a si tft lcd vs ips in stock

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Wider viewing angles are not always welcome or needed. Image you work on the airplane. The person sitting next to you always looking at your screen, it can be very uncomfortable. There are more expensive technologies to narrow the viewing angle on purpose to protect the privacy.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED. If you have budget leftover, you can also add touch screen functionality as most of the touch nowadays uses PCAP (Projective Capacitive) touch panel.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

As you might already be aware, there’s a large variety of versatile digital display types on the market, all of which are specifically designed to perform certain functions and are suitable for numerous commercial, industrial, and personal uses. The type of digital display you choose for your company or organization depends largely on the requirements of your industry, customer-base, employees, and business practices. Unfortunately, if you happen to be technologically challenged and don’t know much about digital displays and monitors, it can be difficult to determine which features and functions would work best within your professional environment. If you have trouble deciphering the pros and cons of using TFT vs. IPS displays, here’s a little guide to help make your decision easier.

TFT stands for thin-film-transistor, which is a variant of liquid crystal display (LCD). TFTs are categorized as active matrix LCDs, which means that they can simultaneously retain certain pixels on a screen while also addressing other pixels using minimal amounts of energy. This is because TFTs consist of transistors and capacitors that respectively work to conserve as much energy as possible while still remaining in operation and rendering optimal results. TFT display technologies offer the following features, some of which are engineered to enhance overall user experience.

The bright LED backlights that are featured in TFT displays are most often used for mobile screens. These backlights offer a great deal of adaptability and can be adjusted according to the visual preferences of the user. In some cases, certain mobile devices can be set up to automatically adjust the brightness level of the screen depending on the natural or artificial lighting in any given location. This is a very handy feature for people who have difficulty learning how to adjust the settings on a device or monitor and makes for easier sunlight readability.

One of the major drawbacks of using a TFT LCD instead of an IPS is that the former doesn’t offer the same level of visibility as the latter. To get the full effect of the graphics on a TFT screen, you have to be seated right in front of the screen at all times. If you’re just using the monitor for regular web browsing, for office work, to read and answer emails, or for other everyday uses, then a TFT display will suit your needs just fine. But, if you’re using it to conduct business that requires the highest level of colour and graphic accuracy, such as completing military or naval tasks, then your best bet is to opt for an IPS screen instead.

Nonetheless, most TFT displays are still fully capable of delivering reasonably sharp images that are ideal for everyday purposes and they also have relatively short response times from your keyboard or mouse to your screen. This is because the pixel aspect ration is much narrower than its IPS counterpart and therefore, the colours aren’t as widely spread out and are formatted to fit onto the screen. Primary colours—red, yellow, and blue—are used as the basis for creating brightness and different shades, which is why there’s such a strong contrast between different aspects of every image. Computer monitors, modern-day HD TV screens, laptop monitors, mobile devices, and even tablets all utilize this technology.

IPS (in-plane-switching) technology is almost like an improvement on the traditional TFT display module in the sense that it has the same basic structure, but with slightly more enhanced features and more widespread usability. IPS LCD monitors consist of the following high-end features.

IPS screens have the capability to recognize movements and commands much faster than the traditional TFT LCD displays and as a result, their response times are infinitely faster. Of course, the human eye doesn’t notice the difference on separate occasions, but when witnessing side-by-side demonstrations, the difference is clear.

Wide-set screen configurations allow for much wider and versatile viewing angles as well. This is probably one of the most notable and bankable differences between TFT and IPS displays. With IPS displays, you can view the same image from a large variety of different angles without causing grayscale, blurriness, halo effects, or obstructing your user experience in any way. This makes IPS the perfect display option for people who rely on true-to-form and sharp colour and image contrasts in their work or daily lives.

IPS displays are designed to have higher transmittance frequencies than their TFT counterparts within a shorter period of time (precisely 1 millisecond vs. 25 milliseconds). This speed increase might seem minute or indecipherable to the naked eye, but it actually makes a huge difference in side-by-side demonstrations and observations, especially if your work depends largely on high-speed information sharing with minimal or no lagging.

Just like TFT displays, IPS displays also use primary colours to produce different shades through their pixels. The main difference in this regard is the placement of the pixels and how they interact with electrodes. In TFT displays, the pixels run perpendicular to one another when they’re activated by electrodes, which creates a pretty sharp image, but not quite as pristine or crisp as what IPS displays can achieve. IPS display technologies employ a different configuration in the sense that pixels are placed parallel to one another to reflect more light and result in a sharper, clearer, brighter, and more vibrant image. The wide-set screen also establishes a wider aspect ratio, which strengthens visibility and creates a more realistic and lasting effect.

When it comes to deciphering the differences between TFT vs. IPS display technologies and deciding which option is best for you and your business, the experts at Nauticomp Inc. can help. Not only do we offer a wide variety of computer displays, monitors, and screen types, but we also have the many years of experience in the technology industry to back up our recommendations and our knowledge. Our top-of-the-line displays and monitors are customized to suit the professional and personal needs of our clients who work across a vast array of industries. For more information on our high-end displays and monitors, please contact us.

Panox Display provides free connectors for clients who purchase more than five products from us. Our product range includes connectors from Molex, Kyocera, AXE, AXG, JAE, Hiros, and more.

Panox Display provides a customized cover glass/touch panel service. We supply cover glass from Gorilla, AGC, and Panda, which all have excellent optical performance. We also supply driver ICs from Goodix and Focaltech.

If your applications are directly connected to a PC, a cellphone, or Raspberry Pi, and you have enough space to insert a board to input video, Panox Display can provide customized Controller/Driver boards with input connections for VGA, HDMI, DVI, DP, Type-C video input, MIPI, RGB, LVDS, and eDP.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

This site uses cookies to store information on your computer. Some are essential to make our site work; others help us improve the user experience. By using the site, you consent to the placement of these cookies. Read our Privacy Statement to learn more.

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

Secondly, BLU (Backlight Unit) usually consists of three components: BEF (Brightness Enhancement Film), DBEF (Dual Brightness Enhancement Film), and LGP (Light Guide Plate).

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

For normally white panels, processd)will be the opposite – known as the polarization rotation effect, light is twisted in a voltage-off stage and can pass through the front polarizer by default, thus displaying white normally. However, when the voltage applied increases, this polarization rotation effect would be gradually diminished. And the light would not be able to pass through the front polarizer anymore without changing its polarization. In this way, certain pixels will appear in different colors.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

2Chen, HW., Lee, JH., Lin, BY.et al.Liquid crystal display and organic light-emitting diode display: present status and future perspectives.Light Sci Appl7,17168 (2018).https://doi.org/10.1038/lsa.2017.168

Schematic diagram of the (a) TN mode, (b) VA mode, (c) FFS mode, and (d) IPS mode. *LC orientations shown are under applied voltages. C/F stands for the color filter.

As previously mentioned, TN mode functions with the polarization rotation effect. Under traditional TN/VA display mode, the liquid crystal molecules are vertically arranged, with a relatively narrow visual angle. When an external force is exerted on the screen, the liquid crystal molecular structure will sink in a herringbone pattern to slowly recover – a pattern called vertical alignment. Therefore, an evident “water ripple” usually appears when the display surface is touched and impacts the user experience. In comparison, the VA mode provides higher contrast. And MVA (multi-domain vertical alignment) is an upgraded version of VA with improved viewing angles.

Under IPS mode, the LC directors are horizontally (homogeneously) aligned, which makes them free from ripple effects when made into touch panels. The drawback is lower transmittance, especially for LCs in a “dead zone”close to electrodes.

In an FFS cell, LC molecules rotate in both vertical and horizontal dimensions, enabling excellent viewing angles, high transmittance, low driving voltage/power consumptions, and high contrast ratio.

3 Yang DK, Wu ST.Fundamentals of Liquid Crystal Devices. 2nd edition. New York, USA: John Wiley & Sons. 2014.4 BOE ADSDS Ultra Hard screen Technology, Restoring Real and Beautiful Life. 2020 BOE Technology Group Co., Ltd. Retrieved December 01, 2020, fromhttps://www.boe.com/en/cxkj/boecx/boecxxqy/dynamic/pecbbd751.html

According to LCD (Liquid Crystal Display) technology and LCD materials, mobile phone LCD assemblies can be classified into 2 types: TFT (Thin Flim Transistor) and OLED(Organic Light-Emitting Diode). TFT display needs with backlight, but OLED is light-emitting, each pixel is creating its own light.

For Original iPhone LCD, 5-8 plus and Xr, 11 is TFT, X-13 Pro Max is OLED (except XR and 11). But in mobile phone aftermarket, there are too many different types and different qualities, which makes customers confused.

What is in-cell? What is OGS or " with TP"? What is COF? What is COG? What is OEM? What is FOG? What is Original Change Glass? What is IPS? What is LTPS? What is a-Si?

HTPS with small size, high precision, and high contrast. Most used in magnified display products. Such as projectors, projection TVs, etc. And cannot be used as a mobile phone display, so we don"t talk about it here.

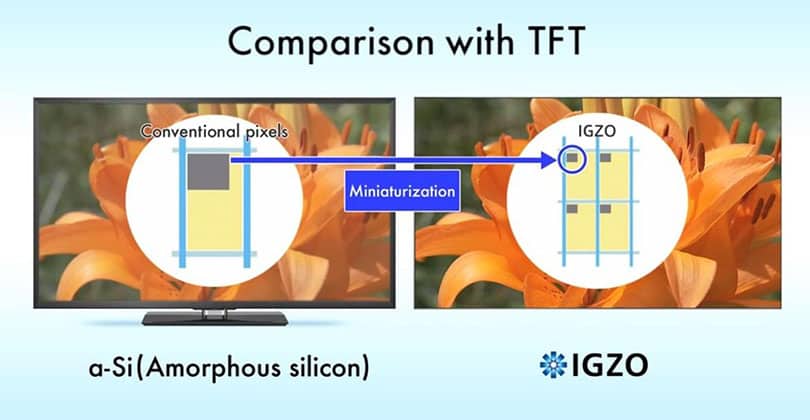

IGZO has 20–50 times the electron mobility than a-Sin. IGZO only has been licensed to Samsung Electronics and Sharp. However, it was Sharp who first implemented IGZO into their smartphones (Aquos Phone Zeta SH-02E), tablets, and 32-inch LCDs. IGZO for mobile phones is only Sharp. Almost all mobile phones on the market didn"t use IGZO.

Because the electrons deflect the liquid crystal molecules through the transistor. Electron mobility fundamentally determines the refresh rates of the TFT device. The smaller mobility, the slower transmission of holes and electrons, and the slower response rate. Can"t physically support high refresh rates.

In order to improve the response performance, can increase transistor size to enhance the migration, but this will lead to the extra TFT device that will occupy the display area pixel area. Therefore, the larger unit transistor area, the single-pixel occupy area is smaller(Pixel Aperture Ratio ), resulting in lower brightness.

Secondly, because the volume cannot be smaller, then the number of pixels per unit area is limited, which means the pixel density is small, which is what we call PPI is low, resulting in low resolution. The image needs to be zoomed, the original image data is lost, and resulting in the blurred image effect.

As we can see electron mobility of a-Si is very low (0.5-1cm2/Vs). But LTPS can deliver a hundred times the mobility than a-Si, and a much higher aperture ratio and PPI is much higher than a-Si resolution.

Compared with LTPS,a-si TFT have those "weakness":a-Si with so much low resolution and low definition. a-Si is 720*1280 with a very blurred display effect.

a-Si with so much bad display performance, but why are there still so many manufacturers producing phone LCDs with a-Si, or why do the customers willing to use a-Si LCD for their phone?

LCDs business has too much competition and wholesalers want to make more profit, they keep pushing suppliers to make LCDs at lower prices. So some of the suppliers start to produce aftermarket phone displays with a-Si to match customers" lower price requirements.

The customers with asymmetric information. End-Users don"t know how to distinguish LCDs qualities. Some of them just chase the price but not quality. That is another reason wholesalers want a lower price.

Now in the market a-Si LCDs for iPhone is TFT with TP but not in-cell. Our ZY a-Si will be in-cell not just TFT with TP. ZY a-Si incell for Xr and 11 ready now, please to get more details.

For more details or questions about in-cell and TFT with TP or about phone LCD display. Please click here to get more information, or Long press and scran the QR code to add me.

IGZO is an acronym for Indium Gallium Zinc Oxide and it’s actually a different type of semiconductor found in the TFT backplane; it’s not a different panel technology altogether.

In comparison to standard aSi-TFT IPS displays, an IGZO-TFT IPS display greatly saves on power consumption, while giving equally accurate and vibrant colors. However, they are much more expensive.

To clear away the confusion, IGZO is not a type of panel but a different type of transistor in the TFT (thin-film-transistor) backplane. Therefore, it can be implemented in all types of panels including TN, VA, IPS and even OLED.

Standard transistors in most of these panels are made of amorphous silicon. So, in this article, we’ll be comparing aSi-TFT IPS panels to the IGZO-TFT IPS panels.

IPS (in-plane switching) panels are found in most high-end LCDs because they’re capable of delivering the most accurate and consistent colors as well as impeccable viewing angles.

LG’s AH-IPS and Nano IPS panels are the latest improvements to the IPS panel technology which offer even more accurate colors and faster response times, while IPS Black improves upon contrast ratio.

The IGZO (Indium Gallium Zinc Oxide) compound semiconductor was licensed by Samsung and Sharp. However, it was Sharp who first implemented IGZO into their smartphones, tablets and 32-inch LCDs.

The IGZO transistor is made from rare metals such as the Indium and Gallium, and therefore it is costly. For instance, the NEC PA322UHD is a 4K resolution monitor with a 14-bit Look-Up Table for precise calibration and covers 99.2% of the Adobe RGB color space.

At the moment, the main advantage of IGZO is its very low power consumption. In comparison to the standard a-Si panel monitor, it can be up to 80%-90% more power efficient due to the higher electron mobility, which is 20-50 times faster than that of a regular panel.

While a-Si panel monitors require more power for the backlighting of higher pixel density displays, IGZO does not – in fact, it can create even brighter images at significantly lower power consumption.

This is ideal for portable devices with high pixel density. In short, IGZO can deliver a better resolution, speed and pixel density, no matter the size of the display.

While the difference between the IGZO-TFT and a-Si-TFT IPS panels may not be meaningful now, especially considering the difference in the price, IGZO will certainly greatly contribute to the future development of displays.

Since it can drastically reduce power consumption and offer stunning pixel density, resolution, and speed, high-quality touch-sensitive transparent displays are getting closer and closer to reality.

Figures 3a–d show optical and SEM (scanning electron microscopy) images of the fabricated CL and CLSE pixel structures. Each structure has the same pixel size (80 μm × 240 μm) and minimum pattern size (5 μm). As shown in Fig. 3d, the white line patterns are the ITO interdigitated pixel and common electrodes. They are well connected to the source electrode and gate line via through holes, and the common electrodes at both ends cover the underlying data lines to prevent electrical noise from being applied to the LC layer. As will be shown later, this noise shield electrode (SE) is what makes the black matrix above the data line unnecessary

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF > 16.6 ms, the frame period of a display panel without flicker being noticeable to the human eye. both panels decrease CR when tOFF is less than 16.6 ms; the CR of the SBM panel decreases faster than the CR of the MBM panel. As shown in the inset, the decrease in CR was due to the increase in dark-state brightness with decreasing tOFF as light leakage increases along the gate line. This light leakage is induced by the voltage Vgp = Vgc = VgON = 30 V applied only for 34 μs during the TFT ON (charging) state, which is 1/488th the duration, tOFF = 16.6 ms, of the TFT OFF (holding) state with Vgp = Vgc = VgOFF = 0 V, but the ratio increases with decreasing tOFF and becomes effective enough to switch on LC layer and induce light leakage. However, it should be stressed again that the CL panel with the normal holding (TFT OFF) time of 16.6 ms does not suffer from the light leakage along the gate line, so the aperture ratio can be increased by removing the BM along the gate line.

(a) Contrast ratio (CR) for CL panels with matrix BM (MBM) and stripe BM (SBM) plotted as a function of tOFF. The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. Vd (= VLC) dependence of (b) brightness and (c) contrast ratio of the CLSE panel. Insets of (b): optical images indicating the elimination of the BM from the CLSE structure (upper left) and the MBM in the conventional structure (lower right). Insets of (c): CLSE panel composed of different areas with three different pixel structures and aperture ratios (ARs), i.e., CLSE structure without BM (60%), CL structure with SBM (52%), and conventional structure with MBM (38%).

Figure 5b,c shows the Vd (= VLC) dependence of the brightness and contrast ratio of the CLSE panel without a BM along the drain line and along the gate line. As shown in the optical images in the insets of Fig. 5c, the CLSE panel has different areas with three different pixel structures and aperture ratios (ARs), i.e., the CLSE structure without the BM (60%), the CL structure with the SBM (52%), and the conventional structure with the MBM (38%). The optical images in the inset of Fig. 5b clearly indicate the elimination of the BM from the CLSE structure and the MBM in the conventional structure. The ratios of the bright area in the CLSE and conventional pixels shown in the red dotted square appear higher than the aperture ratios because the pixel and common electrodes are invisible due to the brightness. The brightness and contrast ratio in each area increase with increasing Vd; the ratios for the CLSE structure without the BM are approximately 160% those of the conventional structure with the MBM, reflecting the difference in aperture ratio.

Figure 6 indicates the effect of bias temperature stress (BTS) on the TFT characteristics. As the stressing time, tS, of the positive gate stress voltage, Vst = + 77 V, increases from 0 to 3600 s, the transfer (Id-Vg) curve shifts in the positive direction (Fig. 6a). Vth is defined as Vg at which Id = 10−12 A and ΔVth is defined as the Vth shift from the initial value via BTS. As shown in Fig. 6b, ΔVth increases logarithmically with increasing tS: ΔVth = 2.17 + 4.93 × log (tS). The mechanism behind the gate-stress-induced Vth shift is electron tunnel injection from the a-Si:H semiconductor into the SiOx gate insulator. For confirmation, ΔVth of MNOS TFTs with different SiOx thicknesses is plotted as a function of the electric field applied to the SiOx layer in Fig. 6c. Here, the thickness of the SiOx was varied (5, 10, 20, 50 nm), while the SiN thickness was fixed at 200 nm. The electric field applied to SiOx, Eox, was calculated using the following equation,

where εo = 3.5 and do are the electrical permittivity and thicknesses of SiOx and εn = 7 and dn = 200 nm are those of SiN. ΔVth linearly increases at a threshold electric field at 4.6 MV/cm on the same straight line regardless of the thickness of SiOx. From these results, we concluded that the Vst-induced Vth shift mechanism is Fowler–Nordheim type tunneling injection

Effect of bias temperature stress (BTS) on TFT characteristics. (a) The transfer (Id–Vg) curve shifts in the positive direction with positive gate bias stress of Vst = + 77 V over the duration of 0–3600 s. (b) ΔVth, defined as the Vth shift from the initial value via BTS, increases logarithmically with increasing tS, following ΔVth = 2.17 + 4.93 × log (tS). (c) ΔVth of MNOS TFTs with different SiOx thicknesses from 5 to 50 nm as a function of the electric field applied to the SiOx layer.

Figure 7a shows the effect of back-channel oxidation (BCO) and passivation (PAS) on the Id-Vg characteristics of the MNOS TFT. The Id-Vg curve with Vth = 5.1 V is further enhanced to Vth = 10.9 V after BCO, although there is a slight degradation of the slope of the current increase in the sub-threshold region. The slope recovers after PAS without any change to the enhanced characteristics

(a) Effect of back-channel oxidation (BCO) and passivation (PAS) on Id–Vg characteristics of MNOS TFT. (b) Vth and Vth standard deviation, σVth, after BTS and after BCO without BTS treatments and (c) SiOX thickness as a function of position along gate-line, x.

The advantage of BCO over BTS is the uniformity of the enhanced characteristics; Fig. 7b shows the distribution of the enhanced Vth as a function of position along gate-line, x, for the MNOS TFTs connected with a 90-mm-long gate line in the TFT substrate after BTS and BCO treatments. The average value of Vth and the standard deviation, σVth, for pristine TFTs before BTS or BCO, are 5.1 V and 0.35 V, respectively. After BCO, Vth is uniformly enhanced, with an average Vth = 11 V and σVth = 0.4 V without increasing σVth. On the other hand, after BTS, Vth is nonuniformly enhanced with an average Vth = 9.3 V and σVth of 1.4 V. In particular, Vth increases linearly as a function of position along gate-line, x. As the gate SiOx thickness linearly decreases, from (54 nm) to (47 nm) with increasing x as shown in Fig. 7c, the increase in ΔVth after BTS with x is due to increase in the electric field applied to SiOx as shown in Fig. 6c and Eq.

It has been shown that the Vth of the MNOS TFT is independent of the gate SiOx thickness when the thickness is more than 5 nm8a, Vth of the MNOS TFT with the BCO treatment becomes almost independent of the BCO SiOx thickness. As shown in the inset, the thickness of BCO SiOx composed of oxidized a-Si:H linearly increases with BCO processing time, and the Vth increase almost saturates at a BCO SiOx thickness greater than 5 nm. Therefore, the enhanced MNOS TFT after BCO has a uniformly high Vth that is robust to thickness fluctuations of the gate and BCO SiOx layers. BCO also has an advantage over BTS in terms of the stability of Vth as shown in Fig. 8b, which plots the annealing time dependence of Vth for BCO and BTS. In this experiment, the stoichiometry (x) of the gate SiOx was 1.78 for BTS and 1.78 and 1.9 for BCO. The annealing temperature in the N2 atmosphere was 200 °C. In the case of BTS, Vth decreased to the pristine value after approximately 5 h of annealing, while Vth decreased more slowly in the case of BCO. In particular, the annealing time required for Vth to fall to 7 V was 7.5 times longer than that of BTS. Increasing the stoichiometry (x) of the gate SiOx dramatically improved the BCO-enhanced Vth to as much as 11 V, which was stably maintained after 24 h of annealing at 200 °C.

(a) Dependence of Vth on thickness of back-channel oxidized (BCO) SiOX. The inset shows the SiOx thickness dependence on the BCO process time for RF powers of 200 W and 500 W. (b) Stability of Vth as a function of annealing time for three different TFTs with gate SiOx stoichiometry, x = 1.78 and bias temperature stress (BTS), x = 1.78 and BCO, and x = 1.9 and BCO. The temperature of annealing in the N2 atmosphere was 200 °C. (c) Band diagram of back-channel oxidized MNOS TFT. The red arrows show the electric dipoles at the SiOX/a-Si:H and a-Si:H/BCO SiOX interfaces.

A schematic band model for the MNOS TFT with the BCO treatment and the sectional structure of the interface between the a-Si:H and gate and BCO SiOx are shown in Fig. 8c. The uniformly high Vth that is independent of SiOx thickness is due to the dipoles generated at the channel and back-channel interfaces between a-Si:H and SiOx8 of reference

The world of smartphones has been busy for the past few months. There have been numerous revolutionary launches with groundbreaking innovations that have the capacity to change the course of the smartphone industry. But the most important attribute of a smartphone is the display, which has been the focus for all prominent players in the mobile phone industry this year.

Samsung came up with its unique 18:5:9 AMOLED display for the Galaxy S8. LG picked up its old trusted IPS LCD unit for the G6’s display. These display units have been familiar to the usual Indian smartphone buyer. Honor, on the other hand, has just unveiled the new Honor 8 Pro for the Indian market that ships with an LTPS LCD display. This has led to wonder how exactly is this technology different from the existing ones and what benefits does it give Honor to craft its flagship smartphone with. Well, let’s find out.

The LCD technology brought in the era of thin displays to screens, making the smartphone possible in the current world. LCD displays are power efficient and work on the principle of blocking light. The liquid crystal in the display unit uses some kind of a backlight, generally a LED backlight or a reflector, to make the picture visible to the viewer. There are two kinds of LCD units – passive matrix LCD that requires more power and the superior active matrix LCD unit, known to people as Thin Film Transistor (TFT) that draws less power.

The early LCD technology couldn’t maintain the colour for wide angle viewing, which led to the development of the In-Plane Switching (IPS) LCD panel. IPS panel arranges and switches the orientation of the liquid crystal molecules of standard LCD display between the glass substrates. This helps it to enhance viewing angles and improve colour reproduction as well. IPS LCD technology is responsible for accelerating the growth of the smartphone market and is the go-to display technology for prominent manufacturers.

The standard LCD display uses amorphous Silicon as the liquid for the display unit as it can be assembled into complex high-current driver circuits. This though restricts the display resolution and adds to overall device temperatures. Therefore, development of the technology led to replacing the amorphous Silicon with Polycrystalline Silicon, which boosted the screen resolution and maintains low temperatures. The larger and more uniform grains of polysilicon allow faster electron movement, resulting in higher resolution and higher refresh rates. It also was found to be cheaper to manufacture due to lower cost of certain key substrates. Therefore, the Low-Temperature PolySilicon (LTPS) LCD screen helps provide larger pixel densities, lower power consumption that standard LCD and controlled temperature ranges.

The AMOLED display technology is in a completely different league. It doesn’t bother with any liquid mechanism or complex grid structures. The panel uses an array of tiny LEDs placed on TFT modules. These LEDs have an organic construction that directly emits light and minimises its loss by eradicating certain filters. Since LEDs are physically different units, they can be asked to switch on and off as per the requirement of the display to form a picture. This is known as the Active Matrix system. Hence, an Active Matrix Organic Light Emitting Diode (AMOLED) display can produce deeper blacks by switching off individual LED pixels, resulting in high contrast pictures.

The honest answer is that it depends on the requirement of the user. If you want accurate colours from your display while wanting it to retain its vibrancy for a longer period of time, then any of the two LCD screens are the ideal choice. LTPS LCD display can provide higher picture resolution but deteriorates faster than standard IPS LCD display over time.

An AMOLED display will provide high contrast pictures any time but it too has the tendency to deteriorate faster than LCD panels. Therefore, if you are after greater picture quality, choose LTPS LCD or else settle for AMOLED for a vivid contrast picture experience.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey