solder lcd display free sample

This article about soldering techniques is the second on a series written by Barbara Dutra, an exchange engineering student from Brazil, currently attending Arizona State University, college of electrical engineering. She is currently an intern at Focus Display Solutions.

The majority of Liquid Crystal Displays require electronic components to be attached to the LCD Glass via a printed circuit board. These components are permanently attached using solder via LCD soldering techniques.

The soldering of electronic components is the act of joining two pieces mechanically by melting a combination of metals that becomes a permanent adhesive once cooled.

There are many types of soldering tools and methods used depending on the application. For example, there is the soldering of mechanical parts with special materials in large equipment such as aviation, or solders used in very small scale applications such as in Surface Mount Devices (SMD) components, and finally there is one extremely delicate type of soldering processes used in the case of the amendment in optical fibers.

All electrical appliances have electronic circuits and these circuits are made up of electronic components attached to a printed circuit board (PCB) using solder. The solder’s primary function is to create a good electrical contact and good mechanical rigidity.

A poor solder connection can seriously reduce or cut the flow of current causing the circuit to fail in its operation. ( Note: A poor LCD solder connection increases the amount of resistance. The higher the resistance the more heat that is generated and the more power required to operate the device. This is a critical concern in battery powered applications that have a LCD and a Liquid crystal module with a backlight.)

The soldering station is used for SMD components in the industrial manufacturing of some PCB assemblies used in such products as display modules, cell phones and computer boards.

Soldering irons have a hollow base with a heating element located inside. Its tip, which is typically copper covered by another material that allows the transfer of heat, becomes heated when the iron is turned on.

The soldering gun contains an iron tip which heats almost instantaneously when the trigger is pressed. It also contains a small lamp to illuminate the place where soldering is taking place. This iron is suitable for heavier soldering applications or large components with thicker terminals that require more heat.

Traditional solder is composed of two low melting point materials, tin and lead. Sometimes, these solders may contain small amounts of other materials for special applications.

This combination of metal alloys create a melting point between 680F to 698F, making it ideal for making joints (permeant bonds) between two metals. The solder is identified from the ratio of tin and lead with the numbers representing the Tin/Lead ratio.

Many countries have banned the use of lead in solder due to pollution potential and risks for human health. Most countries have a dead line of when they plan to remove lead from electronics.

There are exceptions to this ban. Solder used in critical applications such as aviation, military and some medical devices are allowed to use lead. It is believed that bonds using a lead based solder are strong and do not crack over time or in ultra-harsh environments.

The majority of industrial countries now require ROHS approved solder and soldering techniques. The use of ROHS solder in Liquid crystal displays has not increased its cost or lead-time.

There is a belief by some companies that ROHS solder has not been in use long enough to know if it is reliable over several years of use. Their concern is that when the solder is exposed to extreme heat and extreme cold over a long time period, that the solder will crack and allow for open circuits.

PCBs contain copper that is used to create circuit paths, the components are attached to the circuit board with leads that are inserted into holes located on the board. The holes contain copper around the edges that receive the solder.

Before starting the soldering process, a bit of solder is applied to the tip of the soldering iron, this allows heat to be passed from the heating element to the copper contact.

The tip of the soldering iron is briefly placed simultaneously against both the leads of the component and the copper of the trace. The solder flows into the hole and forms a strong electrical bond as the solder cools down to room temperature.

Warning: This operation must be quick so that the soldering iron heat does not damage the track or electronic component. If there is excess solder or join is faulty, the solder can be reheated and removed with the use of the nozzle.

The solder of the SMD components is responsible by the mechanical support and electrical connection between the component and the copper pad on the PCB.

Soldering of SMD"s is more complex for a variety of reasons such as exposure to high temperatures and soldering conditions. The SMD components have very small terminals for soldering, and they are on the copper side of the board that will be exposed to heat. The risk of heat damages to the components is much higher than in a conventional method of mounting components with through-hole.

There are two welding processes: wave soldering and reflux soldering. The majority of Chip on Board (COB) LCDs contain a combination of both SMD (sometimes called SMT for surface mount technology) and through-hole.

In the wave solder process, the board should be reversed to receive the wave soldering, so it is required that the components are pre-pasted with an epoxy adhesive. On a conveyor belt, the board passes through a tub with solder alloy in liquid state.

The machine produces waves of solder (similar to ocean waves) and this solder wave contacts the plate by welding all components SMD terminals mounted on the bottom face of the plate.

In the case of reflux soldering, the components on the LCD are placed on the board that will be carried by a belt into an oven. A solder paste is applied to the plate and this paste is melted in the oven, soldering all components. This process will solder the components of the upper part of board. Then the plate goes to the soldering wave form, where the lower side components are soldered.

When a SMD component is defective or poorly welded, in some cases, the issue can be corrected using a soldering iron. However, an experienced person is required for this to be carried out due to the very precise work involved.

First remove the solder and then the soldering iron. Do not move the terminal until the solder cools and never "blow" on the solder. This may create air bubbles to form creating a poor solder joint and increasing resistance in the circuit or misalignment of the component.

Once the solder is cooled, tap the terminal with a wire cutter to make sure that soldering is secure and cut off the excess terminal with cutting pliers.

Note: "flow soldering" should not be used for soldering printed circuits due to their acidic nature which can corrode from their residues, thereby damaging the components.

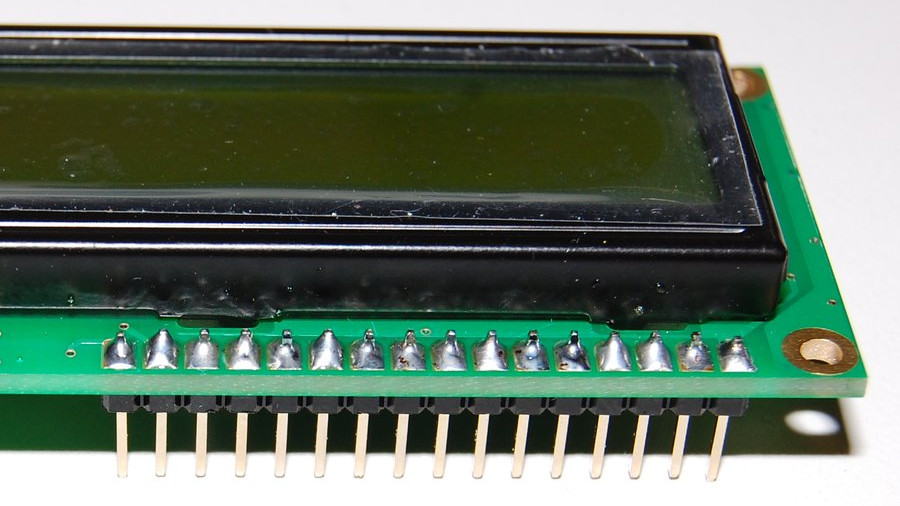

A good LCD soldering joint will be shiny and even, a poor LCD soldering joint will have a dull appearance and be filled with holes or gaps that allow for the component to break free. Also, a poor solder joint will create more resistance.

The LCD soldering may have a good bond with the lead of the component, but a bad contact with the trace on the PCB. This can happen by insufficient heating of the lead, or the printed circuit board is dirty or rusty. Below is an image of this type of solder failure.

The opposite solder issue can occur when the weld has a strong adhesion to the lead of the component, but a bad contact with the component terminal. This problem can be quickly identified since the component will be wobbly and move easily. The cause is the same, insufficient heating of the terminal, terminal or dirty or rusty.

The image below shows a good LCD soldering contact with the trace, but little adhesion to the lead of the component. Note the lack of contact between the lead and the solder.

Another problem is the microspheres: these are isolated spheres that are on the printed circuit board trace when the weld does not bond correctly. The microspheres ( a fancy name for air bubbles) can be formed beneath the solder holding the components to the trace. This condition will create a short circuit.

This can be a major headache since the LCD soldering will look good and you will have a difficult time locating which solder joint is causing the broken circuit.

The image below shows a poor LCD soldering weld that can occur on a solder joint for a LCD Display. The component will behave as if there is no connection at all.

Contact Focus Display Solutions for any questions or concerns you have regarding LCD soldering requirements for LCD displays. We are based in Chandler, Arizona and support customers in the US and Canada.

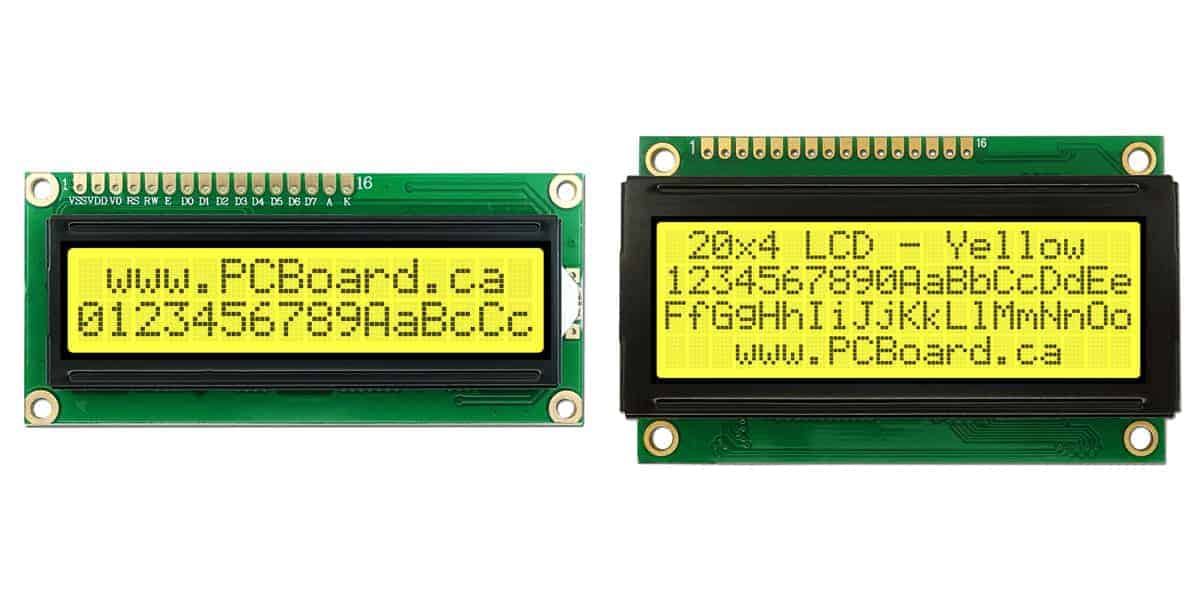

PIN connection is the most widely used connection because it is very steady. Unfortunately, not everyone is an expert at soldering. Every now and then, we can hear customers complaining about the high failure rate after the PINs were soldered on PCB. And I was always wondering if they did the soldering properly. More often than not, it’s the soldering problem. It’s not the quality problem of LCD screen itself. We feel it is our obligation to do some tests to help those who lack experience.

In order to test the impact of the soldering temperature, we deliberately made it 350 degrees Celsius far higher than the normal. The soldering iron head was placed at the distance of 4.0 mm from bottom of LCD screen.

It only took about 4.0 seconds to melt the glue before it bubbled. It would cool down in a few seconds after the soldering iron head was removed and then it solidified slowly and shrank when it was completely cooled.

One interesting idea was that we located the PIN which was responsible for the missing segments of LCD screen and re-soldered it with overheated temperature. Pulled the PIN down a little, which would make it temperately connect in normal again. We could see it displaying the whole diagram for a while. When we were glad that we fixed the LCD screen, the old problem repeated again. It was easy to understand because the overheated temperature damaged the glue and turned the chemical composition into something else. Now the LCD screen was completely damaged and was unrepairable.

Let us try another experiment. We soldered the perfectly normal LCD screen with overheated temperature. It was as sure as the sun comes from the east that the old missing segment problem recurred. I am going to remind everyone here don’t ever solder the PINs with overheated temperature because it will definitely cause the missing segment problem.

Let us hit the PINs with overheated temperature while we don’t use the UV glue to fasten the positions of the PINs. Wait. Is it possible not to use UV glue? Of course, it isn’t. It is never able to fasten the PINs without UV glue. This was just an experiment to explain what would happen in a hypothetical situation. Now we continued the experiment. We put a 350 degree Celsius soldering iron head directly on PIN for 10 seconds and more until the polarizer turned yellow. To our surprise, the LCD screen was working perfectly fine. Now we could conclude that it was UV glue which was overheated that caused the missing segments and other problems. But we can’t make a LCD screen without it.

1. The distance from the soldering iron head to the bottom of LCD screen should be at least 4.0 mm and the temperature should be below 260 degrees Celsius. The time should be less than 4 seconds for the soldering iron head on PINs to avoid making the glue bubble.

2. The soldering iron head should contact two adjacent PINs at the same time and make the heat transfer more evenly. It should form 30 degree angle with PINs because this will make contacting area larger and heat transfer faster. It will be a perfect heating condition if we can make the two adjacent PINs reach the same temperature at the same time.

3. It is forbidden to let the PINs bear any pressure while we are welding the PINs. In order to prevent the displacing of the PINs because of the pressure from outside, it is best if we lay the front surface of LCD screen flat on a table.

The Serial LCD Kit includes all the parts you need to add a serial "backpack" to a 16x2 LCD. The kit includes a pre-programmed ATmega328 microprocessor, which reads a serial stream of data and (after a little heavy-lifting) instantly displays it on the LCD. Interfacing the Serial LCD with an Arduino, or other serial-enabled devices, allows you to easily print GPS coordinates, short messages or any other information onto the LCD.

This tutorial will cover everything you need to know to get up and running with the Serial Enabled LCD Kit. We"ll first go over assembly so you can turn that bag-o-parts into something that hopefully resembles any pictures you may have seen of the kit.

Following assembly, we"ll touch on how to actually use the Serial LCD Kit. Specifically, we"ll go over how you"d use the thing with everybody"s favorite development board, Arduino. There"ll be example code galore, and you can even make your own LCD clock! It"s gonna be pretty crazy...

At a minimum, the required toolsfor assembly are a really basic soldering iron, a bit of solder, and some cutters. In addition to those tools, other items you might find helpful include needle nose pliers, and perhaps a third hand, or vise, to keep everything nice and stable.

Finally, you"ll need something to send a serial stream of data to the display. An Arduino works great (any variety, this isn"t limited to the Uno) if you want to automate the serial data stream. FTDI breakouts or RS-232 level shifters work if you just want to connect the display to your computer and send data via a terminal program. For what it"s worth, this tutorial will focus on connecting the display to an Arduino.

The goal of the Serial LCD Kit is to make controlling an LCD simple and to make wiring to it even simpler. If you wanted, you could abstain from using the serial backpack and wire an Arduino directly up to the LCD. To that point, there are loads of great examples, and even some Arduino libraries, that make interfacing a microcontroller directly to an LCD very easy. However, because the LCD is driven by a parallel interface, those examples require a tangle of wires and anywhere from 6 to 11 pins of the Arduino to control the thing.

The microcontroller on the Serial LCD Kit takes care of all of that nasty wiring, so you only need one pin to control the LCD. The Serial LCD"s on-board microcontroller parses any incoming commands or characters, and then sends the proper data to the LCD over the multi-wire parallel interface. It"s a magic black box, and you don"t have to care how it does its job, just that it does it. So let"s get it built...

What you"ve got in front of you right now is not yet a Serial LCD Kit. First, we"ve got to turn that bag of parts into a Serial LCD Kit, which will require soldering. If you"ve never soldered before, don"t fret! This is one of the easier soldering projects, every part is through-hole, and well-spaced. If this is your first time though, I"d encourage you to take a trip over to one of our excellent soldering tutorials before picking up the iron.

First, pick out the big, ferrari-red PCB. See how one side has white silkscreen printed onto it? This is the top of the PCB. You"ll stick almost every part in on this side and solder the pins to the opposite side. The only time we"ll stray from that is when soldering the LCD, which is the last step.

We"ll solder the lowest-profile parts first, so single out that little 10kΩ resistor. Bend it into a "U" shape and guide the two legs through their mating holes. Now just flip the board over and solder both legs to the bottom of the PCB. If the resistor keeps falling out before you can get it good and soldered, bend the legs out a little bit to better secure it. Try to keep the part as flush as possible with the PCB. After soldering, make sure you clip the excess of the legs as close to the solder joint as possible.

Next, find all four of the yellow ceramic capacitors, and separate them by their 3-digit code. “104” means 0.1uF, while “220” signifies 22pF. Don"t mix these up. Stick the caps into their corresponding, rectangular footprint, flip over the board and solder up both legs. Clip the excess legs. Follow the same process for the white, three-pin JST connector, and the silver, oval crystal.

Pick out the 10uF electrolytic capacitor. It"s a little black, can-looking part. Before plugging it into the board, notice that one of the legs is shorter than the other. Whenever you see this asymmetry, consider it an alert that the part is polarized, which means, in order for the part to work correctly, you have to assemble it in a very specific direction. In this case, the shorter leg signifies the negative pin of the capacitor. If you look closely at this capacitor"s landing spot on the PCB, you"ll notice an inviting white dash which marks the negative pin. Match up the negatives and follow the same soldering/clipping process as usual.

The transistoris also polarized, though all the legs are the same length. This time notice that the package comes in something of a half-circle shape. Pretend you"re plugging a half-circle peg into a half-circle hole, and match up the flat edge of the transistor, with the flat edge printed on the PCB. Solder it just like usual, and work those clippers.

Last, you"ll do up the big, blue trimpot. This part"s polarized, although it"d work either way. You might as well match up the part to the footprint on the board, though. There"s a couple notches on one side of the pot that you can match up to the board. Solder, clip, and dance! You"re done.

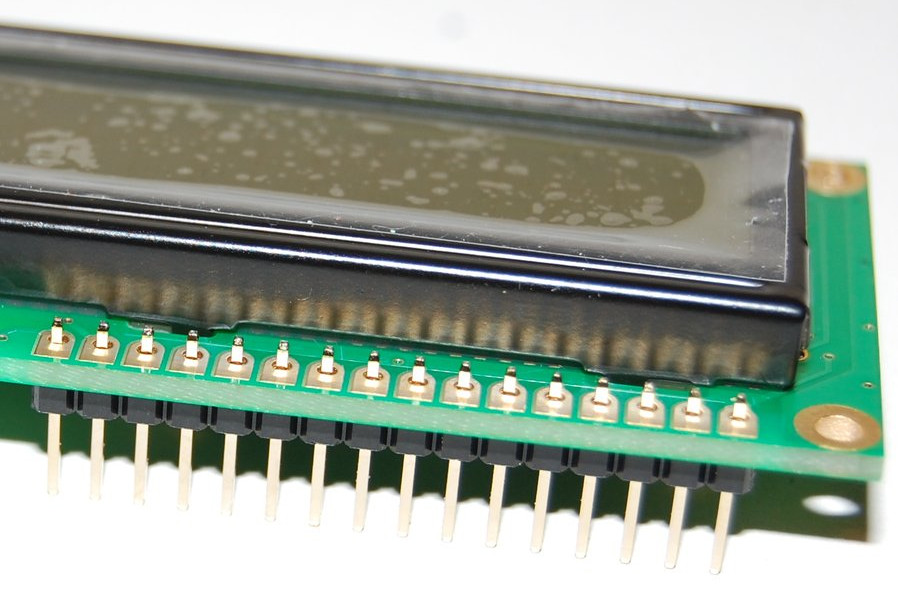

Wait...something"s missing...oh, hi LCD! To connect the LCD to the PCB, we"ve included a straight 16-pin header with the kit. You"ll need to solder this header to both the PCB and the LCD. Solder it first to the LCD, stick the shorter pins into the LCD. Make sure the longer legs are extended out from the back of the LCD and solder all 16-pins on the top side of the LCD. Effort to keep the pins as perpendicular to the LCD as possible.

With the header soldered to the LCD,you"ll finally be able to connect the display to the PCB. Remember, we"re sticking this part into the bottom side of the PCB, and soldering to the top. Solder up all 16 pins, and that should be it.

Before you can display anything on the LCD, you"ll have to connect something to it. Only three wires are necessary to use the Serial LCD Kit: RX, GND and VCC. Plug the included 3-wire jumper cable into its mating JST connector that you soldered onto the PCB. This color coded cable has two wires for power, and one for receiving serial data. The red and black wires correspond to +5V and GND, respectively, and the yellow wire is RX.

You"ll need to figure out how you"re going to powerthe LCD Kit. It doesn"t have a regulator on-board, so it"s up to you to supply a clean, regulated 5V power source. If you"re using an Arduino, you could power the Kit off of the 5V and GND pins – connect red to 5V and black to GND. Otherwise, there"s a ton of options out there for power; you could use a USB adapter, a 5V wall-wart, a breadboard power supply. The list just goes on. Just make sure you"re not supplying any more than 5V (a little less may work, but you"ll lose some brightness).

After powering the Serial LCD Kit, you should notice the backlight turn on. If the contrast is properly adjusted, you might see the splash screen flash for a second or two. Most likely though, the contrast won"t be set correctly, so you won"t see a splash screen. In that case, you may see anything from 32 white boxes to absolutely nothing. You"ll have to be quick about it, because the splash screen only remains for a couple seconds before going blank, but try turning the trimpot knob until you"ve got a good view of the characters on the LCD.

The "Serial" in the Serial LCD Kit can be a little confusing. What it really means is TTL serial, not to be confused with RS-232 serial. The voltage on the RX line should only go between 0 and +5V. If you"re using a microcontroller (like an Arduino) to talk with the LCD, then you most likely don"t have to worry. Just don"t hook up a PC"s serial port straight to the LCD and expect it to survive.

Connect the Arduino to the Serial LCD as follows. If you have a wire stripper, you may want to expose a few millimeters more of wire to allow them to stick really nicely into the Arduino"s headers.

Here"s a simple example sketch, which uses the SoftwareSerial library (which is included with recent versions of Arduino) to instill our Arduino with more than just the one, hardware, serial port. Now we can use the hardware serial port to listen to the serial monitor, and the second serial port can be used to talk to the LCD.

Now, plug in your Arduino and upload the code. Open up the serial monitor, and make sure it"s set to 9600. Type “Hello, world” into the serial monitor and send it over to the Arduino. The LCD should echo your greeting. Take the LCD for a test drive, discover all the characters it can display!

You"ll quickly notice, that the code is severely lacking any sort of clear display command, but don"t think for a second that the Serial LCD Kit doesn"t have a clear display command. It"s got commands up the wazoo! The Serial LCD Kit is set up to accept commands that control the backlight, baud rate, and all sorts of display functionality, like clearing the screen. Have a look at the Kit"s “datasheet”, which lists all of the characters and commands you can send to the display. I wrote that, but I understand if it"s all gobbledygook to you right now.

The commands are divided into three groups: backlight, baud rate, and special commands. Each command requires that you send at least two bytes to the display. For instance to set the backlight, you first have to send the backlight control byte (0x80, or decimal 128) followed by a byte with any value from 0 to 255. Sending a 0 will turn the backlight completely off, 255 will turn it all the way on, 127 will set it to about 50%, and so on. The backlight setting is stored in the Serial LCD Kit"s memory and will be restored when the LCD is turned off and on.

What we really care about right now, though, is clearing the display, which requires a special command. To issue a special command to the LCD, you first have to send 0xFE (or decimal 254) which tells the display to go into special command mode, and wait for a data byte. The clear display command is 0x01 (or decimal 1), that command should be sent immediately after sending the special command byte. So to clear the display we need to send two bytes: 254 (0xFE) followed by 1 (0x01). Check out the datasheet link for all of the special commands. You can do all sorts of fun stuff: scroll the display, turn it on/off and control the cursor.

Our next piece of example code, Serial_LCD_Kit_Clock, delves into sending special commands to the LCD with an Arduino. There are individual functions that clear the display (clearDisplay()), set the backlight (setBacklight(byte brightness)), and set the cursor (setLCDCursor(byte cursor_position)), feel free to copy these and add them to any code you"d like.

This is a good start, but there"s plenty of room for growth. Try adjusting the brightness of the display based on what time it was. Make it the brightest at midnight, dimmest at noon. What else can you do with the code?

Now then, that should be enough to get you on your way to using the Serial LCD Kit with a serial interface. If you"re happy with that, and don"t want your mind blown, I suggest you stop reading here.

Oh, you"ve taken the red pill? Well then you get to learn the Serial LCD Kit"s very deep, dark secret. It may not look anything like one, but the LCD Kit is actually Arduino-compatible. It has an ATmega328, just like the Arduino, and that ATmega328 has a serial bootloader, just like an Arduino. It can be programmed via a USB-to-Serial board. This means you can hook up all sorts of sensors, blinkies and other I/O to the Kit itself, while continuing to use the LCD to display any info you"d like. The 6-pin serial programming port on the right hand side of the PCB can be connected to an FTDI Basic Breakout.

With the FTDI board connected, and Arduino open, simply select the corresponding COM port in the Tools>Serial Port menu, and select Arduino Duemilanove or Nano w/ ATmega328 under the Tools>Boards menu. Though it probably won"t look like it"s doing anything, try uploading Blink, change the LED pin to 9 to at least see the backlight of the LCD flick on and off. Remember, you can download the Serial LCD Kit firmware here. If you ever want to turn it back into a Serial LCD, upload it to the LCD like you would any sketch.

If you want to be really adventurous, and get the most out of the Serial LCD Kit, I"d recommend first taking a trip over to where the Serial LCD Kit"s source code is hosted and getting a good idea how the code works. That firmware is written as an Arduino sketch, and uses a great little Arduino library named LiquidCrystal to control the LCD. The LiquidCrystal library makes controlling the LCD with an Arduino super-simple.

You should also get a good feeling for the kit"s schematic. There are a few Arduino pins that can only be used with the LCD (4-9), but pins 10-13, and all of the analog pins can be used with any device you"d normally connect to an Arduino. The available pins are all broken out on the bottom of the PCB.

Remember, this part is all very extracurricular. Don"t feel at all required to use your Serial LCD Kit as an Arduino. I just wanted to let you know what"s possible with this kit.

Serial LCD Clock Example Sketch - Displays a digital clock on the Serial LCD. This is a good example of how to use special commands, like clear, with the display.

Now I"ll leave you and your Serial LCD Kit in peace. I hope you"ve learned a good amount about the display. I also hope you"re left with questions and ideas about what you"re going to do with it next. If you"ve still got questions about the display, or comments about the tutorial, please drop them in the comments box below or email us.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

The benefit of this kind of construction is low cost — there is no connector involved at all, just the flex soldered directly down to the PCB. The drawback is that the machine used in the LCD manufacturing process to connect them is expensive, and they are near impossible to re-work.

It is possible to hand solder the tail to the PCB. Great care must be taken since the conductors of the tail are completely exposed in the area where they are soldered.

Another approach uses ACF (Anisotropic Conductive Film) combined with heat and pressure to make the electrical connection between the flexible tail and the PCB. This two-step process still uses heat, but the temperature involved is much less than soldering.

For development work, we have found that the SchmartBoards company makes a number of breakout boards in a number of pitches that work with our displays.

For any questions about TAB, COB, COF, COG, hot bar soldering, or what LCD module is best for your product, please contact our knowledgeable and friendly support staff via email, phone, or chat.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

Based simply on the peak temperature a PCB experiences during selective soldering, I can confidently say that you will not have any problems soldering an LCD glass display into your assembly.

Whereas your hand solder iron is at 700F as you say, most selective soldering (at least on our machines) occurs at a tip temperature of 280 Deg C or less. This has obvious advantages not just to the LCD display;in additionyou will notice an absence of measling, lifted pads, etc. on the PCB itselfwhen using a properly configured selective machine.

Speaking for our company only, we have done several samples for customers that had your exact application of an LCD glass display, in addition to customers using our machines that run that application every day.

It isn"t clear whether the LCD is on the solder side or the secondary side from your question, however, ACE has successfully processed boards of both configurations.

I would highly recommend a selective process to anyone looking to improve their through-hole process control and quality, especially if there are heat-sensitive components and PCBs (such as Teflon) that are otherwise vulnerable to a rogue soldering iron.

While we would suggest much more testing before recommending any process, soldering at 700F (370C) is a higher temp range and could require additional considerations. It would also be good to understand if the LED was placed with the pins facing upward, or if this was a through hole application currently being flipped and hand soldered.

Soldering from the top side with a flux core solder and hot iron tip could work better if: perhaps the joint area(s) was pre heated with hot air, the amount of solder was controlled for each joint, and the applied heating time was programmable for each joint, should there be any thermal profile differences.

Soldering from the bottom could yield good results but consideration should be given to: how the precise amount of flux is applied to only those areas/joints desired, The effects of higher temperatures on the soldering pot and the results of additional maintenance, fumes that result from bottom side soldering getting onto the glass LED surface, and possible bridging (if joints are too close together).

Typically, robotic type iron tip soldering can provide a very reliable and repeatable method to solder these types of applications. Cycle rates and volumes would need to be considered since the iron tip systems are a Point to Point soldering method.

Millions upon millions of LCD displays have been selectively soldered using both mass-selective wave and miniature-selective wave (drag) soldering process. It is a very reliable process that is much more robust than hand solder, and much more cost effective.

The process is used for both lead and lead-free applications in automotive, aerospace and other applications. Typical solder times range from 15-seconds per LCD (mass-dip) to a maximum of 1-second per termination in drag solder.

Jess Baker has been in manufacturing management positions for over 47 years. He is the President and founder of Repco Inc., and Robotic Process Systems. He is currently President of RPS Automation a manufacturer of Selective Soldering, and Solderability Test Equipment.

I would suggest using a stencil to apply paste and yes wave the LCD with a controlled reflow oven that you can profile and save the procedure for later projects and re-runs.

I would recommend soldering the LCD glass display with 44 pins to the PCB using a selective wave soldering process, as the selective wave offers a totally controllable and consistent soldering process, eg the temperature of the wave, the wave height, travelling speed and angle of the PCB (dwell time at each pin), the soldering environment (nitrogen gas surrounding the soldering process) and amount of flux applied at each pin.

The advantages using the manual soldering process is the low cost of the manual soldering station vs the high cost of the selective wave soldering machine, and machine size.

3mm clearance is not a problem, for a standard selective wave soldering machine. There are some high end models that can accept as close as 1mm clearance between soldering pads.

Selective soldering is a good option for this application, specifically using a mini-wave process. Depending on the thermal requirements of this LCD, the heat transfer can be controlled by the specific process parameters. These include mini-wave nozzle size, dwell time, and wave height. A selective soldering process will also be better controlled than hand soldering, assuring better consistency both in the soldering process and in fluxing and preheating.

If you"re considering doing this, you have a 25+ year old Corvette. Vibrations, current flow, heat and time conspire to cause internal components to break down and solder joints to break. This manifests itself in the following ways:

25-40W Pencil Soldering Iron with pointed cone tip ($8.99 at Radio Shack - don"t use soldering guns or higher heat soldering irons! If tip of the iron isn"t clean, smooth and tinned, don"t use it - you"ll damage the circuit boards)

Rosin Core Electrical 60/40 Lead/Tin Solder. Don"t use acid core solder or lead-free solder! We supply the correct solder with all of our components which require soldering.

Sunlight causes the LCD polarizing filters to fade, which causes the information on the cluster to disappear. The LCD panels should appear black while the cluster is off. If you can see the colored info when the cluster is off, the polarizing film has faded and should be replaced. Click Here to buy.

Removing Solder: Use the solder wick to remove the solder which holds the old components in place. Place the wick over the solder to be removed and heat the top side of the wick. When it"s hot enough, the solder will flow from the connection to the wick. Use a fresh (copper-colored) piece of wick for each removal.

When soldering, heat the connector lead and the solder pad on the circuit board (simultaneously). Once these two locations are sufficiently heated, feed fresh solder into the joint.

Over time, heat, vibration and bad design cause the board connectors or their solder joints to fail. Not all look as bad as the one in Figure 1, but they almost always need to be replaced.

3) On the bottom circuit board (the one you took out last), remove the old connector using a soldering iron and desoldering braid or another desoldering method of your choice. When the solder has been removed and the connector is ready to be removed, you should be able to pull it away from the board by hand. Don"t use force to remove the connector, as the hole plating (which connects top traces to bottom traces) can be damaged! See Figure 2.

4) The connector will tend to warp when resoldered, which results in unevenly spaced pins. You can prevent this by temporarily installing the top board connector onto the pins of the bottom board connector.

6) Using a soldering iron and desoldering braid (or a desoldering method of your choice), remove the old white connector from the top board. When the solder has been removed and the connector is ready to be removed, you should be able to pull it away from the board by hand. Don"t use force to remove the connector, as the hole plating (which connects top traces to bottom traces) can be damaged!

12) Heat from the factory bulbs causes the riveted connection of the dimmer transistor to become loose over time. Scrape the sides of the heat sink tab (opposite end from the three leads) and then solder it to the large heat sink pad on the bottom board. See Figure 7.

13) Inspect the polarizing filters on the LCD panels. If you see a fade ring around the edges, consider replacing the polarizing filters on the LCD panels. Now is the time to do that repair. Click Here to purchase.

15) If the black paint on the back of the LCD panels has worn through, light will shine through the panel in areas other than the places it should. Use black enamel acrylic paint designed for glass and a small paint brush to repaint that area. Note that we supply the correct paint and a brush if you purchase our LCD Polarizing Film kit. Be careful to avoid areas near the factory graphics, and in the areas of the LCD segments!

If your cluster displays randomly flickering LCD segments along with intermittent backlighting, the onboard power supply (Fig 1) may need to be rebuilt. We sell a kit of parts to replace commonly needed components - Click Here

Special software on the robotic soldering machine is easy to use as standard even for beginners. Function using the formula as a variable, you can make your own programs on the robotic soldering machine.

The robotic soldering machine’s capabilities and built-in sequencer has a simple to operate independently. Furthermore, robotic selective soldering machine can also be treated as a variable function formula, you can create your own original software and set in working conditions.

The J-CAT series of robotic selective soldering machine provide for an economical yet powerful selective solder system with a very small footprint. These Cartesian robotic selective soldering machine have a wide range of sizes for PCB’s up to 500 mm square. They can be programmed for either point or slide solder applications and utilize integral N2 for lead free applications.

User friendly robot teaching is achieved with a large LCD display. Using the block copy function, many other points can easily be entered after the first point is entered (step & repeat).

Recently purchased unit has a different address than the same part number purchased a year ago. It seems that if the small board is marked MH, the address is not going to be 0x27 or 0x20 but 0x3F. With that change of address, this display works and looks great.

On the software side, you have to download and install a new LiquidCrystal_I2C library for Arduino, which has the capability to talk to the LCD display over the I2C bus. Heres a link to the library. Follow the example code for the DFRobot board, which turns out to have the same configuration as this LCD, and it should fire right up for you. The LCD has white characters on a backlit blue background, and looked great.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In 1964, George H. Heilmeier, then working at the RCA laboratories on the effect discovered by Williams achieved the switching of colors by field-induced realignment of dichroic dyes in a homeotropically oriented liquid crystal. Practical problems with this new electro-optical effect made Heilmeier continue to work on scattering effects in liquid crystals and finally the achievement of the first operational liquid-crystal display based on what he called the George H. Heilmeier was inducted in the National Inventors Hall of FameIEEE Milestone.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically use

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey