lcd modules low temperature manufacturer

.png)

Typically, standard LCD modules provide a temperature range of -20°C to +70°C. To meet the need of customers, EVERVISION has developed a series of wide temperature TFT LCD modules with operating temperatures ranging from -30°C to +80°C, and the maximum for some models can reach 85°C.

EVERVISION developed LCD Heater to integrate with our TFT Display Module so that can show optimal view even in low temperature. For materials, heaters can be used with transparent resins, such as glass and poly-carbonate. Our LCD Transparent Heater is made of glass substrate, so we name it “Glass Heater”. It can not only improve the LCD image sticking issue efficiently, but also have heat and humidity resistance advantage.

While directly current flows in ITO"s resistance, it will turn electrical energy into heat. The smaller resistance is (the higher consumption power is), the more heat it can generate. The concept is similar to Traveling immersion coil. When we plug in Traveling immersion coil, the current will flow in metal and generate heat to boil water.

As the result, it shows 4.3 inch TFT LCD Module display functionally under normal operating conditions. However, there is an overlapping at low temperature, because of LC"s physical characteristics. From this experiment, we know that overlapping can be solved by turning on Glass Heater.

Typically, standard LCD display provide a temperature range of 0°C to +50°C. However, this temperature range cannot always meet the needs of such usage. Considering the increasing demand of wide temperature range, several display manufacturers offer wide selection of standard versions that range from -20°C to +70°C. Extended Temperature Solutions for Industrial Applications. As a professional LCD manufacturer, we must follow more closely demands in the market. EVERVISION has developed a series of wide temperature TFT LCD modules with operating temperatures ranging from -30°C to +80°C, and the maximum for some models can reach 85°C. For more information, please contact us.

Expanding the operating temperature range is one of EVERVISION"s strategy to improve the performance of industrial TFT product line. The other display improvement is LCD Transparent Heater that provides optimized visual view even in an extremely low temperature environment.

As a solution, EVERVISION integrate the TFT LCD module, transparent heater(Glass Heater) and heater temperature sensor to control and monitor temperature smartly. With our controller system, it could precisely and rapidly adjust the temperature of TFT-LCD module. Also, it can reduce display power consumption.

Re-engineered modules with custom components that include the light guide plate, custom high-brightness LED backlights, optical films, mold frames, and mechanical structure. Engineering considerations include environmental factors such as altitude, temperature, and vibration. Inadequate attention to critical details can result in premature degradation of LCD performance such as retardation film and polarizer abrasion, image retention, or Mura.

.jpg)

Previously LCDs that operated in extreme cold or extreme heat required bulky built-in heaters and coolers in order to ensure performance. However, the proprietary liquid crystal used in the InfoVue Extreme Temp series eliminates the need for coolers and allowing Lumex to use low-power heaters. This makes the InfoVue Extreme Temp LCDs better able to perform in more hostile conditions.

InfoVue Extreme Temp LCD displays provide reliable, consistent high-quality performance from -40°C to +85°C , making Lumex LCD technology a viable solution for a growing number of applications. The growing demand for high performance LCD technology can be seen in military, freezer, gas pumps/fuel meters, non-automotive transportation, and nonclimate controlled facility applications.

Extreme Temp LCDs also offer significant visual performance benefits, providing full graphic capability and daylight visibility. When combined with LED backlighting technology, a wide range of color options are available. All InfoVue Extreme Temp LCDs are available with either a monochromatic screen with any color of LED backlight, or select negative image option with mono colored pixels and a black background.

InfoVue Extreme Temp LCD displays can be produced in sizes ranging from 8 x 1 to 20 x 4 character displays and 128 x 64 to 320 x 240 pixel graphic displays.

At low temperatures, the liquid crystal fluid maintains its viscosity, allowing the IC to refresh the data logic without any latency in the response time. At the high extreme of the operating temperature spectrum, the polarizer and adhesive materials are able to withstand the heat without warping the film and damaging the optical performance of the LCD module.

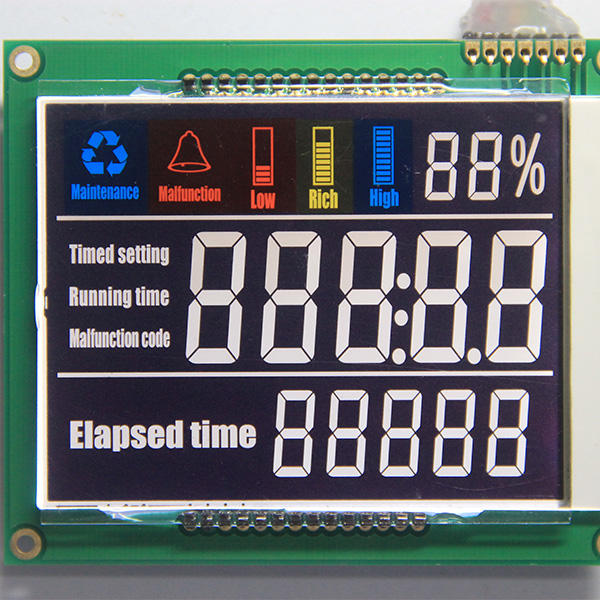

In addition to meeting the stringent quality requirements to withstand high temperature and humidity exposure, our displays also support “smart management” features, in form of a visual interface designed to help control the overall PV or EV application.

There are several industrial applications that require LCD displays to operate in extreme temperature environments such as in military, food processing, gas/fuel pumps, medical, manufacturing, and non-climate-controlled facilities, among others. Take note that typical monitors can only be used in environments with 0�C~50�C temperature range. UV exposure, moisture, and humidity also affect the overall temperature within a specific environment. iTech Company offers a range of LCD monitors that can function properly in a wide working temperature range from -30℃ to +80℃. These products are already proven and tested to maintain its original luminance under such temperatures.

While the range of operating temperature is a relevant consideration for the device to withstand extreme hot or cold environments, other factors must also be taken into account for the overall performance of the device. These includethe clarity of the image, environmental protection, LED backlighting, quality of the components, andvarious options available.

iTech Company’s products are equipped with these useful features to deliver great performance even in harsh working conditions. These are available in different monitor sizes and resolutions. It offers superior image quality with wide viewing angle. Some of the optional features include the touch screen functionality for interactive application and the level of brightness to ensure that the screen content is highly visible in all lighting conditions. Moreover, these wide operating temperature LCD displays are available in different types including open frame, panel mount, andchassis mount.

The manufacture of transistors has always been an energy intensive endeavour. There are many types of transistors, the majority of which are made from silicon. Whilst the manufacturing processes for different types of silicon transistors differ, they all involve multiple process steps that consume high amounts of energy - for example, high temperature and vacuum processes, such as Chemical Vapour Deposition (CVD), ion implantation and sputtering. In some cases this can involve processes up to 1000°C.

However, in the displays industry, the economics are different – the energy consumption is bigger. This is because the transistors need to be produced over large areas - for example to cover your TV screen (and TVs are getting bigger, not smaller). Each year we, as a planet, manufacture around 250 million square meters of transistors for displays. Whilst the temperatures involved in making silicon thin-film transistors used in displays are lower than for semiconductor wafer processing, they still require 300-500°C, depending on type and performance requirements.

In the past few years we have also seen the arrival of flexible OLED displays built onto plastic films instead of glass. This feat of engineering has been achieved by taking the same 500°C silicon thin film transistor process, but building it directly onto a special plastic (polyimide) film substrate that has been designed to withstand these very high temperatures. In the world of flexible displays, high temperature and high cost go hand in hand.

Indeed, the temperature of FlexEnable’s flexible display process is so low that it can choose from a wide range of films for the flexible substrate, including those which are bio-based (not oil-based) and biodegradable. For example, the OLCD process uses a transparent flexible film called “TAC” – tri acetyl cellulose. This, as the name says, is actually a type of cellulose that is usually made from wood pulp – in other words, TAC is made from the same natural raw materials as paper. Indeed cellulose film is increasingly common as a sustainable alternative to plastic in food packaging.

TAC has been used in the displays supply chain for decades – often within the polarisers that sit either side of the glass display cell that you’re probably reading this on. It is used because it has optically excellent properties, is low cost to manufacture and as a result is already manufactured in hundreds of millions of square meters each year.

During the manufacturing process the TAC film is attached to a flat sheet of display glass. At the end of the process the TAC is removed from the glass with a very simple “release” process that requires no expensive capex. This simple process is a key part of why OLCD has low cost – not only because the yield is high, but also because the flat glass carrier is reused for the next display.

FlexEnable’s TFT process is the lowest temperature transistor process ever industrialised. Low temperature is not only about saving energy, it is also about allowing the widest choice of substrates to choose from, including those which are more sustainable, and in doing so bringing the cost of flexible displays down.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

.png)

With the continuous technological advancement, LCD module manufacturers are also seeing the increased applications of LCD module displays. Through the years, LCD modules are becoming more popular and in demand because they are economical, energy efficient, aesthetically-appealing, easily programmable, and has a flexible display.

Today, LCD module manufacturers see the advantages of this technology when it comes to the automotive and healthcare industries. With the help of LCD devices, saving lives becomes easier and more efficient.

LCD modules are used in vehicle dashboards to display the fuel gauge, radiator temperature, odometer, and signal lights, among others. Footages from dash cameras are also projected in the screens. Aside from these, more and more cars nowadays use LCD rear-view mirrors for safer vehicle experience.

Through the LCD screens, the driver can easily be notified regarding a problem with brakes and tires. LCD devices, therefore, help drivers know what is going on with their vehicles. It allows them to address any mechanical problem or adjust their speed before it leads to an accident.

Microtips Technology USA is one of the LCD module manufacturers who have already ventured into developing speedometers, tachometers, radio and dash controls, and gauge clusters in the form of LCDs to enhance the safety and connectivity of vehicles. Our roster of automotive products varies in resolution, size, and interface, depending on your needs.

LCD modules for medical applicatiions make more accurate ailment diagnosis possible. Through processes like magnetic resonance imaging (MRI), it is easier for medical professionals to look inside the patient’s body and examine it.

Furthermore, LCD devices are guiding surgeons in complicated procedures through advanced imaging technologies. The high resolution and depth of field of LCD modules help a medical professional make better decisions and perform clinical operations more accurately.

As an LCD manufacturer, we are committed to helping the healthcare sector streamline their services with healthcare products, such as measurement equipment, wrist-mounted monitoring device, patient health monitors, and other meters for blood pressure, insulin, among others.

We at MicroTips Technology USA are equipped with modern machinery. We also implement strict quality control measures, with quality management certificates ISO9001 and ISO14001, to ensure good quality of our products. If you want LCD module displays for safety that will help you save lives, then choose the devices of top quality.

Because of its transparency and thinness, it can be incorporated into LCD module, such as between liquid crystal and backlight, and between touch panel and liquid crystal.

We support you from the product design stage. We will customize the design such as heater size & shape, wiring, and temperature control, according to the customer’s request.

Whether supplying the heater film alone or as part of the module including the laminated cover glass, touch sensor and LCD display Nissha can support. Our project and QA management experience for film touch sensor programs seamlessly extends to the inclusion of optically clear film heater from development through to mass production.

Are you tired of squinting at a fuzzy, low-quality screen that strains your eyes and makes you want to hurl your computer across the room? Fear not, my friends, because we have the solution to all of your screen-related woes: the LCD screen! But not just any LCD screen, oh no. We"re talking about the top 5 must-have features for an LCD screen that will revolutionize your viewing experience. Buckle up and get ready to feast your eyes on some seriously impressive technology.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey