why should you calibrate a touch screen monitor factory

Screen Calibration has left people scratching their heads for years. Common questions like “Why do I need to calibrate my monitor if my clients aren’t calibrating theirs?” are all too reasonable and provide an interesting argument to the debate. Well, I’m here to tell you, you NEED to calibrate your monitor.

For those flying under the radar: screen calibration is the process, in which you adjust the colors, brightness and various spectrums of your monitor to get the most accurate color results for your photos. Not only is this important for print, but if your monitor is casting too warm or too cool colors, the majority of your clients will be far less impressed with how the images you retouched on that screen look.

There are two major contenders in the screen calibration game – the Datacolor Spyder system and the X-Rite Colormunki. In all honesty, comparing the two screen calibration systems is much like comparing a Ford and Chevy Truck. While there are minor differences between the two, they both largely do the exact same thing – which is correctly calibrate the colors and brightness on your monitor.

Basically, monitors are designed to have a 6500K color temperature and a brightness at 100cd/m² for their default settings. These numbers are great for retouching, however monitors are mass produced, and are unable to hit these number with pinpoint accuracy.

Whether you’re retouching images for your own portfolio or for a client, you certainly don’t want to be editing in the wrong color temperature from the get go, without realizing it.

False. While these types of monitors are highly regarded as the best for retouching and color accuracy, it doesn’t change the fact that they need calibration.

The term IPS monitor, for example, just means that the monitor has a large viewing angle, so that despite looking at the monitor at an angle, you won’t run into issues with color inconsistencies. While these monitors are typically at a higher price point and calibrated upon the manufacturing process, this does not mean they’re still calibrated after a few weeks or month of use.

This answer is simple – look at the rule of averages. If monitors can easily differ 500K in white balance from each other on either side (cool/warm) of the color spectrum, wouldn’t you want to hit bulls-eye in the middle of the two?

If you’re positive your monitor is calibrated at 6500K, and your client’s uncalibrated monitor is set around 6200K, it will still look better on their monitor if your screen was also uncalibrated and set around 6800K.

As a rule of thumb, we recommend calibrating your industrial touch screen if the cursor is more than 0.25″ from the exact center of the point of touch. Doing so will increase the accuracy of the touch response and can make it easier to touch objects with pinpoint precision.

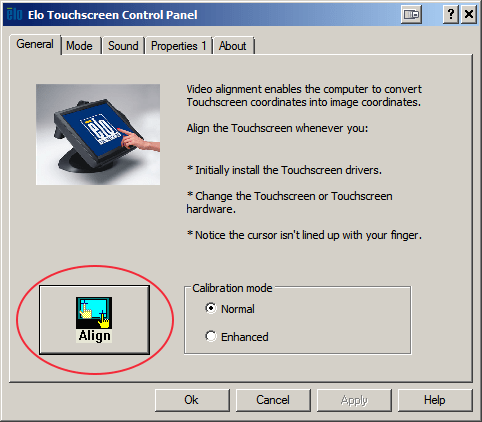

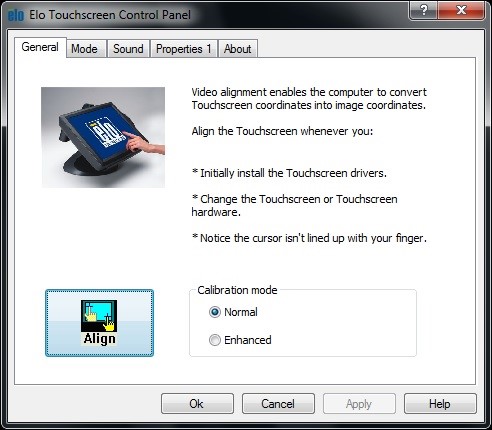

While the level of accuracy provided by the default alignment routine is sufficient for the vast majority of applications, an even greater degree of precision can be achieved by using the enhanced calibration routine provided with some versions of our Windows touch screen driver.

The normal calibration routine for Elo devices consists of 3 points of touch. This gives the drivers an accurate idea of the orientation and size of your monitor. Enhanced calibration consists of 25 points of touch along 4 additional points to establish the corners of your monitor. This routine gives the drivers a perfect picture of every aspect of your touch screen.

Enhanced calibration is a feature for those using Windows who are utilizing the Elo driver 4.8.7b or 5.5.3. You can find out what version you’re using by opening up the Elo Touchscreen Properties from the Windows Control Panel under the About tab. If you’re using a different driver and would like to take advantage of this particular driver it can be found on our Touch Screen Drivers and Downloads page. With these drivers you just need to open the Elo Touchscreen Properties mentioned above. Under the Mode tab you will find two Calibration Mode options – just select “Enhanced calibration.”

Once having done an enhanced calibration, your monitor will continue to work best in the future by doing enhanced calibrations from now on. So, if your monitor works well with normal calibration we recommend continuing to use that method of calibration, otherwise enhanced calibration is a great method for extending the life of a thoroughly used touch screen monitor.

One of the most common questions our Tech Support group receives is how to calibrate the touch screen, usually during the initial installation. To help users through the process, we’ve created this step-by-step guide for Microsoft Windows users.

These instructions apply to Windows versions 7, 8, and 10 when using the USB touch screen interface – there may be small differences depending on your version.

Before calibrating your touch screen, the Elo Touch Screen driver must be installed using the steps in the Installing the Elo Driver section below, unless the drivers were previously installed. If you are unsure whether the driver has been installed, see the Checking for the Elo Driver section.

A driver that was not properly installed could result in a screen that will not calibrate. If there is any doubt, remove the driver using steps in the Removing the Elo Driver section below, then reinstall using the Installing the Elo Driver instructions below.

When installing the Elo Driver for USB touch screens, it is very important that the USB cable is left unplugged until the driver has been successfully installed. The driver may not properly install if the touch screen USB cable is plugged in before the driver is installed.

Downloading the most recent Elo Touchscreen Windows driver from our drivers page is preferred, but the driver can also be found on the CD-ROM that ships with the industrial display. In either case, copy the driver to any location on the machine’s drive.

Note: all Hope Industrial touch screens support both Serial and USB connections, but installation of the Serial connections is not covered by these instructions. Please contact support if any help is needed with the Serial driver installation.

Connect the USB cable from the touch screen monitor to the computer. Windows will detect the device and associate the driver. When this is complete, go to the Calibrating/Aligning the Touch Screen section below for calibration instructions.

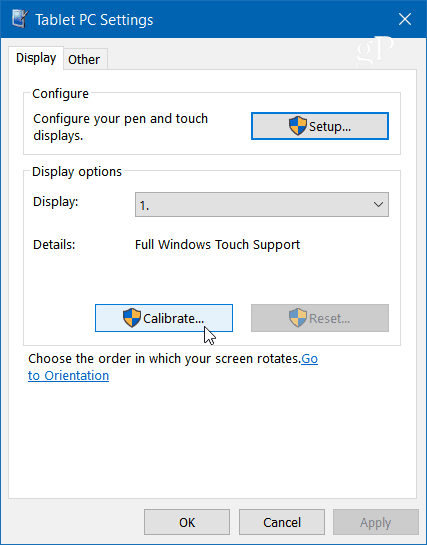

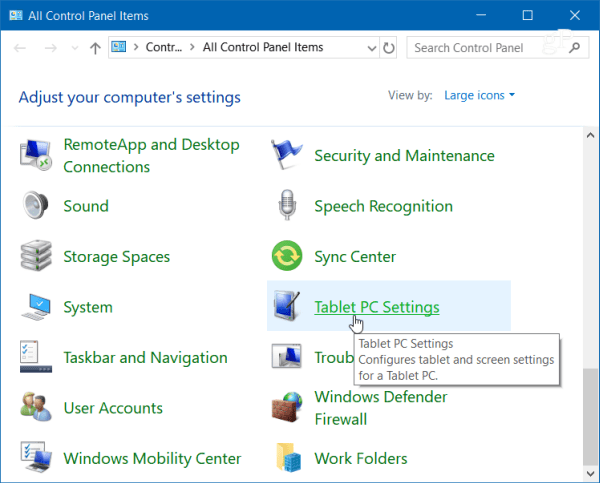

Once the driver is properly installed, the screen can be calibrated.Open the Windows Control Panel. For help opening the Control Panel for your version of Windows here is a guide. Once the control panel is open, select View By > Small icons in the top-right of the window.

The calibration routine will begin, and will present you with a series of targets to press in turn followed by a confirmation screen – just follow the onscreen instructions to complete the calibration.

If the “Elo Touchscreen” icon is in the list of icons, the touch screen driver has already been installed. Proceed to the Calibrating/Aligning the Touch Screen section of this page.

Note that to properly remove the Elo Driver before reinstallation, it is very important to unplug the touch screen USB connection before proceeding. Failure to do so can cause future driver reinstallation to fail.

When re-installing the driver, the USB cable should not be reconnected until the driver installation is successfully completed.Confirm that the touch screen USB cable has been disconnected.

/001-how-to-calibrate-android-touchscreen-4427946-906523dd8d0047768fe9cd13542f421a-e6b172f625874db1bd5f53996b924c0e.jpg)

A touch screen has become ingrained in everyday lives of nearly all planet Earth inhabitants. Of course, the leading role is played by smartphones and tablets. However, other fields that use special purpose equipment keep abreast with the modern trends. Industry is among these fields. In industrial segment, the most popular devices equipped with a touch screen are panel computers and monitors. Typically, the questions on touch screen work arise during device operation – How to connect? How to configure? How to calibrate? etc.. Let us have a closer look at these issues.

As a rule, in panel computers a touch screen controller is defined automatically by the operating system and does not require installation of additional drivers. The only thing that might be necessary is calibration, but it must only be done when a touch screen does not work properly. See more information about calibration below. The connection scheme is somewhat different. Every industrial monitor, which is equipped with a touch screen, has an auxiliary USB or COM cable. This cable connects a monitor to the computer, which a video signal will be displayed from. The rest of the connection algorithm is similar to that of a panel computer.

Under configuration the detection of a touch screen controller in the system is implied, as well as its further proper operation. As it has been already mentioned, the operating system detects touch screen automatically. But what to do if this is not the case? First thing that you will definitely need is drivers. To get the necessary drivers, you may pursue any of the following ways:There are drivers on a disk that comes with the device.

If the disk is lost, you can download drivers from a panel computer/monitor manufacturer’s website, or if you know exactly what touch screen controller is installed in your equipment, e.g. AMT PenMount, you can download drivers from the controller manufacturer’s website.

After transition and opening a tab, you will see a list of drivers available for download for this device. Touch screen driver is always easy to define due to its name. It should include the word “Touch”. Sometimes, all drivers are located on one large archive. It might happen, that you should decide, what OS you need a driver for. Just choose the required one and the downloading process will start.

If you want to download drivers from the controller manufacturer’s website, you should act somewhat different. Typically, manufacturers of industrial panel computers and monitors use controllers made by two companies that have already been mentioned, these are AMT PenMount and EETI. Drivers on manufacturers website are also located in a “Download” tab. You can transfer to it directly from the main page.

You have installed the drivers, and the touch screen is working. You want to move a cursor to the upper left corner, but it goes to the right bottom one. What to do? There is only one solution for such cases – touch screen calibration. Usually, the calibration utility program can be found in the same archive, where the drivers are located. Next, we will a consider touch screen calibration option on the example of one of the most popular panel computer models APPC-1740T from Nexcom.

In APPC-1740T the manufacturer uses a touch screen controller by AMT PenMount. We will install the drivers for OS Windows 7. Download drivers from the manufacturer’s official website. Unpack the archive, once the download is complete. After unpacking, you need to install this utility program. Click on “Setup” file and follow the instructions on the screen. The installation process will take a few minutes. Once the installation is complete, launch the utility program by clicking on the shortcut PenMount Control Panel on the desktop.

After launching, in the “Choose component for configuration” field the program must display a touch screen controller. That means that the utility program has detected a controller within a system and calibration may be started. In this window, you can also see the exact model of the touch screen controller on your computer. In our case, there is the model PenMount 6000 USB installed.

During calibration, you need to click on the points on the screen following the instructions, i.e. click the cursor, hold, release and then move to the next point. It will take you a couple of minutes. After completion, the calibration window will close automatically. Then you may check whether the touch screen operates correctly. If everything is all right, then we may congratulate you on having calibrated the touch screen! If not, then, please contact Technical Support of IPC2U.

The following steps take you through how to calibrate the C5581QT touch screen monitor. When connected to a Dell System running 16.04 or older version of the Ubuntu Operating System (OS).

xinput map-to-output [touch device] [monitor input]: please you have to identify the monitor device number from LS command and what is the video port used HDMI or DP

Open Touch_Screen_Calibration.vi and run the VI on your target. If your monitor is connected via USB, you will see the calibration screen shown in Figure 2.

Disconnect any USB mice attached to the TSM and then complete the on-screen calibration procedure and the settings will be retained on your NI Linux Real-Time target until you format or re-install software.

After the commands are entered, the touch screen monitor connected to your target will bring up the screen shown above in Figure 2. Follow the on-screen instructions to successfully calibrate the touch screen.

Once you have enabled the embedded UI, restart your target for changes to take effect. Upon reboot, you should see a screen similar to this on your monitor:

After the commands are entered, the touch screen monitor connected to your target will bring up the screen shown above in Figure 2. Follow the on-screen instructions to successfully calibrate the touch screen. Remember to disconnect any USB mice connected to the TSM before calibrating.

Windows 10, 8, and 7 are designed to work well with touch-enabled displays, but things can go wrong. When you tap the screen, and it behaves as if you tapped a different place, that usually indicates a calibration issue. Touchscreen calibration usually takes care of that type of problem.

The touchscreen calibration tool works by displaying a pattern on the screen and then overlaying it with a series of crosshairs. By tapping each crosshair in sequence, you show Windows exactly how to configure the touchscreen.

When calibrating a touchscreen, it"s essential to tap the actual location of each crosshair. If you tap anywhere else, you end up with an improperly configured touchscreen that may be unusable. In that case, connect a keyboard and mouse to reactivate the configuration tool.

If you don"t have a keyboard or you don"t see the Windows logobutton, swipe up from the bottom of the screen in Windows 10 or swipe from the right in Windows 8 to access the menu.

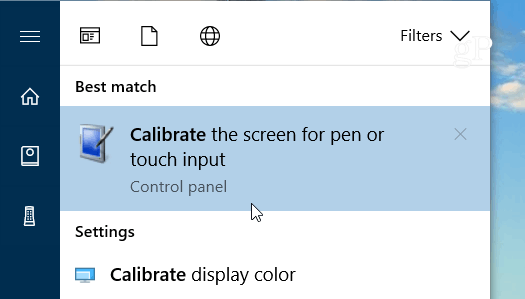

Type calibrate. In Windows 8, you might need to type tablet, and in Windows 7, you might need to type touch. In all three cases, select Calibrate the screen for pen or touch input in the search results.

When you search for calibrate, the first result is typically calibrate display color. Even if Windows highlights this result, this is not what you need. Make sure to select Calibrate the screen for pen or touch input.

Configuration issues don"t cause all touchscreen problems. For instance, if the touchscreen doesn"t work at all, it might be turned off or disabled, or the correct driver might not be installed. In that case, enable the touchscreen or update the drivers.

In other cases, figuring out why a touchscreen doesn"t work can be more complicated. If calibrating your touchscreen didn"t help, check out our in-depth guide to fixing a broken touchscreen.

Some of the first Android devices up to Android 4.0 (Ice Cream Sandwich) had a built-in calibration option. Depending on the device and Android version, the location of this setting varies but is generally at Menu > Settings > Language & keyboard > Touch Input > Text Input. UnderFinger touch precision, tap Calibration tool or Reset calibration.

If you suspect any internal touch screen issues, please see this troubleshooting guide. Touch screen issues are almost always a failure of the display itself.

The internal touchscreens on Gio, Ti, Cobalt 10, and Cobalt 20 do NOT need to be calibrated because the calibration is set by the display manufacturer in the touch screen control card of the display. If the screen doesn"t respond well in some regions, contact ETC Technical Services. Updated firmware and settings for the display can help this issue (this can be applied on a factory repair bench), or internal components on the screen may have experienced a failure (requiring repair).

Calibration is still possible for external Elo touchscreens with the "Calibrate Elo External Touchscreen" button found in the General tab of the shell (this has been removed in Vsn3.0)

If your touch screen IS responding, but is appearing on the incorrect screen (usually this only happens after a reimage), go to the monitor arrangement menu and select "Configure Touchscreens". All screens will appear white with one of them instructing you to touch this screen. After doing so, it will instruct you to hit enter and will continue in the same manner on the next screen. If you have non-touch displays connected, simply click the mouse on screen and/or hit enter to skip those when instructed.

NOTE: i If you are using an optional touch screen (e.g. using an external touch screen with a Tech Cart and docking station), there will be an additional touch screen choice displayed.

Please note that most of our touch screens are factory calibrated and it is unnecessary to calibrate them. In the event the touch coordinates are incorrect, first try to restart the computer and see if that corrects the issue. If not, please give us a call at 847-851-1600

You will then be asked to touch various points on the screen to verify that the cursor appears at the position touched. If the cursor appears at the position touched, click the green arrow to accept and exit out of the calibration program. If the cursor does not appear at the position touched, click the blue curved arrow and the calibration program will run again.

A test screen appears. You may tap various places on the screen or you may drag around; the cursor should follow in either case. Either the Accept button (multi-touch driver) or the green check mark button (single touch driver) must be tapped to permanently store the calibration.

The green bar in the single touch driver is a progress bar – be sure to tap the green check mark button before the bar times out. If the bar times out, the calibration data will be discarded.

Some monitors (those with PCAP or infrared touch technology) will return to the main driver screen immediately after the upper left target is touched (the other two targets will not be displayed and the test screen will not be displayed). This is because these touch technologies are precalibrated at the factory, and a single touch is used only to detect orientation (landscape or portrait) and position if the monitor is part of an array of multiple monitors.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey