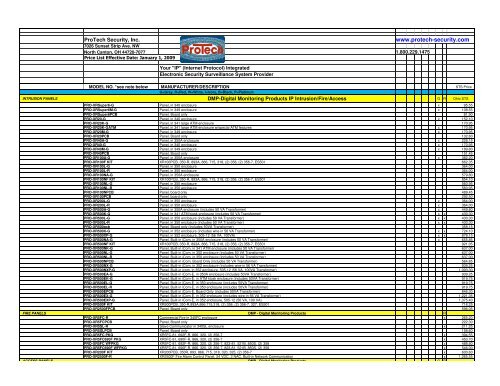

lcd panel scripts pricelist

The script allows you to designate any cargo containers in your grid as the "Entry" and the "Vault" and there can be multiples of them, or several "Entries" can use a common shared "Vault". You can thus build and customize your own trading posts quite freely. Buying and selling can be initiated with a simple button panel press. You need at least one button for selling (if you use "sell any") and then one button for buying each item type ("buy X").

Instead, in the game where you want to setup a trading post, build a programmable block (see the chapter "Setup") and in it"s control panel click "Edit". There you will see the button "Browse Workshop". If you"ve subscribed to the "Simple Trading Script" you"ll see it there. Simply select it and click ok. Then just "check code" and "ok" and you"ve the script in the programmable block.

Caveat: don"t use inventory automatization mods/scripts in ships or bases where you want to use the trading post script, or at least be careful how you set it up so that it doesn"t interfere with the movement of the trading items.

- At least one button panel, although you may want more if you"re offering many different item types for sale. Or, you can make separate trading terminals for different items, if you like.

"Small Cargo Container 5" is not that informative. For your own comfort, in the control panel change the names of the blocks you want to use in the trading script to something meaningful and easy to use so that you"ll know which is which tomorrow, too.

Remember to toggle the "Show text on screen" setting in the LCD panels. By default it"s off. Otherwise you won"t see the script generated texts, there.

Open the control panel of the programmable block "TradeScriptIngots" and there click "Custom Data". In the custom data window enter at least the following configuration text:

These four settings give the names of the blocks used for the "Entry" cargo container, for the "Vault" cargo container, and for the LCD panels. The names must, of course, match those you use. Otherwise the script won"t find them. This is also the way how you can setup a trading post with multiple terminals in different places: simply configure the different programmable blocks to use different cargo containers and different LCD panels.

You can change any of the configs in the programmable block"s custom data while the game is running. Just call the script with Mode=Welcome after that (i.e. hit the button "Start" in the button panel that we defined earlier) so that the script updates the price list.

The welcoming message shown to the player in the CustomerDisplay LCD panel when the script is called with mode "Welcome". The "

" means "new line".

The most obvious problem with a trading post is the possibility of the players simply doing a little "breaking and entering" and just robbing it. You may want to set the access rights carefully and defining the trading post as "indestructible" would be a good idea if there were a simple way to do it. If you *want* to allow raiding attempts then at least setup proper defenses and "foul play" sensors and scripts triggering them.

Everything you will ever need to know about your ship and station displayed in real time on LCD panels in any vanilla games. modded games and servers! Now with cockpit panels support!

Thank all of you for making amazing creations with this script, using it and helping each other use it. Its 2022 - it"s been 7 years already since I uploaded first Configurable Automatic LCDs script and you are all still using it (in "a bit" upgraded form). Its just amazing :)

Every captain wants to have displays that show some useful info. Make your bridge display damaged blocks in engineering, engine room, etc. Make big screen by joining multiple Wide LCDs! Show power output, batteries status, laser antenna connections and much more. Make your docking bay display which landing gears are occupied. Make screens for docking fighers when landing gear is ready to dock so they can nicely see it from cockpit! Make one LCD per container to see its contents.. and much more!

Open your programmable block, click Edit, click Browse Workshop, select Automatic LCDs 2, click OK, Check code, Remember & Exit. Done. Your script is now updated.

If you have problem with some command then read the guide section for that command and make sure you use it correctly. Try to use it on separate LCD by itself so it"s easier for you to see the issue and definitely try some examples!

Olimex-made Linux boards that carry the OLinuXino or SOM name and have an LCD connector would work with the LCD-OLinuXino-7. Unlike the previous iteration of displays, the LCD-OLinuXino-7 has three connectors on it"s back: 0.1"" step connector, 0.05"" step connector, flat ribbon cable connector. This allows the easy connection of boards with big LCD connector and also of boards with small LCD connector (like the LIME boards) and also boards with ribbon connector (like A33). You only need a single cable with the same step on both sides to connect between the LCD and the board.

I bought LCD-OLinuXino-7, a fitting cable, and prepared a card with Olimage, connected everything to the Olimex-made Linux board but when I apply power the setup I get no image on the display. What do I do wrong?

The default Olimage Linux image is not set for LCD video output. Use another way to access the Linux (USB-serial cable is the best idea) and then execute the configuration script "olinuxino-display". Detailed information might be found at Olimage user guide that can be found at our GitHub pages.

The A20 boards are configured to work with resistive touchscreen that uses analog interface. You need to change the hardware configuraiton for the touchscreen to make your board with LCD-OLinuXino-7CTS. Usually you"d need to change the position of a resistor matrix. This requires some soldering experience. Details depend on different boards, refer to the schematic around the LCD connector of your board to figure it out.

The default A20-OLinuXino image is set for a HDMI display and 720p resolution. To use LCD with A20-OLinuXino you need to set proper display settings. Explanation of how to do it via the default script might be found in the wiki article for A20-OLinuXino: https://www.olimex.com/wiki/A20-OLinuXino-MICRO

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Looking for a simple way to add a text display to your Raspberry Pi or BeagleBone Black project? Consider using a character LCD with the Python character LCD library! These classic displays can show a few lines of text, are inexpensive, and easily readable during the day or night with a bright backlight. You can follow this guide to learn how to connect a character LCD to a Raspberry Pi or BeagleBone Black and control the display from your own Python code!

Before you get started it will help to familiarize yourself with the character LCD guide. You will also want to make sure your Raspberry Pi is running the latest Raspbian operating system, and your BeagleBone Black is running the latest Debian or Debian-based distribution like Ubuntu.

When you"re ready to get started, grab a character LCD, contrast adjustment potentiometer (included with Adafruit character LCDs), and a Raspberry Pi or BeagleBone Black. Continue to the next page to learn how to wire the display to your board.

Follow the steps below to wire a character LCD to your development board. Be careful to connect each wire to the correct pins as there are quite a few wires necessary to use the character LCD.

If you would like to permanently turn on the LCD backlight, connect the red, green, blue backlight wires to ground instead of to your development board.

Connect Pi 5V power to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer,LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect Pi ground to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

Wire your BeagleBone Black to the LCD as follows. If you aren"t familiar with how to identify pins on the board, be sure to read the BeagleBone Black GPIO guide.

Connect BeagleBone Black 5V power pin P9_7 to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer, LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect BeagleBone Black ground pin P8_2 to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

To use PWM control of the backlight LEDs, wire your BeagleBone Black to the LCD as follows. Note that this wiring is exactly the same as the non-PWM wiring, except the 3 backlight LED pins (red, green, blue) are moved to different pins.

Connect BeagleBone Black 5V power pin P9_7 to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer, LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect BeagleBone Black ground pin P8_2 to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

Before installing the character LCD library you"ll need to make sure a few dependencies are installed by following the steps below. Make sure your development board has access to the internet so the software can be downloaded.

Once the library is installed you can find a few examples of its usage in the examples subdirectory. If you"re using a monochrome backlight LCD (i.e. single color, like a white on blue LCD) the char_lcd.py script will demonstrate the basic usage.

If you"re using a Raspberry Pi and have wired it according to this guide, you can immediately run the example. However if you"re using a BeagleBone Black or changed the wiring, first open char_lcd.py in a text editor (like nano) and uncomment/comment the lines towards the top that set the LCD pins.

The first part of the script are commands to import modules that will be used. In particular the Adafruit_CharLCD module is imported under the name LCD. Later in the script you can see how classes from the char LCD module are used to interact with the LCD.

The next part of the script configures which pins are connected to the LCD. You can see the Raspberry Pi configuration is uncommented by default, and below it the BeagleBone Black configuration is commented. You can use any digital GPIO pins in the configuration.

This section of the script configures the size of the LCD. By default the code assumes a 16 column, 2 row LCD however you can adjust the configuration to a 20x4 or other size display supported by the HD44780.

The next lines demonstrate basic usage of the LCD display class. The message function can be used to write a string of text to the display (including support for line breaks). The clear function clears the display, and the show_cursor and blink functions specify if the cursor is shown and should blink.

Although not shown above, there are other functions you might find useful on the LCD class. To see details on all functions you can have Python print help text for the class by executing (ignore the >>> prompt, it"s only shown for reference as the Python interpreter):

If you"re using a Raspberry Pi and have wired it according to this guide, you can immediately run the script. However if you"re using a BeagleBone Black or have changed the wiring, edit the script with a text editor and uncomment/change the lines at the top that define the LCD pins.

If you open the file char_lcd_rgb.py in a text editor (such as nano) I"ll describe the important differences between it and the previous char_lcd.py example below.

The first important difference is the configuration of LCD pins. Notice there are now explicit pins defined for the red, green, and blue backlight LEDs.

The Adafruit_RGBCharLCD class inherits from the Adafruit_CharLCD class so it has all the same functionality as demonstrated in the char_lcd.py example. In addition to the basic character LCD functionality the RGB character LCD class adds some functions to set the RGB color of the backlight.

If you"re using a RGB character LCD you can use PWM (pulse-width modulation) for fine control of the backlight color. By turning the different backlight red, green, and blue LEDs on and off very quickly with PWM, it"s possible to precisely control the color of the backlight.

Note that PWM control works best when there"s hardware support for PWM on your development board. The BeagleBone Black has support for up to 8 hardware controlled PWM pins and works great with the RGB character LCDs. However, the Raspberry Pi only has one hardware PWM pin and can be a little more troublesome to use PWM.

The RPi.GPIO library which is used by the character LCD library supports a software implementation of PWM on the Raspberry Pi. This lets you PWM control the RGB backlight even though the Pi doesn"t have 3 hardware PWM pins. In my testing software PWM worked reasonably well with the RGB character LCD backlight. You might notice slightly incorrect colors, but otherwise software PWM is worth a shot to finely adjust the backlight color on the Raspberry Pi.

The char_lcd_rgb_pwm.py file demonstrates usage of PWM backlight control. If you"re using a Raspberry Pi and have it wired to the LCD as described in this guide, you can immediately run the script. However if you have a BeagleBone Black or have changed the wiring, edit the file char_lcd_rgb_pwm.py in a text editor and comment/uncomment the lines at the top which define the LCD pins.

You should see the backlight turned on to different colors for a short period of time, and then a continuous gradient of colors displayed with a message showing the red, green, and blue color displayed on the LCD. For example:

The code for PWM control is very similar to non-PWM control from char_lcd_rgb.py, however there are a few important differences. The first difference is how the Adafruit_RGBCharLCD class is intialized. Notice the enable_pwm=True flag is passed to the constructor/init function:

One problem with using a character LCD is that you give up a lot of GPIO pins to talk to the LCD. Four pins are used to send data, two pins are used for write and clock signals, and another pin or three are used for the backlight for a total of ~6-9 total pins! On a platform like the Raspberry Pi model A/B with only a dozen or so GPIO pins you can quickly run out of pins for other parts of your project. However with chips like the MCP23008 or MCP23017 you can easily add extra GPIO pins to your development board through an I2C interface!

To use an MCP230xx chip with a character LCD you will need to wire the MCP chip to your board"s I2C pins, and then wire the LCD to the MCP chip. Below are examples of wiring an MCP23017 to the Raspberry Pi or BeagleBone Black.

Connect Pi ground to the ground rail of the breadboard, and connect the MCP VSS and address pins, one outer lead of the potentiometer, the LCD ground, and the LCD R/W pin to the ground rail.

Connect Pi 5V power to the other outer lead of the potentiometer, LCD power, and LCD backlight pins. Note that 5 volt and not 3.3 volt power is used to power the LCD!

Connect BeagleBone Black ground pin P9_1 to the ground rail of the breadboard, and connect the MCP VSS and address pins, one outer lead of the potentiometer, the LCD ground, and the LCD R/W pin to the ground rail.

Connect BeagleBone Black 5V power pin P9_7 to the other outer lead of the potentiometer, LCD power, and LCD backlight pins. Note that 5 volt and not 3.3 volt power is used to power the LCD!

The char_lcd_mcp.py file in the library"s examples folder demonstrates the usage of a character LCD (non-RGB version) with an MCP23017 IO extender. Run the script by executing this command inside the examples directory:

First the required modules are imported. Notice the addition of the Adafruit_GPIO.MCP230xx module (imported under the name MCP). This MCP230xx class will be used to talk to the MCP chip and interface with the LCD.

Next the LCD pins are defined in the script. Note that these pin numbers are the MCP chip GPIO pin numbers, and NOT Raspberry Pi/BeagleBone Black pin numbers!

Now the Adafruit_CharLCD class instance is created. The big difference with this line and previous examples is that the MCP23017 class (created with the name "gpio") is passed in as the gpio parameter. By passing in an explicit gpio parameter, the char LCD class will use that GPIO class for talking to the LCD instead of the default development board GPIO pins.

The rest of the example code is exactly the same as the non-MCP character LCD example. You only need to change the setup and initialization of the character LCD class to use the MCP IO extender with an LCD!

The character LCD plate is a great way to add a simple character LCD and buttons to your Raspberry Pi project. Because the character LCD plate is based on the MCP23017 IO expander, the character LCD library easily supports the character LCD plate!

To use this character LCD library with the plate, make sure the library is installed by following the steps on the usage page. Then connect the LCD plate to your Raspberry Pi and execute the char_lcd_plate.py script in the library"s examples folder:

Note that the example assumes an RGB character LCD is attached to the plate, however it will still run with a monochrome LCD (you just might see the backlight turn on and off in different ways as colors as displayed).

When you run the example you should see the backlight run through different colors, and then the display will tell you to press buttons. If you press different buttons on the LCD plate you should see the button name and a different color displayed. Try pressing buttons to see how the script reacts!

Examine the code for the char_lcd_plate.py script to see how to use the character LCD plate code. The usage of the LCD plate is very similar to RGB or monochrome LCD usage, with a few key differences.

The first difference is that you create and instance of the Adafruit_CharLCDPlate class. You don"t need to pass any parameters in to this class" constructor/init function because it is preconfigured for the LCD plate.

The second difference is that the Adafruit_CharLCDPlate adds a function to test if a button is pressed. Notice how the is_pressed function is called for each button, and if it returns True then the button press is detected.

For example to check if the select button is pressed you can call is_presssed(LCD.SELECT), or to check if the right button is pressed you can call is_pressed(LCD.RIGHT).

The OnePlus Nord N20 5G is more powerful than Samsung’s budget phones, and its 1080p OLED screen is sharper than those of other phones in this price range, which typically have lower-resolution LCDs with worse contrast. The N20 5G even offers an in-display fingerprint sensor, a rare feature on budget phones. Though it runs Android 11 out of the box, it’s slated to get Android 12, along with three years’ worth of security updates (through spring 2025). However, it doesn’t function on Verizon’s network.

Direct View LEDAn emerging class of immersive virtual reality / mixed reality systems is based on direct view LED technology to create an alternative to CAVE / Projection VR systems. These systems would be very bright and have a low physical footprint but would have unique facilities requirements including temperature management and power consumption.Cost is variable depending on the area that needs to be covered by LED panels but typically the cost is double to triple that per square foot as a high end CAVE system, i.e. $1 million + depending on size and configuration.

Many modules and example scripts exist in online tutorials, i.e. WorldViz provides demo source codes. Leverage student programmers or your own programming team. WorldViz programming services can be hired at an hourly rate. Most popular VR programming languages:Unity: C#

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey