fluorescent lamp in lcd panel testing free sample

The Color Rendering Index (CRI) is a widely used metric to describe color accuracy and fidelity. It is calculated as an average score on 8 color samples (called TCS or test color samples), with an additional 7 supplemental color samples for the extended CRI (e) metric.

Each of these scores is called Ri, where i represents the TCS number. For example, R9 is a commonly referenced deep red color score and is an important indicator of color quality for many applications.

CRI itself is a single number, and this is both a blessing and a curse. It is a great, convenient metric that is both intuitive and simple to communicate, but at the same time, particular color samples can distort the truth behind whether a light source is truly a high color rendering light source.

The test color samples are used in the calculation of CRI by simulating the reflectance spectrum from a light source under question, and comparing it to a reference source.

Similar to TCS1, TCS2 has low reflectance, but has additional reflectance in the green portion of the spectrum. It is generally not difficult for light sources to score well on TCS2.

TCS3 reflectance is relatively low across the spectrum, and is particularly muted in the red and blue portions of the spectrum. As a result, light sources that have broad emission in the green regions will perform satisfactorily for this color.

TCS5 is very similar to TCS4 but again, blue-shifted slightly. Although there is a stronger emphasis on blue wavelengths, its low overall reflectance and overall even spectrum keeps this from being a significant challenge for scoring well on CRI.

TCS6 is a ultimately a blue color, so it requires relatively accurate presence of blue wavelengths. As such, this score can be a bit more challenging for light sources that have a higher color temperature due as these colors naturally have more blue content.

We switch gears a bit and emphasize both blues and reds, though not exclusively. LEDs can struggle with this TCS in particular due to the uneven blue spike and lack of red color.

With the introduction of the special test color samples, we see a significant shift in the spectral composition of these TCSs. TCS9 is primarily concerned with spectral reflectance at 600 nm and above. Therefore, it is very challenging for light sources to score well on this metric.

TCS11 is similar to TCS3 (strong yellow-green), but with a more blue-shifted relfectance peak. It has a low relfectance profile and is not very challenging for most light sources to score well on.

TCS12 has its primary reflectance that peaks at around 460 nm, with 0 reflectance past 580 nm. This makes it especially important for light sources to have accurate rendition in the 430 - 500 nm range.

For LED sources that use blue light as its excitation source, R12 can be an especially challenging metric to score well on. This is particularly true for higher CCT color points due to the additional emphasis of blue.

TCS13 has strong reflectance at wavelengths past 580 nm, and moderate but diminishing reflectance at shorter wavelengths as well. Because of its relatively unsaturated color, TCS13 is not a particularly challenging color for light sources to render.

TCS15 was developed by Japanese researchers who felt that the original CRI and CRI extended TCS1 through TCS14 were insufficient to capture the ability of a light source to accurately render the color of human skin.

This is of course important in many applications where distinguishing skin tones are critical for the work being done (medical) or aesthetic appearance is important (hospitality, photography).

R15 is not as difficult to score well on compared to R9, but may give a more generally representative result for how a light source would render skin tones.

The Lighting Facts label gives shoppers the information they need to buy the most energy-efficient bulb to meet their lighting needs. The label includes a bulb’s brightness, energy cost, life, light appearance, and wattage. In addition, the principal display panel on the front of packaging focuses on lumens, a measure of brightness, rather than on watts, a measure of the amount of energy used, and includes the estimated yearly energy cost for each bulb. Bulbs themselves also feature lumens, and in the case of CFLs, a mercury disclosure.

The FTC enforces the Energy Labeling Rule. To help you comply with the labeling and reporting requirements for common household light bulbs, FTC staff have prepared answers to some common questions we’ve been asked.

The FTC Lighting Facts label and principal display panel information must appear on packaging for most general service “lamps” with medium screw bases, including most incandescent, compact fluorescent (CFL) and light-emitting diode (LED) light bulbs. The Energy Labeling Rule has several exceptions for various lamp types, so it’s a good idea to review specific definitions for answers about coverage. See 16 CFR § 305.2 and § 305.5.

the correlated color temperature of each lamp included in the package, measured in degrees Kelvin, expressed as “Light Appearance” and by a number and a marker placed proportionately on a scale ranging from 2,600 K on the left to 6,600 K on the right

the ENERGY STAR logo for qualified products, if you wish. Manufacturers who have a signed Memorandum of Understanding with the Department of Energy or the Environmental Protection Agency may add the ENERGY STAR logo to labels on qualifying covered products that are covered by the Memorandum of Understanding

the lamp"s average initial lumens, expressed as a number rounded to the nearest five, next to the word “lumens,” both in minimum eight point font, and

If the total surface area of the product package available for labeling is less than 24 square inches, and the package shape or size cannot accommodate the standard label, you may provide the information using asmaller linear label. See 16 CFR § 305.15.

Specialty consumer lamps include most lamps with a medium screw, candelabra screw, a GU-10, or GU-24 base and a lumen range between 310 lumens and no more than 2,600 lumens, or a rated wattage between 30 and 199. The term does not cover any lamp that qualifies as a general service lamp. The Energy Labeling Rule has several exceptions for various lamp types, so it’s a good idea to review specific definitions for answers about coverage. See sections305.5and305.23of the Rule for details about the coverage.

Manufacturers may use the Lighting Facts label required for general service lamps or the smaller version of the Lighting Facts label for most specialty consumer lamps, as long as it appears on the principal display panel. However, a specialty consumer lamp that is a vibration-service lamp, rough service lamp, appliance lamp or shatter resistant lamp must use the Lighting Facts labels (and follow all other requirements) applicable for general service lamps.

If the required disclosures (i.e., either the abbreviated specialty bulb disclosure or the standard general service lamp label) would not be legible on the front of a single-card blister package due to its size, you may use a smaller label on the principal display panel that says “See Back for Lighting Facts,” and include the full Lighting Facts label on the back of the package.

You must ensure that you enter the correct data for your products. If you have signed a Memorandum of Understanding with the Department of Energy or the Environmental Protection Agency, you may use labels with the ENERGY STAR logo, but only on certified models listed on the ENERGY STAR website. SeeEnergystar.govfor more information.

You must use Department of Energy (DOE) test procedures for any lamps (e.g., general service lamps), covered by those procedures. You may find themhere. See 10 CFR Part 430, 10 CFR Part 431, and 10 CFR § 429.11.

If a lamp is not covered by DOE tests, you must have competent and reliable scientific evidence to support the representations you make on the required label. See 16 CFR § 305.8.

Here is asample of a bilingual label. All the required information must appear in both languages, but you don’t need to repeat numeric characters that are identical in both languages. The amendments don’t allow a trilingual label. See 16 CFR § 305.23.

No. The Rule doesn’t require you to get FTC approval before you label and sell the products. However, you must meet the FTC reporting requirements before you distribute products that are covered by the Rule. You also must comply with the Rule’s testing requirements. See the previous question: What test procedures must I use to support the content of my Lighting Facts label?

If you are a manufacturer of general service lamps or specialty consumer lamps covered by the labeling requirements, you must post images of the Lighting Facts labels for the products on a publicly available website so website retailers can hyperlink to the labels or download them. The label for each model must remain on the website for six months after production of that model ends. See 16 CFR § 305.6.

A manufacturer, distributor, retailer, or private labeler who advertises a general service lamp on a website or in a print catalog that contains the terms of sale, retail price, and ordering instructions for consumers, must disclose clearly and conspicuously, on the page listing the lamp, an image of the Lighting Facts label.

The labels must be clear and conspicuous, and appear in close proximity to the lamp’s price on each page that contains a detailed description of the lamp.

The Rule requires reports for general service incandescent lamps and CFLs. It does not require reports for general service light-emitting diode (LED or OLED) lamps or specialty consumer lamps. See 16 CFR § 305.8.

You can submit the reports required by the FTC through the Department of Energy’s Compliance Certification Management System (CCMS) atregulations.doe.gov/ccms. The reports must contain the same content the Department of Energy requires under its certification rules. See 16 CFR § 305.8 and 10 CFR Part 429.

Yes. You have the option to use the Lighting Facts label on lamps that do not meet the definition of general service lamp or specialty consumer lamp, as long as you comply with all the Rule’s requirements for specialty consumer lamps.

Health and Safety Code section 25210.9 references the current EU RoHS standards. However, the EU is currently debating the definition of “long” lifetime triphosphate lamps. It has been proposed to amend the EU definition “long lifetime” to be > 25,000 hours when tested on a modern electronic ballast (equivalent to an “instant start” ballasts in the US) and turned on and off every 3 hours (“three hour starts”). If the EU amends the RoHS Directive to incorporate this revised criterion for “long lifetime,” it may be applicable in California as well.

Generally, the term “standard life” is used by the lighting industry to describe a fluorescent lamp with a rated life of 24,000 hours or less, when tested on an electronic ballast with three hour starts. This is consistent with the current EU proposal to define “long lifetime” to mean having a rated life of > 25,000 hours.

Manufacturers usually label triphosphate fluorescent lamps with a life > 24,000 hours with a symbol or word to differentiate them from “normal” lifetime lamps (e.g., (LL) long life, (XLL) extra long life, PLUS, (XL) extra life, (SXL) super long life or (XP) extended performance).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Datacolor SpyderX is a breakthrough product, but not for the usual reasons. Instead of creating the absolute best monitor color calibration tool, Datacolor built the Toyota Corolla of colorimeters: an affordable solution that is super simple to use and delivers results that are good enough for most users.

The Datacolor SpyderX is an excellent monitor calibration tool for the price. A new lens design helps the unit to focus more light on the color sensor, improving accuracy on low light readings like dark tones.

Absolutely, yes! Ideally, we all should work on calibrated displays that allow us to evaluate our work according to a universal standard. To base all your decisions regarding color on an unknown variable is the same as drawing on paper with the lights turned off.

The monitor is the main place of interaction between creative professional and digital work. An uncalibrated screen is an unknown variable. Your photographs, illustrations or designs can vary wildly in color from one display to another, and even more during printing, where any misstep can represent a big waste of money. Calibrating your monitor ensures that what you see is consistent from day to day and also follows a known universal standard.

The same logic applies not only to photography but also to all fields that require consistent color — for example, web, graphic and product design. If you care about colors in your work, you need to care about the tools you use to interact with them.

Arguably, purchasing a monitor calibration tool is a worthwhile investment even for general computer usage. Think of it as a relatively inexpensive monitor upgrade that can extract the most quality from your existing display, or get similar color response between two different monitors.

Based on my tests, modern monitors drift very little over time, so it’s safe to rent a colorimeter or maybe even share the cost of one between a group of friends. For less demanding work, calibrating a modern good quality IPS monitor twice a year is perfectly acceptable. My 30” wide gamut Dell display, for example, changed less than 3 dE on the worst color patch over a span of 3 years, which is hardly visible. On average, the difference in 50 color patches as measured by DisplayCAL was negligible at less than 1 dE. I saw worse but still reasonable results when testing a MacBook Pro monitor over time.

Objectively, no. But it is more than enough for most users, including demanding use cases like display calibration for photographers or designers that need to deliver color accurate work to their clients.

The SpyderX Pro sits together with the X-Rite i1Display Studio on the sweet spot for the monitor calibration tool market: around USD 150. The alternatives below that range are simply not worth it and have to make too many compromises in terms of accuracy and longevity to achieve a lower price.

The new lens design helps the unit to focus more light on the color sensor, improving accuracy on low light readings like dark tones. That was my #1 complaint with the Spyder5.

As a byproduct of that, the new SpyderX is also many times faster. Like on a camera, more light reaching the sensor or film means we can get by with a higher shutter speed.

So, what"s the obsession with saving a couple of minutes? Well, it makes little sense for me. I"m a color geek. I enjoy spending half an hour calibrating each of my monitors. But, from an ease of use perspective, faster results are less frustrating and help to reduce the barrier of entry to convince users to calibrate their displays. "It"ll take just a couple of minutes" is a great selling point.

Another crucial change was to improve measuring accuracy and inter-unit agreement, meaning that different devices will measure more closely between each other.

In my own tests, the SpyderX produced color profiles that were virtually indistinguishable from the X-Rite products, either using their respective bundled software or the free DisplayCAL software, which supports most devices on the market and offers more advanced calibration capabilities.

The only area I could see a small difference when switching between profiles was on the most extreme grayscale dark tones below L 12 on the LAB color space.

My main display is an old Dell 30" wide gamut LCD and its main shortcoming is grayscale banding caused by a limited 8 bit LUT. For that display, the SpyderX profile showed a little more banding on the extreme dark tones. On the other monitors tested, a MacBook Pro and a Philips 4K IPS LCD with 109% sRGB gamut, the difference between devices was even closer and I wouldn"t be able to pick which is which on a blind test.

Comparing accuracy and raw performance between multiple devices on a scientific way goes beyond my own means of measuring. I prefer to focus my evaluation on actual results. On that sense, I wouldn"t mind trading my i1Display Pro for a SpyderX. It does everything I need.

But, if you"re looking for the upmost raw performance, the X-Rite devices still have an edge mainly in terms of low light performance. This is when I"ll pass the mic to the people that specialize not on using their monitor calibrators like myself, but on building the actual tools that make it all work.

Tom Huffman, creator of the ChromaPure video calibration software, reviewed the SpyderX and measured raw sensor performance using high-end devices costing thousands of dollars. He concluded that the SpyderX has excellent overall accuracy and repeatability between measurements, although absolute low-light sensitivity still trails behind the X-Rite models.

When it comes to color management systems, Graeme Gill – author of the amazing open source Argyll CMS library – is the person to listen to. In summary, he found the SpyderX to be a good and cheap device, with limitations in terms of low light performance.

Finally, Florian Höch, the developer behind DisplayCAL, noted that the SpyderX doesn"t support external correction matrices for different display technologies. This effectively limits the longevity of the device as those corrections can be used to support new types of displays that may appear in the future.

Compared to the Pro version, the more expensive Datacolor SpyderX Elite can also calibrate digital projectors and offers additional tools to check the quality of your display, more advanced calibration targets for video standards and tools to match multiple displays in a studio environment. It can also calibrate digital projectors.

Most users calibrating their monitors for photography, illustration, print design or even general computer usage should be covered by the standard calibration presets offered on the Pro model.

The most common calibration target for those use cases is 6500K white point color temperature, 2.2 gamma and a luminance value from 90 cd/m2 to 120 cd/m2, depending on how bright is your room.

Users that require special calibration targets can always switch to DisplayCAL, a free software that is compatible with multiple colorimeter models and offers almost endless calibration options. That’s what I use on all of my devices, including the i1Display Pro that is my daily driver since 2012.

The i1Display Studio has a small edge over the Datacolor SpyderX Pro in terms of raw performance, specially in deep dark tones. If both units cost the same price on your local market, I"d go for the i1, unless calibration speed is important for your workflow. In that case, the SpyderX is much faster: less than 2 minutes vs. a little over 5 minutes for the i1.

Actual calibration results are pretty much comparable between both display calibrators and I personally can hardly see the difference when switching back and forth between profiles made with each device. Both units are more than capable of delivering professional grade results.

That said, my pick would be the i1 Display Studio in terms of raw hardware capability. It is basically the same highly regarded sensor as the i1 Display Pro version, but with a firmware that limits it to a slower calibration speed. Hardly a dealbreaker, unless you need to calibrate multiple monitors per day.

In terms of longevity, Datacolor historically supports their devices for a longer time and usually delivers more stable software. The X-Rite model has an advantage here, though, for using external software-based matrix corrections to deal with different display backlight technologies, while the SpyderX has those corrections baked in firmware. What this means in practice is that the i1 can be more easily upgraded in the future as new display technologies emerge.

All things equal, go for the i1Display Studio, but make sure to check the latest prices on your local market. Here in Brazil, for example, the SpyderX Pro can be had for roughly 30% cheaper than the i1Display Studio, making it a much better purchase.

Tip: The i1Display Studio is essentially a rebranding of the previous Colormunki Display product. Both devices share the same hardware, same measurement performance and differ only on cosmetic changes. This may be a good time to buy a discontinued ColorMunki Display if you manage to get it for a great price or used.

The Datacolor SpyderX colorimeter is a small USB device that can precisely measure the color response of your computer screen. By comparing the actual displayed response of known color values, it creates a color profile that is used by the operating system and color managed applications to show correct colors. This process transforms your monitor from an unknown variable into a standard reference and can greatly improve your screen’s image quality by improving tonal response and shadow detail.

The resulting color profile is used by your operating system and any color managed program to adjust its output, making sure that what you see is as similar as possible to other displays, given their intrinsic differences.

These profiles are also used to match colors between other color managed devices. For example, if you have custom color profiles for your display and photo printer, Adobe Lightroom can understand their differences and match their output as closely as possible, or simulate the printer output on your screen.

Before you begin, the first order of business is to verify all your monitor hardware settings and make sure to select the most appropriate initial state for calibration. This means disabling any advanced image processing – features like game mode, enhanced contrast, dynamic backlight, etc – and getting the white point color temperature and gamma curve as close as possible to your desired target, usually 6500K and 2.2 gamma.

If your monitor has adjustable controls for each RGB color channel, turn on the option “Show RGB Sliders option in Identify Controls screen” in the Advanced Settings section. If not, look for preset color temperatures and set it to the closest value available to the desired white point.

Make sure to also check the video card control panel to make sure there’s nothing that could interfere with color output. For example, reduced RGB range or color calibration settings. Our goal is to keep the image pipeline absolutely neutral and make sure nothing interferes with the calibration / characterization process.

Before beginning, let the display to warm up for 30 minutes. Also disable the screen saver and monitor power settings to avoid disruption during the process.

The SpyderX uses a lens to focus light on the sensor. This helps minimize any environmental interference. For example, glare from nearby lights. In any case, it’s a good idea to avoid an overly bright room and any direct light shining on the calibrator while it works. Also make sure the unit sits flush on your screen. I usually tilt my monitor backwards so the colorimeter weight helps it sit tight on the display surface.

SpyderX offers ambient light monitoring and compensation, but I feel this functionality makes more harm than good. In my experience, it’s pretty easy to get incorrect results depending on the colorimeter positioning in relation to the room lights. If you’re doing any work where color accuracy matters, the best approach is to control room lighting to make it consistent throughout the day and within reasonable brightness to minimize visual interference, not the other way around.

The SpyderX uses a step-by-step wizard to guide users along the calibration. All in all, it"s a pretty easy process. The most important decision here is to select the correct display type and calibration target.

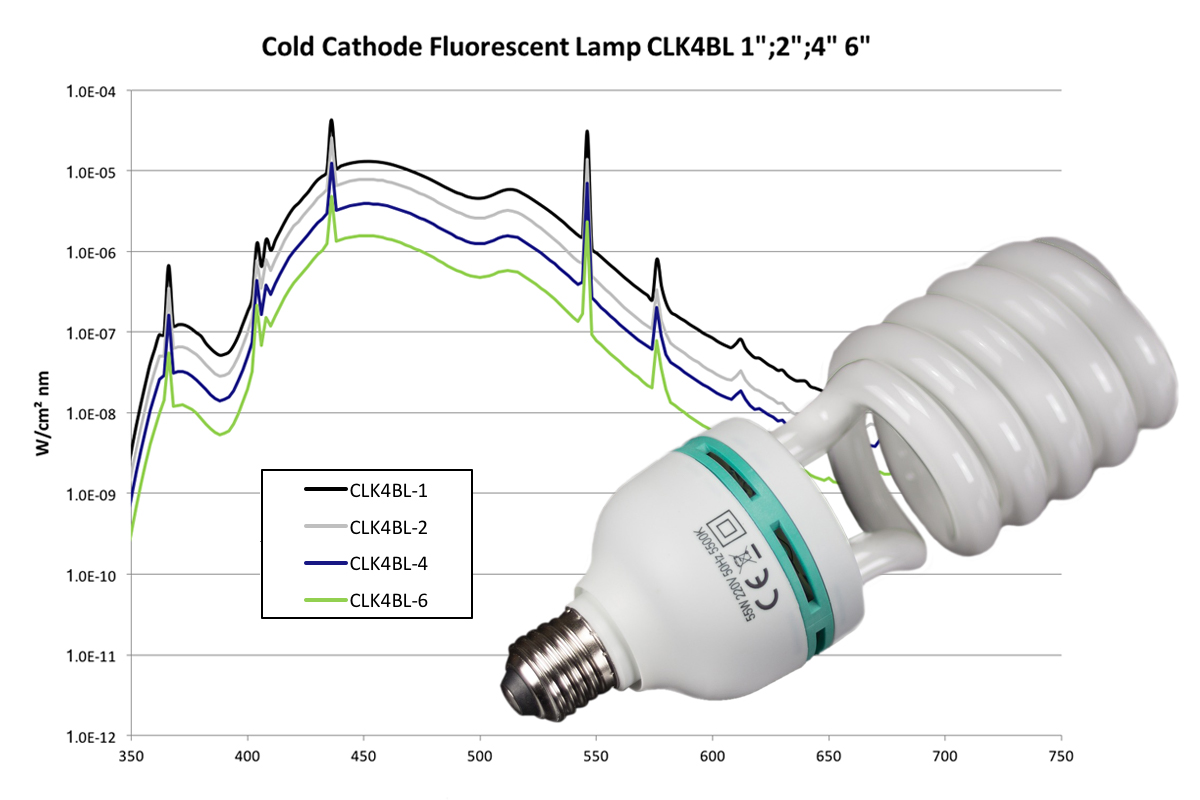

A quick Google search will tell you the correct backlight type for your display. In a nutshell, GB LED displays are pretty rare, old displays are usually CCFL, 2015 and newer Apple iMacs and MacBooks are Wide LED and generic modern laptop or desktop monitors are Standard LED.

As for the target settings, the vast majority of users should pick 6500K, 2.2 gamma, and a luminance target from 90 to 130 cd/m2, depending on room lighting.

As I mentioned above, keep the Room Light setting disabled. I feel that adapting the calibration to room lighting conditions is prone to errors and does more harm than good.

Since the SpyderX is so fast, a good practice is to perform an initial test calibration to make sure all display settings are correct, adjust hardware brightness and color temperature on the monitor on screen controls. This is helpful to make sure all settings are as close as possible to the final target.

My secondary display, for example, was closest to gamma 2.2 when I selected gamma 2.6 on its controls and I was able to catch that difference by observing the profile correction curves using the free ICC Profile Info utility bundled with DisplayCAL.

Another advantage of doing a test calibration first is to get brightness close to your target value – 120 cd/m2, for example – and using native brightness on the final real calibration process.

The goal here is to make the color profile do as little work as possible. The more work the profile and video card LUT do, bigger is the risk of getting banding or harsh tonal transitions, akin to a strong color curve in Photoshop, for example. That"s one of the main selling points of better quality, factory calibrated monitors: they are close to a good standard and need less work to be calibrated.

It"s always a good idea to open the monitor profile and inspect the calibration curves to catch any obvious problems. What we want to see is a reasonably smooth set of lines from dark to light.

Make sure the newly generated color profile is installed on the operating system control panel. Most programs will read it from the OS and don"t need individual configuration.

Most cheap displays use TN displays that are often 6-bit internally, which leads to severe color banding, especially when calibrated to anything outside their native white point. To make matters worse, TN displays are usually very blue, meaning they have a hardware white point over 7500K.

The final nail in the coffin is that they shift colors depending on the viewing angle. Displays with VA panels are much better than TN, but also suffer from color changes depending on the viewing angle.

While we tend to use both terms interchangeably, true monitor calibration means being able to change the hardware response directly within the monitor.

Profiling means characterizing how a particular device reproduces colors and a color profile can be used to compensate and effectively calibrate a display by altering color response at the graphics card level.

Both are not mutually exclusive. A factory calibrated display still requires a colorimeter to create a color profile characterizing that particular unit response. This color profile is required by the operating system and color managed apps so they can understand how the hardware, the monitor itself, reproduces color.

In practice, if you have a display with hardware calibration, make sure to check the updated compatibility lists before purchasing a calibrator. Generally speaking, the i1Display Pro is compatible with all those programs.

If your work budget justifies a bigger invest in color management, I"d opt for the i1Display Pro, which costs about USD 90 more than a SpyderX Pro. As mentioned above, it"s a better hardware in terms of low light measurement and I"ve been using mine for the past 8 years. That difference in price feels smaller when diluted over time or in front of high budget work.

True HDR monitors with very high peak brightness require special devices for calibration. As far as I know, there"s only one reasonably priced device on the market capable of calibrating those devices: the recently launched X-Rite i1Display Pro Plus colorimeter. This special Plus version of the familiar i1Display Pro colorimeter can handle brighter displays up to 2000 cd/m2, including the Apple Pro Display XDR.

It provides much more advanced and flexible options than the bundled software and can be used in a variety of use cases from the most common calibration targets to complex video 3D LUTs or calibration targets specific for video and color grading. The possibilities are almost endless.

What is cool about DisplayCAL is that it brings advanced features and arguably better quality to devices that are usually differentiated only in software bundle. Put in practice, DisplayCAL removes the gap between SpyderX versions and goes much beyond what the Elite version offers.

Speaking specifically about the SpyderX, the only drawback I can see is that using it with DisplayCAL is much slower than with the bundled software. A full calibration can take 20 minutes, depending on the settings.

It"s also a more complicated and less user friendly software for less technical users, while the Datacolor bundled software uses a step-by-step wizard that hides complex decisions in the name of ease of use.

The Datacolor SpyderX is an excellent device that does its job without much fuss. What more could we ask for? I make a point of only writing about products that I personally use and recommend. The SpyderX Pro is an easy pick.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The World"s Most Widely Used Weathering Tester™.Test plastics, coatings, and other materials for durability when exposed to outdoor sunlight, heat, and water.

UV light is responsible for almost all photodegradation of durable materials exposed outdoors. The QUV tester’s fluorescent lamps simulate the critical short-wave UV and realistically reproduce the physical property damage caused by sunlight. Types of damage include color change, gloss loss, chalking, cracking, crazing, hazing, blistering, embrittlement, strength loss and oxidation.

Dew, not rain, is responsible for most of the wetness that occurs in outdoor exposure. The QUV UV test chamber"s condensation system realistically simulates dew and accelerates its effect using elevated temperature.

The condensation process automatically purifies the ordinary tap water used in the system. This is because the process of evaporating and condensing the water onto the specimens is actually a distillation process, which removes all impurities. See LU-0801 - QUV Brochure.

The QUV tester conveniently accommodates up to 48 specimens (75mm × 150mm) and complies with a wide range of international, national, and industry specifications, ensuring the reliability and reproducibility of your test program. Visit our standards page for more information.

The QUV UV tester’s simple, proven design makes it easy to install, easy to use, and almost maintenance-free. It operates completely automatically, 24 hours a day, 7 days a week. Features include:Dual touchscreen user interface for easy operation and programming in 17 user-selectable languages: English, Spanish, French, German, Italian, Japanese, Chinese, Korean, Czech, Dutch, Polish, Portuguese, Russian, Swedish, Thai, Turkish, Vietnamese

This is a simplified version of the QUV tester for the lab where economy is critical. The model QUV/basic uses fluorescent UV lamps and a condensation system for moisture simulation. The model, however, does not include the SOLAR EYE irradiance control. Consequently, the light intensity cannot be adjusted or calibrated. This means the QUV/basic tester cannot be used for high irradiance testing. In addition, periodic lamp replacement and repositioning is required.

Q-Lab recommends the QUV/basic tester for comparative exposures where the test specimens and the control specimens are exposed at the same time, in the same tester.

The most popular QUV model features the SOLAR EYE Irradiance Control, for precise maintenance of UV light intensity. The QUV/se tester uses a proven condensation mechanism to simulate outdoor moisture attack.

The SOLAR EYE system is a precision control system that automatically maintains light intensity through a feedback loop. The controller monitors UV intensity and compensates for lamp aging and variability by adjusting power to the lamps. The SOLAR EYE system provides: Controlled irradiance

The QUV/spray tester has the same functions as a standard QUV/se, but also includes a water spray system. Short periods of spray can be used to create a thermal shock. Longer periods can be used to achieve mechanical erosion. The QUV/spray tester can be set to produce: UV alone, spray alone, or condensation. Deionized water is recommended for all spray applications.

UVC light is used widely in ultraviolet germicidal irradiation (UVGI), a technique used to eliminate harmful viruses and bacteria. This short-wavelength, high-energy UVC light can also degrade the materials and surfaces it disinfects. The QUV/uvc model uses UVC lamps to deliver light concentrated at 254 nm to test for material durability against photodegradation effects resulting from exposure to UVC light. The QUV/uvc tester has multiple safety features to prevent stray UVC light from escaping; it is also not equipped with condensation or water spray.

Model QUV/cwSome industry test methods specify the use of cool white fluorescent lamps for indoor photostability testing. To reproduce these indoor light conditions, the QUV/cw uses ordinary cool white fluorescent lamps. It has a SOLAR EYE irradiance control system that monitors and controls visible light output, rather than UV. See LU-0823 - QUV/cw Summary for more information.Temperature Control

All QUV UV testers precisely control temperature to enhance accuracy and accelerate test results. Although temperature does not normally affect the primary photochemical reaction, it does affect the rate of any subsequent reactions. Therefore, the QUV tester’s ability to control temperature is essential during UV exposure.

Standard specimen holders easily adjust for any thickness up to 20mm (3/4") and allow fast, snap-action specimen mounting. Retaining rings provide positive hold-down and do not require that test specimens be cut to close tolerance. In addition, custom holders are available for mounting various products, such as lenses, larger specimens, and 3-D components. See the accessories tab or our specimen mounting page for more information.

Controls & Optional SoftwareThe Dual Touchscreen Display is designed to be both functional and easy-to-use. The QUV main controller features dual, full-color touchscreen displays and can be programmed in eight user-selectable languages (English, French, Spanish, Italian, German, Chinese, Korean, and Japanese). This system includes complete self-diagnostic error checking, constantly monitoring the status and performance of all systems. It also displays tester error messages and routine service reminders as needed. The multicolor LED status indicator light updates users on the tester’s operational state at a glance.

An external USB port on every QUV tester allows users to perform software upgrades quickly to address key performance issues. For quality systems that require documented proof of test conditions, this USB port can also be used to download tester performance history. Additionally, every QUV tester is equipped with an Ethernet connection. Optional VIRTUAL STRIPCHART PC software allows the user to automatically record and monitor exposure conditions and directly transfer data from the QUV UV test chamber to a Windows-based computer. Data from either the USB export or PC application can be emailed directly to Q-Lab"s technical support desk for expert troubleshooting and diagnostics.

Fluorescent UV lamps are inherently more stable than other types of lamps, including xenon arc lamps. The spectral power distribution (SPD) does not change with lamp aging, even up to 8,000 hours. This gives more reproducible test results, fewer lamp changes, and lower operational costs.

Q-Lab produces more UV lamps than the rest of the weathering industry combined. Q-Lab"s lamps are specially engineered to our own proprietary specifications, based on our 50 years of experience with fluorescent UV technology. We have the most stringent quality control testing in the industry. The result is that the QUV tester provides the most consistent, stable spectrum, year after year.

Several different types of UV lamps are available for different applications, which are listed below. See LU-8160 - A Choice of Lamps for QUV and LU-0823 - QUV/cw Summary for more specific application guidelines

The QUV tester’s UVA-340 lamps give the best simulation of sunlight in the critical short wavelength region from 365 nm down to the solar cut-off of 295 nm. See LU-8052 - SPD for QUV UVA-340.

UVA-340+ LampsUVA-340+ lamps offer the same spectrum as UVA-340 lamps but provide longer lifetime at high irradiance, up to 1500 hours at 1.55 W/m2/nm and 750 hours at the maximum irradiance (1.70 W/m2/nm).

The QUV UV tester’s UVA-351 lamps simulate the UV portion of sunlight filtered through window glass. It is most useful for interior applications, for testing of some inks and for polymer damage that can occur in an environment near a window. See LU-8053 - SPD for QUV UVA-351.

The QUV tester’s UVB-313EL lamps maximize acceleration utilizing short-wave UV that is more severe than the UV normally found at the earth’s surface. Consequently, these lamps may produce unrealistically severe results for some materials. UVB-313EL lamps are most useful for QC and R&D applications, or for testing very durable materials. See LU-8051 - SPD for QUV UVB-313EL.

UVB-313EL+ lamps offer nearly the same spectrum as UVB-313EL lamps but provide longer lifetime at high irradiance, up to 1500 hours at 1.55 W/m2/nm and 750 hours at the maximum irradiance (1.70 W/m2/nm)

UVC lamps deliver high-intensity, monchromatic, short-wave UV light at 254 nm, which is well below the solar cut-on. This wavelength represents the most common type of UVC emission used for disinfection of surfaces exposed to harmful bacteria and viruses. While it can kill these pathogens effectively, UVC light can also cause photodegradation of plastics, coatings, and fabrics. UVC lamps reproduce this damaging irradiance, in order to evaluate durability of materials exposed to UVC light

Also known as FS-40 or F40 UVB, this is the original QUV lamp. FS-40 lamps are still specified in a few legacy automotive test methods. QFS-40 lamps should only be used in the QUV/basic tester. See LU-8050 - SPD for QUV QFS-40.

The QUV UV test chamber’s cool white lamps (used only in model QUV/cw) effectively reproduce and accelerate indoor lighting conditions encountered in office and commercial environments as well as retail display lighting. See LU-8049 - SPD for QUV/cw.

The QUV black panel temperature sensor needs to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV black panel temperature sensor is quick and simple, and is performed with any standard reference thermometer.

Easy Calibration Assures AccuracyFor all models except QUV/basic, the QUV SOLAR EYE irradiance sensor needs to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV tester using the AUTOCAL system is extremely simple. It takes only a few minutes and virtually eliminates human error.

Q-Lab has two classes of devices used for irradiance calibration. The Universal Calibrator system is standard with all new QUV testers and is fully compatible with all previous model, as well as Q-SUN testers. The CR10 is Q-Lab"s legacy QUV irradiance calibration system but remains forward-compatible with all new QUV testers. For more information, see LU-0801 - QUV Brochure.

UC10 smart sensors need to be replaced yearly for a newly-calibrated device. This is the most cost-effective option for most users. UC10 smart sensors can, alternatively, be returned to Q-Lab once per year for an inexpensive recalibration. See Recalibration Return Procedure.

Our calibration labs are accredited to ISO 17025 by the American Association of Laboratory Accreditation (A2LA - Ohio Certificate Number 2382-01, China Certificate Number 2383-02, and England Certificate Number 2383-03). Calibrations are traceable to the U.S. National Institute of Standards and Technology (NIST).

Standard specimen holders adjust for any thickness up to 20mm (3/4") and allow fast, snap-action specimen mounting. Retaining rings provide positive hold-down and do not require that test specimens be cut to close tolerance.

In addition, custom holders are available for mounting various products, such as lenses, larger specimens, and 3-D components. Bottle holders, textile holders and special mountings are also available. See LU-8001 - QUV Sample Mounting or the specimen mounting pagefor more detailed information.

To significantly reduce the cost of running the QUV tester’s optional water spray system, Q-Lab offers an optional water repurification systemthat reuses the water that normally would go down the drain.

In labs where space is a premium, QUV UV testers can be stacked two-high with space saver frames. See LU-0820 - QUV Space Saver Specifications for more detailed information.

Top: two non-integrated compact fluorescent lamps. Bottom: two fluorescent tube lamps. Both types require a ballast in the light fixture. A matchstick, left, is shown for scale.

Typical F71T12 100 W G13 bi-pin lamp used in tanning beds. The (Hg) symbol indicates that this lamp contains mercury. In the US, this symbol is now required on all mercury-containing fluorescent lamps.

Inside the lamp end of a preheat G13 lamp. In this lamp, the filament is surrounded by an oblong metal cathode shield, which helps reduce lamp end darkening.

A fluorescent lamp, or fluorescent tube, is a low-pressure mercury-vapor gas-discharge lamp that uses fluorescence to produce visible light. An electric current in the gas excites mercury vapor, which produces short-wave ultraviolet light that then causes a phosphor coating on the inside of the lamp to glow. A fluorescent lamp converts electrical energy into useful light much more efficiently than an incandescent lamp. The typical luminous efficacy of fluorescent lighting systems is 50–100 lumens per watt, several times the efficacy of incandescent bulbs with comparable light output. For comparison, the luminous efficacy of an incandescent bulb may only be 16 lumens per watt.

Fluorescent lamp fixtures are more costly than incandescent lamps because, among other things, they require a ballast to regulate current through the lamp, but the initial cost is offset by a much lower running cost. Compact fluorescent lamps are now available in the same popular sizes as incandescents and are used as an energy-saving alternative in homes.

Because they contain mercury, many fluorescent lamps are classified as hazardous waste. The United States Environmental Protection Agency recommends that fluorescent lamps be segregated from general waste for recycling or safe disposal, and some jurisdictions require recycling of them.

The fluorescence of certain rocks and other substances had been observed for hundreds of years before its nature was understood. By the middle of the 19th century, experimenters had observed a radiant glow emanating from partially evacuated glass vessels through which an electric current passed. One of the first to explain it was the Irish scientist Sir George Stokes from the University of Cambridge in 1852, who named the phenomenon "fluorescence" after fluorite, a mineral many of whose samples glow strongly because of impurities. The explanation relied on the nature of electricity and light phenomena as developed by the British scientists Michael Faraday in the 1840s and James Clerk Maxwell in the 1860s.

Little more was done with this phenomenon until 1856 when German glassblower Heinrich Geissler created a mercury vacuum pump that evacuated a glass tube to an extent not previously possible. Geissler invented the first gas-discharge lamp, the Geissler tube, consisting of a partially evacuated glass tube with a metal electrode at either end. When a high voltage was applied between the electrodes, the inside of the tube lit up with a glow discharge. By putting different chemicals inside, the tubes could be made to produce a variety of colors, and elaborate Geissler tubes were sold for entertainment. More important, however, was its contribution to scientific research. One of the first scientists to experiment with a Geissler tube was Julius Plücker, who systematically described in 1858 the luminescent effects that occurred in a Geissler tube. He also made the important observation that the glow in the tube shifted position when in proximity to an electromagnetic field. Alexandre Edmond Becquerel observed in 1859 that certain substances gave off light when they were placed in a Geissler tube. He went on to apply thin coatings of luminescent materials to the surfaces of these tubes. Fluorescence occurred, but the tubes were very inefficient and had a short operating life.

Inquiries that began with the Geissler tube continued as even better vacuums were produced. The most famous was the evacuated tube used for scientific research by William Crookes. That tube was evacuated by the highly effective mercury vacuum pump created by Hermann Sprengel. Research conducted by Crookes and others ultimately led to the discovery of the electron in 1897 by J. J. Thomson and X-rays in 1895 by Wilhelm Röntgen. But the Crookes tube, as it came to be known, produced little light because the vacuum in it was too good and thus lacked the trace amounts of gas that are needed for electrically stimulated luminescence.

One of the first mercury vapor lamps invented by Peter Cooper Hewitt, 1903. It was similar to a fluorescent lamp without the fluorescent coating on the tube and produced greenish light. The round device under the lamp is the ballast.

Thomas Edison briefly pursued fluorescent lighting for its commercial potential. He invented a fluorescent lamp in 1896 that used a coating of calcium tungstate as the fluorescing substance, excited by X-rays, but although it received a patent in 1907,Nikola Tesla made similar experiments in the 1890s, devising high-frequency powered fluorescent bulbs that gave a bright greenish light, but as with Edison"s devices, no commercial success was achieved.

One of Edison"s former employees created a gas-discharge lamp that achieved a measure of commercial success. In 1895 Daniel McFarlan Moore demonstrated lamps 2 to 3 meters (6.6 to 9.8 ft) in length that used carbon dioxide or nitrogen to emit white or pink light, respectively. They were considerably more complicated than an incandescent bulb, requiring both a high-voltage power supply and a pressure-regulating system for the fill gas.

Moore invented an electromagnetically controlled valve that maintained a constant gas pressure within the tube, to extend the working life.General Electric’s motivation to improve the incandescent lamp, especially its filament. GE"s efforts came to fruition with the invention of a tungsten-based filament. The extended lifespan and improved efficacy of incandescent bulbs negated one of the key advantages of Moore"s lamp, but GE purchased the relevant patents in 1912. These patents and the inventive efforts that supported them were to be of considerable value when the firm took up fluorescent lighting more than two decades later.

At about the same time that Moore was developing his lighting system, Peter Cooper Hewitt invented the mercury-vapor lamp, patented in 1901 (). Hewitt"s lamp glowed when an electric current was passed through mercury vapor at a low pressure. Unlike Moore"s lamps, Hewitt"s were manufactured in standardized sizes and operated at low voltages. The mercury-vapor lamp was superior to the incandescent lamps of the time in terms of energy efficiency, but the blue-green light it produced limited its applications. It was, however, used for photography and some industrial processes.

Mercury vapor lamps continued to be developed at a slow pace, especially in Europe, and by the early 1930s, they received limited use for large-scale illumination. Some of them employed fluorescent coatings, but these were used primarily for color correction and not for enhanced light output. Mercury vapor lamps also anticipated the fluorescent lamp in their incorporation of a ballast to maintain a constant current.

Cooper-Hewitt had not been the first to use mercury vapor for illumination, as earlier efforts had been mounted by Way, Rapieff, Arons, and Bastian and Salisbury. Of particular importance was the mercury-vapor lamp invented by Küch and Retschinsky in Germany. The lamp used a smaller bore bulb and higher current operating at higher pressures. As a consequence of the current, the bulb operated at a higher temperature which necessitated the use of a quartz bulb. Although its light output relative to electrical consumption was better than that of other sources of light, the light it produced was similar to that of the Cooper-Hewitt lamp in that it lacked the red portion of the spectrum, making it unsuitable for ordinary lighting. Due to difficulties in sealing the electrodes to the quartz, the lamp had a very short life.

The next step in gas-based lighting took advantage of the luminescent qualities of neon, an inert gas that had been discovered in 1898 by isolation from the atmosphere. Neon glowed a brilliant red when used in Geissler tubes.Georges Claude, a Frenchman who had developed a technology and a successful business for air liquefaction, was obtaining enough neon as a byproduct to support a neon lighting industry.electrodes with a lot of surface area, it showed that a major impediment to gas-based lighting could be overcome.

The development of the neon light also was significant for the last key element of the fluorescent lamp, its fluorescent coating.Edmund Germer, who were employees of a German firm in Berlin. A German patent was granted but the lamp never went into commercial production.

All the major features of fluorescent lighting were in place at the end of the 1920s. Decades of invention and development had provided the key components of fluorescent lamps: economically manufactured glass tubing, inert gases for filling the tubes, electrical ballasts, long-lasting electrodes, mercury vapor as a source of luminescence, effective means of producing a reliable electrical discharge, and fluorescent coatings that could be energized by ultraviolet light. At this point, intensive development was more important than basic research.

In 1934, Arthur Compton, a renowned physicist and GE consultant, reported to the GE lamp department on successful experiments with fluorescent lighting at General Electric Co., Ltd. in Great Britain (unrelated to General Electric in the United States). Stimulated by this report, and with all of the key elements available, a team led by George E. Inman built a prototype fluorescent lamp in 1934 at General Electric’s Nela Park (Ohio) engineering laboratory. This was not a trivial exercise; as noted by Arthur A. Bright, "A great deal of experimentation had to be done on lamp sizes and shapes, cathode construction, gas pressures of both argon and mercury vapor, colors of fluorescent powders, methods of attaching them to the inside of the tube, and other details of the lamp and its auxiliaries before the new device was ready for the public."

In addition to having engineers and technicians along with facilities for R&D work on fluorescent lamps, General Electric controlled what it regarded as the key patents covering fluorescent lighting, including the patents originally issued to Hewitt, Moore, and Küch. More important than these was a patent covering an electrode that did not disintegrate at the gas pressures that ultimately were employed in fluorescent lamps. Albert W. Hull of GE"s Schenectady Research Laboratory filed for a patent on this invention in 1927, which was issued in 1931.

While the Hull patent gave GE a basis for claiming legal rights over the fluorescent lamp, a few months after the lamp went into production the firm learned of a U.S. patent application that had been filed in 1927 for the aforementioned "metal vapor lamp" invented in Germany by Meyer, Spanner, and Germer. The patent application indicated that the lamp had been created as a superior means of producing ultraviolet light, but the application also contained a few statements referring to fluorescent illumination. Efforts to obtain a U.S. patent had met with numerous delays, but were it to be granted, the patent might have caused serious difficulties for GE. At first, GE sought to block the issuance of a patent by claiming that priority should go to one of their employees, Leroy J. Buttolph, who according to their claim had invented a fluorescent lamp in 1919 and whose patent application was still pending. GE also had filed a patent application in 1936 in Inman"s name to cover the “improvements” wrought by his group. In 1939 GE decided that the claim of Meyer, Spanner, and Germer had some merit, and that in any event a long interference procedure was not in their best interest. They therefore dropped the Buttolph claim and paid $180,000 to acquire the Meyer, et al. application, which at that point was owned by a firm known as Electrons, Inc. The patent was duly awarded in December 1939.Sylvania Electric Products, Inc., which claimed infringement on patents that it held.

Even though the patent issue was not completely resolved for many years, General Electric"s strength in manufacturing and marketing gave it a pre-eminent position in the emerging fluorescent light market. Sales of "fluorescent lumiline lamps" commenced in 1938 when four different sizes of tubes were put on the market. They were used in fixtures manufactured by three leading corporations, Lightolier, Artcraft Fluorescent Lighting Corporation, and Globe Lighting. The Slimline fluorescent ballast"s public

introduction in 1946 was by Westinghouse and General Electric and Showcase/Display Case fixtures were introduced by Articraft Fluorescent Lighting Corporation in 1946.Westinghouse publicized the new lights through exhibitions at the New York World"s Fair and the Golden Gate International Exposition in San Francisco. Fluorescent lighting systems spread rapidly during World War II as wartime manufacturing intensified lighting demand. By 1951 more light was produced in the United States by fluorescent lamps than by incandescent lamps.

In the first years zinc orthosilicate with varying content of beryllium was used as greenish phosphor. Small additions of magnesium tungstate improved the blue part of the spectrum yielding acceptable white. After it was discovered that beryllium was toxic, halophosphate-based phosphors took over.

The fundamental mechanism for the conversion of electrical energy to light is the emission of a photon when an electron in a mercury atom falls from an excited state into a lower energy level. Electrons flowing in the arc collide with the mercury atoms. If the incident electron has enough kinetic energy, it transfers energy to the atom"s outer electron, causing that electron to temporarily jump up to a higher energy level that is not stable. The atom will emit an ultraviolet photon as the atom"s electron reverts to a lower, more stable, energy level. Most of the photons that are released from the mercury atoms have wavelengths in the ultraviolet (UV) region of the spectrum, predominantly at wavelengths of 253.7 and 185 nanometers (nm). These are not visible to the human eye, so ultraviolet energy is converted to visible light by the fluorescence of the inner phosphor coating. The difference in energy between the absorbed ultra-violet photon and the emitted visible light photon goes toward heating up the phosphor coating.

Electric current flows through the tube in a low-pressure arc discharge. Electrons collide with and ionize noble gas atoms inside the bulb surrounding the filament to form a plasma by the process of impact ionization. As a result of avalanche ionization, the conductivity of the ionized gas rapidly rises, allowing higher currents to flow through the lamp.

The fill gas helps determine the electrical characteristics of the lamp but does not give off light itself. The fill gas effectively increases the distance that electrons travel through the tube, which allows an electron a greater chance of interacting with a mercury atom. Additionally, argon atoms, excited to a metastable state by the impact of an electron, can impart energy to a mercury atom and ionize it, described as the Penning effect. This lowers the breakdown and operating voltage of the lamp, compared to other possible fill gases such as krypton.

A fluorescent lamp tube is filled with a mix of argon, xenon, neon, or krypton, and mercury vapor. The pressure inside the lamp is around 0.3% of atmospheric pressure.fluorescent coating made of varying blends of metallic and rare-earth phosphor salts. The lamp"s electrodes are typically made of coiled tungsten and are coated with a mixture of barium, strontium and calcium oxides to improve thermionic emission.

A germicidal lamp uses a low-pressure mercury-vapor glow discharge identical to that in a fluorescent lamp, but the uncoated fused quartz envelope allows ultraviolet radiation to transmit.

Fluorescent lamp tubes are often straight and range in length from about 100 millimeters (3.9 in) for miniature lamps, to 2.43 meters (8.0 ft) for high-output lamps. Some lamps have the tube bent into a circle, used for table lamps or other places where a more compact light source is desired. Larger U-shaped lamps are used to provide the same amount of light in a more compact area, and are used for special architectural purposes. Compact fluorescent lamps have several small-diameter tubes joined in a bundle of two, four, or six, or a small diameter tube coiled into a helix, to provide a high amount of light output in little volume.

Light-emitting phosphors are applied as a paint-like coating to the inside of the tube. The organic solvents are allowed to evaporate, then the tube is heated to nearly the melting point of glass to drive off remaining organic compounds and fuse the coating to the lamp tube. Careful control of the grain size of the suspended phosphors is necessary; large grains lead to weak coatings, and small particles leads to poor light maintenance and efficiency. Most phosphors perform best with a particle size around 10 micrometers. The coating must be thick enough to capture all the ultraviolet light produced by the mercury arc, but not so thick that the phosphor coating absorbs too much visible light. The first phosphors were synthetic versions of naturally occurring fluorescent minerals, with small amounts of metals added as activators. Later other compounds were discovered, allowing differing colors of lamps to be made.

Fluorescent lamps are negative differential resistance devices, so as more current flows through them, the electrical resistance of the fluorescent lamp drops, allowing for even more current to flow. Connected directly to a constant-voltage power supply, a fluorescent lamp would rapidly self-destruct because of the uncontrolled current flow. To prevent this, fluorescent lamps must use a ballast to regulate the current flow through the lamp.

The terminal voltage across an operating lamp varies depending on the arc current, tube diameter, temperature, and fill gas. A general lighting service 48-inch (1,219 mm) T12

The simplest ballast for alternating current (AC) use is an inductor placed in series, consisting of a winding on a laminated magnetic core. The inductance of this winding limits the flow of AC current. This type of ballast is common in 220–240V countries (And in North America, up to 30W lamps). Ballasts are rated for the size of lamp and power frequency. In North America, the AC voltage is insufficient to start long fluorescent lamps, so the ballast is often a step-up autotransformer with substantial leakage inductance (so as to limit the current flow). Either form of inductive ballast may also include a capacitor for power factor correction.

Fluorescent lamps can run directly from a direct current (DC) supply of sufficient voltage to strike an arc. The ballast must be resistive, and would consume about as much power as the lamp. When operated from DC, the starting switch is often arranged to reverse the polarity of the supply to the lamp each time it is started; otherwise, the mercury accumulates at one end of the tube. Fluorescent lamps are (almost) never operated directly from DC for those reasons. Instead, an inverter converts the DC into AC and provides the current-limiting function as described below for electronic ballasts.

The performance of fluorescent lamps is critically affected by the temperature of the bulb wall and its effect on the partial pressure of mercury vapor within the lamp.

Using an amalgam with some other metal reduces the vapor pressure and extends the optimum temperature range upward; however, the bulb wall "cold spot" temperature must still be controlled to prevent condensing. High-output fluorescent lamps have features such as a deformed tube or internal heat-sinks to control cold spot temperature and mercury distribution. Heavily loaded small lamps, such as compact fluorescent lamps, also include heat-sink areas in the tube to maintain mercury vapor pressure at the optimum value.

A Sankey diagram of energy losses in a fluorescent lamp. In modern designs, the biggest loss is the quantum efficiency of converting high-energy UV photons to lower-energy visible light photons.

Only a fraction of the electrical energy input into a lamp is converted to useful light. The ballast dissipates some heat; electronic ballasts may be around 90% efficient. A fixed voltage drop occurs at the electrodes, which al

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey