lcd module commands free sample

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

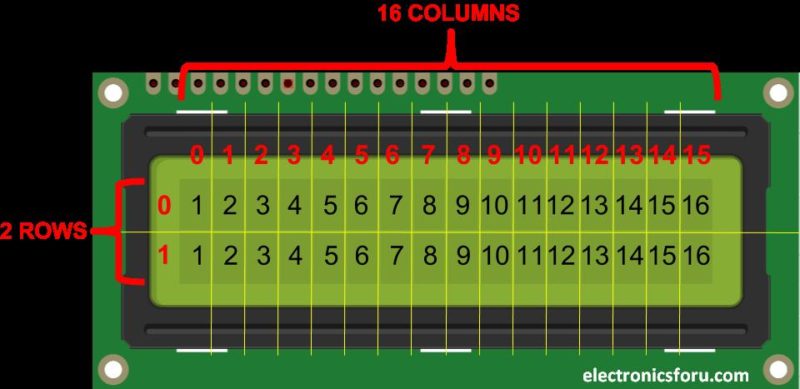

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

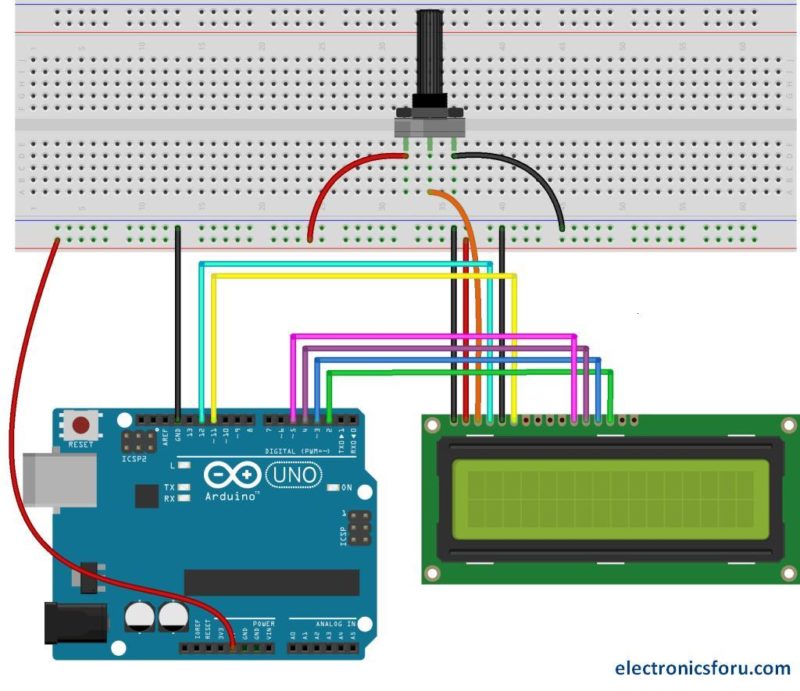

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

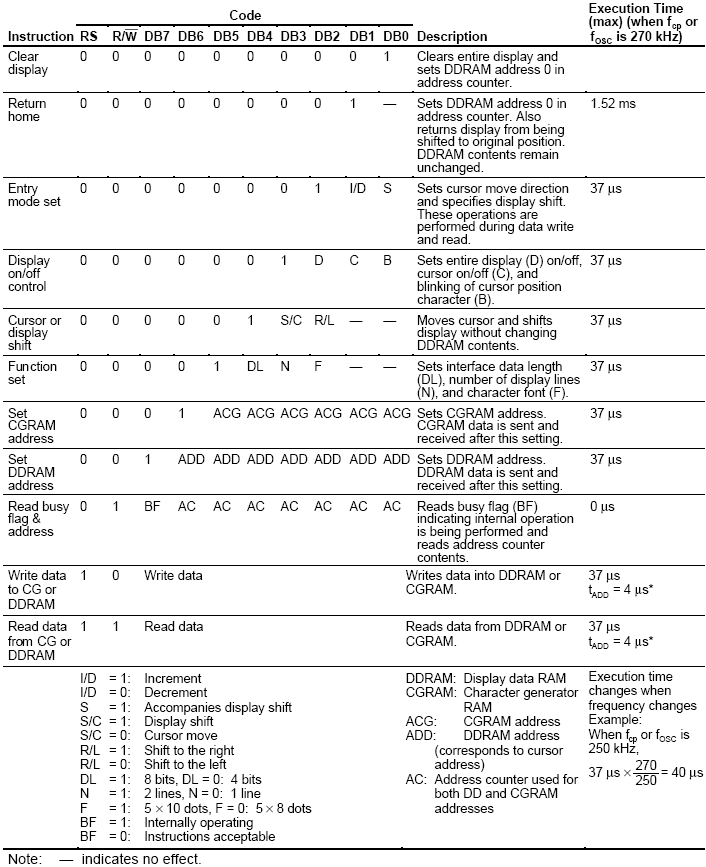

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

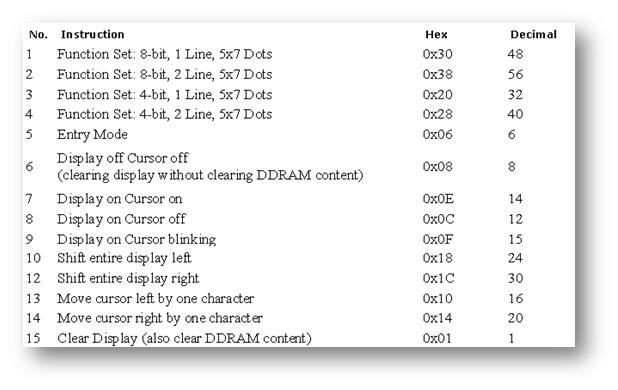

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

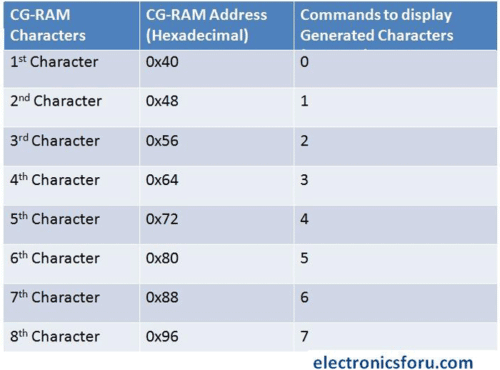

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

Liquid Crystal Display(LCDs) provide a cost effective way to put a text output unit for a microcontroller. As we have seen in the previous tutorial, LEDs or 7 Segments do no have the flexibility to display informative messages.

The LCD is a simple device to use but the internal details are complex. Most of the 16x2 LCDs use a Hitachi HD44780 or a compatible controller. Yes, a micrcontroller is present inside a Liquid crystal display as shown in figure 2.

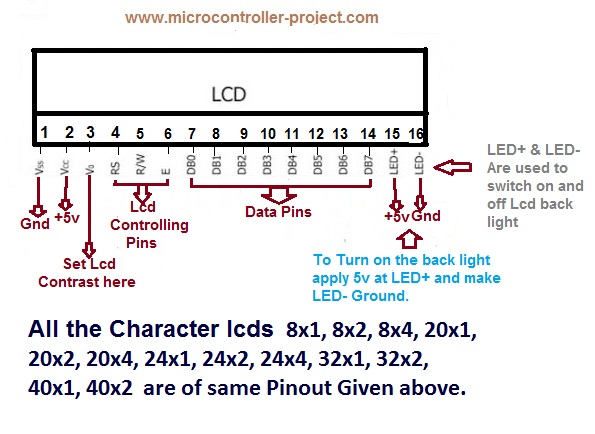

Power & contrast:Apart from that the LCD should be powered with 5V between PIN 2(VCC) and PIN 1(gnd). PIN 3 is the contrast pin and is output of center terminal of potentiometer(voltage divider) which varies voltage between 0 to 5v to vary the contrast.

The LCD module interface with a microcontroller is simple and it is a primitive means of adding a visual appeal to your embedded application. There are two basic types of LCD modules in the market they are, Character LCD and Graphics LCD. Character LCDs are the some of the cheapest means LCD displays available today.

This post is first of a series of four posts that walks through entire process of interfacing an LCD module with a (any) microcontroller with all the basic concepts dealt in detail. Subscribe to our posts and get free updates on these follow-up posts.LCD Module Basic Theory (LCD Controllers, CG&DD RAM, PIN description,Timing Diagram, Commands)

This post will cover the basic theory that you should have a clear understanding of, before getting started with the programming. Some of the sections below are not really essential for the interface but it is a good practice to have a thorough knowledge about what you are indulging in. Whereas some listed below are absolutely mandatory to understand how the LCD module works and to predict how it will behave for a given situation.

The LCD module has display controller that are used to receive the data from the controller and uses it to display the data in a legible format. These controllers have an embedded font set that can be addressed by sending the corresponding ASCII value of the the character to be printed.

Most LCD modules have a HD44780 or compatible controller which is specially designed to build LCDs with one or two lines with a maximum of 40 character positions each. They are ASIC (Application Specific Integrated Circuit). A single HD44780 is able to display two lines of 8 characters each.

This the most common configuration of LCD that most people prefer mostly due to reduced cost and small footprint. In a 16 x 2 line display LCD module, each the two lines have 40 character positions of which only 16 can be displayed at a time. The remaining positions are invisible and cannot be seen. To display the remaining 24 characters, the LCD has an option to move the window of characters displayed to the right or left so that; it appears as though the characters are scrolling. Here is a table of the DD RAM addresses that are within the visible data region. Note that in this module, DD RAM locations 10 to 27 on the first line and 51 to 67 are not covered by the displayable window of 16A character per line.Line/Col0123456789101112131415One000102030405060708090A0B0C0D0E0F

The 20 x 4 display module is a slight variant of the 16 x 2 Module such that, a single 40 character (of which 16 are displayable) line is split up into 2 halves of 20 displayable characters each to make 4 lines. Here the first line displays the first 20 DD RAM locations (00 - 13) and the third line displays the remaining 20 DD RAM locations (14 - 53) of the first line in the case of 16 x 2 LCD Module and the second line displays the first 20 DD RAM locations (40 - 53) and the fourth line displays the remaining 20 DD RAM locations (54 - 67) of the second line in the case of 16 x 2 LCD Module. This is the module that I am using in this post. It has the disadvantage of not being able to scroll but looks better with 4 displayable lines.Here is a table of the DD RAM addresses that are within the visible region.#000102030405060708090A0B0C0D0E0F101112131000102030405060708090A0B0C0D0E0F10111213

7DB0LCD Data Bus line. They are responsible for the parallel data transfer. DB7 is used to check the busy Flag.In 4 bit mode, DB0 to DB3 are not used and are left open.

There are two registers in an LCD, they are Instruction register and the Data register. The register select (RS) pin is used to select either of the two the registers. When held low, the Instruction register is selected and similarly, when it is high, the data register is selected. A write to the data register will write to the Display Data RAM (DD RAM) in the address last pointed by the address pointer. The address pointer is automatically incremented after each write operation.

In the 20 x 4 LCD Module, all the locations of the DD Ram are mapped on to a character position in the display. Hence a write to the data register with proper ASCII code will produce proper displayable character in the screen. You can find a good ASCII table here. Some of the values in the ASCII table are not printable and hence are not mapped on to any character. A write to the DD Ram with one such data will display some glyph that you cannot recognize.

The LCD datasheet comes with a lot of electrical and Mechanical specifications. Though they are not redundant, for now we will consider only the command sheet and the timing diagram without which it is impossible to interface the module.

The command sheet is a table which contains the various commands that can be issued to the LCD module so that it behaves as intended. I have not attached an image of the command sheet as I could not find any of a good readable resolution. So I created a HTML version of the command sheet that you could use at any resolution dYtm, You can find the Command Sheet here (or I should call it command page). The cells that are filled with absolute values have to be used as such and the ones that are having letters are variables and take either 0 or 1 based on the task it has to perform.

Here, D4 to D7 are 0, D3 is 1 and RS and R/W are held low. These are all constant values and hence have to be used as such. But the, bits D0 to D2 are all variables. Depending on the values return at positions B, C and D the following action are performed by the LCD controller,

Lastly, here is another timing diagram that you will be hard pushed find else where. Incidentally, it is not only the software that need to be initialized, but hardware too. You could use hardware timing to initialize the module. Here is its description.

As you know these LCDs have a built in font set and can be used by indexing the ASCII value of the corresponding character. It capable of operating on 8 data lines (D0 to D7) or on 4 data lines (D4 to D7). The upcoming posts will discuss the 8 bit and 4 bit mode of LCD interface. Other than the data lines the LCD needs 3 command lines - RS, R/W and EN. Therefore in total, an LCD interface will need 11 (8+3) or 7 (4+3) pins of the microcontroller.

It is possible to further reduce the total number of port pins required from 7 (4+3) to 6 (4+2) by shorting the R/W pin to ground. If the R/W pin is connected to the ground, the LCD can be used to write data only. Reading from it is not possible. So we are not able to read the busy flag from the module. To live with this disability, we are forced to provide ample amount of delay loops (and hence compromise on the speed of execution) so that the LCD is seldom busy doing thing when new data is given.

The Serial LCD Kit includes all the parts you need to add a serial "backpack" to a 16x2 LCD. The kit includes a pre-programmed ATmega328 microprocessor, which reads a serial stream of data and (after a little heavy-lifting) instantly displays it on the LCD. Interfacing the Serial LCD with an Arduino, or other serial-enabled devices, allows you to easily print GPS coordinates, short messages or any other information onto the LCD.

This tutorial will cover everything you need to know to get up and running with the Serial Enabled LCD Kit. We"ll first go over assembly so you can turn that bag-o-parts into something that hopefully resembles any pictures you may have seen of the kit.

Following assembly, we"ll touch on how to actually use the Serial LCD Kit. Specifically, we"ll go over how you"d use the thing with everybody"s favorite development board, Arduino. There"ll be example code galore, and you can even make your own LCD clock! It"s gonna be pretty crazy...

The goal of the Serial LCD Kit is to make controlling an LCD simple and to make wiring to it even simpler. If you wanted, you could abstain from using the serial backpack and wire an Arduino directly up to the LCD. To that point, there are loads of great examples, and even some Arduino libraries, that make interfacing a microcontroller directly to an LCD very easy. However, because the LCD is driven by a parallel interface, those examples require a tangle of wires and anywhere from 6 to 11 pins of the Arduino to control the thing.

The microcontroller on the Serial LCD Kit takes care of all of that nasty wiring, so you only need one pin to control the LCD. The Serial LCD"s on-board microcontroller parses any incoming commands or characters, and then sends the proper data to the LCD over the multi-wire parallel interface. It"s a magic black box, and you don"t have to care how it does its job, just that it does it. So let"s get it built...

What you"ve got in front of you right now is not yet a Serial LCD Kit. First, we"ve got to turn that bag of parts into a Serial LCD Kit, which will require soldering. If you"ve never soldered before, don"t fret! This is one of the easier soldering projects, every part is through-hole, and well-spaced. If this is your first time though, I"d encourage you to take a trip over to one of our excellent soldering tutorials before picking up the iron.

First, pick out the big, ferrari-red PCB. See how one side has white silkscreen printed onto it? This is the top of the PCB. You"ll stick almost every part in on this side and solder the pins to the opposite side. The only time we"ll stray from that is when soldering the LCD, which is the last step.

Wait...something"s missing...oh, hi LCD! To connect the LCD to the PCB, we"ve included a straight 16-pin header with the kit. You"ll need to solder this header to both the PCB and the LCD. Solder it first to the LCD, stick the shorter pins into the LCD. Make sure the longer legs are extended out from the back of the LCD and solder all 16-pins on the top side of the LCD. Effort to keep the pins as perpendicular to the LCD as possible.

With the header soldered to the LCD,you"ll finally be able to connect the display to the PCB. Remember, we"re sticking this part into the bottom side of the PCB, and soldering to the top. Solder up all 16 pins, and that should be it.

Before you can display anything on the LCD, you"ll have to connect something to it. Only three wires are necessary to use the Serial LCD Kit: RX, GND and VCC. Plug the included 3-wire jumper cable into its mating JST connector that you soldered onto the PCB. This color coded cable has two wires for power, and one for receiving serial data. The red and black wires correspond to +5V and GND, respectively, and the yellow wire is RX.

You"ll need to figure out how you"re going to powerthe LCD Kit. It doesn"t have a regulator on-board, so it"s up to you to supply a clean, regulated 5V power source. If you"re using an Arduino, you could power the Kit off of the 5V and GND pins – connect red to 5V and black to GND. Otherwise, there"s a ton of options out there for power; you could use a USB adapter, a 5V wall-wart, a breadboard power supply. The list just goes on. Just make sure you"re not supplying any more than 5V (a little less may work, but you"ll lose some brightness).

After powering the Serial LCD Kit, you should notice the backlight turn on. If the contrast is properly adjusted, you might see the splash screen flash for a second or two. Most likely though, the contrast won"t be set correctly, so you won"t see a splash screen. In that case, you may see anything from 32 white boxes to absolutely nothing. You"ll have to be quick about it, because the splash screen only remains for a couple seconds before going blank, but try turning the trimpot knob until you"ve got a good view of the characters on the LCD.

The "Serial" in the Serial LCD Kit can be a little confusing. What it really means is TTL serial, not to be confused with RS-232 serial. The voltage on the RX line should only go between 0 and +5V. If you"re using a microcontroller (like an Arduino) to talk with the LCD, then you most likely don"t have to worry. Just don"t hook up a PC"s serial port straight to the LCD and expect it to survive.

Connect the Arduino to the Serial LCD as follows. If you have a wire stripper, you may want to expose a few millimeters more of wire to allow them to stick really nicely into the Arduino"s headers.

Here"s a simple example sketch, which uses the SoftwareSerial library (which is included with recent versions of Arduino) to instill our Arduino with more than just the one, hardware, serial port. Now we can use the hardware serial port to listen to the serial monitor, and the second serial port can be used to talk to the LCD.

Now, plug in your Arduino and upload the code. Open up the serial monitor, and make sure it"s set to 9600. Type “Hello, world” into the serial monitor and send it over to the Arduino. The LCD should echo your greeting. Take the LCD for a test drive, discover all the characters it can display!

You"ll quickly notice, that the code is severely lacking any sort of clear display command, but don"t think for a second that the Serial LCD Kit doesn"t have a clear display command. It"s got commands up the wazoo! The Serial LCD Kit is set up to accept commands that control the backlight, baud rate, and all sorts of display functionality, like clearing the screen. Have a look at the Kit"s “datasheet”, which lists all of the characters and commands you can send to the display. I wrote that, but I understand if it"s all gobbledygook to you right now.

The commands are divided into three groups: backlight, baud rate, and special commands. Each command requires that you send at least two bytes to the display. For instance to set the backlight, you first have to send the backlight control byte (0x80, or decimal 128) followed by a byte with any value from 0 to 255. Sending a 0 will turn the backlight completely off, 255 will turn it all the way on, 127 will set it to about 50%, and so on. The backlight setting is stored in the Serial LCD Kit"s memory and will be restored when the LCD is turned off and on.

What we really care about right now, though, is clearing the display, which requires a special command. To issue a special command to the LCD, you first have to send 0xFE (or decimal 254) which tells the display to go into special command mode, and wait for a data byte. The clear display command is 0x01 (or decimal 1), that command should be sent immediately after sending the special command byte. So to clear the display we need to send two bytes: 254 (0xFE) followed by 1 (0x01). Check out the datasheet link for all of the special commands. You can do all sorts of fun stuff: scroll the display, turn it on/off and control the cursor.

Our next piece of example code, Serial_LCD_Kit_Clock, delves into sending special commands to the LCD with an Arduino. There are individual functions that clear the display (clearDisplay()), set the backlight (setBacklight(byte brightness)), and set the cursor (setLCDCursor(byte cursor_position)), feel free to copy these and add them to any code you"d like.

Now then, that should be enough to get you on your way to using the Serial LCD Kit with a serial interface. If you"re happy with that, and don"t want your mind blown, I suggest you stop reading here.

Oh, you"ve taken the red pill? Well then you get to learn the Serial LCD Kit"s very deep, dark secret. It may not look anything like one, but the LCD Kit is actually Arduino-compatible. It has an ATmega328, just like the Arduino, and that ATmega328 has a serial bootloader, just like an Arduino. It can be programmed via a USB-to-Serial board. This means you can hook up all sorts of sensors, blinkies and other I/O to the Kit itself, while continuing to use the LCD to display any info you"d like. The 6-pin serial programming port on the right hand side of the PCB can be connected to an FTDI Basic Breakout.

With the FTDI board connected, and Arduino open, simply select the corresponding COM port in the Tools>Serial Port menu, and select Arduino Duemilanove or Nano w/ ATmega328 under the Tools>Boards menu. Though it probably won"t look like it"s doing anything, try uploading Blink, change the LED pin to 9 to at least see the backlight of the LCD flick on and off. Remember, you can download the Serial LCD Kit firmware here. If you ever want to turn it back into a Serial LCD, upload it to the LCD like you would any sketch.

If you want to be really adventurous, and get the most out of the Serial LCD Kit, I"d recommend first taking a trip over to where the Serial LCD Kit"s source code is hosted and getting a good idea how the code works. That firmware is written as an Arduino sketch, and uses a great little Arduino library named LiquidCrystal to control the LCD. The LiquidCrystal library makes controlling the LCD with an Arduino super-simple.

You should also get a good feeling for the kit"s schematic. There are a few Arduino pins that can only be used with the LCD (4-9), but pins 10-13, and all of the analog pins can be used with any device you"d normally connect to an Arduino. The available pins are all broken out on the bottom of the PCB.

Remember, this part is all very extracurricular. Don"t feel at all required to use your Serial LCD Kit as an Arduino. I just wanted to let you know what"s possible with this kit.

Serial LCD Clock Example Sketch - Displays a digital clock on the Serial LCD. This is a good example of how to use special commands, like clear, with the display.

Now I"ll leave you and your Serial LCD Kit in peace. I hope you"ve learned a good amount about the display. I also hope you"re left with questions and ideas about what you"re going to do with it next. If you"ve still got questions about the display, or comments about the tutorial, please drop them in the comments box below or email us.

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

Note:if you’re using a module with a DHT sensor, it normally comes with only three pins. The pins should be labeled so that you know how to wire them. Additionally, many of these modules already come with an internal pull up resistor, so you don’t need to add one to the circuit.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey