lcd display commands factory

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB/SRGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer and the hardware connection interface, the LCD panel drivers are mainly grouped into the following categories:

Controller based LCD driver involves multiple steps to get a panel handle, like bus allocation, IO device registration and controller driver install. The frame buffer is located in the controller’s internal GRAM (Graphical RAM). ESP-IDF provides only a limited number of LCD controller drivers out of the box (e.g. ST7789, SSD1306), More Controller Based LCD Drivers are maintained in the Espressif Component Registry

LCD Panel IO Operations - provides a set of APIs to operate the LCD panel, like turning on/off the display, setting the orientation, etc. These operations are common for either controller-based LCD panel driver or RGB LCD panel driver.

esp_lcd_panel_io_spi_config_t::dc_gpio_num: Sets the gpio number for the DC signal line (some LCD calls this RS line). The LCD driver will use this GPIO to switch between sending command and sending data.

esp_lcd_panel_io_spi_config_t::cs_gpio_num: Sets the gpio number for the CS signal line. The LCD driver will use this GPIO to select the LCD chip. If the SPI bus only has one device attached (i.e. this LCD), you can set the gpio number to -1 to occupy the bus exclusively.

esp_lcd_panel_io_spi_config_t::pclk_hz sets the frequency of the pixel clock, in Hz. The value should not exceed the range recommended in the LCD spec.

esp_lcd_panel_io_spi_config_t::spi_mode sets the SPI mode. The LCD driver will use this mode to communicate with the LCD. For the meaning of the SPI mode, please refer to the SPI Master API doc.

esp_lcd_panel_io_spi_config_t::lcd_cmd_bits and esp_lcd_panel_io_spi_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

esp_lcd_panel_io_spi_config_t::trans_queue_depth sets the depth of the SPI transaction queue. A bigger value means more transactions can be queued up, but it also consumes more memory.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the SPI IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::dev_addr sets the I2C device address of the LCD controller chip. The LCD driver will use this address to communicate with the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::lcd_cmd_bits and esp_lcd_panel_io_i2c_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the I2C IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

More LCD panel drivers and touch drivers are available in IDF Component Registry. The list of available and planned drivers with links is in this table.

esp_lcd_panel_draw_bitmap() is the most significant function, that will do the magic to draw the user provided color buffer to the LCD screen, where the draw window is also configurable.

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer, the LCD panel allocation functions are mainly grouped into the following categories:

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

The Uplogix LM83X Local Manager supports an LCD screen and keypad through an optional expansion card. The keypad can be used to configure the Local Manager without the need for a workstation. After configuration, the LCD screen displays system messages during boot and status information during normal operation.

When the Local Manager is powered on, press the Enter key in the center of the keypad to display the menu. Press the Back key below the left arrow key to exit the menu and resume scrolling status information.

Lcd stands for liquid crystal display. Character and graphical lcd’s are most common among hobbyist and diy electronic circuit/project makers. Since their interface serial/parallel pins are defined so its easy to interface them with many microcontrollers. Many products we see in our daily life have lcd’s with them. They are used to show status of the product or provide interface for inputting or selecting some process. Washing machine, microwave,air conditioners and mat cleaners are few examples of products that have character or graphical lcd’s installed in them. In this tutorial i am going to discuss about the character lcd’s. How they work? their pin out and initialization commands etc.

Character lcd’s come in many sizes 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2 etc .Many multinational companies like Philips, Hitachi, Panasonic make their own custom type of character lcd’s to be used in their products. All character lcd’s performs the same functions(display characters numbers special characters, ascii characters etc).Their programming is also same and they all have same 14 pins (0-13) or 16 pins (0 to 15).

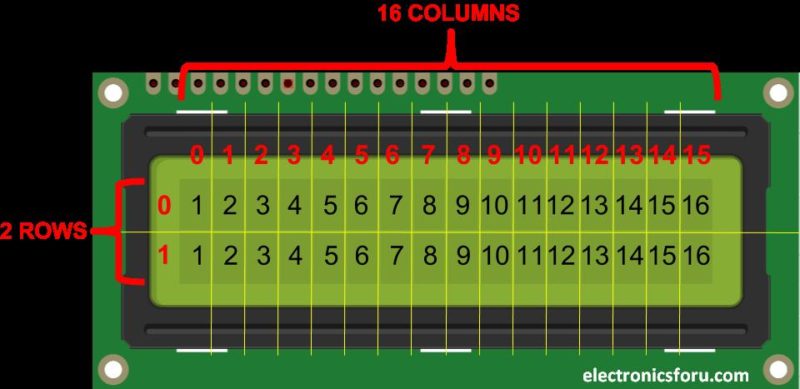

In an mxn lcd. M denotes number of columns and n represents number of rows. Like if the lcd is denoted by 16×2 it means it has 16 columns and 2 rows. Few examples are given below. 16×2, 8×1 and 8×2 lcd are shown in the picture below. Note the difference in the rows and columns.

On a character lcd a character is generated in a matrix of 5×8 or 5×7. Where 5 represents number of columns and 7/8 represent number of rows. Maximum size of the matrix is 5×8. You can not display character greater then 5×8 dimension matrix. Normally we display a character in 5×7 matrix and left the 8th row for the cursor. If we use the 8th row of the matrix for the character display, then their will be no room for cursor. The picture below shows the 5×8 dot matrix pixels arrangement.

To display character greater than this dimension you have to switch to graphical lcd’s. To learn about graphical lcds here is a good tutorialGraphical Lcd’s Working and Pin out.

The picture above shows the pin out of the character lcd. Almost all the character lcd’s are composed of the same pin out. Lcd’s with total pin count equal to 14 does not have back light control option. They might have back light always on or does not have a back light. 16 total pin count lcd’s have 2 extra A and K pins. A means anode and K cathode, use these pins to control the back light of lcd.

Character Lcd’s have a controller build in to them named HD44780. We actually talk with this controller in order to display character on the lcd screen. HD44780 must be properly handled and initialized before sending any data to it. HD44780 has some registers which are initialized and manipulated for character displaying on the lcd. These registers are selected by the pins of character lcd.

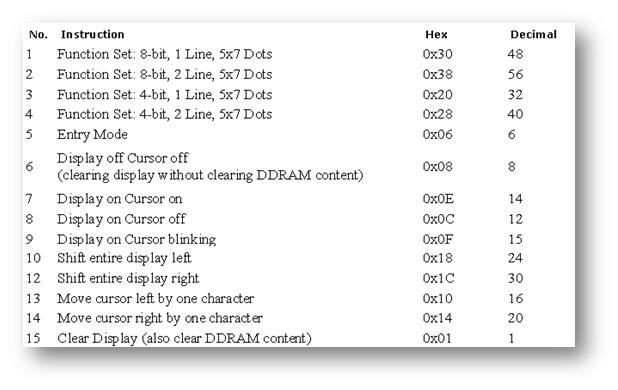

When we send commands to lcd these commands go to Command register and are processed their.Commands with their full description are given in the picture below.When Rs=0 command register is selected.

When we select the register Rs(Command and Data) and set Rw(read – write) and placed the raw value on 8-data lines, now its time to execute the instruction. By instruction i mean the 8-bit data or 8-bit command present on Data lines of lcd. For sending the final data/command present on the data lines we use this enable pin.Usually it remains en=0 and when we want to execute the instruction we make it high en=1 for some mills seconds. After this we again make it ground en=0.

To set lcd display sharpness use this pin. Best way is to use variable resistor such as potentiometer a variable current makes the character contrast sharp. Connect the output of the potentiometer to this pin. Rotate the potentiometer knob forward and backward to adjust the lcd contrast.

NOTE: we can not send an integer, float, long, double type data to lcd because lcd is designed to display a character only. Only the characters that are supported by the HD44780 controller. See the HD44780 data sheet to find out what characters can we display on lcd. The 8 data pins on lcd carries only Ascii 8-bit code of the character to lcd. How ever we can convert our data in character type array and send one by one our data to lcd. Data can be sent using lcd in 8-bit or 4-bit mode. If 4-bit mode is used, two nibbles of data (First high four bits and then low four bits) are sent to complete a full eight-bit transfer. 8-bit mode is best used when speed is required in an application and at least ten I/O pins are available. 4-bit mode requires a minimum of seven bits. In 4-bit mode, only the top 4 data pins (4-7) are used.

Command 0x30 means we are setting 8-bit mode lcd having 1 line and we are initializing it to be 5×7 character display.Now this 5×7 is some thing which every one should know what it stands for. usually the characters are displayed on lcd in 5×8 matrices form. where 5 is total number of columns and is number of rows.Thus the above 0x30 command initializes the lcd to display character in 5 columns and 7 rows the last row we usually leave for our cursor to move or blink etc.

NOTE:You can send commands in hexadecimal or decimal form which one do you like the result is same because the microcontroller translate the command in 8-bit binary value and sends it to the lcd.

Character Lcd’s can be used in 4-bit and 8-bit mode.Before you send commands and data to your lcd. Lcd must first be initialized. This initialization is very important for lcd that are made by Hitachibecause they use HD44780 driver chip sets. Hd44780 Chip set first has to be initialized before using it. If you don’t initialize it properly you will see nothing on your lcd.

In 4-bit mode the high nibble is sent first before the low nibble and the En pin is toggled eachtime four bits is sent to the LCD. To initialize in 4-bit mode:

To learn more about the difference between 4-bit and 8-bit character lcd mode and operation with demo example visit the tutorial link given below. Demo examples are very easy to understand and one can make changes easily in the code. Please also give us your feed back on the post.

We know that December is often a planning and logistics heavy month. We want to let you know what to expect from your display supplier in the coming months. Chinese New Year Every year at this time, we at Crystalfontz are in mid-swing planning for Chinese New Year. Unfortunately for us but luckily for you, … Read more Display Supply Chain: What to Expect in 2021

When working with a 20×4 character LCD, you might be surprised to see the controller set to 2-line mode: Write_To_LCD(COMMAND,0x38); //SET 2 LINE,5*8 FONT Why would a 4-line LCD’s controller be set to 2-line mode? It has to do with the way the LCD glass is laid out. Essentially the display is the right and … Read more FAQ: Why does the initialization code for a 20×4 LCD specify 2-line mode?

What is involved in ISO certification (and annual recertification) and what does it mean for a company to be ISO certified? This post takes a deeper look at everything involved in ISO certification for our LCD electronics-based company.

Confused about the differences between TFTs, LCDs, and OLEDs? What Do They Stand For? How Do They Work? TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the … Read more FAQ: What is the Difference Between a TFT, LCD, and OLED?

Sherman, set the wayback machine to 1985: We are going to take a look at the original HD44780 Data Sheet. Some time back, we wrote about the legendary HD44780 controller, to which the modern character LCD industry owes much of its existence. Having been in the business of designing embedded electronics for some time, we … Read more A Look Back in Tech History: The HD44780 Controller Data Sheet

Did you know that ePaper modules emulate ink used for paper? Check out the meaning of the glossary term electrophoresis and how it relates to ePaper module displays. Need ePaper for Your Project? For assistance in determining what ePaper module is the best one for your application, please contact our knowledgeable and friendly support staff by email, phone, or … Read more A Quick ePaper Primer

Modern Character LCD display modules have been possible since 1987 when Hitachi introduced the HD44780 LCD controller. Since then, Hitachi no longer manufactures this integrated circuit (IC), but modern LCD controller ICs make it a point to be HD44780-compatible. Controller Compatibility The character LCD display modules offered by Crystalfontz America Inc. are no exception to … Read more The Legendary HD44780 Controller

In this digital age, we come across LCDs all around us from simple calculators to smartphones, computers and television sets, etc. The LCDs use liquid crystals to produce images or texts and are divided into different categories based on different criteria like type of manufacturing, monochrome or colour, and weather Graphical or character LCD. In this tutorial, we will be talking about the 16X2 character LCD Modules.

The 16x2 LCDs are very popular among the DIY community. Not only that, but you can also find them in many laboratory and industrial equipment. It can display up to 32 characters at a time. Each character segment is made up of 40 pixels that are arranged in a 5x8 matrix. We can create alphanumeric characters and custom characters by activating the corresponding pixels. Here is a vector representation of a 16x2 LCD, in which you can see those individual pixels.

As the name indicates, these character segments are arranged in 2 lines with 16 characters on each line. Even though there are LCDs with different controllers are available, The most widely used ones are based on the famous HD44780 parallel interface LCD controller from Hitachi.

Vo / VEE Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

The 16x2 LCD modules are popular among the DIY community since they are cheap, easy to use and most importantly enable us to provide information very efficiently. With just 6 pins, we can display a lot of data on the display.

The module has 16 pins. Out of these 16 pins, two pins are for power, two pins are for backlight, and the remaining twelve pins are for controlling the LCD.

If you look at the backside of the module you can simply see that there are not many components. The main components are the two controller chips that are under the encapsulation. There is an onboard current limiting resistor for the backlight. This may vary from different modules from different manufacturers. The only remaining components are a few complimentary resistors for the LCD controller.

In the module PCB, you may have noticed some unpopulated footprints. These footprints are meant for charge pump circuits based on switched capacitor voltage converters like ICL7660 or MAX660. You can modify your LCD to work with 3.3V by populating this IC and two 10uF capacitors to C1 and C2 footprint, removing Jumper J1 and adding jumper J3. This modification will generate a negative contrast voltage of around 2.5V. This will enable us to use the LCD even with a VCC voltage of 3.3V.

To test whether a 16x2 LCD works or not, connect the VDD, GND and backlight pins to 5v and GND. Connect the centre terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND. Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working

There are 16 pins on the display module. Two of them are for power (VCC, GND), one for adjusting the contrast (VEE), three are control lines (RS, EN, R/W), eight pins are data lines(D0-D7) and the last two pins are for the backlight (A, K).

The 16x2 LCD has 32 character areas, which are made up of a 5x8 matrix of pixels. By turning on or off these pixels we can create different characters. We can display up to 32 characters in two rows.

Yes, we can. We can store up to eight custom characters in the CGRAM (64 bytes in size) area. We can create load the matrix data for these characters and can recall when they need to be displayed.

Controlling the LCD module is pretty simple. Let’s walk through those steps. To adjust the contrast of the LCD, the Vo/ VEE pin is connected to a variable resistor. By adjusting the variable resistor, we can change the LCD contrast.

The RS or registry select pin helps the LCD controller to know whether the incoming signal is a control signal or a data signal. When this pin is high, the controller will treat the signal as a command instruction and if it’s low, it will be treated as data. The R/W or Read/Write pin is used either to write data to the LCD or to read data from the LCD. When it’s low, the LCD module will be in write mode and when it’s high, the module will be in reading mode.

The Enable pin is used to control the LCD data execution. By default, this pin is pulled low. To execute a command or data which is provided to the LCD data line, we will just pull the Enable pin to high for a few milliseconds.

To test the LCD module, connect the VDD, GND, and backlight pins to 5v and GND. Connect the center terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND as per the below connection diagram-

Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working.

Let’s see how to connect the LCD module to Arduino. For that first, connect the VSS to the GND and VDD to the 5V. To use the LCD backlight, connect the backlight Anode to the 5V and connect the backlight cathode to the GND through a 220Ωresistor. Since we are not using the read function connect the LCD R/W pin to the GND too. To adjust the contrast, connect the centre pin of a 10KΩ trimmer resistor to the VEE pin and connect the side pins to the VCC and GND. Now connect the registry select pin to D12 and Enable pin to D11.

Now let’s connect the data pins. The LCD module can work in two modes, 8-bit and 4-bit. 8-bit mode is faster but it will need 8 pins for data transfer. In 4-bit mode, we only need four pins for data. But it is slower since the data is sent one nibble at a time. 4-bit mode is often used to save I/O pins, while the 8-bit mode is used when speed is necessary. For this tutorial, we will be using the 4-bit mode. For that connect the D4, D5, D6 and D7 pins from the LCD to the D5, D4, D3 and D2 pins of the Arduino.

The following Arduino 16x2 LCD code will print Hello, World! on the first line of the display and the time the Arduino was running in seconds on the second line.

Now let’s discuss the code. As usual, the sketch starts by including the necessary libraries. For this tutorial, we will be including the LiquidCrystal library from Arduino. This library is compatible with LCDs based on the Hitachi HD44780, or any compatible chipset. You can find more details about this library on the Arduino website.

Let’s create an object to use with the LiquidCrystal library. The following line of code will create an object called lcd. We will be using this object in the entire code to access the library functions. The object is initialized with the pin numbers.

Now let’s look at the setup()function. The lcd.begin function is used to initialize the LCD module. This function will send all the initialization commands. The parameters used while calling this function are the number of columns and the number of rows. And the next function is lcd.print. with this function, we have printed the word Circuit Digest! to the LCD. Since the LCD cursor is set to home position within the lcd.begin, we don’t need to set any cursor position. This text will stay there for two seconds. After that, the text will scroll from left to right until the entire text is out of the display. To scroll the display to the right, we have used the function lcd.scrollDisplayRight. After that, to clear display, we used lcd.clear, this will clear any characters on the display.

Now let’s look at theloop function. The for loop will count from 0 to 9, and when it reaches 9, it will reset the count and repeat the process all over again. lcd.setCursor is used to set the cursor position. lcd.setCursor(8, 1) will set the LCD cursor to the eighth position in the second row. In the LCD, the first row is addressed as 0 and the second row is addressed as 1. And the lcd.print(i) will print the count value stored in the variable i to the display.

Wrong characters are displayed: This problem occurs usually when the LCD is not getting the correct data. Make sure you are sending the correct ASCII value. If you are sending the correct ASCII characters, but still showing the wrong one on the LCD, check your connections for loose contact or short circuits.

Display shows Black boxes or does not show anything: First thing to do in these situations is to adjust the contrast voltage by rotating the variable resistor. This will correct the contrast value and will give you a visible readout.

Contrast is Ok, but still no display: Make sure to provide a sufficient time delay in between sending each character. Because if you don’t give enough time to process the data the display will malfunction.

Contrast and delay are ok, but still no display: Make sure you are powering the LCD from a 5V source. By default, these displays won’t work with a supply voltage below 5V. So if you are using the display with a 3.3V microcontroller make sure to power the display from 5V and use level shifters in between the display and the microcontroller.

In this project we will provide the input voice using Google Voice Keyboard via a Android App (BlueTerm) and print the text on 16x2 LCD using Raspberry Pi.

In this tutorial we are interfacing a Liquid Crystal Display (LCD) module with the Raspberry Pi Pico using Micropython to display strings, and characters on the LCD.

We used some Python scripts to find the local IP address of your Raspberry Pi on the network and display it on the 16x2 LCD Screen. We also added the script in the Crontab so that it can be run on every 10 minutes and we will have the updated IP address every time.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey