led lcd panel failure and faults in stock

3. #If all the above is OK, measure the LVDS voltage value. Under normal conditions, the LVDS signal’s RX+/ RX-voltage value is about 1.2v, and RX+/ RX-difference value is about 200mV. At the same time, the resistance of the LVDS signal to ground and the resistance between the LVDS signal pairs can be measured (100 ohms). If there is an exception to these values, try replacing the ASIC.

1. #Confirm whether the COF on side X is hot compared with the normal temperature, whether there is fracture or wear crack, and whether the COF is burnt.

4. #Determine whether the gate IC is OK. There is a signal test point on the back of COG-IC, and the green paint can be scraped for measurement confirmation; If there is a gate IC problem, which IC fault can be confirmed. The confirmation of gate IC fault is only for analysis when you are interested, and this method is not recommended.

3. #Confirm whether the RSDS value is correct, normal RSDS is about 1.2v, and the signal difference is about 200mV; At the same time, we can confirm the resistance between RSDS signal (normal 100 or 50 ohms) and RSDS resistance to ground. If the voltage is NG, check if the ASIC and X-COF are hot.

1. #Adjust the VR knob to see whether it can be adjusted and whether the screen performance changes. At the same time, confirm the VCOM value (about 7v), if NG, replace the VR knob.

2. #Confirm VGH/VGL voltage (about 30V VGH and -6v VGL), and confirm whether it is DC/DC loop NG or COF IC NG; The corresponding resistance of disconnected VGH and VGL can determine whether it is a DC/DC problem or a COF-IC problem. If it is DC/DC NG, try to replace UP1 or confirm whether the corresponding transistor is OK.

3. #If the whiteness changes significantly with the view Angle, and above 1&2 analysis is all OK, polarizer NG or CELL NG can be basically determined.

2. #Confirm whether there is 12V input, if not, confirm whether the connector is OK, and confirm the resistance value of 12V voltage to earth; If conn. NG, change conn.; If 12V is short-circuited to the ground, disconnect FP1 to determine the short-circuiting circuit.

3. #Confirm whether FP1 is open; if open, replaces fuse. If the 12V accessory of this model has a reverse diode, confirm the continuity of the diode and check whether it is burnt.

B. Confirm VAA resistance to ground at VAA test point of R plate (A short circuit usually occurs), disconnect the corresponding capacitance of the following 3 COF, and confirm VAA resistance to the ground again. If OK, replace the capacitor, if NG, replace COF. If VAA is still NG, confirm DC/DC loop as all models.

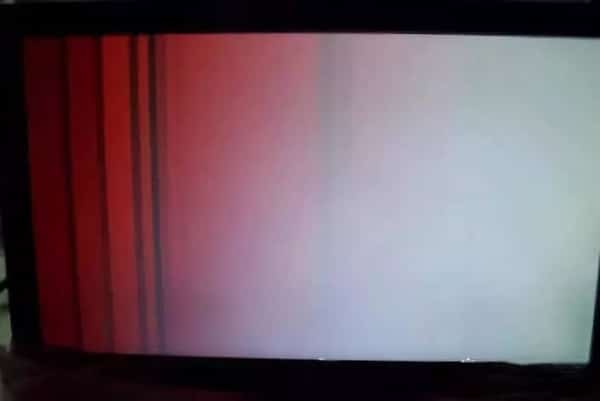

3. #Shaking module, if vertical lines disappear or reappear, then it can be judged that the possible cause is COF pin broken, and the crease should be found under the OM microscope.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

3. #Disassemble the backlight, confirm whether there is a short circuit with broken skin on the lamp strip, whether the plug of the lamp strip is fully integrated with the socket, whether the pin is aslant/off, whether the connector is off, and whether the LED bead is black and injured.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Things tend to break all the time. Of course, you might think that buying a quality item (in this case, a quality LED display panel) will prevent this from happening. And it will, for a few months or even a few years. But no matter how well you take care of something, things tend to wear down, especially after long periods.

And unfortunately, accidents can happen too. If you have an LED display panel outside, the chances of your display breaking down are much bigger than if your display were to be indoors. This risk is mostly caused by various conditions, such as rain, snow, hail, wind, and so on.

But don’t think that indoor LED displays can’t get damaged due to accidents too. Accidents can happen when cleaning your panels or during maintenance controls.

Now, when you see your LED display not working, it’s only natural to panic. Quality LED wall displays can get pretty pricey, and you don’t want to replace the whole display. But even getting your display fixed can get pretty pricey.

(2)check whether the signal input is normal. If there is confusing color, then check the signal contact of the first abnormal LED module in the direction of signal input. You can examine it by plugging in and out multiple times. If there is a problem, you can choose to replace the flat cable.

(3)Check whether the power pins of the 74HC138 decoding chip and 4953 line management chip are poor welding or suffering short circuits. If yes, repair them or change new chips.

Connect the positive electrode of LEDs with the black probe and the negative electrode with the red probe. If the LED lamp bead is on, means it still works. If the light bead doesn’t light on, means it is bad. Then you have to replace it.

(1)Signal cable not connect well (No displaying on a row of modules), Check the signal cable connection and reconnect, also check the power supply for the first module in the row.

(2)Power supply not connect well (no displaying on one corner of a cabinet), Check if the related power supply is working normally and the connection is good.

(1)Check the signal cable connection and reconnect, also check the power supply for the first module in the row. (2)Check whether the flat cable is working normally. If any problem, reconnect the cable. (3)Change a LED display module to see whether the color missing phenomenon disappears.

This problem may be caused by the failure of the pins of the driver IC that controls this row. First, position the corresponding driver IC. You can find it through the circuit diagram, and replace it and drive it.

How to replace driver IC?First, test the IC card. Second, remove the defect IC. Third, add solder. Fourth, get rid of excess solder. Fifth, test it.How to replace LED lamp bead?Remove the gel around the LEDs with sharp tools such as a tweezer until the pins are exposed.Use a tweezer to keep the lamp bead in place, and solder it with soldering iron at a temperature around 40°C (too high a temperature will damage the LED display) for less than 3 seconds.Install the right light beads on the PCB board (the long probe of the LED lamp bead is the positive electrode, and the short one is the negative electrode. And the square hole on the PCB board is for the positive electrode while the round hole is for the negative electrode).Meltdown a little solder wire and touch it with the solder tip, then solder the LEDs and PCB board with the solder wire. Finally, seal the LED display with the same type of gel.

(1)No AC power input, Check whether the LED display screen has already been powered on. Turn on the swift of the power distributor, the power indicator should be on.

(6)Find out whether is a mistake in the setting of the DVI card. According to the right steps of controlling system operation, setting up the LED studio software and reconnect the signal cable.

(3)Check whether the LED studio setting has a mistake or not. If there is any problem, setting up the LED studio software and reconnect the signal cable based on the controlling system operation steps.

(3)Check whether the LED studio setting has a mistake or not. If there is any problem, setting up the LED studio software and reconnect the signal cable based on the controlling system operation steps.

(1)Check whether the sending card and receiving card are working normally. If the green indicator is off or keeps lightning it means there is no signal.

(4)Check whether the LED studio setting has a mistake or not. If there is any problem, setting up the LED studio software and reconnect the signal cable based on the controlling system operation steps.

(1)Check whether the sending card and receiving card are working normally. If the green indicator is off or keeps lightning it means there is no signal.

(2)Check whether the LED studio setting has a mistake or not. If there is any problem, setting up the LED studio software and reconnect the signal cable based on the controlling system operation steps.

This may be caused by the lack of cascading files. Send the cascading file again, and plug the internet cable of the computer into the output port near the indicator lamp of the LED sending card.

The reason can be the wrong setting of sending card and functional card. Please restore the default setting and store the setting, and control the minimum brightness values larger than 80.

(1)If there is no displaying on a single row, it may represent the signal input has some problems. Check it, replug it and also check the power connection for the first module in the row.

This is a normal phenomenon that represents the LED display board is ready to work. This garbled displaying will disappear basically within two seconds and the screen will run normally then.

(3)Check the power supply of both the control computer and the LED display screen. When there is an inadequate power supply for the LED display cabinet, the screen will flicker when the screen displaying the whole white picture.

If it does not flash, restart it, and check whether the green light is flashing regularly before entering the win98/2k/XP system. If flashing, go to step 2.Please check whether the DVI cable is connected properly. If the problem is not solved because of sending a card, graphics card, and DV cable, please replace it separately and repeat step 3.

(6)Check whether the green indicator (data light) of the receiving card flashes synchronously with the green indicator of the sending card. If yes, go to step 8, and check whether the red light of the power supply is still on.

However, if the problems are not solved after the repairment, then the trouble may happen in the LED receiving card. Replace the receiving card and repeat step 6.

Now, let’s say you find the source of your LED wall issue. There are two possible outcomes after you do this. If you’re tech-savvy or if you have an in-house maintenance worker, then you can probably fix the issue yourself.

But oftentimes your LED screens problems can be more complex, especially with outdoor LED displays. In that case, the best solution is to hire a professional LED maintenance worker to check the whole display, troubleshoot the issue, and fix it.

Of course, as many people say, prevention is the best cure. So you shouldn’t wait for your LED panels to break drown. Instead, you should have a professional come and look at your LED displays regularly and perform maintenance check-ups. This will decrease the chances of your display walls randomly shutting down.

Fixing up LED wall displays is not an easy nor cheap task. However, there are ways to prevent this from happening. You can always ask professionals to come regularly and check up on your displays, but the issues all stem from the LED screens.

If you will get low-quality LED screens, then of course that the panel will be prone to more breakdowns. But if the panel you purchase is of superior quality, then the chances of it breaking down are smaller.Where can you find that kind of LED wall display? Well, you don’t have to look that far because we have them! You can contact us to find out which LED Screens would suit your business.

MMyy SSppeecciiaall R Reeqquueesstt::Please cannot give this E-book away for free and you do not have therights to redistribute this E-book anywhere on web.

Disclaimer And/ Or Legal NoticesThe reader is expressly warned to consider and adopt all safety precaution that might be indi-cated by the activities herein and to avoid all potential hazards. This E-Book is for INFORMA-TIONAL PURPOSES only and the author do not accept any responsibilities or liabilities result-ing from the use of this information. While every attempt has been made to verify the infor-mation provided here, the author cannot assume any responsibility for any loss, injury, errors,inaccuracies, omissions or inconvenience sustained by anyone resulting from this information.Most of the repair tips and solution given should only be carried out by suitable qualified elec-tronics engineers/technicians. Please be careful as all electrical equipment is potentially dan-gerous when dismantled. Any perceived slights of policy, specific people or organizations areunintentional.

Limit of Liability/ Disclaimer of WarrantyThe author Imran Ashraf and publisher of this E-book and the accompanying materials have, Complied from various sources and also own knowledge of repair filed and his best efforts inpreparing this book. The authors and publisher make no representation or warranties withrespect to the accuracy, applicability, fitness, or completeness of the contents of this Book.They disclaim any warranties (expressed or implied), merchantability, or fitness for any par-ticular purpose. The reader is expressly warned to consider and adapt all Safety precautionsthat might be indicated by the activities here in and to avoid all potential hazards. By followingthe instructions contained herein, the reader willingly assumes all risks in connection withsuch instructions. The authors and publisher shall in no event be held liable for any loss orother damages, including but not limited to special, incidental, consequential, or other damag-es. As always, the advice of a competent legal, tax, accounting or other professional should be12|Pag e

sought. No this parts of this E-book/Guide/Manual shall be reproduced or transmitted by anymeans, electronic, mechanical, photocopying, printing and recording or otherwise . Any unau-thorized use of this material is prohibited. All product illustration, product names and logo aretrademark of their respective manufacturers. If you have any information regarding the ille-gal reselling or duplication of the E-book, please report it to Imran_usa9@yahoo.com for yourreward.

This E-book Dedicate to my late father Muhammad Ashraf, my Sweetfamily and my Friends around the globe and My Pakistani friendNaseeb Jan, they all helps me and support me a lot for preparationthis great e-book, Thanks all of you.

COLLECTION OF TRICKS & HOW-LED LCD TV SERVICE FROMVARIOUS SOURCES RELIABLE TECHNICIANsHere is I reveal a big secrete of Panel repairing for you and a Chance to earn big moneyfrom it, Some LCD panel failures could possibly mistake for T-Con board issues. Otherthan damage to the LCD glass, most panel failures are isolated to a particular area of thescreen. Since the T-Con disperses the pixel data to groups of line and column drive IC’ssituated on the outer edges of the panel, it is unlikely that more than one of these IC’swould fail at the same time. Multiple columns of struck on or stuck off pixels are there-fore, more likely to be the fault of the T-Con circuits. The same applies to a single rowof lit or unlit pixels. The T-Con simply cannot cut out a single line of information.

L.C.D L.E.D T.V Panels Connection and Voltages UnderstandingHere we talking about the main voltages and pin connection of L.C.D and L.E.D T.Vs Panels, every technician should know where to test and how to check voltages of eachconnection as they mention in Service Manual or schematic diagram or at least youshould know the basic working voltages.

5. VGH Supply LCM driver output Around 12v+ to 19.5v+ 6. STV Vertical Sync Input. The rising Pulse edge of STV begins a frame of data. The STV input is used to generate the high-voltage STVP output. 7. CPV1 Vertical Clock-Pulse Input. CPV1 Pulse controls the timing of the CKV1 and CKVB1 outputs, which change state (by first sharing charge) on its falling edge.

8. CPV2 Vertical Clock-Pulse Input. CPV2 Clock pulse controls the timing of the CKV2 and CKVB2 outputs, which change state (by first sharing charge) on its falling edge.

9. V.COM out Common signal output TFT Signal pulse 10. POL in Supply input common sig- Signal nal 11. VDC in Supply +5.0v min 12. VON Gate-On Supply. VON is the posi- Around 20v+ tive supply voltage for the CKV_, CKVB_, and STVP high-voltage driver outputs. 13. V-OFF Gate-Off Supply. VOFF is the Around 8V- negative supply voltage for the CKV_, CKVB_, and STVP high- voltage driver outputs.

Brief Details of Panels Connection PointsVDD VDD is the logic supply input for the scan driver.VON Gate-On Supply. VON is the positive supply voltage for the CKV_, CKVB_, andSTVP high-voltage driver outputs.VOFF Gate-Off Supply. VOFF is the negative supply voltage for the CKV_, CKVB_,and STVP high-voltage driver outputs.STV Vertical Sync Input. The rising edge of STV begins a frame of data. The STVinput is used to generate the high-voltage STVP output.CPV1 Vertical Clock-Pulse Input. CPV1 controls the timing of the CKV1 and CKVB1outputs, which change state (by first sharing charge) on its falling edge.CPV2 Vertical Clock-Pulse Input. CPV2 controls the timing of the CKV2 and CKVB2outputs, which change state (by first sharing charge) on its falling edge.EN Enables the MAX17121. Drive EN high to start up the MAX17121 after a de-lay time, which is set by a capacitor at DLY.CKVB1 High-Voltage Scan-Drive Output. CKVB1 is the inverse of CKV1 duringactive states and is high impedance whenever CKV1 is high impedance.CKVB2 High-Voltage Scan-Drive Output. CKVB2 is the inverse of CKV2 duringactive states and is high impedance whenever CKV2 is high impedance.CKVBCS2 CKVB2 Charge-Sharing Connection. CKVBCS2 connects to CKVCS2whenever CPV2 and STV are both low (to make CKV2 and CKVB2 high impedance)to allow CKV2 to connect to CKVB2, sharing charge between the capacitive loadson these two outputs.CKVCS2 CKV2 Charge-Sharing Connection. CKVCS2 connects to CKVBCS2whenever CPV2 and STV are both low (to make CKV2 and CKVB2 high impedance)to allow CKVB2 to connect to CKV2, sharing charge between the capacitive loadson these two outputs.STVP High-Voltage Scan-Drive Output. STVP is connected to VOFF when STV is45|Pag e

low and is connected to VON when STV is high and CPV1 is low. When both STVand CPV1 are high, STVP is high impedance.DLY Startup Delay Setting. Connect a capacitor to adjust the delayDISH VOFF Discharge Connection. Pulling DISH below ground activates an inter-nal connection between VOFF and GND, rapidly discharging the VOFF supply. Typ-ically, DISH is capacitive connected to VDD, so that when VDD falls, VOFF is dis-charged.VCOM Operational Amplifier Output

CKV High-Voltage, Gate-Pulse Output. When enabled, CKV toggles between itshigh state (connected to GON) and its low state (connected to GOFF) on each fall-ing edge of the CPV input. Further, CKV is high impedance whenever CPV and OEare both low and whenever CPV is low and OECON is high.CKVCSCKV Charge-Sharing Connection. CKVCS connects to CKV whenever CKV ishigh impedance to allow connection to CKVB, sharing charge between the capaci-tive loads on these two outputs.CKVBCS CKVB Charge-Sharing Connection. CKVBCS connects to CKVB when-ever CKVB is high impedance to allow connection to CKV, sharing charge betweenthe capacitive loads on these two outputs.CKVB High-Voltage, Gate-Pulse Output. CKVB is the inverse of CKV during activestates and is high impedance whenever CKV is high impedance.STVP High-Voltage, Start-Pulse Output. STVP is low (connected to GOFF) whenev-er STV is low and is high (connected to GON) only when STV is high and CPV andOE are both low. When STV is high and either CPV or OE is high, STVP is high im-pedance.STV Vertical Sync Input. The rising edge of STV begins a frame of data. The STVinput is used to generate the high-voltage STVP output.OECON Active-Low, Output-Enable Timing Input. OECON is driven by an RC-filtered version of the OE input signal. If OE remains high long enough for the re-sistor to charge the capacitor up to the OECON threshold, the OE signal is maskeduntil OE goes low and the capacitor is discharged below the threshold through theresistor.OE Active-High, Gate-Pulse Output Enable. CKV and CKVB leave the high-impedance charge-sharing state on the rising edge of OE.CPV Vertical Clock-Pulse Input. CPV controls the timing of the CKV and CKVBoutputs that change state (by first sharing charge) on its falling edge.GND Logic GroundDISH GOFF Discharge Input. Pulling DISH below ground activates an internalconnection between GOFF and GND, rapidly discharging the GOFF supply. Typical-ly, DISH is capacitively connected to IN, so that when VIN falls GOFF is discharged.VDD Supply Input. Logic supply input for the VCOM calibrator. Bypass to GNDthrough a minimum 0.1μF capacitor.WPN Active-Low, Write-Protect Input. When WPN is low, I2C commands are ig-nored and the VCOM calibrator settings cannot be modified.SCLS Alternate I2C-Compatible Clock Input. When WPN is high, SCLS connects toSCL to drive SCL from an alternate clock source.SCL I2C-Compatible Clock Input and OutputSDA I2C-Compatible Serial Bidirectional Data Line56|Pag e

WPP Write-Protect Output. WPP is the inverse of WPN. It can be used to controlactive-high, write-protect inputs on other devices.SET Full-Scale, Sink-Current Adjustment Input. Connect a resistor, RSET, fromSET to GND to set the full-scale adjustable sink current that is VBOOST / (20 xRSET). IOUT is equal to the current through RSET.VL 3.3V On-Chip Regulator Output. This regulator powers internal analog cir-cuitry for the step-up regulator, op amp, and VCOM calibrator. External loads up to10mA can be powered. Bypass VL to GND with a 0.22μF or greater ceramic capaci-tor.BGND Amplifier GroundBOOST Operational Amplifier Supply Input. Connect to VMAIN (Figure 2) andbypass to BGND with a 1μF or greater ceramic capacitor.OUT Adjustable Sink-Current Output. OUT connects to the resistive voltage-divider at the op amp input POS (between BOOST and GND) that determines theVCOM output voltage. IOUT lowers the divider voltage by a programmableamount.POS Operational Amplifier No inverting InputNEG Operational Amplifier Inverting InputVCOM Operational Amplifier OutputSHDN Shutdown Control Input. Pull SHDN low to disable the step-up regulator.The VCOM calibrator, op amp, and scan driver functions remain enabled.IN Step-Up Regulator Supply Input. Bypass IN to AGND (pin 34) with a 1μF orgreater ceramic capacitor.LX Switching Node. Connect inductor/catch diode here and minimize trace ar-ea for lowest EMI.PGND Power Ground. Source connection of the internal step-up regulator powerswitch.FB Feedback Input. Reference voltage is 1.24V nominal. Connect external resis-tor-divider midpoint here and minimize trace area. Set VOUT according to: VOUT= 1.24V (1 + R1/R2).COMP Compensation Input for Error Amplifier. Connect a series RC from COMP toAGND. Typical values are 180k and 470pF.AGND GroundGOFF Gate-Off Supply. GOFF is the negative supply voltage for the CKV, CKVB, andSTVP high-voltage driver outputs. Bypass to PGND with a minimum of 0.1μF ce-ramic capacitor.GON Gate-On Supply. GON is the positive supply voltage for the CKV, CKVB, andSTVP high-voltage driver outputs. Bypass to VMAIN or PGND with a minimum of0.1μF ceramic capacitor.EP Exposed Backside Pad. Connect to the analog ground plane through multi-ple vias to enhance thermal performance.

CKVB1 High-Voltage Scan-Drive Output. CKVB1 is the inverse of CKV1 duringactive states and is high impedance whenever CKV1 is high impedance.STVP High-Voltage Scan-Drive Output. STVP is connected to VOFF when STV islow and is connected to VON when STV is high and CPV1 is low. When both STVand CPV1 are high, STVP is high impedance.CKVB2 High-Voltage Scan-Drive Output. CKVB2 is the inverse of CKV2 during

active states and is high impedance whenever CKV2 is high impedance.CKVBCS2 CKVB2 Charge-Sharing Connection. CKVBCS2 connects to CKVCS2whenever CPV2 and STV are both low (to make CKV2 and CKVB2 high impedance)to allow CKV2 to connect to CKVB2, sharing charge between the capacitive loadson these two outputs.CKVCS2 CKV2 Charge-Sharing Connection. CKVCS2 connects to CKVBCS2whenever CPV2 and STV are both low (to make CKV2 and CKVB2 high impedance)to allow CKVB2 to connect to CKV2, sharing charge between the capacitive loadson these two outputs.CKV2 High-Voltage Scan-Drive Output. When enabled, CKV2 toggles between itshigh state (connected to VON) and its low state (connected to VOFF) on each fall-ing edge of the CPV2 input. Further, CKV2 is high impedance whenever CPV2 andSTV are both low.STV Vertical Sync Input. The rising edge of STV begins a frame of data. The STVinput is used to generate the high-voltage STVP output.CPV1 Vertical Clock-Pulse Input. CPV1 controls the timing of the CKV1 and CKVB1outputs, which change state (by first sharing charge) on its falling edge.CPV2 Vertical Clock-Pulse Input. CPV2 controls the timing of the CKV2 and CKVB2outputs, which change state (by first sharing charge) on its falling edge.N.C. Not ConnectedEN Enables the MAX17121. Drive EN high to start up the MAX17121 after a de-lay time, which is set by a capacitor at DLY.DLY Startup Delay Setting. Connect a capacitor to adjust the delay based on tDE-LAY= CDLYx 410kI.GND GroundDISH VOFF Discharge Connection. Pulling DISH below ground activates an inter-nal connection between VOFF and GND, rapidly discharging the VOFF supply. Typ-ically, DISH is capacitive connected to VDD, so that when VDD falls, VOFF is dis-charged.VDD Supply Input. VDD is the logic supply input for the scan driver. Bypass toGND through a minimum 0.1FF capacitor.VOFF Gate-Off Supply. VOFF is the negative supply voltage for the CKV_, CKVB_,and STVP high-voltage driver outputs. Bypass to GND with a minimum of 1FF ce-ramic capacitor.VON Gate-On Supply. VON is the positive supply voltage for the CKV_, CKVB_, andSTVP high-voltage driver outputs. Bypass to GND with a minimum of 1FF ceramiccapacitor.CKV1 High-Voltage Scan-Drive Output. When enabled, CKV1 toggles between itshigh state (connected to VON) and its low state (connected to VOFF) on each fall-ing edge of the CPV1 input. Further, CKV1 is high impedance whenever CPV1 andSTV are both low.CKVCS1 CKV1 Charge-Sharing Connection. CKVCS1 connects to CKVBCS1whenever CPV1 and STV are both low (to make CKV1 and CKVB1 high impedance)to allow CKVB1 to connect to CKV1, sharing charge between the capacitive loadson these two outputs.CKVBCS1 CKVB1 Charge-Sharing Connection. CKVBCS1 connects to CKVCS1whenever CPV1 and STV are both low (to make CKV1 and CKVB1 high impedance)to allow CKV1 to connect to CKVB1, sharing charge between the capacitive loadson these two outputs.78|Pag e

FAULT: Blurred image and not clear with slow motion like ghost, Checktest points at T-con DVDD=3.3v VDD=12v Vcom=5.6v Voff=-8vVref_FB=1v Gref=12v seems all normal while VGH=11v and Von=0vNow the voltage VGH should be 24v based on the MAX17126 i.c,Now itssure that MAX17126 is faulty.

Solution: As an alternative supply instead VGH and Von I use injection of24v volts from the back light power supply, to be more safety majors I putup their respective series 100 ohm 0.25watt input, Now set works verygood.

1. S-PWB with gate PCB (Side Pads) We found many open connection and we use jumper wire (I took this kind of wires from old dc motor of tape recorder)

2. S-PWB without PCB (Side Pads) we also found open connection in these types of panels but fixing these types of panels is very extra ordinary delicate art and you1112 | P a g e

3. S-PWB without Gate Driver PCB or Chip (No Side Pad) Chance is very low for modification of this kind of panels, but we still using some tricks on that.

Panel Cut-CircumcisionLED, LED panel damage of this kind is one of the damage that is often experienced. Alt-hough in a different shape or position, such as partial or one-third of the panel, but thesource of the damage is still almost the same. We can try to modify the source voltagesupply part (output voltage I.c scan MAX 17108) in order to supply voltage could beclose to normal, because we know that this kind of panel does not have the FPC to Rawdriver (scan driver).

1. Unloading the entire casing panels to ensure that there is no path FPC (col- umn) was burned. 2. Check all output voltages power Ic TCON correction when there were fewer than all system voltages. 3. Bias problems arise here, in the IC MAX17108 scan driver. All normal volt- age, but when flickering appears, then the level output voltage at pin 13-22 de- creased, but remained constant in Ic output power (24V). 4.Coba disconnect pin out 21 lines leading to the FPC / panel, and re-measure the voltage in the no-load condition (on tv), usually be constant pin 21 (+ / _ 24v). 5. There is two alternative / option here could i.c are damaged (replace), or in- deed the damaged panel. 6.When panel is damaged we can do a direct jumper between voltage power1415 | P a g e

ICs out with path way in at FPC / panel we broke up earlier, r 10 ohm jumper with a couple / safety. 7.Wait for a minute, and observe, if there is no path at FPC burning, and the whole ic in TCON in normal temperature means successfully .But there is no possibility of modification Set up the track FPC burning, meaning that the panel is already severe (failed) clincher in cir- cumcision (cut) ckv track, ckvb mas instead von, Voff one of circumcision Ante- cedent circumcision (cut) ckv track, ckvb mas instead von, Voff one of circumci- sion Samsung not succeeded in connecting again replace the existing right that vv posts kb etc.In Panel Repair and Modification we try to connect open links from PCB to Pads asshown in picture there is Side PCB Gate Driver boards of Panel, Some times we cutsSignals like CKV Tracks.

Defect The image is not clear with horizontal stripes.Solution: Was found On the recommendation by my friend, Cuts the track signalsCKV1, CKV2, CKVB1, CKVB2, STVP, and VOFF not planted, artifacts found. Runningfootage disappeared, increased clarity, some loss of rows left to repair.

Here we show you the new TAB COF I.Cs and there is a method with pasting and bond-ing using with machine, these kind of Tab are available in world market like china andSingapore, you can order online from the internet.

Analysis of maintenance: power on check the backlight is bright, detecting screen pow-er supply 12V normal. Normal remote control switch machine, indicating the controlpart of the motherboard is working properly. Focusing on the logic board on the checkLogic board mainly by the format converter and DC/DC converter circuit. Because thescreen is not lit, so focus on DC/DC converter circuit check, for easy maintenance, abrief analysis at the circuit control process.VCC-PANEL enter the UP1, 21, 22 feet, converted through a chip from the 18th pin(SWB) UP5 output 2.5V voltage regulators get 1.8V provides format conversion chipsupply. UP1 11th foot (DRN) DP7, C227, UP1 foot booster circuit consisting of an outputvoltage of around -5.6V VGL provides negative pressure for driving power.2.5V UP1chip detected after work, LP7, LP2, DP2, DP6, UP1 feet (SW) 5 pin (SW) internal circuitvoltage boosting circuit start? Work? the output voltage of 16V, UP1 feet (GD) providesan open signal for QP1 and QP2, 16V over QP1,QP2 VDA voltage driving circuit forpower supply.

When the above circuit normally work, VAAP vetted by DP5, CP18, UP1 feet (DRP) con-sisting of internal voltage boosting circuit was working properly, and got VGHP byRP21 current voltage, VGHP QP8 output voltage of 22V about VGH provide power forthe drive.

The UP1 10th pin voltage is 0V, normally pin 10 should be able to detect the 2.25V ofDC voltage, AC test 5V AC voltages, but measuring AC and DC voltage not detected.Measurement of resistance the feet on the ground, nothing suspected UP1 foot internaldamage, troubleshooting after replacement.

Analysis of maintenance: Power the inspection showed that the machine startsnormally, but hold on longer, after and lit a white screen, sound and other functions arenormal, so the fault identified on the logic board.

First detection logic board the road powered, found VGHP detection points no voltage,and normally this detection points due 19.5V voltage, again measuring other severaldetection points voltage normal, remove logic board, measuring VGHP voltage outputend on to resistance for 0 volts, apparently this problem is due to no VGHP voltagecaused, dang remove filtering capacitor CP19 , complex measuring VGHP output end onto resistance recovery normal, will logic board loaded back original machine, boot faultremained, again measuring still no VGHP voltage.

Test UP1 pin forward normal DC 5V output 2.25V and communication, VAA 13V nor-mal voltage detection point, led to the identification of VGHP voltage is for DP5-freeway, Directly after the replacement boot test after normal 19.5V voltage VGHP voltageoutput, machine back to normal.

Formation because the failure analysis VGHP voltage is provided to gate-level of highpotential, which opens the gate-level voltage, when LCD LCD screen loses the voltagewill cause internal TFT LCD LCD screen is not working properly with this type of fault.

Conclusion: logic board mainly consists of a format converter and DC/DC convertercircuit. By the process of analyzing and removing these two faults, we can see that mostof the fault lies with the logic board DC/DC converter circuit. For the maintenance ofthis portion of the circuit, as far as the structure of its circuits are not difficult to under-stand, the key point is to familiarize yourself with its timing control and 5 large voltageDC/DC converter circuit. Also needed a mention of is, in we of maintenance practice ex-ploration in the found, logic board Shang by with of components in market is complete-ly can procurement to of, and price very low, on above two a fault of maintenance, itsmaintenance cost are insufficient 30 USD, only for Board level maintenance price ofone-tenth, so for LCD TV logic board of maintenance not only is technology level of de-velopment and beyond, and also is more with Future of.

Fault: Black screen When testing regimes on board T-Con, it was revealed that thedrain of the transistor Q101, instead of 12 volts in just 0.5. Transistor Q101 (markingWZ) - P-channel field researcher. Through the transistor, organized DC-DC power con-verter after replacing all return, the picture is back to normal.

Many Friends of mine ask me For Self Monitoring System of LCD LED TVs’Actually in some brands Like Sony Sharp Panasonic and many other havetheir own detecting method of problems, they use Front LED blinks as acode, when you trying to service these types of Brands you should awareBlink codes of specific models, here is an example of few LCD LED TVs’ forunderstanding blinks code.

Study CasePanel failure of LCD-TV using BN07-00364A (V260B1-L04) -LE26R32,LE26R81, We usually met below symptoms:This is a Test Case and this will be helps you a lot in future repairing.

Blank image (white) at startup, correct image appearing after 5-20 min - sometimes overblank Image appear some H-lines, the number of lines and position on display is different atconsecutive startups. During operation, the image becomes “still” and after turning towhite, disappearing. In both above cases the display is sensitive when torsion it, close tomoment the image appear (first case ) or “still” ( second case ) .The cause of above symptoms is the failure of one of contacts between the first IC-FPCB inthe upper-left corner of display and upper long and narrow PCB of display. Unlike the rest ofFPCBs with drivers for vertical lines , this one have some circuits that just passing through it, to some circuits over panel glass , and through these , to the first of three drivers for H-lineson left side of panel glass . The access to “long-and-narrow” PCB in the upper part of display, and to FPCBs is onlypossible after removing of front metal frame of LCD display (fixed in 10 screws) .The T-Con board must also be removed.

you haven’t done operations of similar complexity. In pictures P01, P04, P05, P06 isdescribed the correspondence between pads on first upper H-driver (please note thatpads are accessible below H-driver FPCB when LCD display is on the table) .

For easily access to pads and to avoid the dust and foreign materials to enter betweenbacklight and LCD-panel, carefully and gently lift up the driver FPCB and fix it with adhe-sive tape in vertical position to don’t excessive stress the FPCB, but enough to can access thepads with scalpel, tester and soldering iron. If you consider unsafe lifting of driver FPCB, isbetter to lift the whole LCD-panel (glass) and put it “up side down “ , but take care of anydust and foreign object to avoid dirty the display . Take care also of driver FPCBs betweenthe long upper PCB and display, don’t excessive stress them.

The most frequent circuit found interrupted is that one corresponding to pad numbered 10( P01.jpg ) and indicated in P03D.jpg . For easily measurement, please measure the continuity of this circuit to the pad numbered10 in P06.jpg, near the connector to T-Con board.

You can read below the normal resistance values for all circuits (all are so big valuesbecause of thin circuits on the glass) . There are also the normal voltage value that can be measured during function and thevoltage drop on each circuit (where is not specified, is below 0.1mV)Please note that pads numbered with 11, 12, 14 are not connected, so don’tmeasure them. st1 -> 1 line (-5.5V)2 -> 13Ω ( -5.51V , 7mV )3 -> 17Ω ( +21V , 12mV )4 -> 13Ω ( -5.51V , 8mV )5 -> 50Ω ( 3.29V , 4.1mV )6 -> 61Ω ( GND , 3.5mV )7 -> 91Ω ( 3.3V )8 -> 84Ω ( 917mV )9 -> 84Ω ( 1.73V )10 -> 84Ω13>20Ω(+5.37V)15 -> 84Ω ( 3.3V)2728 | P a g e

In case you find interrupted circuit corresponding to pad 10 (or resistance >> 84 Ω), this must be bypassed with a thin wire 0.15 mm ( thermoplastic insulation prefera-bly ) . Please cut first the wire at 120mm length and tin it with soldering iron ( max 1mm ) .Also ,tin with soldering iron ( adjusted at 270°C )the pad numbered 10 on FPCB , only where paintis scratched ( P07.jpg ) . Please use normal soldering alloy (40/60) not Lead-free .

All these operations must be done with the display disconnected (and completely isolatedfrom any metal part of table), using the antistatic bracelet connected to soldering ironground contact.

Please solder an end of prepared thin wire to pad 10 (P08.jpg, P09.jpg) .Release the driverFPCB by carefully and gently unstuck of adhesive tape. Don’t excessive stress the FPCB.Prepare a 5mm strip of adhesive tape and stick the FPCB ( P10.jpg ) .Position carefully thewire ( P11.jpg ) , fixing it from place to place with thin ( 3mm) strips of adhesive tape .Findthe crossing hole numbered 10 in P04.jpg , P05.jpg and tin it with soldering iron .

Solder the end of wire on prepared cross hole ( P13.jpg , P14.jpg , P15.jpg ) - or to abovespecified point , and after , fix the rest of wire (P13.jpg ) .

In case you don’t find at first measurement an evident interruption of circuit corre-sponding to pad 10, before solder the wire to cross hole connect again the ohmmeterbetween end of wire and pad 10 near connector, and gently touch the side of upperdriver FPCB (the side near the display side) and look for a resistance variation. If youdon’t observe any variation, you must search another interrupted circuit, and bypass ittoo. ( 10 must be bypassed anyway ) .

Here we show you different type of panels and Modifications:PPaanneell M M226600T TWWR R11 Manifestations of the same defect and the reason is similar,Many times we found VGL, VGH, open circuit with the circuit board, Use thin wire forreconnection.BBooaarrdd11

When you try to Modify LCD Panels you should know the Basic knowledge ofthese connection as I mention.1: VGH: V gate high refers to the gate-level of high potential, which is open, the gate-level voltages.

4: VgoffH: V gate off high the gate-level close the high voltage level (used in a third-order-driven, to get rid of when you closed a gate-level by the storage capacitor (CS ONGATE) caused by voltage change), it basically can be thought of as the value of Vgoffl+VcomSome IC information above only refer to VGH and VGL, because this IC support second or-der-driven, some IC information above VGH, VGL, VGOFFH, VGOFFL, it is because of this ICsupport second-order and third-order driven. VDDG,VEEG for second order-driven GATEswitching levels.

5: VCOM: Deflection of LCD reference voltage; VDDA on the PCB through the voltage di-vider circuit split into 10~14 Group, as IC VGMA the output of the internal DAC referencevoltage through the PCB potentiometer circuit, resulting in multiple sets of reference volt-age, IC internal voltage divider circuit can be reduced.

Fault: Braking out with periodic disappearance and falling in inhibiting verticalcolored stripes.Measurements of the left side showed.Von -11.8 ohms , CPV2 -114,8 Ohm , CPV1 - 114,9 ohm , STV - 118,2 OhmIn any case, they duplicated (pic1 and pic2) But with the right side interesting:Von - open permanentCPV1 - 121,3 OhmCPV2 - 119,0 ohmSTV - is 115.7 ohms, breakage,duplicated (see pic3 and pic4) .Note the sequence of different signals on the sides andCPV2 CPV1.Here we show you connection in yellow mark for circuit board.

Symptoms: when you turn on a dark gray background, sometimes turning into whitedark gray. May be involved with the normal image if distort plug supply. When thenormal image after a while the right half of the mattress can go vertical stripes pillars.When you turn on a gray background, it was revealed the absence of voltage 13,3 V,VGH, VGL with MAX1518E. Solution: In the end, after three days of suffering with this panel, MAX1518E re-placement several times (initially went astray with MAX1518E, panel and lay downmattress I could see only a certain part of the left panel), the throttle PWM entire bind-ing - was identified B1 unpredictable the choke plate on the right mattress for 3,3 V (J3connector 16-19pin) on decoders, which gave an overload when the MAX1518E andmaintenance thereof in protection or the right half of the strip if the throttle broke offafter the normal image.

CURE: first tried to loop tape slapped: CKV2, CKVB2. The image became normal, theband was not, but began to show artifacts (toffee), and only on the schedule! When thegraph disappears, and a minute later they disappeared. From static channel icons didnot show up. Finally on the right side strap cut the conductors: CKV2, CKVB2 and putthem together. Artifacts were gone, out. Normal, but there was a band barely noticea-ble. (Most on a blue background)

DIAGNOSING A FAILED T"CON BOARD All video inputs received by the video process circuits are handled on a frame-by-frame basis. The video frames are converted and scaled to 8 to 10 bit RGB information.It is virtually impossible for the video process circuit to cause a problem on a specificarea of the screen. Failures on this board usually appear as distortions, color levelshifts, video level shifts or noise that involves the entire picture. The T-Con can gener-ate symptoms that appear to be video process related, but the video process circuitcannot produce the symptoms of a failed T-Con board circuit.

T"CON FAILURES Failures in the timing control circuits of the T-con can produce symptoms of absolute-ly no video or generate lines and patterns that usually cover all or a substantial part ofthe screen. Determining if the T-Con is the cause of a ‘No Video’ condition is a bit moredifficult since there are no indications on the screen to analyze. Negative picture alsocomes from bad Gamma correction i.c of AS-15F, many of the Sony TV models of the lastfew years will detect a T-Con that has completely failed. The communications data be-tween the video process circuits and the T-Con will cease to communicate, if the T-Confails completely. This will cause the TV to shut down and display a diagnostic code, in-4243 | P a g e

dicating a failure of the T-Con. Not all chassis designs have this feature and it is notfound on older models. The typical scenario when this failure arises is for the techni-cian to bring a video process board to the repair location.

It is usually safe to assume that the problem lies on the T-Con board, if the replacementvideo board dos not give a solution to the problem since it is highly unlikely that a re-placement board with the same failure was received. One trick to check most T-Consfor functionality is to loosen the LVDS connector at the T-Con while unit is turned ON.Handle the LVDS connector with care and be certain to fully release the lock tabs. Gen-tly rock the cable in and out of the connector while observing the screen for any re-sponse.

Depending on the chassis, the symptoms of the screen ma be gentle white flashes, in-termittent colored lines, or a screen full of random patterns. The idea at this point is toprovoke some kind of response on the screen. Another helpful procedure is to rapidlyheat and/cool the T-Con with a hot air devices or circuit coolant and watch for patternsappear on the screen, Here we show some different voltages and signals of SamsungBN96-07611C T-Con board for understanding when you test t-con boards you shouldknow the basic voltages.

SOLUTION:This is a typical AS-15-F Problem and we show the Solution By pass method, just openpin 20 and pin 23 and use jumper wire pin 18 to R431 set works fine, you can use thistrick in many other brands.

Understanding of LVDS cable failuresAlthough the problem with LVDS cable or connectors can generate symptoms of T-Confailures this usually tends to be intermittent and wiggling of the connectors will usuallyprovoke a change in the symptom on the screen. LVDS cable and connectors have be-came rather robust over the past few years. Technicians who damage them cause mostproblems and this is generally quite oblivious upon close examination.

T-CON REPLACEMENT In many instances, replacement of the T-Con board will be relatively straight forward.In some case, the other boards may have to be loosened or removed to allow access tothe mounting screws and clearance to remove the T-Con board. The issue of most con-cern is keeping track of the heat transfer pads, stand offs and insulators. The T-Con isheavily shielded and it is ease to have one or more of these components accidentally fallout of the assembly when removing. T-Con assemblies that use multiple heat transferpads must be removed slowly and every attempt must be made to keep the shield andcircuit board together as they are removed from the unit. Check for any service bulle-tins pertaining to the model and panel design that contain the subject lie of T-Con heattransfer pad locations’ for pictures to show the proper location of these components.This site itself has covered disassembly procedure to some model LCD TVs, here. Pull

Remove the screw from the LVDS cable ground strap so the cable can be moved away.Unplug the connector to inverter board and remove harness from the retainer. Removeall screws securing the board sub-chassis to the panel. Pull the top of the board towardyou and downward to allow access to the bottom screws securing T-Con. The positionof screws and disassembly method may vary set to set.

Carefully unpeel the conductive tape from the top bracket taking care not to tearthem. Leave the tape attacked to the T-Con shield. Remove the top bracket coveringthe gate and source driver components. This will allow access to the upper flat cableconnectors, if any. Carefully lift the locking tabs securing the flat cables. Leave the fatcables attached to the T-Con and shield assay. The T-Con board will have an insulatingpad between it and the LCD panel that will cause the board to stick. Not much effort isrequired to release it. The goal at this point is to remove the board and shield togetherso as to avoid dropping heat transfer pads and insulators located between the front ofthe board and the shield. If successful, both components should stay together as insu-lated. Note the spaces mounted on the backside of the board. These will need to betransferred to the replacement board. Lift the circuit board upward slowly while ob-serving the location of the heat transfer and insulating pads. In most cases the heattransfer pad will remain attached to their appropriate ICs and the insulating pads willbe struck to the shield. If anything falls off, use the instruction to return them to theirproper position. Transfer all heat and insulating pads along with the flat cables to thereplacement board. Once the components have been transferred to the front of the cir-cuit board, attach the shield and flip the assembly. Transfer any spacers or insulatingpads to the replacement bard. Temporarily secure the T-Con board to the shield withelectrical tape. This helps in preventing movements of the circuit bard while installingthe assembly back into the LCD panel. Once the T-Con assay is secured to the panel, in-sert and lock the flat cables.

Vertical or Horizontal Lines: Defective Panel likely but also T-CON, LVDS, or MainBoard. Use Test Patterns in Factory Service Mode to determine error.

ALIGNMENTS:1. Check/Set Option Bytes:2. Check/Perform Firmware Upgrade for all repairs.3. Perform reset in Service Mode & Plug and Play if Main board is replaced.

Toshiba 32AV500PSGSome Times Problem similar types like a bad T-con or a Bad Panel but in Toshiba32AV500PSG we Found Bad eeprom in main board Fault, See this picture.

Defect: low-contrast negative image with a blue-green moiré in the light areasand dark red on. When you turn on AV signal without a dark screen instead of uniform-ly red. Screen, Have tested T-CON normal (compared with a working t-Con), flashingeeprom (bin with the worker) did not produce results. SDRAM also found good.

QUANTA QD32HL01, T-CON V32C SF0.17MB15E MAIN-3,BP 17PW15-8FAILURE: When the screen is dark then (1 min) horizontal bars passing through acouple of minutes in the 1-3 inch vertical column.

SSOOLLU UTTIIO ONN:: Here is I reveal a big secrete of Panel repairing for you ConnectBracket T-CON side board with matrix checkpoints VGL I use a thin Enameled wire ofcopper to the end (of course wires) can use the side pad VGL point, Inverter board alsohad bad electrolytes capacitor and were replaced with new one, Set works like new.

Horizontal stripes Panel Number T315XW01 VC V This is a T315XW01 VC V Panel and its used in many LCDs T.Vs and Very common Fault in this kind of panel famous for open VGH and VGL Top Board to Side motherboard of Panel contacts VGL and VGH respectively open when its test by digital meter, I put a two jumper wires between (See Arrow mark) VGL and VGH to side board VGL and VGH points, Now panel Works Fine. I fix many of them.

Problem low contrast, whitish imageBy Measurements on T-con showed VGL -5.5V,VDA 13.3 V, VGH 20.2 V, VDD 3.3 V, andHere VCM 3,2 V instead of the 5,6 V. removing R117 and icing diode resistor chain fromthe point to point VCM VDA and is limiting zener voltage of 5.6 volts the problem was

Here is I reveal a big secrete of LED Panel CLAA215FA04SLED panel CLAA215FA04S As it turned out, the problem is quite typical for these pan-els open signal VDDG_FLK. Only problem is only that the "pads" no checkpointVDDG_FLK, which can be soldered, link wire directly to the track. Here I can show youthe check points Solder VDDG_FLK to Board.

SAMSUNG LE26C350DW SAMSUNG LE26C350DW and they use PanelT260HA01-DB.Problem: Plain white screen now here is I reveal a big secrete for you its OOppeennVVGGH H Sold a thin link wire to VGH Side board and Panel VGH point….Happy Repairing Day.

LCD TV Use Panel V315B1-L01 T-CON V315B1-C01Symptom: When using the screen goes blank, white screen appears with bandspropagate at Different times but in10 minutes. They appear faster in heated ma-chine.

I reveal a big secrete for you !In the diagnosis of detecting the absence of VGL And understated VGH (18V).Now Here is I reveal a big secrete of this fault its Periodic open capacitor C45 1,8nFconnect to processor pin 41. Replace with new capacitor restore the original picture.

Problem: Bands appear immediately after switching on the power supply, all othervoltages are normal in power supply.Now I reveal a big secrete for you!Point STV-1 between the top-and medium-side driver board are open. Sold a thin wirewith STV-1 to side board, Now Set works fine.

Now I Pick a piece of insulated wire and soldered point V ON ,the T-CON board via re-sistor 15k ohms with +20 V (VD806, C817 +) on plate -PLT 203-2 BP + inverter.(See themodification Method in picture two).

Fault: Some times pictures comes and went blank with black screen, Here is I reveala secrete for you, this is just because of interment open linksvon,vcom,cpv1,cpv2,stv,vdd,voff, use a thin wire for connection.

Panel LC420WX5 Used in Many LCDs TVs’ LG, PHILIPSDefect; Dark screen, insulation and OSD interment problem. Picture come and blankhim self, some times its come back him self. Inscription on Shield panels LC42WX5 (SL)(D1) on the T-Con LC42WX5-SLC2

VGH VGL,VCOM,5v and other shows in pictures you can soldered from the lefttabs to driver upper board ,use a thin wire to reconnect it. (Many Thanks to my RussianFriend)

Samsung Panels major problem at No Supply Von-24V to side drive. Its was caused tofaint image, some times slow motion picture Von on the panel jumper and the thin wireto circuit board as show in picture

Cure: Von should be 24v volts but there is nothing at side pad, I use thin wire forconnection V-on as I show in picture where and how to sold the jumper wire.

Samsung LE32R71Composition: Scalar SVP-PX56, VIDEO RAM K4D263238, percent S3F866B, and PanelAUO. Photo number 1 and number 2: Taken from Solution: Problem was resolved byreplacing the chip scalar IC500 SVP-PX56-7256.A so- same for a given fault is possiblemanifestation failure of IC222 (RAM K4D263238) X500 (28 MHz) replacement.

INGREDIENTS: CPU, IT ALSO SCALAR MICRONAS VCT6973G SOLUTION: IN THE SERVICE MENU TO PERFORM EEPROM CLEAR B (RESTORE NVM DATA TO DEFAULT VALUES EXCEPT ADJUSTMENT DATA). SO ALSO, IN CASE OF FAILURE OF THE RESET SERVICE MENU, PROBLEM SOLVED BY FLASHING MICRONS. HERE I TELL YOU HOW? LOG IN SERVICE : 1 - UNPLUG THE AC POWER CORD OF TV SET TO FORCE POWER OFF. 2 - WHILE HOLDING DOWN THE "VOL (-)" AND "INPUT" KEYS ON THE SET AT ONCE, PLUG IN THE AC POWER CORD TO TURN ON THE SET. THE LETTER K APPEARS ON THE SCREEN. 3 - NEXT, HOLD DOWN THE "VOL (-)" AND "P (V)" KEYS ON THE SET AT ONCE. 4. THE SERVICE MENU K_MODE: TURN OFF THE TV FROM THE NETWORK , PRESS THE VOL (-7273 | P a g e

Samsung LTA320WT-0Problem is the failure of the backlight (CCFL).At the time of inclusion, clearly visible uneven illumination, where light-dead payattention. First photo spot is seen in the lower right corner. Treatment method is sim-ple- change the lamps.

CASE:LCD LG 22C30 (T.con board so one panel) Problem lit only plain white screenExperience on a small screen LCD LG - plain white screen lights can usually be causedby Last LVDS cable to the panel not getting supply (6 or 12v) Fuse-chip to supply todisconnect panel .SOLUTIONSAfter opening the rear cabinet cover - directly open the lid cover panel-boardFuse check-chip LVDS connector is very close and disconnect or break Try using alter-nate fuse fusible resistors ohm 1/4W 0:22 and as a result directly out of the picturescreen .Its relief me that panel not damaged.Dictionary: Fusible resistors (FR) is a resistor that specifically designed it all as a fuse.Signs of this type of resistor is dirty white body or abu2 (not shiny). Commonly foundfor example in the fly back circuit supply to the instructions in the vertical or 180V.

Model: Sony KDL-40W3000 Panel:LTY400HA01 Fault:Frequent vertical stripes in the image across the screen Solution Problem T-CON boardwas in comparison modes and charts with the workers managed to localize the defectcame under suspicion SDRAM (IKM1- K4D263238) - dips in packages targeted,unfortunately Sony does not allow repair T-con boards and provide SDRAM.

Apparatus BBK model LD1906K,Fault: lay in the fact that when the image appeared in just 30 seconds, the red almostwas not there, in service mode, it was clear that the scale of adjustment red 10 units(the other more 100deleny), after adjusting the image became normal, but still turnedoff in standby incorporating image in just 30 seconds to appear, but the red color is notlost. If you disconnect from the network and a minute later to include all repeated to-gether with the loss of the red color.

HITACHI C20-LC880SNTFAULT : Trouble-C warming from 5 to 20 minutes (cold) a horizontal bar moves verti-cally then another and another, 10 seconds through out completely disappears, theproblem occurs only with a tuner, AV on all normal.

Plasma panel Samsung PS-42E7SSnow on the screen with spots on providing participants Ghosting color shadowProblem resolved by replacing Y-MAIN , Y-SCAN Boards.

SONY KDF-E42A11E Composition K4D263238G-VC36TMemory of the video decoder SDA5550 M TTX CXA2069Q S2-Compatible 7-Input 3-Output Audio / Video Switch B11 MSP3411G Multi standard Sound Processor FamilyWith Virtual Dolby Surround NEC UPD61120 CPU TC58DVM72A Flash D1216AATA-6B-E ELPIDA MEMORY CXD1975 largest percent under the radiator and unprinted Plus abunch of small things The faulted memory of the video K4D263238G-VC36T

SONY BRAVIAAbsolutely identical symptoms manifestations malfunction. The problem was resolvedResoldring scalar (the largest m / BE diagram on the board under the radiator). Thetruth indefinitely TV to turn on and was seen picture, conjures up thoughts about theproblems with the Scalar I.c.

KDL46X3500 UNEVEN BACKLIGHTINGDefect: lights in the center of the raster for defects in KDL46X3500.TV have a newtype of LCD (from SAMSUNG) with four blocks bulbs 16pcs. In each block, two invertermaster slave, 4 powerful high transformer, two in each inverter. BLK and WHT con-fused with the plant in the second KDL52H Driver IC IC6701 on both outputs gavecommon mode.

LCD SAMSUNG SYNC MASTER MODEL: 932 MP A PANEL: MODELNO: M190EN04 V.7Made in China (S1) on the control board: MODEL: RT19FS (US) No REV: MP1.1 proces-sors: IC400 GENESIS gm1501H LF- ic701 MICRONAS VCT 49XYF C7Fault: Planted voltage 2.5 volts, Jumper the S486. LF 25 = 2.5V. In principle, a simpleDefect, and calculated quickly, works again fine.

PHILIPS LC4.1EAB DISPLAYS ON QUANTA 26PF3320Fault: No picture and sometimes colored vertical thin black horizontal stripes acrossthe screen (see photo). problem is caused by the fact that the LCD panel productionQD26HL02 QUANTA DISPLAYS INC used signaling and power supply from MAINBOARD ( on the main board on which connector LVDS) for GATE BOARD (board on theside of the panel) on wirings on the glass.

Solution: Allowed to exclude the flat cable between the boards, but if the signal trans-mission paths acceptable resistance to power is too high and the GATE BOARD is de-energized.

Fault: The screen is horizontally moved on top of the bottom band image isnot visible but the graphics is visible clearly, if a signal DVI input on the pic-ture shows. Other AV inputs also strip.

SAMSUNG LE32S81.Composition: Main CPU - MT8202, FBE -SDP64, PanelAUO T315XW02.Fault: Slowly illuminates the image, turning into two part .Pre diagnostics detectmissing voltage VGH1 (25V) DC / DC converter T-CON.

PHILIPS26PF9946/12, CHASSIS AND LC4.2E PHILIPS 26PF9320 in thesame chassis. Panel LC260W01 (LPL). All in: *Problem: one of the addresses with a defective hand there is no signal on the controlpoint SSP1 (Source Scanning Right Start Signal)Cure: On the operating side, from the point of SSP1, wire catches on with the samename to be defective.

HITACHI 37LD9000TA NA TV scalars on Genesis FLI8532-LFProblem: Stripes, ghost pictures. Customer says with warming up about an hour torestore the picture. Been with me this was not In this paper, 6 months, the defect be-came apparent at 4 months. Capacitors tested voltage signed on board (5v, 12v, 24v,3.3v, 1.8v) are also normal, normal pulsation. Flex on the matrix tested. Composition-Genesis FLI8532-LF Scalar MSP4458 Multi standard Sound Processor CompatibleCXA2069Q S2-7-Input 3-Output Audio / Video Switch HDMI SIL9011CLU bit (50degrees basked scalar). When focus forum chain VS warmed scalar using alcohol-rosinflux. Warming because: 1min and 2min 280grad 360grad soldering station withoutnozzle top. From a distance of 25-30mm After warming image back to normal Opera-tion.

TV LG 42PX3RVA-ZC MF-056A chassis, Panel PDP42V706A2PSU J006AProblem: Plasma with green stripes in the form of image noise,Structure: Y SUS 42V7 P / n 6870QYE011D Z SUS 42V7 P / n 6870QZE017DCTRL 42V7 P / n 6870QCE020C Stresses on ZSUS + VS187.9V, VA 64.9V, +5.4 V YSUS VS187.9V, +5.4 V, IC 19 DC / DC 15,3 V PSU voltage on all present and normal: 3,4 V, 6V,12V,

This is a Pin data of above Panel main connection shows in picture, Connection soldwith thin wires to Pads to T-con board STVR – 142 pin; OE1 – 141pin; CKV – 150pin;VGL – 5pin; OE2 – 142pin; STV – 150pin; and VGH – 8pin.

Panel M260TWR1 Open fields STV signal change on the side of the driver, if the finger could move on theside, the picture may appear on leads, use jumper wire for connection VGL, VGH, 3.3v

PPaanneell V V226600B B11 Major Problem of this panel you should use jumper wire.Should Have DRL1, 3.3V and side pad should have GRL2 3.3V. D-drain, G-gate, respec-tively, DRL is the power of column drivers and GRL lowercase .

PANEL LTF400HA03 APPENDIX I33VVBC-X01. MAJOR OPENCONNECTION FOUND.HERE WE SHOW YOU STV, CPV1, CPV2, VON, VOFF, R1-1,R1-2CONNECT THESE WIRES WITH SOFT HANDS.

Fault panel. Solution - Reduce stress VOFFE from-12V to-19V. In the T-con in-stalled DC-DC MAX1722, change resistor RD18 leg FB3 12kOm with nominal 7.5 ohms.VOFFE voltage drops to-19V, double vision disappears, only the top of the image thereare hardly identify blackout strips.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey