear type liquid crystal to cause the more common, as the temperature changes and form liquid crystal state. For the lyotropic liquid crystal, we need to consider the situation of molecules dissolved in a solvent. When the concentration is low, the molecular and mixed and disorderly, which are distributed in the solvent of the isotropic solution, but when higher concentration is greater than a certain critical concentration, because the molecule has no enough space to form mixed and disorderly, the distribution of molecular began to gather to form part of the rules, To reduce the space of the block. Therefore form different sex (anisotropic).

The solution so types lyotropic TFT screen molecules in the appropriate solvents reaches a certain critical concentration, the formation of liquid crystal state. Type lyotropic liquid crystal is one of the best examples that is soap. When soap bubbles in the water will not be at once into a liquid, and the bubble in the water for a long time, after the formation of white matter, is its liquid crystal state.

Due to the structure of the liquid crystal molecules for different parties (Anisotropic), so caused by the photoelectric effect will vary because of a different direction, in short, that is, the liquid crystal molecules in the dielectric coefficient and refractive index, and so on photoelectric properties have different sex, so we can use these properties to change the intensity of the incident light, so that the formation of gray-scale, to apply on the display component. We’ll discuss below, is one of the characteristics of liquid crystal belongs to the optical and electrical related, about the following items:

Our dielectric coefficient can be separated into two directions respectively is epsilon / / (and point to parallel component) and epsilon coming (a component perpendicular to the pointing vector). When the epsilon / / > epsilon coming then called the dielectric coefficient of different parts of LCD, can be used in parallel coordination. And epsilon / / < epsilon is called the dielectric coefficient of the different part coming negative type of TFT screen, only can be used in vertical coordination will need the photoelectric effect. When the applied electric field, the liquid crystal molecules will vary with dielectric coefficient is positive or negative, To determine whether the orientation of the liquid crystal molecules is parallel or perpendicular to the electric field, to determine whether the light penetrates. Now on most commonly used type TN LCD TFT LCD that belongs to the dielectric coefficient are type liquid crystal. When the dielectric coefficient of square difference Δ epsilon (= epsilon / / – epsilon) comes, the greater the LCD of the critical voltage (threshold voltage) will be smaller. So the LCD can be in the low voltage operation.

Liquid crystal molecules are also known as heterotropic crystals because they are mostly formed from rod-like or saucer-like molecules, and thus have different physical properties that are parallel to or perpendicular to the long axis of the molecule. Like the dielectric perp, the refractive index is also divided into vectors perpendicular to and parallel to the vector, namely, n // and n perpendicular to each other.

In addition, for uniaxial crystal, there are two different definitions of refraction coefficient, one is no, which refers to the refraction coefficient of ordinary ray, so it is shortened to no, and ordinary ray refers to the electric field component of its light wave is perpendicular to the optical axis, and the other is ne, which refers to the refraction coefficient of extraordinary ray. The extraordinary ray is referred to as the light of the electric field component parallel to the optical axis. At the same time, it defines the birefringence (birefringence) Δ n = no-no for the above two refractive index differences.

In accordance with the described above, the lamellar liquid crystal, linear liquid crystal, and LCD screen for cholesterol levels, because of its long liquid crystal molecules like a stick, so point to the direction of the vector and the molecular long axis parallel. To be defined with reference to the refraction coefficient of a single optical axis crystal, it will have two refractive indexes, respectively is perpendicular to the direction of the long axis of the liquid crystal n coming (= ne) and parallel to the long axis of the liquid crystal direction n / / (= no), so when the incident light liquid crystal, will be affected by two refractive indexes, cause in the vertical long axis of the liquid crystal and LCD long axis parallel to the direction of the speed of light will be different.

If with the molecular long axis parallel to the direction of light speed, when less than perpendicular to the speed of the molecular long axis direction, which means that parallel the molecular long axis direction of refractive index is greater than the vertical direction of the refractive index (because the refractive index is inversely proportional to the speed of light), is the one – no > 0. So the birefringence Δ n > 0, we think that it is called optics is a type of LCD, and lamellar liquid crystal and LCD are all belong to the optical is almost linear LCD. If the light of the parallel to the direction of the long axis was faster, On behalf of the flat to the governor of the axis of the refractive index is less than the vertical direction, so the birefringence Δ n < 0. We call it is the optical negative type of LCD. The cholesterol liquid crystal optical negative type of LCD.

For example, the elastic constant (kappa 11, kappa 22, kappa 33) contains the three most important constants: kappa 11 is the elastic constant at splay, kappa 22 is the elastic constant at the twist. Kappa 33 refers to predominating the elastic constants of bending (bend). The other as the coefficient of viscosity (viscosity coefficients and eta), will affect the rotational speed of the liquid crystal molecules with reaction time (response time), its value as small as possible. But this feature is affected by temperature is the largest. In addition to magnetic susceptibility (magnetic susceptibility), but also because of liquid crystals of different sex, Divided into c / / c coming. And the difference of magnetic susceptibility is defined as Δ c = c / / – c coming. In addition to the conductance coefficient (conductivity), and so on the photoelectric properties. Liquid crystal properties of the most important are the dielectric coefficient and refractive index of liquid crystal. The dielectric coefficient is determined liquid crystal under the influence of the electric field to the characteristics of the liquid crystal molecules, while the refractive index is liquid crystal in the light of its important parameters influencing the light path. The LCD is in using the liquid crystal itself of these features, the appropriate use of voltage, to control the rotation of the TFT LCD molecules, in turn, affect the direction of the light, to form different grayscale, a tool for displaying images. Of course, LCD itself is not alone as the monitor, also need other materials to help, Below, we will introduce the composition of various materials and operating principle of TFT LCD display.

I remember in high school physics class, when to teach the relevant physical properties of light, to do a lot of physical experiments, the purpose is to prove that light is a wave. And the marching direction of light waves, and the electric field and magnetic field perpendicular to each other. Light itself of the electric field and magnetic field component at the same time also is perpendicular to each other. That is to say with the electric field and magnetic field component direction, each other is two parallel to each other. (see figure 7) and the role of the polarizing film is like a fence, usually will be cut off a component perpendicular to the fence, With a fence parallel component only permitted through. So if we picked up a piece of the light polarization slabs, feel like wearing sunglasses, the light became dark. But if the two pieces of polarizing film ideas together, it won’t be the same. When you rotate the two pieces of the relative Angle of the polarizing film, you will find that as the relative Angle is different, the brightness of the light will be more and darker. When two polaroids fence Angle perpendicular to each other, Light was completely failing. (see figure 8) and a liquid crystal display is to use this feature. Use upper and lower two pieces of fences between perpendicular slant plate, filled with liquid crystal, recycle electric field control liquid crystal rotation, to change the direction of light, so that different electric field sizes, can form different gray-scale brightness.

The upper and lower two layers of glass are mainly to grip the LCD with. Below the glass layer with Thin film transistor (thin film transistor, TFT screen), while the layer above the glass with a Color filter (Color filter). If you notice (see figure 3), these two pieces of glass are in contact with the side of the LCD screen, not smooth, but with jagged grooves. The main purpose of the groove with the hope of a long rod, liquid crystal molecules will line up along the grooves. In this way, Liquid crystal molecules are arranged neatly. Because if it is smooth and flat, the arrangement of the liquid crystal molecules will not neat, causing light scattering, forming a light-leaking phenomenon. In fact, this is just a theory that told us to put the glass and LCD interface, complete processing so that the arrangement of liquid crystal has a certain order. But in the actual manufacturing process, and can not be with such a groove, the distribution of glass is made usually in glass coating on the surface layer of the PI (polyimide), and then a cloth to do the action of friction (rubbing), In order to make the surface molecules of PI no longer be scattered and arranged in a fixed and uniform direction, this layer of PI is called the coordination membrane, and its function is just like the grooves in the glass in FIG. 3, which provides the interface conditions for the uniform arrangement of liquid crystal molecules and allows the liquid crystals to be arranged in a predetermined order.

We can know from figure 10, when there is no applied voltage between the upper and lower two pieces of glass, the arrangement of LCD will be in accordance with the match to the membrane of the upper and lower two pieces of glass. For TN type of LCD, and match to the film’s point of view of the poor to 90 degrees. (see figure 9) so the liquid crystal molecules are arranged by the up and down automatically rotate 90 degrees when the incident light passes through the upper polarizing film, the polarization of light waves will only order direction. Through the liquid crystal molecules, the liquid crystal molecules rotate for 90 degrees, so when the waves reach the lower polarizing film, the polarization direction of the light just turned 90 degrees. The polarizing film of the lower and upper polarizing film, 90 – degree Angle is just the differences. (see figure 9) so can smoothly through the light, but if we applied voltage between the upper and lower two pieces of glass, because the type TN LCD for the dielectric coefficient of different sex more positive type of LCD (epsilon / / > epsilon coming, represent the parallel direction of the dielectric coefficient is larger than the dielectric coefficient of the vertical direction, so when the liquid crystal molecules are influenced by an electric field, will tend to be parallel to the orientation of the electric field direction.), so we can see from figure 10, At this time, the polarized light wave passing through the upper polarizer will not change the polarization direction when passing through the liquid crystal molecule, so it cannot pass through the lower polarizer.

The so-called NW (Normally white), is to point to when we don’t apply voltage on the LCD screen panel, we can see the panel is pervious to light, also is bright, so-called Normally white. But on the other hand, when we don’t apply voltage on the LCD panel if the panel is not pervious to light, the look is black, it’s called NB (Normally black). We have just mentioned in figure 9 and figure 10 all belongs to the configuration of NW, also we can know from figure 11, For type TN LCD, located in the upper and lower glass is perpendicular to the membrane, and the difference between NB and NW just lies in the relative position of the polarizing film is different. For NB, the fluctuation of the polarizing film polarity is parallel to each other. So when the NB no applied voltage, the light will be because the polarity of the LCD to rotate 90 degrees to be pervious to light. Why there are NW and NB these two kinds of a different configuration of the polarizing film? Mainly for different applications. Commonly used in a desktop computer or notebook computer, most of the NW configuration. That’s because, if you notice, generally the use of computer software environment, you will find that most of the entire screen is a bright spot, that is to say, computer software for the application of white background and black text. Since on the point of the majority, using NW is more convenient, of course. Also because the NW window does not need to add the voltage, the average will compare to save electricity. In turn, said that the application of the NB environment mostly belongs to the screen for the application of black.

The STN LCD and TN LCD are very similar in structure, the main difference between TN LCD, the arrangement of the liquid crystal molecules, the rotation angle from top to bottom. A total of 90 degrees and type the STN LCD liquid crystal molecules are arranged, the rotation angle will be greater than 180 degrees, usually is 270 degrees. (see figure 12) because of its rotation Angle is different, its characteristics different. We from figure 13 TN type and type the STN LCD voltage of the transmittance curve can know, when the voltage is low, the light penetration rate is very high. With a high voltage, the light of the penetration rate is very low. So they belong to the Normal White polaroids configuration. When the voltage in the middle position, the change of type TN LCD curve is flat, and the change of the STN LCD type curve is steep. So in TN type LCD, when transmittance change from 90% to 10%, corresponding to the voltage difference is larger than the STN LCD. We mentioned before, in the liquid crystal display, The different characteristics of TN and STN will result in TN type LCD, which has more grayscale changes than STN type LCD, so generally TN type LCD has 6~8 bits of changes. It is 64 ~ 256 gray-scale changes. Type the STN LCD for a maximum of 4 bits are only 16 orders of gray-scale changes. In addition, the STN type and TN LCD has a different place is the reaction time (response time) general type the STN LCD it’s response time to type in more than 100 ms and TN LCD its response time is 30 ~ 50 ms as shown in the image change quickly for the STN LCD type ghosting effect phenomenon is easy to happen.

TFT LCD Chinese translation of the name is called a thin film transistor liquid crystal display, from the beginning, we mentioned LCD voltage control is needed to produce gray. And the use of a thin-film transistor to generate the voltage, to control the transition of liquid crystal display, is called a TFT LCD. From the point of the cross-section structure of figure 8, between upper and lower two layers of glass, with LCD, will form a parallel plate capacitor, we call it the CLC (capacitor of liquid crystal). Its size is about 0.1 m3, But on the practical application, the capacitance and unable to keep the voltage to the next time to update the data in the picture.

That is to say, when TFT is good to the capacitor charging power, it is impossible to maintain voltage, until the next TFT this point charge again. (in general of 60 Hz screen update frequency, need time to keep about 16 ms.) as a result, there were changes in voltage, displayed gray scale is not correct. Therefore generally on the design of the panel, we will add a storage capacitor CS (storage capacitor is about 0.5 pF). So charged electric voltage can keep until the next update screen. But the right, long on the glass TFT itself, just use a transistor to make the switch. Its main work is to determine the LCD source voltage on the driver whether to charge to this point. As for this point more charge to high voltage, so as to show how the gray-scale. It is outside of the LCD source driver.

If you have a chance, take a magnifying glass, close to the LCD screen. You will find that as shown in figure 9 shows. We know that red, blue and green, are the so-called primary colors. That is to say, using the three kinds of color, can produce a variety of different colors. In a lot of flat-panel displays, this principle is used to show the color. We put the RGB 3 kinds of color, is divided into independent three points, each has different gray-scale changes, then the three neighboring RGB display point, as the basic unit of a display, Pixel is that this a pixel, and can have different color changes. Then for a need for a 1024 * 768 resolution display screen, we just let the composition of the flat panel display with 1024 * 768 pixels, can show a picture of the right. In figure 9, each point between the Black part of RGB is called the Black matrix. We can find that looking back on it in figure 8Black matrix is mainly used to cover do not intend to previous to light part. Such as some ITOs walk the line, or Cr/Al walk the line or are part of a TFT. This is why we in figure 9, the highlight of each RGB, it seems, is not a rectangle, and also on the top left corner is a piece of black matrix cover part, this part of a black missing Angle is the location of the TFT.

Figure 9 shows the common arrangement of color filters. Stripe is most commonly used in OA products, such as laptops, desktop computers, etc. Why is stripe used in this application? More often than not, the reason is now software is the Windows interface. That is to say, we can see the screen content, is composed of a pile of boxes of various sizes. The strips, just can make the edge of the box, look more straight, and there won’t be a straight line, look have the feeling of burrs or serrated. But if it is applied in the AV products, just not the same. Probably because the TV signal is a character, the character of the line is not straight, the contour is a mostly irregular curve. So in the beginning, the Use Mosaic arrangement used in AV products is (Mosaic, or called arranged diagonally). But the latest AV products, more have been improved to use triangle arrangement (triangle, or known as the delta). In addition to the above arrangement, still have a kind of arrangement, which is called a square arrangement. It is not the same as the first few, it is not three-point to as a pixel, but with four points as a pixel. And just four points are combined to form a square.

The CRT screen, it is using a high-speed electron gun that emits electrons, hits the phosphors on the silver screen, so as to produce the light, to show the picture. LCD itself, however, can only control the brightness of the light through, no glowing function itself. Therefore, a liquid crystal display must be combined with a backplate, to provide high brightness, brightness, and uniform distribution of the light source. We can see in figure 14, of the backplate of the main parts are CCFL (cold cathode tube), reflex plate, guide plate, prism sheet, Diffuser plate, and so on. Tubes are the main light-emitting parts, by a light guide, everywhere. The light distribution and baffle will be limited only to the TFT LCD light direction. Finally, by prism sheet and help diffuser, the light evenly distributed to all areas, provide TFT LCD a bright light. While TFT LCD is borrowed by the rotation of the voltage-controlled liquid crystal, control through the brightness of the light, so as to form different grayscale.

Another box in figure 14 glue and spacer structure of two kinds of ingredients. The box adhesive USES is to make the LCD panel in the upper and lower two layers of glass, to be able to stick close and to provide a panel of LCD screen molecules, cut off from the outside world, so the box plastic as its name suggests, is around and around in the panel to the liquid crystal molecules box limited to within a panel. The spacer is mainly provided two-layer glass support, it must be distributed evenly on the glass, or a part but uneven distribution cause spacer gathered together, it will block the light, It is also unable to maintain the appropriate gap between the upper and lower glass, which will lead to uneven distribution of electric field and affect the performance of the crystal grayscale.

A very important specification of LCD is brightness, and the most important factor to determine the brightness is the opening rate. What is the opening rate? Is simple light can pass through the effective area proportion. 17, let’s look at the picture to the left of figure 17 is an LCD display from directly above or below the past structure. When the light is emitted through the backplate, not all of the light can be through the panel, like for LCD source driver chip and the gate driver chip signal line, and TFT itself, the stored voltage is the use of storage capacity, etc. These places besides incomplete pervious to light, but also because the light through these places is not under voltage control, to display the correct gray-scale, so have to use the black matrix to cover, in order to avoid interference to other correct brightness of the light area. So the effective area of the previous to light, it’s just like figure 17 shows area on the right. This piece of the effective area of the previous to light and the ratio of the total area is called the opening rate.

When the light is emitted from the backlight plate, it will pass through the polarizer, glass, LCD screen, color filter, etc. It is assumed that the penetration rate of each part is as follows:

Color filter:27%(assume that the material itself has a penetration rate of 80%, but since the filter itself is painted with color, only light waves of that color can be allowed to pass through. For RGB primary colors, only one of the three colors can be allowed to pass through. Therefore, only one-third of the brightness is left.

STONE is industrial screen manufacturers, provide a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, TFT screen module, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable forindustrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

Since 1993 we offer LCDs and LCD system solutions. We are always up to date with the latest technology and are looking for the best products for our customers. Our TFT display range includes high-quality displays:

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 2.4" TFT LCD, 2.8" TFT LCD, 3.2" TFT LCD, 3.5" TFT Display, 4.3 inch TFT LCD, 5 TFT LCD, 5.6 TFT LCD, 5.7 inch Display, 7 " TFT LCD, 8" TFT, 9" TFT, 10.1" TFT LCD, 10.2" TFT LCD, 12.1" TFT LCD , 12.3" TFT LCD (diagonal size of the active area) and so on . There are more than 250 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers" requirement.

Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

Raystar is a global leading LCD panel supplier and specialized in producing TFT LCD Panel, including Color TFT, Monochrome TFT Display and bar type TFT Display. Raystar Color TFT displays are available in various resolutions and offers a wide product range of small to medium-sized TFT-LCD modules from 0.96” to 12.3". The interface options are in MCU / RGB / SPI / UART / 8080 / LVDS. TFT Panel with control board or TFT LCD Panel with micro controller are also available.

Color TFT LCDs (Thin Film Transistor LCDs) give your product a beautiful appearance with high-resolution, full-color graphics. Our modern, automated LCD factories can create custom TFT displays for extreme temperature functionality, sunlight readability, shock and vibration durability, and more. Whether you need a stand-alone TFT LCD display or fully integrated assembly with touch and cover lens, custom FPC, or custom backlight, our experienced team can develop the right solution for your project.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

When simplicity, functionality and performance is what you need, our monochrome active and passive LCD displays provide the answer. Lightweight and compact, with ultra-low power consumption, our state-of-the-art mono LCD displays deliver optimum clarity and brightness with striking visual graphics. We also offer sunlight readable solutions as well as customized and bespoke displays to match your every requirement.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey