connecting tft lcd touch screen with nodemcu esp8266 supplier

Simply put: that TFT requires a lot of GPIO pins - 10 at an absolute bare minimum, but better if you have more available. The ESP8266 doesn"t have many IO pins - and some of them are very sensitive about what they can be connected to without affecting the boot process.

If you are careful with your GPIO selection it may be possible to work with that screen. There are no specific requirements for what pins need to be connected to where (as far as hardware functionality goes), so it"s up to you to find the right combination that doesn"t cripple the boot process (stay away from GPIOs 0, 2 and 15 if you can).

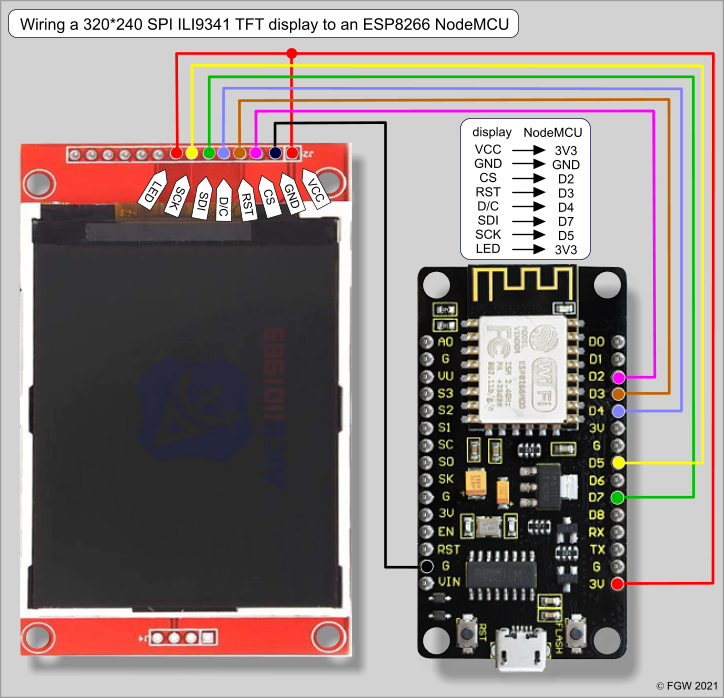

The ILI9341 TFT module contains a display controller with the same name: ILI9341. It’s a color display that uses SPI interface protocol and requires 4 or 5 control pins, it’s low cost and easy to use.

The resolution of this TFT display is 240 x 320 which means it has 76800 pixels. This module works with 3.3V only and it doesn’t support 5V (not 5V tolerant).

The ILI9341 TFT display board which is shown in project circuit diagram has 14 pins, the first 9 pins are for the display and the other 5 pins are for the touch module.

Pins D5 (GPIO14) and D7 (GPIO13) are hardware SPI module pins of the ESP8266EX microcontroller respectively for SCK (serial clock) and MOSI (master-out slave-in).

The first library is a driver for the ILI9341 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “ili9341” and choose the one from Adafruit).

The ILI9341 TFT display is connected to NodeMCU hardware SPI module pins (clock and data), the other pins which are: CS (chip select), RST (reset) and DC (data/command) are defined as shown below:

Full Arduino code:The following Arduino code is from Adafruit ILI9341 library (graphicstest.ino) with some modifications in order to work with the above circuit diagram.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

New to the ESP8266? Start here! The ESP8266 is a Wi-Fi System on a Chip (SoC) produced by Espressif Systems. It’s great for IoT and Home Automation projects. This article is a getting started guide for the ESP8266 development board.

New to the ESP8266? You’re in the right place. This guide contains all the information you need to get started with this amazing board. Learn what is an ESP8266, what is it used for, how to choose an ESP8266 development board, how to upload your first program, and much more.

It can be used as a standalone device, or as a UART to Wi-Fi adaptor to allow other microcontrollers to connect to a Wi-Fi network. For example, you can connect an ESP8266 to an Arduino to add Wi-Fi capabilities to your Arduino board. The most practical application is using it as a standalone device.

With the ESP8266, you can control inputs and outputs as you would do with an Arduino, but with Wi-Fi capabilities. This means you can bring your projects online, which is great for home automation and internet of things applications. Why is the ESP8266 so popular? Mainly for the following reasons:

Low-power: the ESP8266 consumes very little power when compared with other microcontrollers and can even go into deep sleepmode to consume less power;

Wi-Fi: the ESP8266 can generate its own Wi-Fi network (access point) or connect to other Wi-Fi networks (station) to get access to the internet. This means the ESP8266 can access online services to make HTTP requests or save data to the cloud, for example. It can also act as a web server so that you can access it using a web browser and be able to control and monitor your boards remotely.

Compatible with the Arduino “programming language”: those that are already familiar with programming the Arduino board, were happy to know that they can program the ESP8266 in the Arduino style.

Compatible with MicroPython: you can program the ESP8266 with MicroPython firmware, which is a re-implementation of Python 3 targeted for microcontrollers and embedded systems.

There is a successor of the ESP8266—the ESP32. The ESP32 combines Wi-Fi and Bluetooth and is dual-core. If you want to start with any of these boards, we recommend getting an ESP32. If you already have an ESP8266, don’t worry. It works great, it has a huge community and it does the job for most DIY IoT projects.

There are several versions of the ESP8266 modules as shown in the picture below. The ESP-01 and ESP-12E are the most popular versions. You’ll find a wide variety of development boards with ESP-12E or ESP-12F chips.

These come with all the needed circuitry to apply power, upload code, easy access to the GPIOs to connect sensors and actuators, an antenna for the Wi-Fi signal, and other useful features.

There is a wide variety of ESP8266 boards from different vendors. While they all work in a similar way, some boards may be more suitable for some projects than others. When looking for an ESP8266 development board there are several aspects you need to take into account:

USB-to-UART interface and voltage regulator circuit. Most full-featured development boards have these two features. This is important to easily connect the ESP8266 to your computer to upload code and apply power.

Pin configuration and the number of pins. To properly use the ESP8266 in your projects, you need to have access to the board pinout (like a map that shows which pin corresponds to which GPIO and its features). So make sure you have access to the pinout of the board you’re getting. Additionally, some boards have more accessible GPIOs than others. That’s a factor you should take into account depending on your project features.

Size. There is a wide variety of ESP8266 development boards with different sizes. Some boards benefit from a small form factor, which might be very practical depending on your project features. Usually, smaller boards have a small number of available GPIOs like the ESP-01.

Antenna connector. Most boards come with an onboard antenna for the Wi-Fi signal. Some boards come with an antenna connector to optionally connect an external antenna. Adding an external antenna increases your Wi-Fi range.

The best ESP8266 development board for your project will depend on what you intend to do. If you’re just getting started with the ESP8266 board, we recommend using theESP8266-12E NodeMCU Kit.

The ESP12-E NodeMCU Kit is one of the most used ESP8266 development boards. It features 4MB of flash memory, access to 11 GPIO pins, and one analog-to-digital converter (ADC) pin with 10-bit resolution. In addition, the board has a built-in voltage regulator, and you can power up the module using the mini USB socket or the Vin pin.

Uploading code to the board is as easy as uploading code to the Arduino. There’s no need for an FTDI programmer or extra circuitry, as it has a built-in USB-to-serial converter. Most boards come with the CP2101 or CH340 chips.

It comes with an onboard antenna for Wi-Fi signal, and comes with RST and FLASH buttons to reset the board and put it into flashing mode. There is a blue LED internally connected to GPIO 2, which is very practical for debugging.

This is the ESP8266 board model we use more often in our Wi-Fi and IoT projects. It is very versatile, and it’s great for beginners. So, if this is your first time with the ESP8266, this is the module we recommend: ESP8266 12-E NodeMCU Kit.

The ESP-01 is super small and fits in any enclosure, so it’s perfect for finished projects. However, it is very limited in the number of accessible GPIOs and doesn’t have a built-in voltage regulator, so you need to use a 3V3 power source or add a voltage regulator to drop the input voltage to 3V3. Additionally, it doesn’t come with a USB-to-serial converter, which means you need an FTDI programmer or a specific programmer board to upload code.

The WeMos D1 Mini offers 4MB flash memory, 11GPIOs, and 1 ADC pin in a minimal and small setup. The community has developed a wide variety of shields for the D1 mini board, which allows you to build small and simple setups with almost no wiring required. You just need to stack the shields to connect multiple peripherals. It comes with a built-in voltage regulator and USB-to-UART converter, which makes it easy to upload code. For these reasons, this might also be a good choice for beginners.

There are many other versions of different ESP8266 boards. Most boards work in a similar way. Just make sure they are suitable for your project requirements.

The most widely used ESP8266 NodeMCU development boards are the ESP8266-12E NodeMCU Kit, the Wemos D1 Mini, and the ESP-01. We’ll show you the pinout for those boards. A pinout is like a map that shows which pin corresponds to which GPIO and its features. This way, you should know which GPIOs to use if you need to use SPI, I2C, ADC, or others.

If you get a different board, you should be able to find its pinout with a quick google search. Here we’ll just take a quick look at the pinout. We recommend reading the following article that shows a detailed explanation of the ESP8266 pinout and how to use its GPIOs: ESP8266 Pinout Reference: Which GPIO pins should you use?

Usually, all boards come with power pins: 3V3, GND, and VIN. You can use these pins to power the board (if you’re not providing power through the USB port), or to get power for other peripherals (if you’re powering the board using the USB port).

One important thing to notice about the ESP8266 is that the GPIO number doesn’t match the label on the board silkscreen. For example, D0 corresponds to GPIO16 and D1 corresponds to GPIO5. When programming your boards using Arduino IDE, you must use the GPIO number and not the number on the silkscreen. This applies to most ESP8266 boards.

Different ESP8266 GPIOs have specific features, so you must choose the pins for your projects wisely. Otherwise, you may end up getting unexpected results.

We recommend taking a look at our ESP8266 GPIO guide which shows in great detail the function of each GPIO and how to pick the best GPIOs for your project:

There are many different ways to program the ESP8266 using different programming languages: Arduino C/C++ using the Arduino core for the ESP32, Micropython, LUA, and others.

Our preferred method is programming the ESP8266 using the “Arduino programming language” with Arduino IDE or VS Code. For beginners, we recommend getting started with Arduino IDE.

To program your boards, you need an IDE to write your code. For beginners, we recommend using Arduino IDE. While it’s not the best IDE, it works well and is simple and intuitive to use for beginners. After getting familiar with Arduino IDE and you start creating more complex projects, you may find it useful to use VS Code with the PlatformIO extension instead.

If you’re just getting started with the ESP8266, start with Arduino IDE. At the time of writing this tutorial, we recommend using the legacy version (1.8.19) with the ESP8266. While version 2 works well with Arduino, there are still some bugs and some features that are not supported yet for the ESP8266.

Don’t install the 2.0 version. At the time of writing this tutorial, we recommend using the legacy version (1.8.19) with the ESP8266. While version 2 works well with Arduino, there are still some bugs and some features that are not supported yet for the ESP8266.

In the Arduino IDE, you can find multiple examples for the ESP8266 board. First, make sure you have an ESP8266 board selected in Tools> Board. Then, simply go to File> Examplesand check out the examples under the ESP8266 section.

You just need to go to Tools > Board > Boards Manager, search for ESP8266, and check the version that you have installed. If there is a more recent version available, select that version to install it.

First, make sure you have an ESP8266 selected in Tools> Board. If you’re using the ESP8266-12E NodeMCU Kit as shown in previous pictures, select the NodeMCU 1.0 (ESP-12E Module) option. If you don’t know what’s your board, you can always select the Generic ESP8266 Module.

Warning: you must use a USB cable with data wires. Some USB cables from chargers or power banks are power only and they don’t transfer data—these won’t work.

1)Go to Tools > Board, scroll down to the ESP8266 section and select your ESP8266 board. If you don’t know what’s your board, the Generic ESP8266 Module usually works fine for most boards.

After connecting the ESP8266 board to your computer, if the COM port in Arduino IDE is grayed out, it means you don’t have the required USB drivers installed on your computer.

If you want to build your own IoT and Home Automation projects with the ESP8266 boards and need some help getting started, we have the best resources for you.

Home Automation with the ESP8266: this is our premium ESP8266 eBook. Learn how to use the ESP8266 to automate your house. Even if you are an absolute beginner, you’ll be able to follow along and come up with your own IoT projects.

We hope you’ve found this getting started guide useful. I think we’ve included all the required information for you to get started. You learned what is an ESP8266, how to choose an ESP8266 development board, and how to upload new code to the ESP8266 using Arduino IDE.

With the TFT display you can display colorful images or graphics. This module has a resolution of 480 x 320. This module includes the SD card socket and SPI FLASH circuit.

This is a tiny display with just 1 x 0.96 Inch. This display has a black background, and displays characters in white. There are other similar displays that can show the characters in other colors.

For an upcoming new project I wanted a colour (UK spelling) LCD screen (ideally OLED), 256×256 (or greater) resolution and nice and cheap. It was not an easy 2 minute task. There were no OLED screens offering what I wanted (that I could see at the time). So compromises were made, in the end I purchased a 128×128 pixel screen (none OLED) for around $3.50 (£3.20, 3.50 Euro). Not as cheap as I thought I might get one for but the cheapest I could find. There were a lot of sellers offering this screen and it’s shown below.

As can be seen from the connections it accepts both 5V and 3.3V with the 5V side having a pre-soldered pin header. This particular one was ordered from Ali-Express and had a picture of a cartoon boy on the screen. I suspect buying any with the same pin connections will give you the same screen as the one above.

For my new project (after the Space Invaders one, see https://www.xtronical.com/programming-series-space-invaders-on-arduino/), I wanted a screen where I could directly port the Arcade graphics and screen layout without too much messing about re-designing graphics. But for the price point I wanted this proved impossible. Most arcade games of the early 80’s did not go above 256 pixels in any give direction so porting the graphics should be easy I thought. At half the resolution I hope that transferring the graphics will not be too tedious and that in most cases I can simply reduce the number of pixels in each image by half.

Due to the planned game being more advanced than Space Invaders I needed a processor with more memory and speed than the Arduino could offer. Enter the ESP8266 processors which offer faster speeds and lots and lots more memory. Wifi is also available but will not be required for this project unless we implemented a World High Score Table perhaps! There are newer versions, ESP32, available with even more power but are more expensive and we don’t need that level of performance for this project. I’m using a NodeMCU from Lolin, which is basically a breakout board for the ESP8266 so that you can use it easily on breadboards or small production runs using through hole.

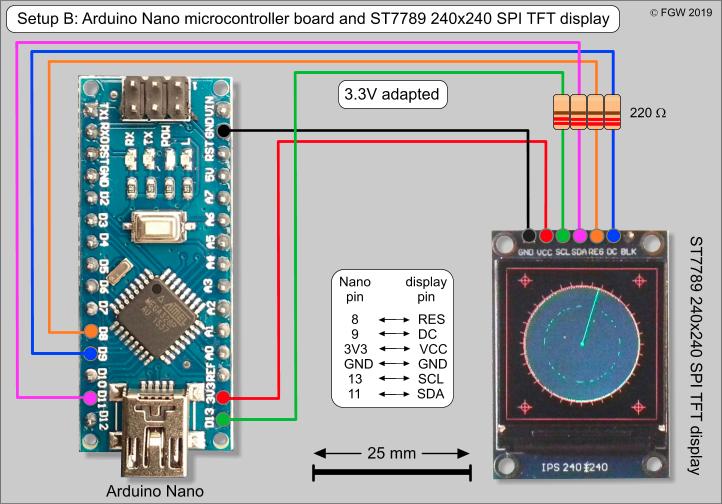

Connections – very careful now!Looking at the back we can see +3v3 (this screen can be powered from 5v as well), several grounds (Gnd) and SCL/SDA. This shouldmean that this device is an I²C device and can be easily connected to our Arduino. Err… Think again. This screen gave me no end of problems as connecting it to the I²C connections and running any demo I could find on the internet did not get anything on the display. I went back and looked at the listing for this device, it stated SPI Bus not I²C ! So it began to become apparent that this screen had an SPI interface. SCL and SDA would logically seem to be SPI clock and data (MOSI) respectively but other pin labels didn’t match normal SPI protocol labels. Reading several resources for other different screens and looking at the source code for the examples in the Arduino IDE Examples library lead me to find the correct connections to power and use this screen.

Power is self explanatory. LED adds a little extra brightness to the screen but it does still work if not connected. I’ve seen resistors added in series here and even variable ones to vary the brightness but I’ve ran it directly connected on this screen with no issues and wouldn’t want it dimmer as its not ultra bright. It is actually on even when not connected giving adequate brightness in my opinion. SCL is the SPI clock and goes to the NodeMCU’s hardware SPI pin (pin D5). SDA is actually the SPI MOSI connection and goes to the NodeMCU’s SPI MOSI pin (D7). RS is a Regsiter Select pin for ST7735 driver chips, this maps to a variable called TFT_DC in the Adafruitcode (explained later) that I was using for testing. This controls whether we are sending a command to the ST7735 chip or actual data. I think that Adafruit call it DC meaning Data Control, but I’m not sure. On some boards it may even be referred to as A0. For our purposed we connect it to D4. RST is the screen reset and and is connected to pin D3. These last two can connect to any NodeMCU pins that are not used for other functions. CS is Chip Select (usually referred to as Slave Select in the SPI protocol) and again can connect to any pin but I use D2. If this is pulled low then this device can receive or send data on the SPI bus. If only one device in your design you could pull this low permanently and not use D2.

Driver CodeWhen presented with this board (as mentioned above) it was difficult to work out where wires should go and what driver software I needed for the display. Looking at the solitary chip on the board and Googling revealed nothing. So I went back to the sellers listing and found buried deep in a sub-page description the phrase “7735 drive”. Googling this revealed Adafruit had written some drivers for this chip for a board they had created (which also had an SD card slot on it as well). It was not surprising I didn’t find the 7735 chip on the board as this chip is designed to by embedded onto the back of the screen. It was being armed with this source code and other web pages dealing with different chip sets but similar displays that I managed to work out (with a little trial and error) the connections talked about previously above. Initially I used the Adafruit driver code but gave issues with this screen (as it was designed to work with the one they sell). Look below.

Also when the screen orientation is rotated (in software) so you can write to the display any way up then more things either correct themselves or mess up again.

Fixing the ST7735 driver to work with this screen.So we have some work to do still to make this work well with our display. The driver we have used to get this up and running was not designed for this display exactly. Things appear clipped and off screen. There were other issues with colour (i.e. red was blue and blue was red amongst other colour problems) and other graphics routines were not correct. I won’t bore you with all the tiny re-writes I did but just supply you with the new driver for this particular display. This driver is very specific, i.e. only targeting this display and resolution but it may well work with many other similar displays. At the time of writing I have no other displays to test with but will be expanding the driver code as and when required. The full driver code is available from the link below, add it into your Arduino in the usual manner (Adding libraries to the Arduino IDE.)

Load up the example code that should now be available at “Files->Examples->XTronical ST7735 Library->GraphicsTestESP8266”. This is basically the Adafruit example with just some tiny changes (It goes through all the tests for each rotational position of the screen) so that it uses the new driver file and slightly altered initialisation routine.

There is an issue with the line drawing routine within the Adafruit GFX library, so this part of the original demo was removed. Basically it forces the NodeMCU to reset. As I’m not going ot be using this I’ve decided for now to ignore this issue.

"Upper layer" main development board contains ESP32-PICO-D4 SiP, battery connector & charger circuit with LiPo charge status LEDs, Reset & pull-up IO0 buttons, and a green LED on GPIO4.

Clone of the SparkFun ESP32 Thing board. Compact ESP32 based development board with battery connector, and the typical development board component accoutrements.

Version 2.0 of this board (1) corrected polarity labeling on bottom silk-screened battery symbol and (2) changed the LiPo battery connecter direction.

Development board/module with ESP-WROOM-32 module, USB-to-UART, Reset & Boot (IO0) buttons, Li-ion battery connector & charger, two Grove connectors, LED on IO2, and three indicator LEDs.

The ESP32-LyraTD-MSC Audio-Mic HDK (hardware development kit) combines the ESP32-LyraTD-MSC ("audio-mic development board") with a secondary "top" board.

The ESP32 touch sensor development kit, ESP32-Sense Kit, is used for evaluating and developing ESP32 touch sensor system. ESP32-Sense Kit consists of one motherboard and multiple daughterboards. The motherboard contains a display unit, a main control unit and a debug unit. The daughterboards have touch electrodes in different combinations or shapes, such as linear slider, wheel slider, matrix buttons and spring buttons, depending on the application scenarios. Users can design and add their own daughterboards for special usage cases.

Features an xBee socket with switchable VCC voltage (3.3 V or 5 V), so 2G (SIM800) and 3G (SIM5360) xBee modules will work on it to provide cellular network access.

ESP-WROOM-32 based development board with SH1106 OLED display (128×64 pixels), RJ-45 Ethernet connector, CAN-bus connector, Micro USB connector, USB-to-UART bridge, LiPo battery connector and charging circuit.

Board with MEMS Microphone (ICS-43434) and class-D amplifier embedded 1-channel DAC (Maxim MAX98357A); intended for Amazon Alexa experimentation and development.

ESP32 development board with ePaper display, TI PCM5102A DAC, ICS43434 MEMS Microphone, CP2102N USB-to-UART bridge, microSD card slot, and LiPo charger.

Circular board with ESP-WROOM-32 module, Ethernet (LAN8720A), stereo audio CODEC (WM8978), microphone, 3.5 mm audio receptacle, USB-to-UART bridge (CP2104), Micro USB connector, and SD card slot.

Has column-similar/redundant dual-row connections along the longest sides for easier stand-alone use without a breadboard (but still could be used with a breadboard).

2× Ethernet (optional), 1× Serial Port RS-232/485, OLED 0.96″ 128×64 (optional), power supply with UPS (optional), U.FL (I-PEX) antenna mount(s), and ExCard extension modules support.

SPI0 is permanently reserved for cache access to the flash chip. SPI1 is connected to the same pins via an arbiter and is used to write to flash. You can use SPI1 to also write to other peripherals connected in parallel with the flash (but with another /CS), however, this is tricky to implement because it means you can"t simultaneously access flash anymore. Thats why it"s not in the driver yet.

This is a 3.5” IPS capacitive Touchscreen Display. The module, with a resolution of 480x320, adopts ILI9488 as driver IC and SPI (4-line) communication mode. The board integrates touch chip GT911, employing I2C communication to realize multiple touchpoints controlling. The module also integrates an SD card slot allowing you to easily read the full-color bitmap. There are two modes of wiring supplied, normal pin header wiring and GDI. The latter one requires to work with a main controller board with a GDI interface (e.g. FireBeetle-M0). You can use it with only one FPC line plugging in, which reduces the complexity of the wiring. Furthermore, it features high resolution, wide viewing angle, and simple wiring, which can be used in all sorts of display applications, such as, IoT controlling device, game console, desktop event notifier, touch interface, etc.

@brief Constructor When the screen uses hardware SPI communication, the driver IC is st7789, and the screen resolution is 240x320, this constructor can be called

@brief Constructor When the screen uses hardware SPI communication, the driver IC is st7789, and the screen resolution is 240x320, this constructor can be called

screen.drawRGBBitmap(/*x=*/(screen.width()-100)/2,/*y=*/(screen.height()-100)/2,/*bitmap gImage_Bitmap=*/(const unsigned uint16_t*)gImage_GrayscaleBitmap,/*w=*/100,/*h=*/100);

screen.drawRGBBitmap(/*x=*/(screen.width()-100)/2,/*y=*/(screen.height()-100)/2,/*bitmap gImage_Bitmap=*/(const unsigned uint16_t*)gImage_GrayscaleBitmap,/*w=*/100,/*h=*/100);

screen.drawRGBBitmap(/*x=*/(screen.width()-100)/2,/*y=*/(screen.height()-100)/2,/*bitmap gImage_Bitmap=*/(const unsigned uint16_t*)gImage_GrayscaleBitmap,/*w=*/100,/*h=*/100);

(ESP8266 + LwIP W5500 / W5100(S) / ENC28J60) Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

Fully Asynchronous UDP Library for ESP8266 using W5x00 or ENC28J60 Ethernet. The library is easy to use and includes support for Unicast, Broadcast and Multicast environments.

Simple GSM shield Credentials Manager for Blynk and ESP32 / ESP8266 boards, with or without SSL, configuration data saved in LittleFS / SPIFFS / EEPROM.

Simple GSM shield Credentials Manager for Blynk and ESP32 / ESP8266 boards, with or without SSL, configuration data saved in LittleFS / SPIFFS / EEPROM.

Simple Async WiFiManager for Blynk and ESP32 (including ESP32-S2, ESP32-C3), ESP8266 with or without SSL, configuration data saved in either LittleFS, SPIFFS or EEPROM. Now working with new ESP8266 core v3.0.1 and ESP32 core v1.0.6

Simple WiFiManager for Blynk and ESP32 (including ESP32-S2, ESP32-C3), ESP8266 with or without SSL, configuration data saved in either LittleFS, SPIFFS or EEPROM. Now working with new ESP8266 core v3.0.0 and ESP32 core v1.0.6

CRMui3 WebFramework build a web app (Web UI) for ESP8266 and ESP32 in your project in minutes! / CRMui3 WebFramework для esp8266 и esp32. Позволяет быстро и просто создать веб интерфейс для настройки и управления устройством.

Directly interface Arduino, esp8266, and esp32 to DSC PowerSeries and Classic security systems for integration with home automation, remote control apps, notifications on alarm events, and emulating DSC panels to connect DSC keypads.

ESP32 (including ESP32-S2, ESP32-S3 and ESP32-C3), ESP8266 WiFi Connection Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

Light-Weight MultiWiFi/Credentials Async WiFiManager for ESP32 (including ESP32-S2, ESP32-S3 and ESP32-C3) and ESP8266 boards. Powerful-yet-simple-to-use feature to enable adding dynamic custom parameters.

Start serving a local webpage if cannot connect to WiFi, also include Buffer for to WiFi client to prevent small packets with partial messages being sent.

Library to detect a multi reset within a predetermined time, using RTC Memory, EEPROM, LittleFS or SPIFFS for ESP8266 and ESP32, ESP32_C3, ESP32_S2, ESP32_S3

Library to configure MultiWiFi/Credentials at runtime for ESP32 (including ESP32-S2, ESP32-S3 and ESP32-C3) and ESP8266 boards. With enhanced GUI and fallback web ConfigPortal.

Light-Weight MultiWiFi/Credentials Manager for ESP32 (including ESP32-S2, ESP32-S3 and ESP32-C3) and ESP8266 boards. Powerful-yet-simple-to-use feature to enable adding dynamic custom parameters.

Arduino has always helped to build projects easily and make them look more attractive. Programming an LCD screen with touch screen option might sound as a complicated task, but the Arduino libraries and shields had made it really easy. In this project we will use a 2.4” Arduino TFT LCD screen to build our own Arduino Touch Screen calculator that could perform all basic calculations like Addition, Subtraction, Division and Multiplication.

Before we actually dive into the project it is important to know, how this 2.4” TFT LCD Module works and what are the types present in it. Let us take a look at the pinouts of this 2.4” TFT LCD screen module.

As you can see the pins can be classified in to four main classifications such as LCD Command Pins, LCD Data Pins, SD Card Pins and Power Pins, We need not know much about the detailed working of these pins since they will be take care by our Arduino Library.

You can also find an SD card slot at the bottom of the module shown above, which can be used to load an SD card with bmp image files, and these images can be displayed in our TFT LCD screen using the Arduino Program.

Another important thing to note is your Interface IC. There are many types of TFT modules available in the market starting from the original Adafruit TFT LCD module to cheap Chinese clones. A program which works perfectly for your Adafruit shield might not work the same for Chinese breakout boards. So, it is very important to know which types of LCD display your are holding in hand. This detail has to be obtained from the vendor. If you are having a cheap clone like mine then it is most probably using the ili9341 driver IC.You can follow this TFT LCD interfacing with Arduino tutorial to try out some basic example programs and get comfortable with the LCD screen. Also check out our other TFT LCD projects with Arduino here:

If you planning to use the touch screen function of your TFT LCD module, then you have to calibrate it to make it work properly. A LCD screen without calibration might work unlikely, for instance you might touch at one place and the TFT might respond for a touch at some other place. These calibrations results will not be similar for all boards and hence you are left on your own to do this.

The best way to calibrate is to use the calibration example program (comes with library) or use the serial monitor to detect your error. However for this project since the size of buttons is large calibration should not be a big problem and I will also explain how you can calibrate your screen under the programming section below.

The 2.4” TFT LCD screen is a perfect Arduino Shield. You can directly push the LCD screen on top of the Arduino Uno and it will perfectly match with the pins and slid in through. However, as matters of safety cover the Programming terminal of your Arduino UNO with a small insulation tape, just in case if the terminal comes in contact with your TFT LCD screen. The LCD assembled on UNO will look something like this below.

We are using the SPFD5408 Library to get this arduino calculator code working. This is a modified library of Adafruit and can work seamlessly with our LCD TFT Module. You can check the complete program at the end of this Article.

Now, you can use the code below in your Arduino IDE and upload it to your Arduino UNO for the Touch Screen Calculator to work. Further down, I have explained the code into small segments.

As said earlier we need to calibrate the LCD screen to make it work as expected, but don’t worry the values given here are almost universal. The variables TS_MINX, TS_MINY, TS_MAXX, and TS_MAXY decide the calibration of the Screen. You can toy around them if you feel the calibration is not satisfactory.

As we know the TFT LCD screen can display a lot of colours, all these colours have to be entered in hex value. To make it more human readable we assign these values to a variable as shown below.

Okay now, we can get into the programming part. There are three sections involved in this program. One is creating a UI of a calculator with buttons and display. Then, detecting the buttons based on the users touch and finally calculating the results and display them. Let us get through them one by one.

This is where you can use a lot of your creativity to design the User Interface of calculator. I have simply made a basic layout of a calculator with 16 Buttons and one display unit. You have to construct the design just like you will draw something on MS paint. The libraries added will allow you to draw Lines, Rectangle, Circles, Chars, Strings and lot more of any preferred colour. You can understand the available functions from this article.

Another challenging task is detecting the user touch. Every time the user touches somewhere we will able to how where the X and Y position of the pixel he touched. This value can be displayed on the serial monitor using the println as shown below.

Since we have designed the box with width and height of 60 pixel each and have four Rows and for columns starting from (0,0). The position of each box can be predicted as shown in below picture.

Now, since we know the position of all the boxes. When a user touches anywhere we can predict where he has touched by comparing his (X,Y) values with the value for each box as shown below.

The final step is to calculate the result and display them on TFT LCD Screen. This arduino calculator can perform operation with 2 numbers only. These two numbers are named as variables “Num1” and “Num2”. The variable “Number” gives and takes value from Num1 and Num2 and also bears the result.

When a use presses a button, one digit is added to number. When another button is pressed, the previous one digit is multiplied with 10 and the new number is added with it. For example, if we press 8 and then press 5 and then press 7. Then first the variable will hold 8 then (8*10)+5=85 then (85*10)+7 = 857. So finally the variable will have the value 857 with it.

The working of this Arduino Touch Screen Calculator is simple. You have to upload the below given code on your Arduino and fire it up. You get the calculator displayed on your LCD screen.

You have to press the “C” to clear the value on screen each time after performing a calculation. Hope you understood the project and enjoyed building something similar. If you have any doubts feel free to post them on forums or on the comment section below. See you next time with another interesting project until then happy computing!!

One of the advantages of ESP Easy (and my favorite, without a doubt), is that it allows us to connect to our project many different accessories without having to program or complicate our lives with firmware modifications or adaptations. Some of the most interesting elements are the screens, or «displays«.

In AliExpress you can buy the SSD1306 display for about 3 Euros, shipping included, from this link. It is a store with many positive reviews and shipping is by AliExpress Standard Shipping, so you should have it at home in about two weeks.

AZDelivery 0.96 Inch OLED Display I2C SSD1306 Chip 128 x 64 Pixels I2C Display Module with White Characters Compatible with Arduino and Raspberry Pi with E-Book Included!

✔️️ Easy screen connection with Raspberry Pi and other microcontrollers by I2C interface via only four pins! Thanks to the integrated display adapter, the module can be connected to the I2C bus immediately.

✔️ This product includes an E-Book that provides helpful information on how to get started on your project, helps with quick setup, and saves time in the setup process. We provide a series of application examples, comprehensive installation guides, and libraries.

IMPORTANT: These instructions are for displays that work with 5V power supply. Make sure your display is powered at 5V. If your screen is powered at 3.3V, you will have to connect the VDD pin of the display to one of the pins marked 3.3V on your NodeMCU or Wemos D1 Mini (on some boards the silkscreen of this pin can be "3V" or "3V3").

The connection to another board, different from the NodeMCU based on ESP8266, or another one based on ESP32, will be very similar. We will only have to pay attention to the change in the pins. Here is the connection diagram with the Wemos D1 Mini, for example:

Here you will see the list of devices that you have created (if there is any, if you are doing it, as in the example, with the CO2 meter the sensor should appear)

As you have seen in the previous point, you have eight lines of text in which you can display both a fixed text (in the previous example, in line 1 the fixed text «CO2 METER» is shown with two spaces in front so that it appears centered on the display).

You can see that the nameof the device is «CO2" and the valuethat we want to show on the screen is «PPM«, therefore, we will have to put in the line in which we want to show it [CO2#PPM].

Notice that you have a column to indicate the number of decimalswhat do you want displayed. If the value must be an integer without decimals, you can put a 0.

If you want to display the current time on screen, using %systime%", or you need it for some other reason, you have to take into account that the ESP8266 has no internal clock so it needs to consult the internet time.

Although the process is straightforward, and shouldn"t give anyone too many headaches, I have recorded a video with step-by-step instructions for adding the display.

Note that "Display - OLED SSD1306 / SH1106 Framed» takes some more memory from ESP8266 that the «Display - OLED SSD1306«, so on devices with many sensors connected or many rules long lines could give you memory problems (normally it shouldn"t give you any problems).

I have write the article MH-Z19B FALSE CO2 Sensorsand the accompanying video, with two MH-Z19B sensors connected (one original and one fake), the SSD1306 display and three WS2812B LEDs without any problem, and there is still free memory for more things.

If you want you can write directly on the screen from the rules using the command oledframedcmd, , (command must be a single parameter so if it includes spaces or commas you will have to write it between parentheses, as in the following example), which gives you much more control.

In the following example rule, the value CO2#PPM updates instantlyon the screen each time it changes. Also, if CO2#PPM is less than 400, it displays the message "Initializing ..." instead of its value.

If you put more lines than the display is capable of showing, it will show the different lines in different screenswhat they will go through one after another (you can change the time between screen jumps).

Here you can see a CO2 meter prototype with two 1.3 ″ OLED displays, in one it shows the CO2 concentration permanently and in the other it can show different data, such as temperature, humidity, etc.

As we have seen before, the OLED display has an I2C address that the ESP8266, ESP32 or another microcontroller uses to communicate with it. What we need to connect two displays to a single microcontroller is that each display has its own I2C address and simply, we will connect them in parallel and we will use them as if they were two completely independent screens.

IMPORTANT: It is particularly important that you make sure to use OLED displays that allow changing the I2C address (many do not allow it), if not, you will not be able to do it this way (you would need an I2C multiplexer, which complicates things a bit). A little further down I leave you the links to the screens that I use and that allow I2C address change.

For example, this 1.3 ″ OLED screen (larger than the normal ones, which are 0.96″) allows to change I2C addresses, between 0x78 and 0x7A, by moving a resistance:

You simply have to add in the configuration (Devices tab) two devices «Display - OLED SSD1306 / SH1106 Framed» (exactly the same as we have seen before with a single screen) and configure each one independently, with the data we want:

Sometimes I2C addresses may not match what you put on the screen (For example, in this screen that I have used, in the silkscreen it says that the addresses are 0x78 and 0x7A but the real addresses are 0x3C and 0x3D.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey