lcd module 1602a qapass datasheet pdf supplier

LCD display for replacing a broken one or for creating something new. This LCD display can be used easily with Arduino, Raspberry Pi, Intel Edison or any other embedded system you want to work with.

Due to the ancient LCD controller technology made by Hitachi, the board controller requires 5VDC operating voltage. In order to easily use this display with say Raspberry Pi (3,3VDC) you need to hack this display a bit. In order to make it work with lower operating voltage, add a 8pin voltage converter such as ICL7660 (or similar) onto the space indicated with label U3. Then populate C1 and C2 with 10µF SMD capacitors and remove J1 solder bridge. To finalize the job enable the voltage converter by soldering a solder bridge across the J3 contact pins. You have now an LCD display capable of operating with lover operating voltage.

Directory Summarize Shape dimension Module mainly hardware description The external interface module Command instructions Ceading and writing operation sequence Software initialization...

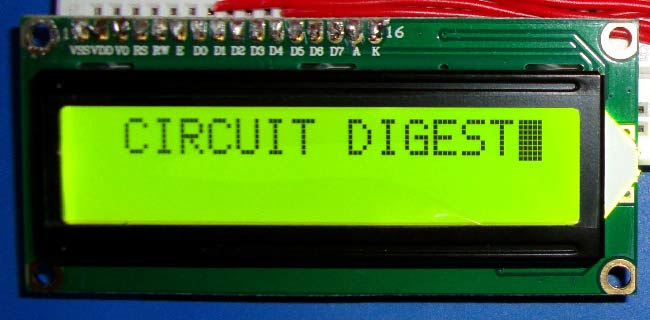

Summarize (1602A QAPASS )is an industrial character type LCD, can also shows that 16 x02 namely 32 characters. (16 column 2 line) Second:module size (pictured) Three:pin interface specifications table Numbers symbols pin pin that Numbers symbols that Numbers symbols Pin that...

1 foot: for to power VSS. 2 feet: VDD take 5 V is power. 3 feet: VL for LCD contrast the adjustment, and then when the power is the weakest contrast, grounded contrast the highest, and the contrast Through high can produce the "ghost", when used, can pass...

4. 1602 LCD instructions in time sequence that 1602 LCD module internal controller of article 11 control instruction, as the chart shows: Numb instructions Clear display Cursor to return to Buy input mode Display the on/off control The cursor or character shift Buy function Buy character CunZhuQi...

4: control command table 1602 LCD module of reading and writing, and the screen and light mark operation operations are through the instructions of programming realize. (note: 1 for high Level, 0 for low level) Instruction 1: clear display, instruction code 01 H, the cursor is reset to address 00 H position. Instruction 2: the cursor reset, the cursor to return to address 00 H.

The basic operation sequence table Graph: read operation sequence Graph: write operation sequence 1602 LCD RAM address mapping and standard word stock list. Liquid crystal display module is a slow display device, so in the execution eachinstruction before must affirm module mark is busy low electricity Flat, said were not busy, otherwise this instruction failure.

LCD 16X2 Blue Backlight provides a 16 characterX2 line LCD with I2C interface for easy control by a uC. 16X2 Blue Backlight LCD-1602 IIC I2C 16-Character 2-Lineare extremely common and is a fast way to have your project show status messages.

LCD 16×2 is composed of a 16 character x 2 line LCD display with a blue backlight and white characters. Each of the characters are composed of a 5 x 8 dot matrix for good character representation.

The module offers a resolution of 480×320 pixels and comes with an SD card slot through which an SD card loaded with graphics and UI can be attached to the display.

The module is also pre-soldered with pins for easy mount (like a shield) on either of the Arduino Mega and Uno, which is nice since there are not many big TFT displays that work with the Arduino Uno.

Large TFT LCD display based on the ILI9486 controller. Compared to the popular 2.4″ model the active area of the screen is practically twice. As well as the resolution.

The Arduino Mega2560 module is a 3.5-inch TFT LCD module with 480×320 resolution and 65K color display. It uses 16-bit line parallel port communication, and the driver IC is ILI9486.

The module includes an LCD display, 5V ~ 3.3V level to the circuit, can be directly plugged into the Arduino mega2560 development board, also supports SD card and SPI Flash function expansion.

The 3.5 inch TFT LCD Screen ILI9486 480X320 Display comes with 480×320 pixels with individual pixel control. It has way more resolution than a black and white 128×64 display.

As far as I know, if all the connections and power busses are correct, and you"re using series protection resisters between the 5V LCD and the 3.3V Propeller pins, then the on power up all "generic" HD44780 LCD"s will be in factory default 8-bit data mode and must be programmed (initialized) by the driver first to work in 4-bit mode. You do not need all eight (db0-db7) LCD pins connected to initialize to 4-bit mode (db4-db7 connected).

I"m using a 5V (only) 4x20 P/N YB2004A HD44780 compatible LCD with blue background and white characters in 4-bit mode. Many have used this particular LCD module with success.

All the LCD data I/O and control lines are connected to the 3.3V Propeller via 4.7K resistors for protection. All my connections to/from the LCD are less than around 3 inches and connected directly to the prop pins on my tried and true home-brew DIP Propeller dev board.

The first time I connected the brand-new out-of-the box LCD and ran the jm_lcd4_ez driver object it worked fine. Just as expected from what I can see in the driver demo object when properly configured for my 4x20 LCD connected to the Prop-I.

The contrast is set properly on my LCD from the first succesful run of the jm_lcd4_ez object. My LCD likes 0.7V on the contrast pin, which from my experience is correct. At the moment I"m setting the contrast from the wiper of a small Bournes PCB mount 10K multi-turn pot with the pot"s end-leads connected between 5V and GND. 5V is connected to the CW rotation wiper end.

Tip: If you don"t want to use a pot to set the contrast, try putting a signal diode like a 1N914/1N4148 diode with cathode to ground in series with a 4.7K or 10K resistor to 5V, then connect the diode cathode to the LCD"s contrast pin. This should set your contrast pretty-much correct without having to use a pot or a fixed divider. But before doing this you may want to verify your LCD contrast is OK with around 0.7V on the contrast pin with a pot first.

With the backlight on the 5V bus is reading about 4.9V, so the backlight isn"t overloading the 5V power bus. The backlight is drawing around 110mA which is as expected for this 4x20 LCD. My 5V bus is regulated via a venerable 7805 regulator fed with 8V.

Next, with the jm_lcd4_ez driver working, and without making any changes to the driver example code, I reloaded the previously working jm_lcd4_ez object code into the Prop RAM.

Any type of power on/off reset and reload of the object doesn"t work. Now the LCD just sits with the top-most line and third line from the top all pixels on and the other two lines blank. I think this may be the correct initial power on display for the 4x20 LCD. I remember with 16x2 HD44780 LCDs that power on reset with no data coming in results typically in the top line being all pixels on and the second line being blank.

As I remember, these generic HD44780 LCD"s don"t have any hardware reset pin. The LCD"s are reset to factory defaults upon power up with no non-volitile storage on the LCD. You have to properly re-initialize the LCD for data-pins used (4 or 8) etc. in software upon first power-up every time. If this is indeed true in my case, then I shouldn"t be seeing this problem unless there is a hardware interconnect problem.

Next I added a three second delay to both of the objects mentioned above right after power up and before the LCD is initialized. This was just to make sure everything settles down before communication with the LCD starts.

1. For a third time, reconnect and recheck the LCD/Prop interconnections. Maybe make the leads shorter or reduce the 4.7K protection resistors to something like 2.2K (in desperation).

The "4-bit Parallel LCD driver" by Chris Gadd in Obex is very well documented, worth a read IMO. Unfortunately for me I"m trying to use a 4x20 LCD, this object is for 16x2 only. I"m not sure if this matters for a simple test though. I may give it a try:

* Recheck all your LCD connections. Keep them short. Try to separate the pins for the control lines to reduce cross-talk (the four data connections typically all need to be contiguous). I do not recommend trying to drive the LCD via a "plug breadboard". Make a direct connection cable with series resistors "mash-up" cable instead. An old floppy drive connector/cable cut down (short) with soldered series 1/4 or 1/8 Watt resistors can be used for this in a pinch. Apply some hot glue to the resistors to keep them in parallel, at least for the four LCD data pins, if you are separating the I/O control pins.

* Be SURE to use series protection resistors between the 5V LCD and the 3.3V Propeller to prevent damaging the Propeller during power-up and LCD initializatoin or LCD read.

* Recheck how you are setting the LCD pins in the driver object. Check the pins with a logic analyzer if you have one (I use the Open Bench Logic Sniffer).

* Try putting a waitcnt delay of several seconds in your LCD demo object before the LCD initialization occurs to allow things to settle down before the LCD driver starts communicating with the LCD. This example will introduce a wait of 3 seconds:

* Try the LCD without the backlight on. Maybe the backlight is overloading your 5V bus. The backlights take a lot of current. If you do use the backlight, make sure the 5V bus voltage is within tolerance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey