lcd display commands manufacturer

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

We know that December is often a planning and logistics heavy month. We want to let you know what to expect from your display supplier in the coming months. Chinese New Year Every year at this time, we at Crystalfontz are in mid-swing planning for Chinese New Year. Unfortunately for us but luckily for you, … Read more Display Supply Chain: What to Expect in 2021

When working with a 20×4 character LCD, you might be surprised to see the controller set to 2-line mode: Write_To_LCD(COMMAND,0x38); //SET 2 LINE,5*8 FONT Why would a 4-line LCD’s controller be set to 2-line mode? It has to do with the way the LCD glass is laid out. Essentially the display is the right and … Read more FAQ: Why does the initialization code for a 20×4 LCD specify 2-line mode?

What is involved in ISO certification (and annual recertification) and what does it mean for a company to be ISO certified? This post takes a deeper look at everything involved in ISO certification for our LCD electronics-based company.

Confused about the differences between TFTs, LCDs, and OLEDs? What Do They Stand For? How Do They Work? TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the … Read more FAQ: What is the Difference Between a TFT, LCD, and OLED?

Sherman, set the wayback machine to 1985: We are going to take a look at the original HD44780 Data Sheet. Some time back, we wrote about the legendary HD44780 controller, to which the modern character LCD industry owes much of its existence. Having been in the business of designing embedded electronics for some time, we … Read more A Look Back in Tech History: The HD44780 Controller Data Sheet

Did you know that ePaper modules emulate ink used for paper? Check out the meaning of the glossary term electrophoresis and how it relates to ePaper module displays. Need ePaper for Your Project? For assistance in determining what ePaper module is the best one for your application, please contact our knowledgeable and friendly support staff by email, phone, or … Read more A Quick ePaper Primer

Modern Character LCD display modules have been possible since 1987 when Hitachi introduced the HD44780 LCD controller. Since then, Hitachi no longer manufactures this integrated circuit (IC), but modern LCD controller ICs make it a point to be HD44780-compatible. Controller Compatibility The character LCD display modules offered by Crystalfontz America Inc. are no exception to … Read more The Legendary HD44780 Controller

WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.govEDWARDS 3-LCDANN

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

With CS (Chip-Select) the corresponding peripheral device is selected by the LCD Controller. This pin is mostly active-low. In the unselected state the SDO lines are hi-impedance and therefore inactive. The clock line SCL is brought to the device whether it is selected or not. The clock serves as synchronization of the data communication.

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

Connector ports for devices such like cameras, displays, basebands, and RF interfaces are standardized under MIPI Alliance specifications. These specifications include design, manufacturing costs, structural complexity, power consumption and degree of EMI.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

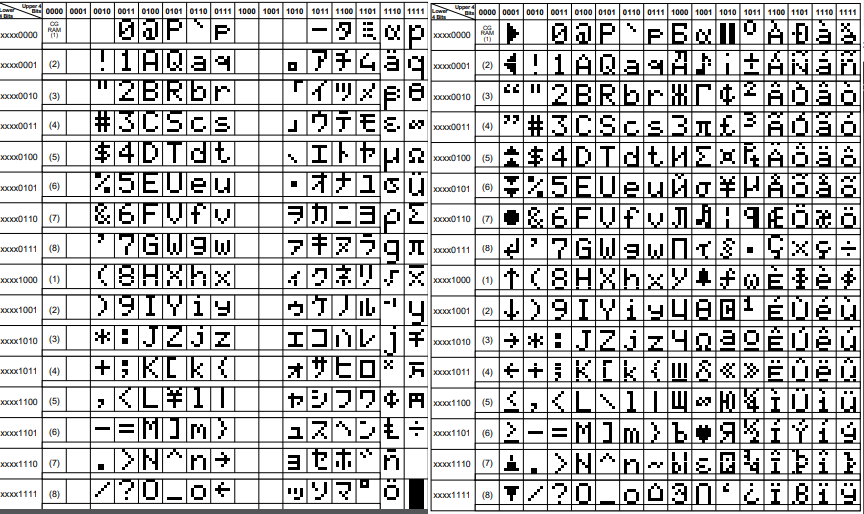

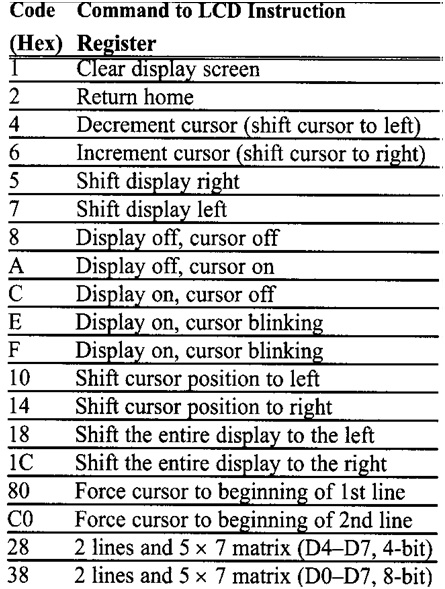

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Lcd stands for liquid crystal display. Character and graphical lcd’s are most common among hobbyist and diy electronic circuit/project makers. Since their interface serial/parallel pins are defined so its easy to interface them with many microcontrollers. Many products we see in our daily life have lcd’s with them. They are used to show status of the product or provide interface for inputting or selecting some process. Washing machine, microwave,air conditioners and mat cleaners are few examples of products that have character or graphical lcd’s installed in them. In this tutorial i am going to discuss about the character lcd’s. How they work? their pin out and initialization commands etc.

Character lcd’s come in many sizes 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2 etc .Many multinational companies like Philips, Hitachi, Panasonic make their own custom type of character lcd’s to be used in their products. All character lcd’s performs the same functions(display characters numbers special characters, ascii characters etc).Their programming is also same and they all have same 14 pins (0-13) or 16 pins (0 to 15).

In an mxn lcd. M denotes number of columns and n represents number of rows. Like if the lcd is denoted by 16×2 it means it has 16 columns and 2 rows. Few examples are given below. 16×2, 8×1 and 8×2 lcd are shown in the picture below. Note the difference in the rows and columns.

On a character lcd a character is generated in a matrix of 5×8 or 5×7. Where 5 represents number of columns and 7/8 represent number of rows. Maximum size of the matrix is 5×8. You can not display character greater then 5×8 dimension matrix. Normally we display a character in 5×7 matrix and left the 8th row for the cursor. If we use the 8th row of the matrix for the character display, then their will be no room for cursor. The picture below shows the 5×8 dot matrix pixels arrangement.

To display character greater than this dimension you have to switch to graphical lcd’s. To learn about graphical lcds here is a good tutorialGraphical Lcd’s Working and Pin out.

The picture above shows the pin out of the character lcd. Almost all the character lcd’s are composed of the same pin out. Lcd’s with total pin count equal to 14 does not have back light control option. They might have back light always on or does not have a back light. 16 total pin count lcd’s have 2 extra A and K pins. A means anode and K cathode, use these pins to control the back light of lcd.

Character Lcd’s have a controller build in to them named HD44780. We actually talk with this controller in order to display character on the lcd screen. HD44780 must be properly handled and initialized before sending any data to it. HD44780 has some registers which are initialized and manipulated for character displaying on the lcd. These registers are selected by the pins of character lcd.

When we send commands to lcd these commands go to Command register and are processed their.Commands with their full description are given in the picture below.When Rs=0 command register is selected.

When we select the register Rs(Command and Data) and set Rw(read – write) and placed the raw value on 8-data lines, now its time to execute the instruction. By instruction i mean the 8-bit data or 8-bit command present on Data lines of lcd. For sending the final data/command present on the data lines we use this enable pin.Usually it remains en=0 and when we want to execute the instruction we make it high en=1 for some mills seconds. After this we again make it ground en=0.

To set lcd display sharpness use this pin. Best way is to use variable resistor such as potentiometer a variable current makes the character contrast sharp. Connect the output of the potentiometer to this pin. Rotate the potentiometer knob forward and backward to adjust the lcd contrast.

NOTE: we can not send an integer, float, long, double type data to lcd because lcd is designed to display a character only. Only the characters that are supported by the HD44780 controller. See the HD44780 data sheet to find out what characters can we display on lcd. The 8 data pins on lcd carries only Ascii 8-bit code of the character to lcd. How ever we can convert our data in character type array and send one by one our data to lcd. Data can be sent using lcd in 8-bit or 4-bit mode. If 4-bit mode is used, two nibbles of data (First high four bits and then low four bits) are sent to complete a full eight-bit transfer. 8-bit mode is best used when speed is required in an application and at least ten I/O pins are available. 4-bit mode requires a minimum of seven bits. In 4-bit mode, only the top 4 data pins (4-7) are used.

Command 0x30 means we are setting 8-bit mode lcd having 1 line and we are initializing it to be 5×7 character display.Now this 5×7 is some thing which every one should know what it stands for. usually the characters are displayed on lcd in 5×8 matrices form. where 5 is total number of columns and is number of rows.Thus the above 0x30 command initializes the lcd to display character in 5 columns and 7 rows the last row we usually leave for our cursor to move or blink etc.

NOTE:You can send commands in hexadecimal or decimal form which one do you like the result is same because the microcontroller translate the command in 8-bit binary value and sends it to the lcd.

Character Lcd’s can be used in 4-bit and 8-bit mode.Before you send commands and data to your lcd. Lcd must first be initialized. This initialization is very important for lcd that are made by Hitachibecause they use HD44780 driver chip sets. Hd44780 Chip set first has to be initialized before using it. If you don’t initialize it properly you will see nothing on your lcd.

In 4-bit mode the high nibble is sent first before the low nibble and the En pin is toggled eachtime four bits is sent to the LCD. To initialize in 4-bit mode:

To learn more about the difference between 4-bit and 8-bit character lcd mode and operation with demo example visit the tutorial link given below. Demo examples are very easy to understand and one can make changes easily in the code. Please also give us your feed back on the post.

Тhis time I will present you a simple way to control 16x2 LCD Display via Windows PC software. For this purpose, we use an Arduino microcontroller, which in this case has the function of an interface between the Display and the USB port of the Computer. Also the LCD display can be controlled directly through the LPT port, but nowadays that port is no longer used and has been replaced by USB.

I use Open Source software for Windows LCD Smartie that you can use to show lots of different types of information on your LCD or VFD. The program has built in support for many systems statistics (i.e. cpu load, network utilization, free disk space...), downloading RSS feeds, Winamp integration and support for several other popular applications. Supported devices include displays based on the Hitachi HD44780 LCD controller like in our case, the Matrix Orbital Serial/USB LCD, and Palm OS devices.

- Arduino microcontroller, and LCD display which are connected according to the given schematic diagram, and it is powered directly from the USB port.

I mounted the device in a box from a previous project, and is a stand-alone device that can be placed on top of the computer case or somewhere else. Оtherwise the original idea was to mount the LCD screen to the plastic of 5.25-Inch drive bay and be an integral part of the PC.

First, we unpack the .zip archive into a specific folder. Then the LCDT.dll matrix orbital driver should be placed in the "displays" folder. This is actually a driver for the 16x2 LCD display. You can download these archives at the link below. Next, we start the program and select the LCD display plugin, then we set the startup parameters according to the port occupied by the Arduino microcontroller. Now the simplest option is to enter some text in these fields which actually represent the two rows of the LCD display. If we have connected everything exactly according to the instructions, when we press the apply button, the written text should appear on the LCD display. Lcd Smartier has built in support for many systems statistics (i.e. cpu load, network utilization, free disk space, Winamp integration, BBC World News, Email details, game stats, and many more. It is also possible to integrate several different plugins that can be downloaded from the official site and forums. As for the Arduino, the given code should be uploaded, but I should mention that the code is compiled with the LiquidCrystal-1.0.0 Library which you can also download from the link below. LCD Smartie also has support for the popular Winamp player software.

Thanks for the response it is quite difficult to monitor a 20 pin protocol but I quite managed to monitor 4 pins (RS , CS , WR , and one random data line) while I was constantly sending data 0xffff(image bellow) . But I think I found something more critical , from the initialization code I tried to remove all the `send_data` lines and the results on the screen was exactly the same! I can interpret that as follows: the send_data command does not work and also some initialization commands worked as they didn"t require any data and some others didn"t but those that worked made the screen to look like it was responding correct.

There are a lot of different LCD Displays out there and a lot of them can be tricky to get working. All of them require some sort of backback which converts the serial or I2C commands sent to it in to what is displayed on the screen, but these commands can change between manufacturers and even models.

Digole Digital Solutions provide a huge range of LCD Displays and the great thing about them is they can be used in either Serial or I2C mode selectable by soldering a small jumper in place. The company themselves are still a pretty small, new company so I am told but that doesn"t mean the support isn"t there either. It is.

The other great thing about them is that they all use the same commands across the whole range, so once you have the datasheet for one, you have it for them all. Once you learn the commands that need to be sent to display text or position text, display an image or clear the screen then you know it for them all.

I plan to get hold of all Digole displays to ensure they will all work the same way and explain which are able to display graphics, custom fonts etc. and which can"t. Bear with me on this, funds are a little tight so they will come in one by one, I am in talks with Digole to see if I can secure some kind of discount which will help make this a more comprehensive tutorial however as they are pretty new and small that may not happen.

The 1602 LCD is probably going to be the more popular one. It"s a nice, easy to see, but is limited to text only and is 16 characters long by 2 characters high so space is restricted a little.

All of the Digole units are capable of displaying text and do so in the same way. The following examples assume you have set the module to I2C mode, however if you use serial the command is almost the same, just substitute I2CWrite(0,0x27 for SendSerial(Port,9600

When you first turn the unit on, power it up or whatever you want to call it you will get a welcome screen. By default it will display the baudrate (9600) or I2CAddress (0x27). Before displaying text you will want to clear this.

CLear screen and set the display position to first column and first row (x=0,y=0), for graphic LCD it also sets the font to default and turns off the cursor.

First, put the cursor in the position you want it in, x and y values are needed, x is the horizontal position and y the vertical. On a 16x2 display you only have 2 choices for the y value, 0 being the top row and 1 being the bottom. The x value is from left to right, 0 to 15, so 0,0 is top left, 15,1 is bottom right.

Setting the Display Mode for on coming command, the available values are: "!""~" not, "|"" or, "^" xor, "&" and, this means the next drawing pixel will logic operation with the pixel already on screen.

Display Image, 1st is the x position, 2nd is the y position, 3rs is the image width, 4th is the height, then following is data. Each byte present 8 pixels, if the image width is not divided by 8 the last byte of a row will only contain a few pixels, eg for width 9 to 16 you need 2 bytes for a row.

That is the EZ-Robot logo in data form at 128 pixels wide. So this is what needs to be entered in the command. However, I2C has a limit of 256 bytes per transmission, the above code is bigger and therefore needs splitting in half (or more section). The easiest way is to do it line by line, the code is given line by line so it takes any guess work out of it but it does display the image being drawn line by line on the display. Not a deal breaker but some may not like it.

So, to display the EZ-Robot logo across the top of the display the EZ-Script would be like this (note, I split the logo in half vertically before passing it through the converter rather than line by line);

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey