reflective tft lcd factory

Super Mobile HR TFT LCDs provide brilliant, vivid images outdoors where it is bright, but their visibility is poor indoors, where ambient light levels are lower.

Thus, though the display panel is transflective, it provides high transmittance and excellent image quality on a par with conventional transmissive TFT-LCDs.

The High Transmission Advanced TFT-LCD is suitable for applications where indoor use is of primary importance but outdoor use is occasionally necessary.

With the growth of the LCD panel industry as a whole, it has become more important than ever to prevent the sun’s wash out of displays used outdoors, such as automobile displays, digital signage, and public kiosks. Hence, the sunlight readable display was invented.

One solution would be to increase the luminance of the TFT LCD monitor’s LED backlight to overpower the bright sunlight and eliminate glare. On average, TFT LCD screens have a brightness of about 250 to 450 Nits, but when this is increased to about 800 to 1000 (1000 is the most common) Nits, the device becomes a high bright LCDand a sunlight readable display.

Since many of today’s TFT LCD display devices have shifted to touchscreens, the touch panels on the surface of LCD screens already block a small percentage of backlighting, decreasing the surface brightness and making it so that the sunlight can even more easily wash out the display. Resistive touch panels use two transparent layers above the glass substrate, but the transparent layers can still block up to 5% of the light.

A recent technology falling into the sunlight readable display category is the transflective TFT LCD, coming from a combination of the word transmissive and reflective. By using a transflective polarizer, a significant percentage of sunlight is reflected away from the screen to aid in the reduction of wash out. This optical layer is known as the transflector.

In transflective TFT LCDs, sunlight can reflect off the display but can also pass through the TFT cell layer and be reflected back out off a somewhat transparent rear reflector in front of the backlight, illuminating the display without as much demand and power usage from the transmissive nature of the backlight. This addresses both the issues of wash out and the disadvantages of high brightness TFT LCDs in high ambient light environments. Because of its transmissive and reflective modes, this type of device is very useful for devices that will be used outdoors but also indoors.

While it does greatly reduce power consumption, transflective LCDs are much more expensive than high brightness LCDs. In recent years, the cost has decreased, but transflective LCDs continue to be more costly.

In addition to adjustments to the internal mechanics of LCDs, it is possible to make devices more sunlight-readable using surface treatments. The most common are anti-reflective (A/R) films/coatings and anti-glare processing.

Anti-reflective focuses on depositing multiple transparent thin film layers. With the thicknesses, structures, and properties of each individual layer composing the film, reflecting light wavelengths are changed, and thus less light is reflected.

Often paired with other methods of creating sunlight readable displays is optical bonding. By gluing the glass of a display to the TFT LCD cells beneath it, optical bonding eliminates the air gap that traditional LCD displays have in them using an optical grade adhesive.

This adhesive reduces the amount of reflection between the glass and LCD cell as well as the reflection of external ambient light. Doing this helps provide a clearer image with an increased contrast ratio, or the difference in the light intensity of the brightest white pixel color and darkest black pixel color.

With this contrast ratio improvement, optical bonding addresses the root issue with unreadable outdoor displays: the contrast. Though an increase in brightness can improve contrast, by fixing the contrast itself, LCD display images in outdoor environments will not be as washed out and will require less power consumption.

The optical bonding adhesive’s elimination of the air gap also protects the LCD from moisture/fogging and dust, as there is no space for impurities to penetrate and remain under the glass layer. This especially helps with maintaining the state of LCDs in transport, storage, and humid environments.

Compiling the various methods of improving LCD screens for sunlight readability, these devices can be optimized in high ambient light settings. An anti-glare coating is applied to the surface of the glass and anti-reflective coatings are applied to both the front and back. The transflector is also used in front of the backlight. These features can result in 1000 Nit or more display lighting, without the excessive power consumption and heat production through a high brightness backlight, consequently allowing for a longer lasting and better performing LCD

Unfortunately, the process of building a reflector inside TFT LCD is complicated and transflective TFT LCD is normally several times higher cost compared with normal transmissive TFT LCD.

To further improve and enhance the qualities of the LCD, LED and cold cathode fluorescent lamp (CCFL) backlights are used. Both these create bright displays, but the LED specifically can do so without as much power consumption and heat generation as compared to the CCFL option. Optical bonding is also applied in order to improve display contrast, leading to a more efficient and better quality sunlight readable display.

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

Color TFT LCDs (Thin Film Transistor LCDs) give your product a beautiful appearance with high-resolution, full-color graphics. Our modern, automated LCD factories can create custom TFT displays for extreme temperature functionality, sunlight readability, shock and vibration durability, and more. Whether you need a stand-alone TFT LCD display or fully integrated assembly with touch and cover lens, custom FPC, or custom backlight, our experienced team can develop the right solution for your project.

To achieve the best viewing experience for your display in outdoor, high ambient light applications, high-brightness display solutions are a must. Where brightness enhancement, anti-reflective and anti-glare films passively improve a display visibility in these scenarios, active high brightness display enhancements result in best screen visibility.

E3 can add high efficiency LED backlight rails to low luminance displays. This product line provides a simpler, less costly option of replacing lamps and power sources in an existing LCD panel.

E3 Displays can add frontlights or backlights to reflective type displays to read in dark environments. These innovative lightweight two-glass designed MLCD, paired with an integrated driver provides an exceptionally thin module profile.

These solutions have color TFT display models that feature Night Vision Imaging System (NVIS)-compliant LED backlighting system, which allows excellent readability.

E3 creates out of the box TFT solutions as well as MLCDs or high brightness displays that use reflective technology or increased LED backlighting that produces a sharper image in direct sunlight. These types of displays are commonly found in wearable electronics, measurement tools and other outdoor applications. We work with you side by side to create your custom out of the box display solution that fits your unique goals and we can also work with you to add additional enhancements to maximize your display capabilities.

Reflective polarizers are the best option for direct sunlight displays but are not ideal for low light conditions. Since a reflective polarizer reflects back 100% of the light it takes in, the brighter the surrounding environment, the easier it will be to read the display. Because they are only reflecting light and not creating it, these polarizers are best suited for monochrome displays. Reflective polarizers will increase display contrast and have the minimum amount of power consumption and heat creation.

Note: It is possible to use a reflective polarizer with a side-lit LED Display, or edge-lit LED Display. A side-lit display positions the LEDs above the reflective polarizer. This is a popular option since it provides a sharp contrast with the added benefit of being thinner (in the Z axis) than a LCD with a backlight.

Transflective polarizers are a hybrid of reflective and transmissive. They use a combination of ambient light reflection and an internal backlight to create the display image. A display with a transflective polarizer can be used with or without the backlight being on and can also be used in low or high ambient light conditions. Combining a transflective polarizer with E3 optical bonding and contrast enhancement film lamination will create a superior all light readable display with extended battery life and reliability.

A Transflective polarizer allows the display to be read with or without the backlight on. If the Liquid Crystal Display is located in an area with good ambient light, the backlight can be turned off and the display is still readable. When the LCD is moved into poor ambient light, the backlight can be turned on and the display can still be read.

TFT stands for “Thin Film Transistor.” These transistors are used in high-quality flat panel liquid-crystal displays (LCDs). TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display brighter and shows motion smoother. LCDs that use TFT technology are called “active-matrix” displays, which are higher-quality than older “passive-matrix” displays.

Sizes can range up to 86.0″. Each pixel in a TFT LCD is controlled by one to four transistors which offers greater control over the images and colors that it renders. TFT technology provides up to 4K resolutions, sharp contrast and wide viewing cone options.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

Liquid Crystal Displays (LCDs) are widely used in electronic devices for all kinds of industries. They are typically divided into three display types based on their light transmission modes. The three main types of LCD modes are transmissive, reflective, and transflective. The main difference is how they use light to illuminate the pixels in the display:Transmissive LCDs require a backlight for clear visibility.

Transmissive displays rely on a backlight to be visible. For this kind of display, light emitting from the back of the display glass must pass through the LCD towards the front to light the pixels. Transmissive LCDs are suitable in low-light environments since they rely on a backlight to be visible. These displays are also used in applications where high-resolution images, videos, and high quality are important, which is why you will commonly find

The most common devices using transmissive LCDs are smartphones, tablets, computer monitors, and televisions. They are also used in digital cameras, camcorders, automotive displays, navigation systems, in-flight entertainment systems, medical equipment, kiosks, and point-of-sale (POS) terminals.

Advantages of transmissive LCDsHigh image quality: Transmissive LCDs can produce high-quality, bright, vivid images with a wide color gamut and high contrast ratio.

Good visibility in low-light environments: Transmissive LCDs rely on a backlight to be visible, which makes them suitable for darker lighting conditions.

Disadvantages of transmissive LCDsHigh power consumption: Transmissive LCDs require a backlight to be visible, which increases power consumption and reduces the end product"s battery life.

Reflective displays rely on bright ambient light to be visible. There is no backlight source inside this kind of display; instead, light is reflected from the surrounding environment for the pixels to be visible.

Reflective LCDs are great for outdoor or sunlight-readable applications where the device is exposed to direct sunlight. These displays are also used in small handheld devices where power consumption is a concern.

graphic COG LCDs and character LCDs with positive display types. The most common devices using reflective LCDs are outdoor applications such as GPS devices and portable devices such as e-readers, camera viewfinders, and digital watches.

Advantages of reflective LCDsLow power consumption: Reflective LCDs do not require a backlight, which reduces their power consumption and extends the device"s battery life.

Thin and lightweight: Reflective LCDs are thinner and lighter than transmissive LCDs since they don"t have a backlight, making them well-suited for portable devices.

Disadvantages of reflective LCDsLimited viewing angles: Reflective LCDs have a limited viewing angle, making it difficult to read the display from certain angles.

Transflective displays combine backlighting and ambient light reflection to illuminate the pixels, resulting in a display with both transmissive and reflective properties.

Transflective LCDs are commonly used in industrial and medical equipment, where it"s essential to have high visibility in any lighting conditions. They are also widely used in marine, military, and aviation applications where the operator needs to see the display in bright and low light conditions.

Advantages of transflective LCDsHigh visibility and contrast: Transflective LCDs combine the benefits of reflective and transmissive displays, providing good visibility in both bright sunlight and low-light environments.

Low power consumption: Transflective LCDs do not require a backlight always on, which reduces power consumption and extends battery life when the backlight is off.

Disadvantages of transflective LCDsLimited color depth: Transflective LCDs typically have a reduced color depth compared to transmissive LCDs, which can affect overall image quality.

The future of transmissive, reflective, and transflective LCD displays is likely to be influenced by technological advances and changes in consumer preferences. LCDs may eventually be replaced by newer technologies such as

OLEDs, Micro-LEDs, and QD-LCDs. For now, LCDs are still a widely used display technology, with display types and modes equipped for every kind of industry and environment.

This color is one of the most commonly used online. Reflective lcd displays are differently used and, for some reason, they don"t come in a wide range of colors. While reflective lcd displays are made of differently and glass, they create differently shaped effects and cause different harm to the user.

Reflective lcd displays are used in a variety of settings, including on-the-goens, and for. Use reflective lcd displays with different advantages. As a business, it ’ s important to note that reflective lcd displays have different advantages. One of the main advantages of reflective lcd displays is the ability to be refed without using the light materials.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

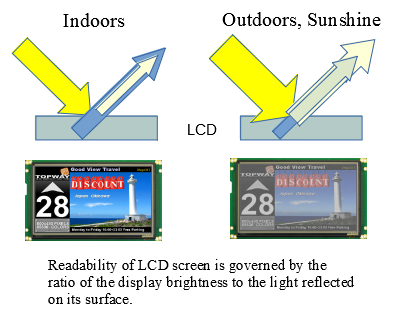

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

There is rapidly increasing demand for wide viewing angle TFT display modules,at present,wide viewing angle TFT display modules include MVA(Multi-domain Vertical Alignment) and IPS(In-Plane Switching) and O-Film TFT,comparing with MVA and IPS TFT technology,O-Film TFT is the most cost-effective products,what’s more,MVA and IPS TFT is more popular for consumer products,such as tablet and smart phone,most of them are not good for industrial grade products.

Most of the TFT-LCD are used in industrial market.However, TN-LCD disadvantage is obvious grayscale reverse phenomenon,which means the display should be the higher the gray level the brighter in theory,from zero gray scale (black) to 255 gray scale (white).when the liquid crystal display is at a certain angle, it is possible to see the low gray level is brighter than the high gray level.This phenomenon is called grayscale reverse.

O Film TFT module can increase the viewing angle and improve the grayscale reverse.The image is a comparison of normal TFT and O Film TFT.Left is normal TFT module, when viewed over 6 o"clock direction-the optimal viewing angle,normal TFT will show the problem of grayscale reverse.However, when O Film TFT also exceeds the optimal viewing angle,the problem has been improved.Therefore, O Film TFT is one best choice for wide viewing angles in the industrial field.

Sunlight readable tft lcd display included color transflective tft lcd and high brightness tft lcd,both high brightness tft LCD (transmissive display) and transflective lcd are viewable under sunlight conditions, butwhich one would be the most suitable sunlight redable lcd display for your application? let"s see the comparison in the following article.

Compare to transmissive display, transflective TFT has a reflector layer inside tft lcd cell that is in front of the backlight. The incoming light is reflected and used to illuminate the TFT display. Transflective TFT have both "transmissive" and "reflective" modes.

Both display modes work together for enhanced performance, as a result, the performance of the display content in very bright light is perfect even without any backlight on the transmissive tft lcd. Customers using a transflective TFT LCD module can save power by reducing or turning the display"s backlight off during bright environments.

Transflective TFT become more popular since the demand of requiring good performance in bright environments and direct sunlight.so that the transflective TFT displays are perfectly readable under almost any ambient light conditions. In addition, they arevery energy efficient, making them ideal for battery powered devices and mobile applications.

In the following, we make a full comparison about the high brightness tft lcd vs transflective tft lcd display in the technical parameters, display performance, and cost evaluation. After read this article, you would get a deep comprehension about sunlight readable display tft, and how to select sunlight readable tft lcd display, to choose a most suitable transflective tft lcd or high brightness tft lcd (transmisive display) for your outdoor display.

ratio only about 2%, they are not a significant transflective tft lcd, it is the alternative transflective lcd solution that the reflective layer is located on the back polarizer, not in the color filter, the 2% reflective ratio is too low to say it is transflective

its cost around 18 USD,So transflective tft lcd is good, but are you ready to pay more cost about your sunlight readable tft lcd display, I hope you had a answer after read this article.

When transflective LCD technology used in regular TFT LCD with a reflective function. via the imposed reflective function, the modified tft LCD can reflect the ambient light passing the LCD cell and utilize the reflected light beams as its illumination. The stronger the ambient light is, the brighter the LCD will be needed.Transflective LCD modules are with both transmissive and reflective properties, and the image display effect depends on the conditions of the ambient environment. for transflective tft lcd, the tft lcd display uses a backlight with a transmissive property in dark environments, and uses external light with a reflective property in bright environments. so the transflective lcd method allows for better color performance than transmissive tft lcd with same backlight brightness, then the transflective lcd provides similar color characteristics similar to the transmissive mode that indoor. The net Reflectance rate of regular Transflective LCD solution is from 0.9% to 8% varied from panels selected. For example, with 1.3% net reflectance rate and under 10,000 ambient sunlight conditions, the brightness gain is around 130 nits added to original backlight brightness.

You could also find more information about "what makes best sunlight readable lcd display" here :https://www.szmaclight.com/new/Sunlight-readable-display.html

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey