audi lcd display repair made in china

Tom replaced the display on the first cluster, and replace the display along with the four stepper motors for the guages to resolve the twitching and delayed movement on the second cluster.

There are some rare cases that the cluster may be not repairable. If that"s the case, we will either issue you a full refund or source out a replacement cluster and transfer the mileage and vin data (you will be responsible for the replacement cost).

The Audi A4 & S4 LCD Screen Repairing (1.8T) service that we offer has made us a preferred service provider based in Grand, Canada. We guarantee that we use all genuine parts and components in case any part needs to be replaced during the screen repairing process. We also offer service for Audi A4 & S4 LCD Screen Repairing (2.8T).

The owner of this website (www.audiworld.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

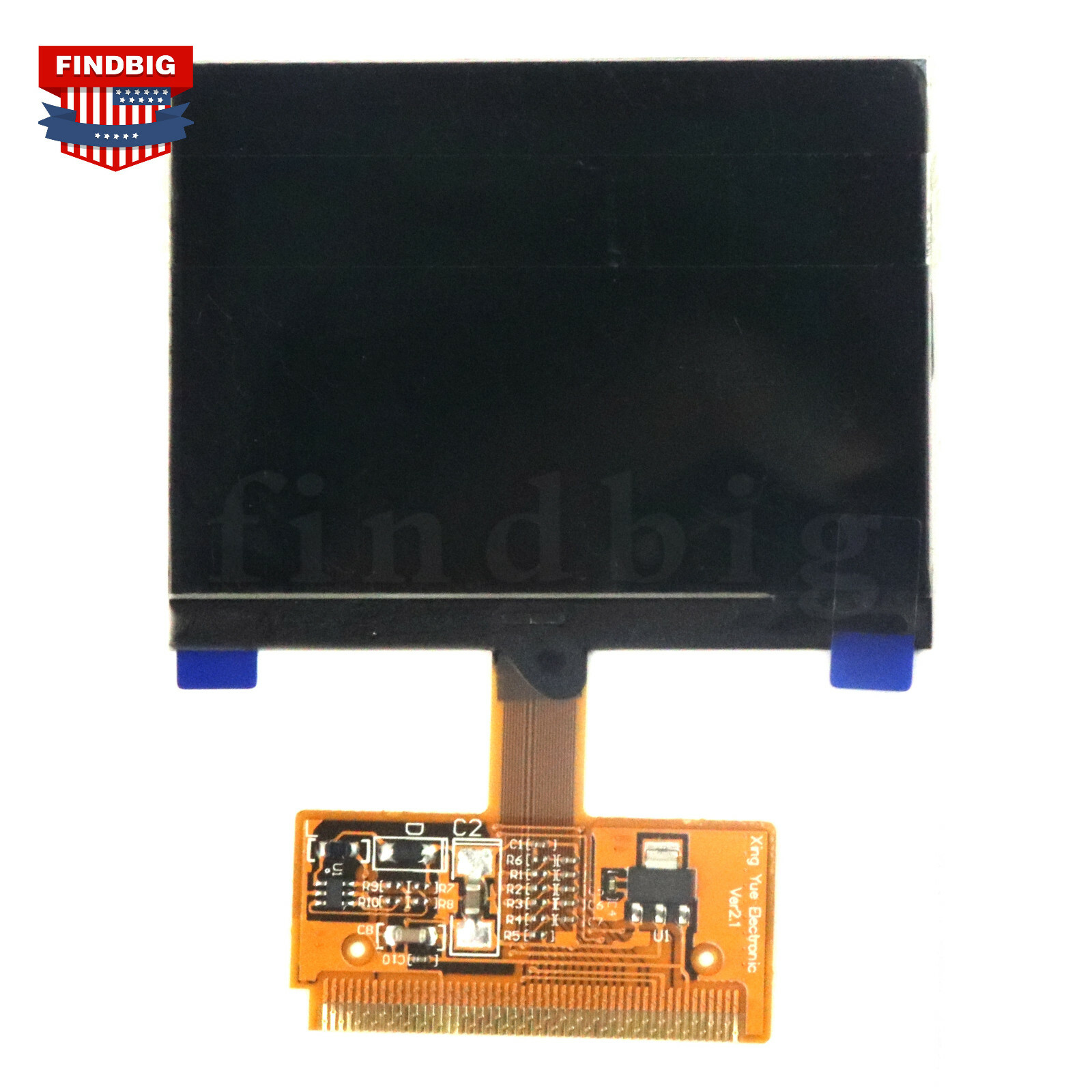

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

very nice and complicated work but...my question is, where can I find a ribbon cable like this? I have a keyboard Technics KN2000 with a display not working because the cable was disconnected from both the glass display and the circuit board. Thank You!

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey