lcd modules low temperature in stock

{"specs":[],"skus":[{"id":4095,"useViewType":false,"productId":307,"templateId":1,"code":"","name":"6 digit low temperature LCD screen,GDC0689","stock":0,"price":0.00,"retailPrice":0.00,"weight":0.00,"status":"1","isDefault":"1","createDate":"2021-09-28 14:36:28","updateDate":"2021-09-28 14:36:28","productSkuSpecs":[],"moq":1,"skuId":0,"chargedWeight":0.00}],"specConfs":[]}

At low temperatures, the liquid crystal fluid maintains its viscosity, allowing the IC to refresh the data logic without any latency in the response time. At the high extreme of the operating temperature spectrum, the polarizer and adhesive materials are able to withstand the heat without warping the film and damaging the optical performance of the LCD module.

In addition to meeting the stringent quality requirements to withstand high temperature and humidity exposure, our displays also support “smart management” features, in form of a visual interface designed to help control the overall PV or EV application.

Previously LCDs that operated in extreme cold or extreme heat required bulky built-in heaters and coolers in order to ensure performance. However, the proprietary liquid crystal used in the InfoVue Extreme Temp series eliminates the need for coolers and allowing Lumex to use low-power heaters. This makes the InfoVue Extreme Temp LCDs better able to perform in more hostile conditions.

InfoVue Extreme Temp LCD displays provide reliable, consistent high-quality performance from -40°C to +85°C , making Lumex LCD technology a viable solution for a growing number of applications. The growing demand for high performance LCD technology can be seen in military, freezer, gas pumps/fuel meters, non-automotive transportation, and nonclimate controlled facility applications.

Extreme Temp LCDs also offer significant visual performance benefits, providing full graphic capability and daylight visibility. When combined with LED backlighting technology, a wide range of color options are available. All InfoVue Extreme Temp LCDs are available with either a monochromatic screen with any color of LED backlight, or select negative image option with mono colored pixels and a black background.

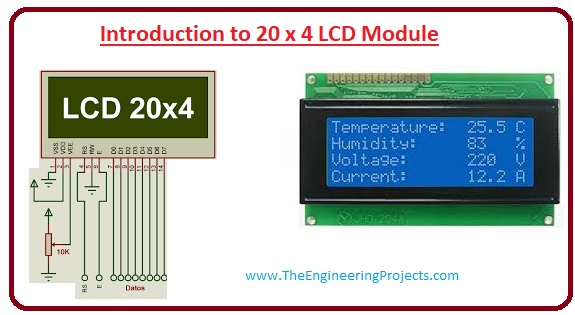

InfoVue Extreme Temp LCD displays can be produced in sizes ranging from 8 x 1 to 20 x 4 character displays and 128 x 64 to 320 x 240 pixel graphic displays.

This note will discuss the operating and storage temperatures for LCDs. Each LCD has a specified operating and storage temperature listed in the specification sheet of the display and its controller. Typically, this temperature is specified as -20°C to 70°C for the operating temperature and -30°C to 80°C for the storage temperature. Considerations should be made when operating or storing the display near the maximum and minimum temperatures.

For applications where the display must operate in extreme temperature environments, measures can be taken to avoid damaging the display and the embedded display controller. This resource will discuss the precautions and preventions of operating and storing a display at the maximum and minimum temperatures specified.

The environment a display is operated and stored in can have effects on things such as: voltage, contrast, signal integrity, and system performance. The effects of temperature on the display become more significant at the two extremes. Common display temperature ranges can be found as three common sets. Below are the three most common temperature ranges for LCDs. The temperature ranges can be confirmed in the datasheet of the display and its controller.

At very high temperatures, the effects can be seen on the electronic components and the liquid crystal of the display. The effects from an environment that is too hot will cause a darkening of the display, decreased/limited visibility, unreliable communications, and potential damage to the IC due to increased conductivity. The liquid crystal in the display will begin to degrade at very high temperatures. Overheating the display can cause dark spots to appear or result in a fully dark screen.

Both internal and external heat should be taken into consideration when operating the display. The environmental heat can contribute to overheating the device internally. The most common source of internal heat generation is from the backlight. The backlights can operate at high voltages and current consumptions to supply power to the backlight LEDs. This internal heat generation should be considered in high temperature environments.

To prevent internal and external overheating, fans and vents can be incorporated into the system to keep the display within the specified operating conditions. Precautions to avoid moisture entering the system should be taken when including vents. Moisture can cause electrical shorting, especially at high operating temperatures.

Contrast can be affected when a display is operated in ultra-high temperatures. Higher temperatures result in an increase in conductivity. This means that less voltage is required to provide the same contrast to the pixels. These effects can become more prominent when using graphic or character LCDs. Undesired effects such as a black screen can occur if the operating environment is above the specified temperature range.

The liquid crystal that is used in the display can get disoriented at very high temperatures. At these temperatures, the liquid crystal molecules can become unaligned and light will not pass through as desired. This disorientation of the liquid crystal molecules can result in a dim or partially dim image on the display. The viscosity of the liquid crystal decreases at high temperatures. The causes unreliable control of the pixels, feedback on the display, and deeper colored images.

Operating and storing a display at temperatures higher than the specified ranges can cause permanent damage to the device. Melting of display properties can occur if operating or storing the display at temperatures that exceed the limits.

A display that is operated or stored at very low temperatures will have the opposite effects in comparison to high temperatures. The effects of cold temperatures can be seen as a slowed response time, increased power consumption, reduced contrast, and a non-operational display. Storing and operating a display in low temperatures will have fewer permanent effects than at high temperatures.

At low temperatures, the liquid crystal in the display will begin to freeze. This causes reduced mobility of the liquid crystal molecules and light cannot pass through as intended. This can cause reduced visibility and reduced color depth of the displayed image. Opposite to a very hot environment, the contrast will be reduced at low temperatures.

The effects of extremely low temperatures on a display are less likely to be permanent than in hot temperatures. The likely outcome of operating a display below the recommended range is that the display will not turn on. This removes the opportunity for internal circuits to short. Once the display is returned to a temperature within the specified range, the liquid crystal will typically return to normal behavior.

Different liquid crystal fluid has different temperature properties. Extreme temperature liquid crystal exists for certain applications but can be more expensive. Twisted nematic (TN) LCD’s have the temperature ranges listed in this note.

Semiconductors operating in very low temperatures will have decreased conductivity due to increased resistance. The LCD controller, often incorporated on the glass of the LCD, will operate at lower speeds in very cold environments.

Response times can also slow in displays that are operated in very cold environments. The semiconductor will react less quickly due to the higher viscosity and power consumption. The voltage required by the system will increase to compensate for the increased resistance. This applies to signal voltages and backlight voltages of the display.

Compensations to adjust for cold environments can include heaters, voltage regulators and thermistors to adjust power determined by temperature. Temperature compensating IC’s can be included in the applications on both ranges of the temperature spectrum.

It is strongly recommended to operate and store the display within the specified temperature ranges to avoid damaging the display. Operating the display at temperatures that exceed the specified range can cause the display to malfunction, become unreliable and cause permanent damage to the device. Precautions can be taken to compensate for the environment and to avoid exceeding the specified ranges.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

This is ultra low temperature (-25℃~10℃) 2.13 inch e-paper display with 212*104 resolution. It has 24 pins FPC connection, optional FPC connector, also communicated via SPI interface, with embedded controller(COG package) and on-chip stored waveform, supports black and white.

In view of so many advantages: ultra low temperature, near 180 degree view angle, readable under sunlight, GDEW0213V7LT is a very good choice for applications like:

.png)

When we operate LCD display in an extremely low temperature environment, the screen may turn dim or go black and if it left in such conditions for extended periods, which may cause permanent damage to the display.

The LCD in cold temperatures may cause misreading because of the response time of LC (physical characteristics). It will turn slowly and make the screen overlap. (Figure 1)

See Figure1 (a), it shows a stable color screen before switching. Then, it will change to Figure1 (b) after switching. This overlapped situation is due to LC’s physical characteristic that it turns slowly at low temperature. After a while, the overlapped screen will become clear; however, you can still see the shadow beneath as Figure 1 (c); Figure 1 (d) is the final result after switching.

Typically, standard LCD modules provide a temperature range of -20°C to +70°C. To meet the need of customers, NEXT VISION DISPLAY has developed a series of wide temperature TFT LCD modules with operating temperatures ranging from -30°C to +80°C, and the maximum for some models can reach 85°C.

NEXT VISION DISPLAY developed LCD Heater to integrate with our TFT Display Module so that can show optimal view even in low temperature. For materials, heaters can be used with transparent resins, such as glass and poly-carbonate. Our LCD Transparent Heater is made of glass substrate, so we name it “Glass Heater”. It can not only improve the LCD image sticking issue efficiently, but also have heat and humidity resistance advantage.

While directly current flows in ITO’s resistance, it will turn electrical energy into heat. The smaller resistance is (the higher consumption power is), the more heat it can generate. The concept is similar to Traveling immersion coil. When we plug in Traveling immersion coil, the current will flow in metal and generate heat to boil water.

As the result, it shows 4.3 inch TFT LCD Module display functionally under normal operating conditions. However, there is an overlapping at low temperature, because of LC’s physical characteristics. From this experiment, we know that overlapping can be solved by turning on Glass Heater.

NEXT VISION DISPLAY provide different thickness of Glass Heater from 0.4 mm to 1.1mm and it can easily attach to our TFT LCD Module and IPCT (PCAP). Apart from installing convenient, it is specially designed to assure optimal quality for our clients. Using connector and supply stable current to control TFT LCD Module. (Figure 3)

In summary, when selecting an LCD display for an extreme temperature environment, the first thing designers need to evaluate is the operating environment: temperature, moisture, and humidity. Additionally, they also need to consider what will be displayed on the screen: display performance, clarity and correct information. With all these factors, it will help select the best display for the application.

However, NEXT VISION DISPLAY Glass Heater is designed to deliver optimum performance in low temperatures in order to accommodate for diverse industrial applications. It also ensure safe operation of display keeping control panels operational in inclement conditions or clearing surfaces of unwanted snow, ice, or condensation. In particular, it is possible to integrate with TFT LCD Display.

It’s an ideal solution for TFT display to operate in cold environment. NEXT VISION DISPLAY integrate the TFT LCD module, LCD transparent heater (Glass Heater) and heater sensor to control and monitor temperature smartly. With our controller system, it can precisely control the heater on or off and then rapidly adjust the temperature of TFT-LCD module. Also, it can reduce display power consumption. Moreover, all series of TFT-LCD module can be integrated with heater control board to make it automatic temperature controlled and would not be subjected to its maximum operating temperature range as stated in the specifications.

According to the popularization of display applications, the TFT LCD display have to adapt the Extreme Temperature and Different EnviromentsFIRST Components/ Evervision’s Wide Temperature TFT LCD Series are designed specifically for operation in harsh environments and under changing temperature. Furthermore, we have a solution for low temperature environment. Let’s find out!

The LCD in cold temperatures may cause misreading because of the response time of LC (physical characteristics). It will turn slowly and make the screen overlap. Additionally, it may cause permanent damage to the display if LCD panel left in such conditions for extended periods.

Fortunately, there are a number of solution such as specialty liquid crytals (LCs) and other materials for application requiring the use of a display in extreme environmental condition. FIRST Components/ Evervision Wide Temperature TFT LCD Display overcome these challenges through the use of applied heating and cooling solutions.

At present, the common TFT LCD modules on the market have a wide range of definitions of -20~70 °C. For industrial control, vehicle and outdoor products, this temperature range always can’t meet the needs of such usage.

Fortunately, our Wide Temperature TFT LCD Display can work under extreme environments with operating temperatures ranging from -30°C to +80°C, and the maximum for some models can reach 85°C. These TFT displays are full color LCDs available in industry standard sizes rangingfrom 3.5″ to 15.6” TFT LCD display and widely used in cold or heat condition throughout the world.

In low temperature environment, liquid crystals will be condensed and cause the screen blanked out. In order to prevent the problem, you may need to add a Glass Heater to your TFT LCD Module.

It can optimize the LCD visual clarity and operate normally by heating up to the right temperature. With Glass Heater, displays and touch screens remain usable in cold, high humidity/low dew point environments and locations where ambient temperature can change quickly.

In the design of the LCD screen, the selection of what temperature range of liquid crystal materials will be considered. Usually, our TFT LCD screen work is divided into normal temperature 0-50 degrees, wide temperature -20-70 degrees, super-wide temperature -30-80 degrees, even customers will choose -40 degrees of extremely special materials to design. So, does the LCD still work at the limit temperature?

Actually, this question is a little ambiguity, as we know, for example, the wide temperature scope of work is – 20-70 degrees, so first of all, in less than 20 degrees below 0 and higher than 70 degrees of circumstances, the LCD panel will not be able to work in theory, but, if you haven’t reached 70 degrees and the temperature of minus 20 degrees, but already very close to, can be said to be the limiting temperature, the LCD screen can work normally?

This problem is also a problem many customers will put forward, many customers use the wide temperature LCD, in the case of very low temperature, the word becomes very weak, and in the case of very high temperature, the word becomes very deep, how is this?

In fact, the LCD screen goes a long way to explaining the principle, the LCD panel to display all sorts of design or pen, is due to the liquid crystal box of LCD in work, andliquid crystal, just as its name implies is liquid, must be affected by the environment, high-temperature liquid crystal will be fever, flow speed, the feedback is on display, color is very deep. Under the condition of low temperature, the liquid crystal will start to crystallize and flow slowly, and the color on the display will become very shallow. It is not that it cannot display normally, but the display time will be much slower than the normal temperature.

So everyone should be able to understand, the operating temperature of the LCD screen, that is, in this temperature range it is able to work, not because of environmental factors do not display or do not refresh the situation.

Generally speaking, the wide temperature LCD screen, for example, starting from 5 degrees below zero and 50 degrees centigrade, the speed of the display will begin to change, to minus 20 degrees and 70 degrees above freezing, reached the limit temperature, feedback to the screen is no display or a dark state, already can’t use, so liquid crystal often advise clients, if the actual temperature is close to the limit temperature, it must choose a wider temperature range of LCD screen.

STONE has more than 20 years of industrial LCD production experience. STONE HMI solutions are now widely used in a variety of industrial embedded areas of advanced civil products: such as home and office automation, medical equipment, beauty machines, vending machines, power control systems, and excavators.STONE is highly recognized by national instruments, state grid corporation of China, Thyssenkrupp Elevator, and other partners for all kinds of equipment, such as gas stations and charging piles, that require a stable operating temperature of TFT LCD screen and relatively severe operating environment.

The LogTag® UTREL30-WiFi temperature data logger automatically uploads real-time temperature data to your LogTag® Online cloud account via your existing wireless network. It features a large, easy-to-read display, along with many familiar attributes known from the LogTag® family of data loggers. These include non-volatile memory for up to 16,129 temperature readings and a statistical memory, storing maximum and minimum reading as well as alarm duration for each of the last 30 days.

16,129 temperature readings. 67 days at 6 minute logging.Day summary statistics memory (for display on LCD): up to 30 days of Min/Max/duration and alarm trigger statistics.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

On non-touch LCDs apply no pressure to the LCD surface and ensure no impact can be made by end users to it. There is no specification for pressure or impact on non-touch LCDs.

Avoid excessive and pointed force on the back of the chassis of the LCD which can damage the backlight structure and cause hot spots on the display or permanent damage to the unit

COG Modules with Multiple-Time Programmable memory are sensitive to photon excitation. Under intense exposure to strong ambient light, MTP cells can lose its content before the specified memory retention time span. By design, the IC is expected to be mostly shielded in operation.

If the LCD glass breaks and the LCD liquid materials escape, avoid contact with bare skin. Wash exposed skin with soap and water immediately and dispose of the product according to local materials handling procedures.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey