tn vs tft lcd panel made in china

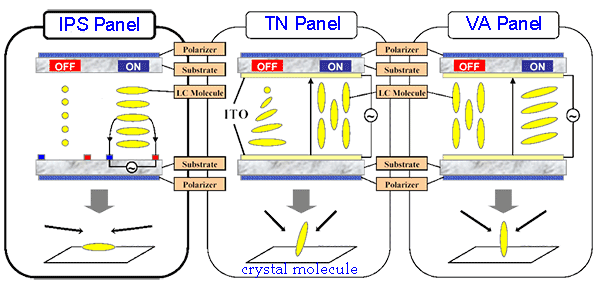

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Lcd Display With Tn Panel, Transparent Lcd Screen, Latop Lcd Screen, Waterproof Lcd Touch Screen,Lcd Advertising Screen. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. The product will supply to all over the world, such as Europe, America, Australia,Nepal, Bhutan,Washington, Birmingham.With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Tn Lcd Panel, Tft Computer Monitor, Industrial Touch Lcd Monitor, Custom Touch Lcd Displays,Marine Lcd Display. In addition, we would properly tutorial the purchasers about the application techniques to adopt our items plus the way to select appropriate materials. The product will supply to all over the world, such as Europe, America, Australia,kazakhstan, Latvia,Plymouth, UK.Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Everyday, we look at LCD display, TV, cell phone, monitor. It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

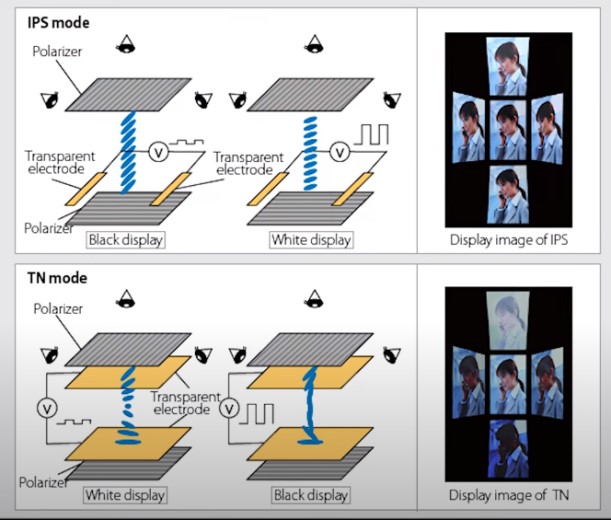

TN is the most mature technology in LCD panel manufacturing. When there is no voltage difference between the two transparent electrodes, liquid crystal molecules are twisted 90 degrees, in combination of upper and bottom polarizers, allows light to pass through LCD. As voltage applied, crystal molecules are untwisted and aligned to the same direction, blocking light.

In IPS panel, crystal molecules are parallel to the glass substrates at initial stage, LCD is off. When the in-plane electrodes is charged, crystal molecules are rotated, modifying light"s direction. Which lights up the LCD display.

As its name suggests, VA panel"s liquid crystals are aligned vertically without charged. When a voltage is applied, the molecules tilt and modifying light direction.

So in summary, TN panels twist, IPS panels use a parallel alignment and rotate, while VA panels use a perpendicular alignment and tilt. These difference create LCD display with distinctive performance.

IPS LCD is the clear winner in this aspect. It has 178/178 viewing angle ratings. Which means you can look at IPS LCD display from any angle without the image shifting in color and contrast. VA LCD has pretty wide viewing angle, too. But it has contrast shifts at off-center angles. As for TN LCD, viewing angle is its weakest point.

Most TN LCDs have 6-bits colors. Manufacturers use frame rate control (FRC) to enhance its color performance. For IPS and VA panels, you can still find 6-bits entry level LCD. But most of them are 8-bits. And IPS technology can provide natively 10-bits colors.

Color gamut is another part that VA and IPS panels shine at. The best TN LCD can reach sRGB gamut. VA panels typically start with full sRGB coverage, and get to around 90% DCI-P3 coverage. With IPS LCD panel, you could find the best ones full DCI-P3 and Adobe RGB coverage. That is why you see most professional grade LCD displays use IPS panel.

There is no inherent differences among the three panel technologies, because LCD backlight is the main factor here. However, there is a big gap in terms of contrast ratio. TN LCD panel tends to have the lowest value among the three. IPS LCD screen sits in the middle can reach 1500:1. For VA panel, the best one can exceed 4500:1 easily. VA LCD display provides far darker screen than TN & IPS. That is why they are used in vehicle dashboard.

TN panel does have an advantage when it comes to refresh rate. The panel offers the best refresh rate and response time. This is the reason why most gaming LCD monitors are made of TN panel.

TN LCD provides the best refresh rate and economic solution. If your application requires wide viewing angles and good color presentation, VA panel is probably the choice. While IPS has the best overall visual performance, in general it is more expensive than the other two.

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

TN TFTs remain very popular among competitive PC gaming communities, where accuracy and response rates can make the difference between winning and losing.

VA, also known as Multi-Domain Vertical Alignment (MVA) dislays offer features found in both TN and IPS screens. The Pixels in VA displays align vertically to the glass substrate when voltage is applied, allowing light to pass through.

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

IPS is superior in contrast, brightness, viewing angles, and color representation compared to TN screens. Images on screen retain their quality without becoming washed out or distorted, no matter what angle they’re viewed from. Because of this, viewers have the flexibility to view content on the screen from almost anywhere rather than having to look at the display from a front-center position.

IPS displays offer a slightly lower refresh rate than TN displays. Remember that the time for pixels to go from inactive to active is measured in milliseconds. So for most users, the difference in refresh rates will go unnoticed.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

VIS024TN01 is a 2.4″ TFT LCD display module model that adopts TN type LCD with 240*320 resolution. CTP (Capacity Touch Panel) or RTP(Resistive Touch Panel) can be added according to user requirements.

The 2.4-inch TFT-LCD is probably the most sold LCD panel size in the world in terms of unit shipments. It has a wide range of applications and life cycle.

Based on the substantial and long-term shipments of 2.4 inch TFT LCD panels, we can guarantee a stable supply of this LCD display module throughout the life cycle of your product.

Based on the 2.4 inch LCD’s high stability, low price, and excellent storage and operating temperature range, this type of LCD display module can be widely used in feature phones, smart homes, pos machines, industrial instruments (meters), and small medical equipment and other products.

Many people know what the characteristics of TFT LCD screens are, but do you know what are the characteristics of TFT LCD screen material? Today, we will tell you about the knowledge of the characteristics of TFT LCD screen materials.

With the rapid development of TFT array-driven liquid crystal display technology, in recent years, TFT LCD not only occupied the high-end display market such as portable notebook computers but also challenged the desktop display with the improvement of the manufacturing process and cost reduction. Because the TFT array directly drives the liquid crystal molecules, the cross-distortion effect is eliminated, and the display information capacity is large; the use of low-viscosity liquid crystal materials greatly improves the response speed, which can meet the needs of video image display. Therefore, compared with TFT display, TN type, and STN type liquid crystal display have made a qualitative leap and become one of the most promising display technologies in the 21st century.

TFT also adopts the principle of TN type electro-optic effect, but the TFT LCD material is different from the traditional liquid crystal material. In addition to good physical and chemical stability and a wide operating temperature range, TFT LCD materials must also have the following characteristics:

(4) The optical anisotropy (Δn) is matched to the TFT to eliminate the rainbow effect for greater contrast and wide-angle field of view. The range of △n value should be between 0.07~0.11.

At present, among the TFT LCD screen materials, TN type LCD screen has gradually entered a recession period, the market demand is gradually shrinking, the production capacity is excessive, the price competition is fierce, and there is no investment value. STN-type LCD will gradually enter a mature stage, the market demand will grow steadily, and the production technology will be fully mature. The TFT-type LCD is entering a new round of rapid growth, and the market demand will increase sharply, and it is expected to become one of the most promising display materials in the 21st century.

Although liquid crystal materials whose end groups are cyano groups, such as biphenyl and phenylcyclohexane liquid crystals, have been widely used in TN and STN LCDs, their viscosity is higher than that of fluorine-containing liquid crystals with the same molecular structure. These unfavorable factors limit the application of this type of compounds in TFT LCDs. The ester liquid crystal has the characteristics of simple synthesis method, wide variety, and wide phase transition range, but its high viscosity greatly reduces the dosage in TFT formulation. Therefore, the development of new liquid crystal compounds that meet the above requirements has become the focus of liquid crystal chemistry research.

The liquid crystal materials have developed rapidly with the development of liquid crystal devices, from biphenyl nitrile, esters, oxygen-containing heterocyclic benzenes, and pyrimidine ring liquid crystal compounds to cyclohexyl (bi) benzene, diphenylacetylene, ethyl bridge bonds and various fluorine-containing aromatic ring liquid crystal compounds. Japan has synthesized difluoroethylene liquid crystal compounds with stable structure, and its molecular structure is more and more stable, and it continuously meets the performance requirements of STN and TFT LCDs.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

TFTs can be formed by amorphous silicon (denoted α-Si TFT), by poly-crystalline silicon (LTPS for Low Temperature Poly Silicon), or by semiconducting metal oxides (Ox-TFT or IGZO-TFT for Indium Gallium Zinc Oxide).

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

China is home to various TFT LCD panel manufacturers, all offering exceptional services and high-end products. China remains one of the top sources for TFT LCD panel manufacturing, as they have been producing some of the best quality panels available on the market. Many Chinese technology companies specialize in providing these superior TFT LCDs, and several of them have even managed to make it into the top ten list of China"s leading TFT LCD panel producers. These companies are known for their efficient service, impressive product lineup, reliability, innovative approach to design, and customer service excellence. If you are looking for an excellent China-based supplier for TFT LCD panels, it would be wise to consider one of these top 10 China TFT LCD manufacturers.

China is a leading producer of TFT LCD panels, with industry leaders such as BOE Technology Group Co., Ltd. (BOE) at the forefront of innovation. Founded in 1993, BOE has developed a comprehensive business structure featuring port products and services for information exchange as well as healthcare solutions like its revolutionary MLED technology. In 2021, BOE boasted an impressive 70,000 independent patent applications, and more than 90% of its new patent applications are for invention patents. Additionally, over 35% of those inventions" patents can be found overseas in the United States, Europe, Japan, South Korea, and other countries. China"s TFT LCD panel manufacturers continue developing their technology by innovating on existing models such as LCD screens and LCD panels to provide better solutions for customers worldwide.

China-based Tianma is a highly reputable TFT LCD panel manufacturer with over 30 years of expertise in the display solutions industry. Since 1983, the company has grown to become a trusted China TFT LCD panel provider, and in 1995, it obtained a public listing on China"s Shenzhen Stock Exchange. With tech and production capabilities at the top of their game, Tianma specializes in SLT-LCD, LTPS TFT-LCD, AMOLED, In-cell/On-cell integrated touch technology, Flexible Displays, Force Touch TED Plus, fingerprint recognition under/on-screen and Mini/Micro LED segments. They have set the benchmark for future innovative developments in terms of LCD panels, LCD screens, and more. Offering unbeatable support services around the globe that are coupled with advanced technology makes Tianma a forerunner for China TFT LCD panel manufacturers.

China"s IVO is one of the top 10 China TFT LCD panel manufacturers and has been making a name for itself since 2005. From its Kunsan Jiangsu base, it now employs more than 3000 staff, including 400 dedicated R&D employees. IVO also boasts a G-5 TFT panel production line, and its products are used in a variety of cutting-edge applications: 60% for notebook displays, 23% for smartphones, and 11% for automotive uses. This makes it an important player in the China TFT LCD market as well as gaining great recognition worldwide in the notebook display industry.

With China being one of the leading suppliers in the global TFT LCD market, 4th in the top 10 manufacturers is TCL CSOT. This China TFT LCD panel manufacturer has been expanding its production capacity with continuous developments in technology and gaining a more solid global presence. According to the latest TV shipment stats, China"s CSOT has ranked 3rd in the world for producing TVs and 1st for supplying domestic 6 major brands since 2014. Furthermore, it holds strong places on the world scale when it comes to 55-inch UD product shipments (1st worldwide) and 32-inch UD product shipments (2nd). G6 LTPS-LCD production line is also amongst its highly lauded products, boasting second place in small and medium sizes with the most accelerated growth rate. Focused on independent innovation-driven development, TCLCSOT reinforces its position as China"s leader in TFT LCD screen technology by accumulating 12185 patent applications since 2019.

China"s TFT LCD panel manufacturer, Truly Semiconductor Co., Ltd., was established in 1991 and dedicated to TN-LCD production and became the first China-based CSTN/LCD line producer in 1995. In 2003 they obtained the OLED patents from Kodak, followed by mass production of TFT-LCD modules in 2012 and breakthrough technology in mobile 3D displays. Their 2013 production launch of naked-eye 3D displays for phones and tablet computers solidified their position as China"s top 10 TFT LCD manufacturers. To expand its portfolio further, it invested in Truly (Huizhou) Smart Display Co., Ltd., which specializes in G4.5 AMOLED and TFT displays. Truly sets an example for China"s other TFT LCD panel manufacturers through its sustained 25 years of research and development, innovation, and brand recognition.

Foxconn Technology Group founded China’s TFT LCD panel manufacturing company, Innolux, in 2003. With its headquarters and factory located in Longhua Foxconn Technology Park in Shenzhen and over 14 production bases situated across China like Nanjing, Ningbo and Foshan, Innolux is known for its comprehensive vertical integration that enables cutting-edge display technology research and development. The high quality and reliability of TFT LCD panels manufactured by Innolux have made them available to be used by some of the major global electronics giants like Apple, Lenovo, Hewlett-Packard Panda, Nokia, and Motorola. Furthermore, its amalgamation with Chi Mei Electronics and Tong Bao Optoelectronics in March 2010 has led to a significant improvement in the level of the world plane display industry.

Founded in 2001, China"s top 3 TFT LCD panel manufacturer HKC has come a long way since its inception. The company designs, manufactures, and markets a full range of TFT LCDs from 1 inch to 60 inches with an annual sales amount reaching up to half a billion USD. As it looks for global expansion opportunities, HKC has established branch companies in Russia and India and formed strategic relationships with customers worldwide. In 2010, the China-based firm moved into a new industrial park and is now capable of producing 1 million displays per month. Thanks to advanced technologies and excellent quality control standards, HKC has been praised by its customers both at home and abroad and continues to prove itself as a reliable China TFT LCD panel manufacturer.

Panda is one of China"s top 10 TFT LCD manufacturers, utilizing cutting-edge technology from China Electronics (CEC) to offer a wide range of products such as crystal resonators, thermal-sensitive crystals, ordinary oscillators, voltage-controlled oscillators, and temperature-compensated oscillators. These are used in various applications of TFT LCD screens that can be found in products like LCD TVs, monitors, and laptops. Panda studies customers" requirements with utmost care and provides reliable services and quality products. With the help of its diverse pricing strategy, it assists its clients in finding value for their money across global markets.

China has a flourishing automotive technology industry, and Eagle Tech is one of China"s top ten TFT LCD panel manufacturers. They understand the special requirements of their use environment, such as moisture-proof, dust-proof, anti-glare, high brightness, sun leakage resistance, and temperature resistance, in order to ensure the optimal performance of their displays. Having years of experience in providing Resistive touch screens, PCAP touch screens, and IPS panels make Eagle Tech the trusted electronic display manufacturer for automotive technologies to meet consumer expectations.

China is the leading source of TFT LCD panel manufacturers, and Eagle Tech has been making a name for itself as one of China"s top 10 TFT LCD manufacturers. Not only do they offer quality automotive TFT LCDs in sizes ranging from 3.5" to 21.5", but their products boast excellent durability as well; if you are looking for a reliable China TFT LCD provider that can deliver quality products for your applications, look no further than Eagle Tech.

TFT LCD manufacturing is an incredibly important part of the technology industry, and Century Technology (Shenzhen) Co., Ltd. (CTC) is one of China"s top 10 TFT LCD manufacturers. In addition, CTC invests in global optoelectronics industry personnel who specialize in TFT-LCD research and development, as well as manufacturing display panel products such as laptops, PCs, monitors, and LCD TVs. The production line project was installed during the eleventh five-year plan to position CTC at the forefront of TFT-LCD production lines for the Pearl River Delta region. Looking ahead to late 2008, this ambitious project will be put into action – it is sure to leave a lasting impact on the growth of TFT production globally.

China is the world"s largest producer and exporter of TFT LCD panels, making it a great resource for any company looking to purchase them. China is home to some of the world"s most respected TFT LCD manufacturers, with the top 10 China-based TFT LCD panel manufacturers providing displays that consistently exceed industry requirements. All ten have been commended for their amazing product designs, expertise, and quality standards. Collectively, these companies serve customers all over the world by producing panels that are reliable and high-performance – making China an important resource for businesses seeking out cost-effective TFT LCD panels.

China is quickly becoming the leader in TFT LCD technology. The top 10 China TFT LCD manufacturers are a testament to this, as they provide outstanding quality at competitive prices without sacrificing any of the standards that people have grown to expect from China"s expertise and craftsmanship.

It"s clear that China is fast becoming an unstoppable force when it comes to LCD panel production and innovative screen solutions. With its ability to make efficient panels for various applications, China is respected around the world for its skillful production of TFT LCD panels and screens. Additionally, with these reliable manufacturers trying to ensure maximum customer satisfaction with competitive pricing and high-quality products, China has become a trusted source of LCD screens worldwide.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey