lcd screen without backlight manufacturer

A wide variety of lcd without backlight options are available to you, such as original manufacturer, odm.You can also choose from datasheet, lcd without backlight,as well as from tft, ips, and standard lcd without backlight,

Newhaven 160x100 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C160100CZ-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 3V supply voltage and is RoHS compliant.

As a specialist in transparent Displays we are often asked whether T-LCDs can be used in ambient light, i.e. without a backlit showcase box which it does as you can see in the video attached. But clearly the image quality is not as crisp and bright without a backlight directly behind the display. For some clients this made it difficult to make a decision on the way forward so we made this specific video so you and any other viewers can see just how good it is in standard normal ambient light!

This just shows the quality of the transparent screen with direct sunlight rather than LED backlighting, still looking great but obviously offering a lower % of transparency than LED backlights would give. This is why we always encourage LED lighting when customers ask for our advice on lighting and how transparent displays work without lighting and in shop windows. Below is an example of how the panels look but obviously it is not sunny all year long in the UK, as in many other countries, unfortunately.

For more information on our Transparent LCD products or our transparent display products please contact us via email or simply call our UK office on +44(0)1634 791 600

DASUNG"s 3rd Generation E-ink Monitor-Paperlike 3 (Paperlike HD), 13.3” E-ink Screen (Carta & Flexible), 2200*1650 Retina Display. Just Like a Real Paper. Fast nearly as LCD. No Back Light. No Blue Light. No Screen Flash. You can Type, Code, Browse the Web, etc. Work well with any Equipment (HDMI). Support PC/ Mac/ iPhone/ iPad and so on.It is the best monitor to protect your eyes.

This DASUNG"s Paperlike HD monitor uses electronic paper. For those not familiar with this technology it is also sometimes called "electronic ink or electrophoretic display, are display devices that mimic the appearance of ordinary ink on paper. Unlike conventional flat panel displays that emit light, electronic paper displays reflect light like paper. This may make them more comfortable to read, and provide a wider viewing angle than most light-emitting displays. The contrast ratio in electronic displays available as of 2008 approaches newspaper, and newly (2008) developed displays are slightly better. An ideal e-paper display can be read in direct sunlight without the image appearing to fade."

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

LCD Panel are used for TV,Personal Computer, Mobile Phone, Degital Camera etc widely. LCD Panel can not emit light by itself. To emit light, it need the backlight(light source) on the back of LCD Panel. Minebea develops and manufactures the parts used for backlight and backlight using LED light source,for Mobile phone, PC application.

As below picture,Backligt are made with some optical parts.Key parts of Backligtht Unit are light guide plate and housing frame. Minebea"s principal competitive advantages are its ultraprecision machining and mass production technologies. Injection mold die need sub-micron ultraprecision machining and stable injection mold technologies.Minebea has amassed precision ball bearing"s technologies enables it to achieve levels of precision unmatched by its competitors. Minebea also uses these technologies for in-house parts, modl die,tooling and product of Backlight Unit.The function of light guide plate are transforming positional light source to surface light on display uniformly and efficiently.It realize optical design by own optical simulation and independently developed design program. Minebea assembles Backlight Unit by the technologies it put parts into limited space, greatly contributing to the precision and reliability. Minebea put into force exhaustive environmental control at Thai and China factories and enable manufacturing the bulk of Backlight with high quality and stable supply.

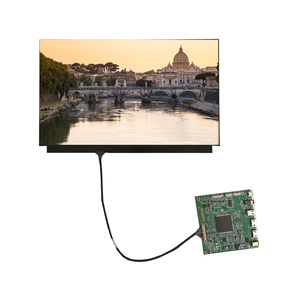

As an Industrial LCD module distributor, we can supply a wide range of TFT LCDs in many sizes. Common resolutions are QVGA, VGA, SVGA and XGA. Wide aspect ratio displays are also available in many similar sizes and resolutions such as WQVGA, WVGA, WSVGA, and WXGA.

Our industrial LCD suppliers are manufacturers with different capabilities specially designed for a wide variety of industrial applications. High-brightness, sunlight readability and long life product guarantees are some of the special features available.

Get in touch to work closely with one of our LCD Solutions Specialists to determine the perfect display for your project. We can also recommend and supply the proper LCD controller board, inverter, LED driver, cables, touch screen, or other associated enhancement.

Sun Vision Display panels are100% reflective, meaning they have no backlight whatsoever. This makes them an excellent computer monitor solution for people looking to reduce blue light exposure or other common issues reported by people withcomputer-related vision syndromes. It also makes them an incredible solution for advertising in sunny places, where it can be difficult to view other display technologies - all without racking up hefty energy costs.

LCD panelscan be categorized as flat-panel displays. What makes them distinct from other display technologies is the layer of liquid crystal material within. In this thin layer, liquid crystal molecules are aligned between two glass substrates. On the inner surfaces of each of those substrates lie electrodes that control charge carriers like electrons that then interact with the liquid crystals, creating an electric field that runs through them; this, in turn, can change the alignment of the crystals, also changing the overall behavior of the molecules. On the opposite sides of the substrate, polarizers are used to control the levels of light passage, affecting the overall image of the display.

Unlike CRT monitors, LCD monitors cannot illuminate themselves, and so they require a light source: the backlight. This backlight is most frequently made of the well-known LEDs which stand for light-emitting diodes. Sourced from the backlight, light is moved through the back polarizer and back substrate, into the liquid crystals. Now, the light waves can behave in a variety of ways. Backlight used in LCD displays can be LED (Light Emitting Diode) backlight or CCFL (Cold Cathode Fluorescent Lamp) backlight. LED backlights use less power which becomes more popular, while CCFL is lower cost for large size LCD displays such as large LCD TV. Recently, quantum dots technology is used to increase the LCD contrast.

Electrodes are the controlling factors of the liquid crystal behavior, and thus also the light behavior. By conducting or not conducting a current into the crystal layer, the light may or may not be able to pass through the liquid crystals in a manner that will allow passage through the polarizer. Because of this role, electrodes in LCDs are often made of indium tin oxide (ITO). ITO has good conducting properties and can also make for a transparent electrode which is essential to the appearance of displays today.

How the electrodes affect the liquid crystal alignment can vary depending on the method of alignment used (twistednematic,multi-domain,in-planeswitching). For example, twisted nematic liquid crystals are oriented in a twist when no electric field is present which then polarizes the light passing through the layer; when the electrodes apply the field in full, the twist will straighten out, no longer polarizing the light, and so no light passes. In each of these alignment types, the electrodes are placed differently within the structure, altering the properties of the display, such as width of viewing angle, power consumption, and response time. Despite these different alignment methods, the liquid crystal layer’s purpose remains the same: to polarize the light so that the polarized light passes through to the surface of the display. By polarizing the light transmitted from the backlight, the liquid crystal molecules play a role in how much of the light passes through the polarizing filters, whether it be all, none, or a partial amount.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

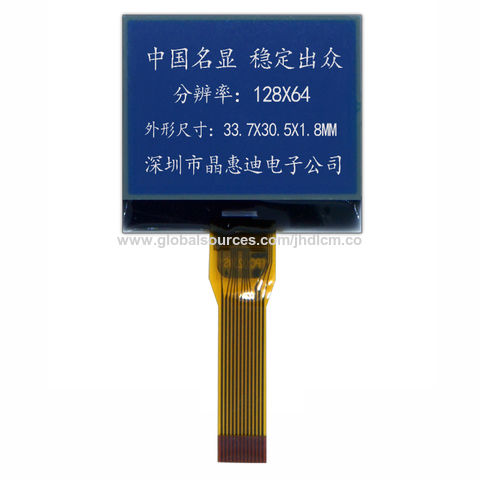

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

www.distrelec.com : my email-address was not accepted, so I had to use another one. The prices on the website are without taxes/VAT. The payment failed, and I got a message that perhaps it was paid and perhaps not. So I have to wait another day to see if it was paid. When I log out, the order was canceled. I can not store the items, so I made a screendump and I probably have select the items again tomorrow.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey