lcd screen light spot factory

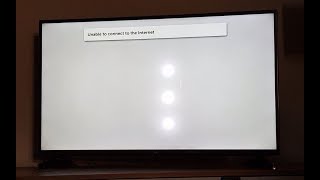

Typically we see a lot of sets with some sort of backlight problem - this is mostly because people and manufacturers like to run the sets with the backlight at 100%. Unfortunately with LED backlit sets this causes LEDs to fail, often just outside of the warranty period. Below we list the common faults and list the best ways to fix them.

If you have some dark or black spots on your LCD screen, then it"s typically a sign that one or more of the LEDs on the backlight strips has gone bad. In the case of edge lit LCDs you will see that an entire line on your screen appears to be darker than the rest.

If you are proficient with desoldering and re-soldering of surface-mounted electronic components / have a hot air rework station then you can buy the individual leds and swap out just the damaged ones on the strip, although we would not recommend this due to the amount of effort and the possibility of the replacement LED having a slightly different colour temperature or brightness.

If you have white spots or very bright areas on your screen - then it"s very likely that one or more of the small lenses that are glued to the front of the LEDs in your set has either fallen off or moved.

If this is the case then you can take the set apart, and re-glue the lens to the LED. We will warn you however that this is a very delicate procedure to get the lens lined up exactly and so that the light output exactly matches all of the other LEDs. If you are not confident then we would recommend purchasing replacement strips and swapping the strips out entirely - new / replacement strips come with the lenses already glued / attached so you will not need to worry about alignment.

Typically you will be looking for faulty / leaking capacitors on the LCD Power Board - although capacitors can sometimes fail and not show any visual signs. If you are able to confirm that the power board is operating correctly, then the next think to check would be the LED strips themselves. A quick visual check to look for burned or damaged LEDs may indicate where the problem is.

Warning: Disassembling your LCD set to get to the backlights is a complicated and delicate process, please be very careful when removing the LCD as it is very easy to crack it or damage the thin ribbon cables.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

A polarizer is an optical plate that allows only light from a certain direction to pass through. It is an optical element that converts natural light into straight polarized light. The mechanism of action is to make the vertical direction light pass through the straight incident light after passing through the vertical polarizer, and the other horizontal direction light is absorbed, or use reflection and scattering and other effects to make its shade.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

A high-quality picture of digital television depends on the correct setup of the equipment, a good receiver, and the correct operation of the monitor. Over time, even the quality models of Sony, Samsung, LG equipment, white spots may appear on the TV screen. To eliminate them, you need to find out the cause of the breakdown, decide if you can fix the TV by yourself or if you should refer the equipment to professionals.

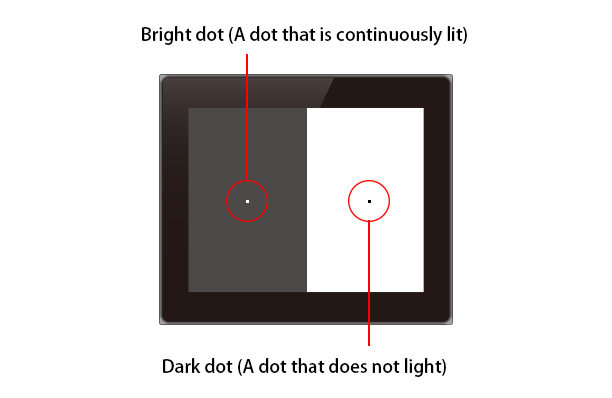

So What Are White Spots on TV?LCD TV Screens are comprised with thousands of tiny pixels, and they cycle through 3 basic colors; blue, red, and green and they create an image. The problem arises when a pixel gets stuck in the “on” position, and it appears as a white dot. Hot pixels come with defined edges and they are either square or straight lines.

White spots (or dots) on the TV screen are the result of a damaged processor and the overheating process during warm summer temperatures.Another reason that can be the cause of white spots on the TV screens is spikes or surges as electricity supplies can vary throughout the year.On top of every LED of your TV, there sits the reflector. These white dots on your TV screen are the results of a fallen reflector. The number of dots has corresponded to the number of fallen reflectors.

To eliminate the problem of white spots on your screen, you just need to carry out simple manipulations at home. Keep in mind that only professionals can fix more complicated failures. Regardless of the place where the repair can be, the reasons for white spots include:

If light spots appear on the LCD TV screen, you will need a clean soft cloth and remote control to remove them. The second thing to do is adjust the TV settings. This can be done by adjusting the backlight and screen brightness:

Important! In the process of changing the brightness level, the intensity of the white spots should change. If they remain unchanged, the settings are not the cause of the defect.

If wiping the screen, checking that the brightness and contrast settings are correct, and loosening the screws did not get rid of the white spots on the LCD TV screen, you can replace the matrix. It is better to contact specialists for this, but if you have experience with television equipment, you can carry out repairs on your own.

Important! It is best to carry out repairs with soft cotton gloves. You need to disconnect the cables carefully and smoothly. If you damage them during the repair process, you will have to replace them or buy a new plasma, LCD TV.

If your TV is under warranty and white spots appear during this period, take it to a service center. Masters will diagnose, exclude, or confirm the presence of a factory defect. The TV will be repaired for free or with a big discount.

Black spotsand most of the streaks are removed in other ways. The general repair option is possible only in case of system failureswhen a reboot of the equipment or restoration of factory settings is required.

White spots are something that can appear on any TV whether it is new or used. What you need to know is that you need to react in a timely manner and know how to deal with them. In this article, we have described the detailed procedure, and guided you through the entire process. If you have a warranty, use it. I hope you have understood the cause of white spots and that you will solve it with the help of this article.

Thanks guys! I just replaced the leds for my tcl 55 inch tv and after bout a week I started seeing the bulbs on the left side of the screen. Since the tv was an awesome find and the bulbs were like 30 bucks on eBay I’m fighting the inevitable being going back in and fixing that plastic deflector post. The screen is extremely fragile so if u don’t wanna pay 14 bucks at Home Depot for them window suction cups that were well worth the money For loners like myself lol, make sure u get another person to help u with the screen panel once it’s been dislodged . Especially if it’s a big honker. Nothing more scary than popping it out by urself and get stuck in a very bad situation as in u can almost hear the crackin of the screen Or knowing that I’d u take one more step this here screen will crack .

It can be quite annoying and even distracting to have a white spot on your laptop screen, if you also have a white spot on your laptop screen, you’re not alone. Many laptop users have this problem, and we know it can be quite frustrating.

Luckily, there are a few things you can do to fix it, and with a little effort, you can get rid of it and keep your screen looking perfect. In this article, we’ll show you how to fix white spot on laptop screen.

White spot on laptop screen can be caused by a variety of reasons, ranging from screen damages ( Hardware issues ) to software issues, we will discuss each of these in detail.

One of the main causes of a white spot on a laptop screen is a dead pixel. A dead pixel is a pixel that is no longer functioning properly and is unable to display any color. If you have a dead pixel on your screen, it will likely appear as a white spot. Mostly, dead pixels are the result of a manufacturing error and are commonly seen on laptop screens.

A stuck pixel is a bright dot of color that appears on a LCD screen. It is caused by a defective cell in the screen that is permanently turned on. Stuck pixels are fairly common and can be found on all types of LCD screens, from TVs to laptops to smartphones.

It’s very common for screens to get damaged, especially laptop screens. So a screen damage can be one of the most common causes of white spots on laptop screens. When the screen is damaged, the pixels in that area are no longer able to properly display color.

This can cause the area to appear white, black, or any other color depending on the severity of the damage. A few common causes of screen damage on laptop screens include:

One potential cause of bright spots or white dots on a laptop screen is loose LED reflectors. Most LCD screens, including TVs, laptops, mobile phones, etc, have reflectors that are used to direct the light from the LED backlights towards the LCD panel.

The LCD reflector is located under the screen, if one of the reflector is loose, it causes the light to scatter in different directions and creates a white spot on the screen.

Laptop screens are designed to display high-resolution images and videos. However, hardware failure can cause a white spot to appear on the screen. This is caused by a process called screen bleeding, and it’s a pretty common problem.

Screen bleeding is a very annoying problem, but luckily, it’s usually pretty easy to fix. In most cases, you can just restart your laptop and the white spot will go away. However, if the problem persists, you may need to replace the LCD panel.

Other hardware failures faulty graphics card or inverter. In some cases, it can also be caused by a loose connection. Well, that was all about the causes of the white spot on your laptop screen; however, in order to fix them, we will show you four ways.

In order to remove white spot on laptop screen, we have come up with four ways that will help you to get rid of white dot. let’s discuss each of them in detail:

As I have discussed above, the white spot can be caused by a dead pixel or a stuck pixel, so If you want to fix the pixel issue, you have to first find out which pixel fault is causing the white spot – dead pixel or stuck pixel.

If you find that there is one specific color on the effected area of your screen, then it is a stuck pixel. However, if there is no light on that area, then it is a dead pixel. So if you find out that the spot is due to stuck pixel, the best course of action is to power off your laptop and then power it back on again.

There is an online tool named JScreenFixthat can fix the stuck pixels on your screen, its a free tool, I hope visiting this site might help you fixing your stuck pixel of laptop screen.

As we said one a the reason of white spot appearing on your laptop screen is the loose LCD reflectors, so in order to fix loose led reflector we have to reach to , follow our below steps carefully:

The second step is to detach your laptop body in order to reach the screen display. In some laptops, speakers come in the way of reaching the display panel. So, if your laptop also have speakers in the way, you will likely need to remove the speakers, so carefully disconnect them from the main circuit board.

Make sure that the glue is dry before reassembling all the laptop components back. As, the LED reflector are now tightened. Finally, turn on your laptop and check for white spots again; they should be gone by now.

If none of the above techniques worked for you, it finally time to replace your laptop screen in order to get rid of the white spot. However, if your laptop is still under warranty, it may be more beneficial for you send it back for repair or replacement.

Replacing a laptop screen can be quite expensive, and you likely don’t want to pay for it out of pocket. But if you don’t have any warranty remaining, then you have no choice remaining and you have to replace your laptop screen at your own expense.

There is a well-known saying that “prevention is better than cure.” With that in mind, here are some useful tips on how to avoid small white spots on laptop screen.

When looking to buy a new laptop, be sure to thoroughly test it for any white spots on the screen. To test for white spots, increase the laptop brightness to full, move your eyes around the screen and look for any bright spots. Pay special attention to the corners and edges of the screen.

This physical test is not conclusive. To test in detail, you can run a screen test with a tool like Eizo Monitor Test. This will help you easily identify any faulty pixels on your laptop screen.

If you have a laptop, you know that the screen is one of the most important parts of the device. A small bump or drop can easily crack the screen, and once that happens, you’re looking at a costly repair. One way to protect your laptop screen is to invest in a protective case.

These cases can help cushion the screen from impact and can even help prevent scratches. There are a variety of different cases on the market, so you can find one that fits your needs and budget.

If you’re worried about your laptop screen, a protective case is a great way to keep it safe. Browse the selection of cases online or in your local electronics store and find the perfect one for your laptop.

It’s common to see people working on their laptops in bed, and often they may fall asleep mid-work. However sleeping with your laptop, you may risk damaging the screen display. So it’s always good to put your laptop aside before going to bed and prevent your laptop from any physical damage.

If your laptop has a touch screen, don’t press too hard. Touch screens are designed to work with a light touch, and applying too much pressure can damage the screen. If you’re not sure how much pressure to apply, start with a light touch and increase the pressure until the cursor moves.

If you have white spots on your HP laptop, there are a few possible causes. It could be a hardware issue, like a dead pixel or a stuck backlight. Or, it could be a software issue, like a corrupted driver or an incompatible program.

If you’re not sure what’s causing the white spots on your laptop, the best course of action is to contact HP support. They can help you troubleshoot the issue and determine the best course of action. In some cases, you may need to send your laptop in for repair. But, in other cases, a simple software update may be all that’s needed to fix the issue.

If you’ve ever had a dead pixel on your screen, you may have wondered if there’s any way to fix it. Unfortunately, once a pixel is dead, there’s no way to bring it back to life. However, there are some steps you can take to prevent dead pixels from occurring in the first place.

Dead pixels usually occur when the screen is exposed to too much pressure. So if you’re worried about getting a dead pixel, be careful not to press too hard on your screen. You can also try to avoid screen burn-in by using screen savers and dimming your screen when you’re not using it.

While there’s no way to fix a dead pixel, there are ways to prevent them. So if you’re worried about dead pixels, be careful with your screen and try to use screen savers and dimming.

While having white spots on your laptop screen can be frustrating, there are several potential causes for them. In this blog post, we explore the most common causes of white spots on laptop screens. We have also provide four different ways on how to remove them from your laptop screen.

As display/screen issues cannot be easily fixed and costly to repair as well, so we recommend taking care of your laptop and following our tips mentioned above to avoid white spots on your screen in the future.

It"s not a dead pixel it"s a bright little spot. The colors still work normally but on a white background the spot appears especially bright and on a black background it"s a little subtle bright dot. (On a black background it appears like a greyish color.) It"s not a single pixel, it looks like about 3 pixels and it sort of fades, it"s not a sharp 3 pixel block that immediately stops it fades out over the course of about 3 pixels.

White or bright spots on your Samsung Tv screen are common problems. If you are a Samsung user facing this bright spots issue, too. You must be here to find a solution to these spots. Relax, this is not a big deal many Samsung users face the same issue especially when their Tv get older.

Some questions likewhy are these spots appearing on the screen? And How you can get rid of them can reflect in your mind. Shortly, these loose reflectors are the main cause of this problem. Once these reflectors are repaired you can get rid of these irritating spots.In this article we will discuss briefly:Reason for these bright spots

If you see white spots on your Samsung Tv screen these are due to stuck pixels inside the screen. But many times there are dead pixels that cause black spots instead of white spots on the screen.

It is wrong to say that the white spots on the screen appear due to the damaged or moved reflectors of the LED Screens. Samsung LED TVs are not made using any reflectors.

Therefore, there is not any concern of damaged reflectors to these white spots in LED TVs. Some Samsung TVs like LG TVs use reflectors and may have white spots when the reflectors move from their position.

But these reflectors really belong to the bright spots that appear on the LG screen. Whenever the reflectors get misplaced from their location you will see some bright spots on the screen.

The main reason for the bright spots on any Samsung Tv screen is the reflectors. Reflectors can really affect the visuality of your Tv screen. When these reflectors inside the Tv get loose they cause bright spots. Reflectors are basically used to spread the light instead of emitting it at a single point.

But, when these reflectors move to any other location they cannot work properly. Due to this all lights inside the Tv shine at a single point. Then you see a bright spot on that particular point. In this way, bright spots appear on the Samsung Tv screen due to the reflectors.

Before we start our step guide about the bright spots. Here is one thing you should be aware of. Thething you should know is the opening of the Tv. It means you have to open the Tv to start the repair process.

Once you have unscrewed all the screws from the back of the screen. It’s time to remove the back cover of your Tv screen. For this purpose, you may need to lift up the cover. It may be a little harder so use a prying tool to make a gap between the Tv and its cover.

Now to make the repair process easier place or flip your Tv in such a position that your Tv back faces the roof. No need to worry about the components. Samsung TVs are lightweight that can prevent damage.

You have to unscrew the edges of the screen to remove your Tv screen. A pry tool can be used to lift up the frame of the screen. Now, you will see ribbon cables disconnect these cables carefully from the screen.

After removing the cable you will see a diffuser panel inside your Tv. These Diffuse the light from the reflectors. You have to lift these diffusers to see the reflectors

Just beneath the diffuser panel here are the reflectors. There are some lenses that are misplaced from their location and cause spots. These lenses might be loose and moved from their place. You need to regulate the reflectors in place.

The second last step to follow is returning the screen and then the cover of the Tv back to their place. First, Return and screw your screen and its frame. Secondly, Screw the cover of the Tv back carefully.

Some lenses are present inside the Tv. LED lights shine through these lenses. When these lenses move to any other location reflectors shine the lights at a single point that causes White spots on the screen.

No, LED lights do not burn out. There is not any filament that can cause the burning of LED lights. LED TVs are just like LCD TVs. They last as long as a Transistor due to the semiconductor material.

Bright spots on Samsung TVs never look good on the screen. These spots are due to the reflectors when they move to another location. We have already discussed all the steps to fix this problem. Make sure you follow the steps carefully, moreover, following the tips may become easier for you.

Lg tv has white dots on screen,how to fix white spots on lg led tv.how to fix white dots on lg led tv.how to fix white dots on lg tv screen,Tagslg tv white s...

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

The 100,000-hour figure assumes that every diode will be running at full brightness, consistently — which, on an LED screen, is virtually never the case. The lifespan figure can also be misleading because it indicates when a diode degrades to half-brightness, not completely dark. Many other variables affect an LED display’s lifespan; you can’t rely solely on the number on the diode spec sheet.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The quality of your display’s power supply — and how hard it drives the diodes — can have a significant impact on your screen’s lifespan. The other components being powered, such as fans and electrical components, have their own lifespans as well, which are also impacted by the power supply.

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

When it comes to cleaning, flat-screen TVs and LCD screens require special care and a gentle touch. With the wrong technique, you can easily scratch the screen or damage the surface"s antiglare coating. Even rubbing too hard can cause pixels (the tiny dots that compose images on computer monitors and TV screens) to burn out and stop working permanently. Most household cleaning products are too harsh to use on electronic devices with LCD or OLED screens, so choose your TV cleaning strategy carefully. These tips on how to clean a TV screen will help protect your device while ridding it of dust, smudges, fingerprints, and streaks.

To avoid damage to your TV while cleaning, only use gentle products. Never wipe the screen with paper towels, abrasive sponges, or coarsely woven rags, which can cause scratches. Instead, use high-quality, finely woven microfiber cloths to clean TV screens, recommends cleaning expert Leslie Reichert.

You should also avoid cleaning products that contain alcohol or ammonia. These types of cleaners can remove antiglare coatings and cause images to become cloudy or distorted. A simple swipe with a microfiber cloth ($9 for 5, Amazon) is typically all that"s needed to remove dust and other debris from the screen"s surface. When more than a light dusting is required, however, use the guidelines below for the best way to clean a TV.

Practice preventative measures so you won"t have to clean TV screens often. Keep food, drinks, and kids away from TV and computer screens to eradicate risks of messy splatters and fingerprint smudges. During your weekly house cleaning, lightly dust the screens with a microfiber cloth to prevent dust buildup.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure. Accidental damage is not covered under the standard warranty of the product. Such damage is often the result of a drop or an impact on the LCD screen or any other part of the product which may render the device non-functional. Such types of damage are only covered under an Accidental Damage service offering which is an optional add-on to the basic warranty of the product. Accidental Damage must not be confused with an occasional dead or stuck pixel on the LCD panel. For more information about dead or stuck pixels, see the Dell Display Pixel Guidelines.

The LCD glass on the display is manufactured to rigorous specifications and standards and will not typically crack or break on its own under normal use. In general, cracked, or broken glass is considered accidental damage and is not covered under the standard warranty.

Internal cracks typically occur due to excessive force on the screen. This can be the result of some object hitting the screen, a drop, attempting to close the lid while an object is on the keypad area, or even holding the laptop by its screen.

Spots typically occur due to an external force hitting the screen causing damage to the LCD panel"s backlight assembly. While the top layer did not crack or break, the underlying area was compressed and damaged causing this effect.

If your Dell laptop LCD panel has any accidental damage but the laptop is not covered by the Accidental Damage service offering, contact Dell Technical Support for repair options.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically used in clocks, watches and small appliances.

Mini-LED: Backlighting with Mini-LEDs can support over a thousand of Full-area Local Area Dimming (FLAD) zones. This allows deeper blacks and higher contrast ratio.

Today, most LCD screens are being designed with an LED backlight instead of the traditional CCFL backlight, while that backlight is dynamically controlled with the video information (dynamic backlight control). The combination with the dynamic backlight control, invented by Philips researchers Douglas Stanton, Martinus Stroomer and Adrianus de Vaan, simultaneously increases the dynamic range of the display system (also marketed as HDR, high dynamic range television or FLAD, full-area local area dimming).

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure (prism sheet) to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

A pink elastomeric connector mating an LCD panel to circuit board traces, shown next to a centimeter-scale ruler. The conductive and insulating layers in the black stripe are very small.

A standard television receiver screen, a modern LCD panel, has over six million pixels, and they are all individually powered by a wire network embedded in the screen. The fine wires, or pathways, form a grid with vertical wires across the whole screen on one side of the screen and horizontal wires across the whole screen on the other side of the screen. To this grid each pixel has a positive connection on one side and a negative connection on the other side. So the total amount of wires needed for a 1080p display is 3 x 1920 going vertically and 1080 going horizontally for a total of 6840 wires horizontally and vertically. That"s three for red, green and blue and 1920 columns of pixels for each color for a total of 5760 wires going vertically and 1080 rows of wires going horizontally. For a panel that is 28.8 inches (73 centimeters) wide, that means a wire density of 200 wires per inch along the horizontal edge.

The LCD panel is powered by LCD drivers that are carefully matched up with the edge of the LCD panel at the factory level. The drivers may be installed using several methods, the most common of which are COG (Chip-On-Glass) and TAB (Tape-automated bonding) These same principles apply also for smartphone screens that are much smaller than TV screens.anisotropic conductive film or, for lower densities, elastomeric connectors.

Monochrome and later color passive-matrix LCDs were standard in most early laptops (although a few used plasma displaysGame Boyactive-matrix became standard on all laptops. The commercially unsuccessful Macintosh Portable (released in 1989) was one of the first to use an active-matrix display (though still monochrome). Passive-matrix LCDs are still used in the 2010s for applications less demanding than laptop computers and TVs, such as inexpensive calculators. In particular, these are used on portable devices where less information content needs to be displayed, lowest power consumption (no backlight) and low cost are desired or readability in direct sunlight is needed.

A comparison between a blank passive-matrix display (top) and a blank active-matrix display (bottom). A passive-matrix display can be identified when the blank background is more grey in appearance than the crisper active-matrix display, fog appears on all edges of the screen, and while pictures appear to be fading on the screen.

STN LCDs have to be continuously refreshed by alternating pulsed voltages of one polarity during one frame and pulses of opposite polarity during the next frame. Individual pixels are addressed by the corresponding row and column circuits. This type of display is called response times and poor contrast are typical of passive-matrix addressed LCDs with too many pixels and driven according to the "Alt & Pleshko" drive scheme. Welzen and de Vaan also invented a non RMS drive scheme enabling to drive STN displays with video rates and enabling to show smooth moving video images on an STN display.

Bistable LCDs do not require continuous refreshing. Rewriting is only required for picture information changes. In 1984 HA van Sprang and AJSM de Vaan invented an STN type display that could be operated in a bistable mode, enabling extremely high resolution images up to 4000 lines or more using only low voltages.

High-resolution color displays, such as modern LCD computer monitors and televisions, use an active-matrix structure. A matrix of thin-film transistors (TFTs) is added to the electrodes in contact with the LC layer. Each pixel has its own dedicated transistor, allowing each column line to access one pixel. When a row line is selected, all of the column lines are connected to a row of pixels and voltages corresponding to the picture information are driven onto all of the column lines. The row line is then deactivated and the next row line is selected. All of the row lines are selected in sequence during a refresh operation. Active-matrix addressed displays look brighter and sharper than passive-matrix address

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey