tft lcd gate driver ic factory

For TFT-LCD panel manufacturing, gate driver circuit with amorphous silicon thin-film transistor (TFT-ASG circuit) plays an important role. In this paper, we propose two different ASG driver circuit topologies to improve crucial dynamic characteristics and then optimize them with circuit sizing by simulation-based evolutionary method which integrates genetic algorithm and circuit simulator on the unified optimization framework [1]. The first circuit consisting of fourteen a-Si:H TFT devices is designed for the specifications of the rise time

A not-for-profit organization, IEEE is the world"s largest technical professional organization dedicated to advancing technology for the benefit of humanity.

Have your product stand out with the DT050ATFT display - our 5” TFT LCD module with full viewing angle. The full viewing angle feature allows the display contents of the LCD to be visible from practically any angle. It"s a cost-effective enhancement compared to using an IPS display. The 5" TFT has 800 x 480 RGB resolution and supports 24-bit parallel RGB input mode. The LCD uses two driver ICs to drive the display: a source driver with TCON (Ilitek ILI6122) and a gate driver (Ilitek ILI5960). It also is available with either a resistive touchscreen or capacitive touchscreen panel. This 5 inch LCD is an ideal option for a variety of digital devices including video or POS systems.

This article will take you through a high level overview of all of the parts of a TFT LCD display. The vast majority of what I have read on the internet makes this whole issue massively complex. I’m quite sure that this complexity problem is a real reflection of the serious design and manufacturing complexity in these displays and drivers. That being said, to get a conceptual understanding is much simpler, and is the point of this article.

A significant amount of my learning about this subject came from a 195 page powerpoint presentation by Dr. Fang-Hsing Wang entitled “Flat Panel Display : Principle and Driving Circuit Design“. He has graciously allowed me to reproduce a few of his images. This dude knows way way more about these circuits than I do and I would encourage you to read his work.

The fundamental element in a TFT display is the liquid crystal. These elements have the property that the crystals will align from horizontal (which blocks the light) to vertical (which lets most of the light through) based on the electric field applied to them. Basically, you shine light through the liquid crystal, which blocks some or all of the light, the remainder of the white light then goes through a color filter to make red, green, or blue. It works like this:

This architecture means that every pixel in the display will require a red, green and blue element. And, you will need to control the voltage on all of the elements (which will be quite a lot on a screen of any size)

What does the schematic for one element in a pixel look like? And where is the T(transistor) in the TFT? The three letter acronym TFT stands for a thin film transistor that is physically on the top of the LCD matrix right next to each liquid crystal element. Here is a schematic model for one element in the array. C-LC represents the capacitance of the liquid crystal. CS is a storage capacitor that is used to hold the electric field across the liquid crystal when the transistor is OFF. To apply a voltage across the LC you just turn on the gate and apply the correct voltage to the column commonly known as the source.

You should notice that the “back” terminal of the two capacitors is called “VCOM” and is physically on the other side of the liquid crystal matrix from the TFT. All of the liquid crystal backsides in the display are connected to the same VCOM. A bit of painfulness in this system is that the CS capacitor leaks, which means that the LCD changes state which means that each pixel must be updated, properly called refreshed, on a regular basis.

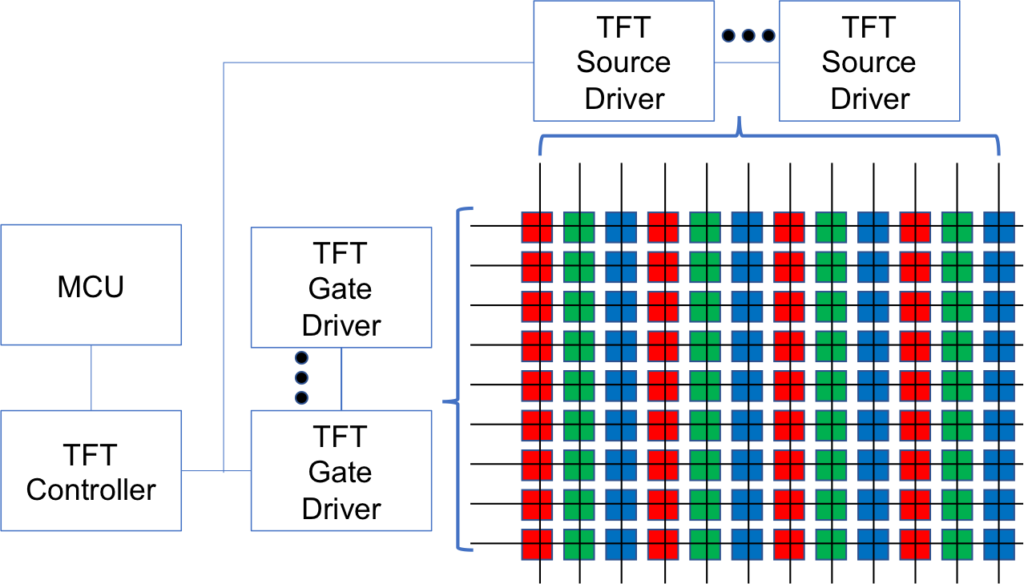

We know that each pixel has three three thin film transistors, three capacitors, three color filters (red, green and blue) and that we need to control the voltage on the source/drain of each transistor in order to cause the right amount of light to come through the liquid crystal. How do we do that? The first step is to arrange all of the pixels in a matrix. Each row of matrix has all of the gates connected together. And each column of the matrix has all of the sources tied together. In order to address a specific pixel RGB element, you turn on the correct row and then apply a voltage to the correct column at the right time.

If you have been thinking about this system you might have done a little bit of math and figured out that you are going to need an absolute boatload of source and gate driver signals. And you would be right! For example, a 4.3″ screen with 480×272 will require 480x272x3 elements which are probably organized into 480 rows by 816 columns. This would require a chip with at least 480+816=1296 pins, that is a lot. It turns out that for small screens <=3.5″ there are chips with enough pins to do the job. But, for larger screens, it requires multiple chips to do the job. The “…” in the picture above shows the driver chips being cascaded. The next thing to know is that “TFT Glass” usually has the driver chip(s) embedded into the screen at the edge (you can see that in the picture from Innolux above).

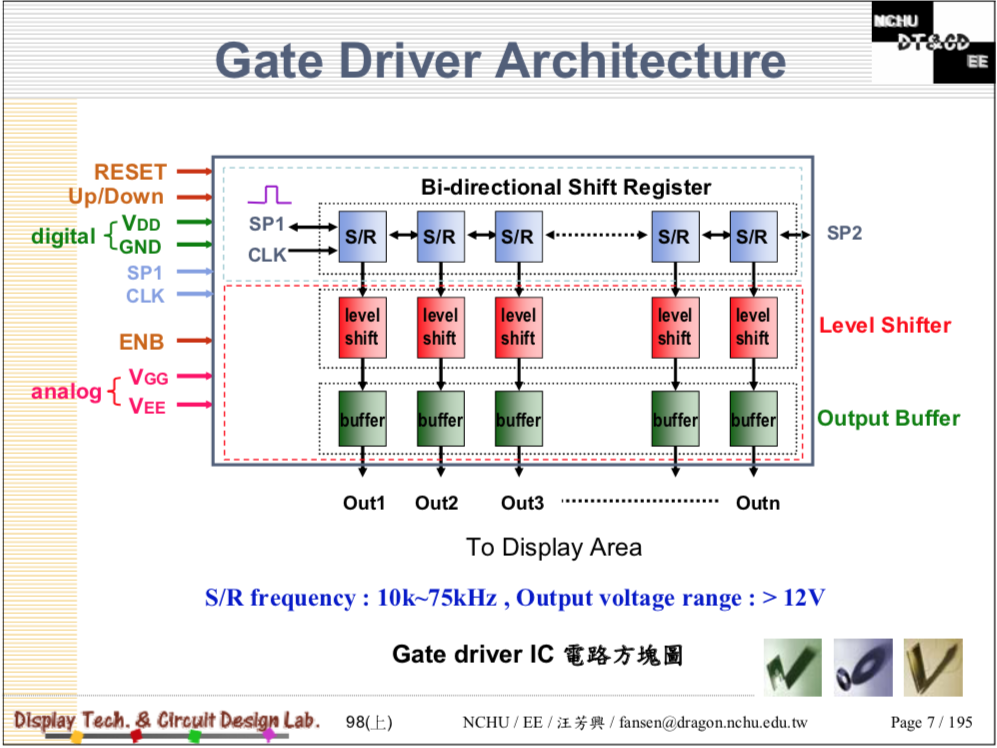

You must put a quite high voltage source >20v and drain <-10V across the liquid crystal at the right time to get it to do its thing. In order to pass that source voltage, the gate must be turned on at the right time to the right voltage, this is the purpose of the Gate Driver IC. The gate driver is conceptually simple and Dr. Wang drew a nice picture on page 7 of his presentation. You can see that it is basically a shift register, with one element per gate. You shift in a “1” and then clock it through the entire shift register which will have the effect of applying a 1 to each gate.

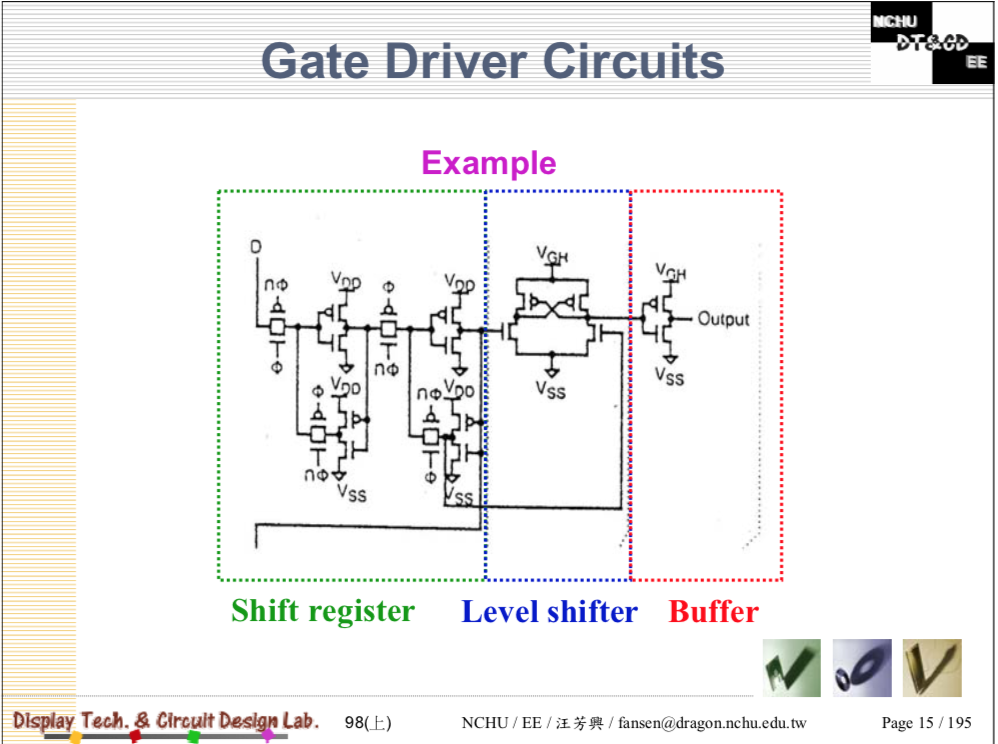

However, a 3.3v logic 1 is not anywhere high enough to drive the gate so that it can pass the much higher source voltage. So, you need to level shifter and a buffer to get the “right” voltage. On page 15, Dr. Wang made a nice picture of this circuit as well.

It turns out that this picture is conceptually correct, but the exact implementation has “a lot going on”. You can read about the next layer of circuit design in his presentation on pages 15-35.

In its most basic form, the TFT source driver is responsible for taking an 8-bit digital input value representing the value of an individual LCD element and turning it into a voltage, the driving the voltage. Like this:

In reality there is some compromise of chip size, number of pins and time that is made by multiplexing pins, columns and rows. For example, many of the small screens appear to have 1 column driver for all of the reds, 1 driver for the blues and one for greens.

What appears to happen in real life on bigger screens is some combination of column and row multiplexing. In one display that I found there were 2x the number of rows which allows the columns to be multiplexed 2-1. The display is 1024×600. That requires 1024*3 RGBs in the column = 1536 pins. This means that you need to double the number of gate drivers, resulting in 1200 pins in the row direction. Here is a picture from their datasheet.

The last issue that I will address in TFT LCD drivers is called Gamma Correction or more simply Gamma. Gamma is an intensity adjustment factor. For any given digital intensity input, you will need a non-linear translation to a voltage output on the source. For example a doubling of digital input (so that a pixel appears twice as bright) you will not double but instead will have some non-linear translation of the output voltage.

The good news is that this gamma correction is built into the display drivers. From my reading, this is sometimes done with digital processing, and sometimes done with an analog circuit. But in general, it appears to be tuned and programmed into the driver by the panel vendor for these smaller display.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Liquid crystal display (Liquid Crystal Display, LCD) has that fuselage is thin, power saving, the many merits such as radiationless, be widely used.As: LCD TV, mobile phone, personal digital assistant (PDA), digital camera, computer screen or notebook computer screen etc., occupy an leading position in flat display field.

Liquid crystal display major part on existing market is backlight liquid crystal display, and it comprises display panels and backlight module (backlight module).The principle of work of display panels is at thin-film transistor array base-plate (Thin Film Transistor Array Substrate, TFT Array Substrate) and colored filter substrate (Color Filter, CF) liquid crystal molecule is poured between, and on two plate bases, apply driving voltage to control the sense of rotation of liquid crystal molecule, so that the light refraction of backlight module is out produced picture.

In active liquid crystal display, each pixel is electrically connected a thin film transistor (TFT) (TFT), the grid (Gate) of thin film transistor (TFT) is connected to horizontal scanning line, drain electrode (Drain) is connected to the data line of vertical direction, and source electrode (Source) is then connected to pixel electrode.Horizontal scanning line applies enough voltage, the all TFT be electrically connected on this horizontal scanning line can be made to open, thus signal voltage on data line can writing pixel, controls the penetrability of different liquid crystal and then reaches the effect controlling color and brightness.GOA technology (Gate Driver on Array) i.e. array base palte row cutting technology, is utilize the array process of display panels to be produced on tft array substrate by gate driver circuit, realizes the type of drive of lining by line scan to grid.GOA circuit has the advantage that can reduce production cost He realize narrow frame design, is applicable to liquid crystal display.

According to the difference of the active layer material used, GOA circuit can be divided into amorphous silicon (Amorphoussilicon, a-Si) GOA circuit, indium gallium zinc oxide (Indium Gallium Zinc Oxide, IGZO) GOA circuit, low temperature polycrystalline silicon (Low Temperature Ploy Silicon, LTPS) GOA circuit etc., often kind of GOA circuit can use different processing procedures again.LTPS, owing to having the advantage of high electron mobility and technology maturation, is widely used by the GOA circuit in small-medium size LCD at present.

Along with the development of display technique, people have higher requirement to the attractive in appearance of LCD, and the width of frame, as one of aesthetic key element, is subject to the great attention of each LCD manufacturer.Many factors all can affect the border width of LCD, and as frame glue material, cutting technique, board precision etc., except above-mentioned factor, the width of GOA circuit is also one of important influence factor.

Figure 1 shows that the basic functional principle schematic diagram of GOA circuit.GOA main circuit will have two basic functions: first is input scanning pulse signal (Gate pulse) function, drive the sweep trace (Gate line) in panel, open the TFT in viewing area, data line (Data line) can be charged to pixel; Second is shift LD function, after the n-th scanning pulse signal G (n) has exported, can control the output carrying out (n+1)th scanning pulse signal G (n+1), and hand on according to this by clock signal.

Figure 2 shows that the basic structure block diagram of GOA circuit under CMOS processing procedure.This GOA circuit is made up of four parts: latch (Latch), Sheffer stroke gate (NAND), buffer unit (Buffer) and reset cell (Reset), described latch is electrically connected Sheffer stroke gate and reset cell, and described Sheffer stroke gate is electrically connected latch and buffer unit.Reset signal input reset cell, input signal and the first clock signal input latch, second clock signal input nand gate, outputs signal and exports from buffer unit.Because buffer unit is output stage, need to have very strong driving force, in usual buffer unit, the size of TFT is very large, takies very large arrangement space, is unfavorable for the width reducing LCD frame.

Please refer to Fig. 3 and Fig. 4, the buffer unit in existing GOA circuit comprises by the first metal layer 10, second metal level 20 and is located at multiple TFT that the active layer 30 between the first metal layer 10 and the second metal level 20 forms; The grid of each TFT is formed by the first metal layer 10, and the source electrode of each TFT is formed by the second metal level 20 with drain electrode, and source electrode lays respectively at the both sides of grid with drain electrode; The source electrode of the corresponding TFT of active layer 30 and the region of drain electrode are ion heavily doped region 301, source electrode and the drain electrode of TFT are connected with the ion heavily doped region 301 of active layer 30 respectively via a via hole 601, the region between the source electrode of the corresponding TFT of active layer 30 and drain electrode is channel region 302.Because this existing buffer unit only uses the first metal layer 10 to form the grid of TFT, the channel region 302 of active layer 30 is positioned at above grid, thickness is thin, impedance is large, in order to the driving force of Promoting Layered Buffer device unit, usual needs increase the length of channel region 302, although this kind of method increases the driving force of buffer unit, the width of buffer unit also can increase thereupon, the width of corresponding GOA circuit increases, and is unfavorable for the width reducing LCD frame.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey