lcd module commands made in china

Graphic LCD module is used to display Chinese characters and graphics in lattice form. Every 8 points make up one byte, each point is represented by a binary bit, and a bright spot is displayed on the screen when the point stored in 1 is displayed; the point stored in 0 is not displayed on the screen, and the commonly used 16 *16 Chinese character dot matrix is composed of 32 bytes. Taking T6963C, a widely used LCD driver controller in China, as an example, the 16*16 dot matrix font of "Guo" character is displayed in Fig. 1. 32 byte values corresponding to the right-hand font of Fig. 1 can be obtained by extracting the font of "Guo" character in the way of left-hand, right-hand and top-down by the font extraction software. By writing these bytes into the display buffer of the LCD controller in a certain order, the 16 *16 character "Guo" can be displayed on the LCD screen. Similarly, a 24*24 Chinese character needs 72 bytes, which is stored as shown in Table 1. Chinese characters of other specifications are stored by analogy.

The extracted Chinese characters are input into the LCD controller by a single chip computer, and the required Chinese characters can be displayed on the LCD module display screen according to the settings. Figure 2 is a typical interface circuit between LCD module and MCU. In the figure, 8051 single chip computer which is widely used in our country is chosen as MCU, 12864 (128 *64) LCD module is used, and the built-in LCD driver controller is T6963C of Toshiba Company of Japan. In the circuit, the address line A12-A15, WR and RD signals are decoded by GAL16V8 to the chip selection signal of the chip. The LCD decoding address is 0xE000, which connects the address line A0 with the C/D of the LCD control port. LCD controller receives data when A0 is low and command code when A0 is high. Therefore, the LCD data port address is 0xE000, and the LCD command port is 0xE001. Keil C51 is used for programming. The following definitions can be made in the program:

The data line of MCU is connected with the data port of LCD controller through 74HC245 bidirectional buffer. The selected signal/LCD_CS of LCD controller is used as the enabling signal of 74HC245. The write signal/WR of MCU controls the direction of data transmission. When the WR is low, the MCU data is written into the LCD controller; when the WR is high, the CPU reads the data and status of the LCD controller.

As a 2inch IPS display module with a resolution of 240 * 320, it uses an SPI interface for communication. The LCD has an internal controller with basic functions, which can be used to draw points, lines, circles, and rectangles, and display English, Chinese as well as pictures.

The 2inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

The LCD supports 12-bit, 16-bit, and 18-bit input color formats per pixel, namely RGB444, RGB565, and RGB666 three color formats, this demo uses RGB565 color format, which is also a commonly used RGB format.

For most LCD controllers, the communication mode of the controller can be configured, usually with an 8080 parallel interface, three-wire SPI, four-wire SPI, and other communication methods. This LCD uses a four-wire SPI communication interface, which can greatly save the GPIO port, and the communication speed will be faster.

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

The demo is developed based on the HAL library. Download the demo, find the STM32 program file directory, and open the LCD_demo.uvprojx in the STM32\STM32F103RBT6\MDK-ARM directory to check the program.

image.cpp(.h): is the image data, which can convert any BMP image into a 16-bit true color image array through Img2Lcd (downloadable in the development data).

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

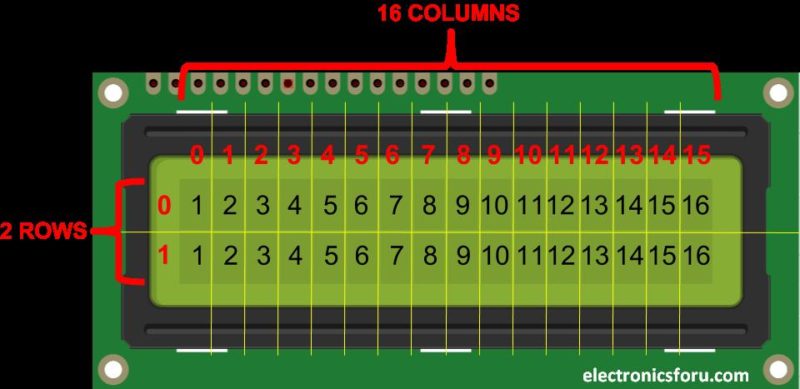

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

In the previous chapter, we have discussed how a character LCD is interfaced with a PIC microcontroller in 8-bit mode, where we used predefined characters stored in the LCD to display our data. In this article, we will learn more about the LCD and how we can create and use custom characters.

For making custom patterns we need to write values to the CGRAM area defining which pixel to glow. These values are to be written in the CGRAM address starting from 0x40. CGRAM has a total of 64 Bytes. For LCD using 8×5 dots for each character, you can define a total of 8 user defined patterns (1 Byte for each row and 8 rows for each pattern).

Custom characters are assigned fixed display codes from 0 to 7 for pattern stored in the location pointed by CGRAM address 0x40, 0x48, 0x56… and so on. So, if the user wants to display second pattern (pattern stored at CGRAM address 0x48), simply call the data function with value 1 as an argument at a desired location in the LCD.

To display the sequence in the LCD, we need to specify the position on LCD and which pattern to display at the position. Provide adequate delay in between frames to observe the sequence distinctly.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey